Preparation method of lubricating oil anti-wear agent

A technology of antiwear agent and lubricating oil, which is applied in the field of preparation of lubricating oil antiwear agent, can solve problems such as poor component compatibility, unstable raw material compatibility, precipitation, etc., achieve low friction coefficient, increase oxidation induction time, Good oxidation stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

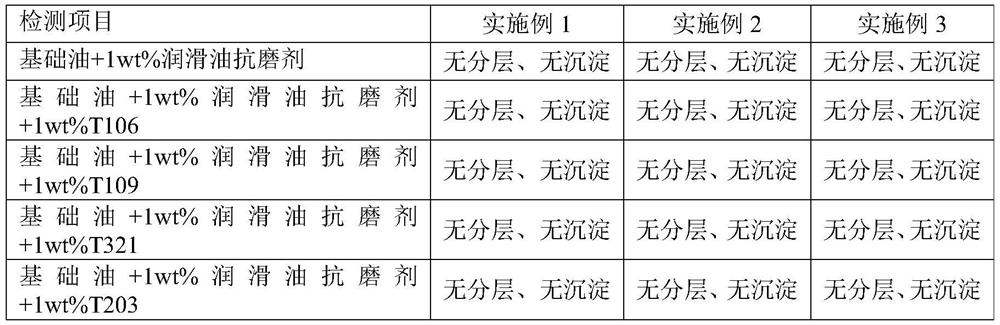

Examples

Embodiment 1

[0044] The lubricating oil antiwear agent is specifically prepared according to the following steps:

[0045]A. In terms of parts by mass, put 100 parts of n-butyl acrylate, 0.5 parts of initiator azobisisobutyronitrile AIBN and 80 parts of ethyl acetate into the reaction kettle with agitator and condenser, and put s , 1.5 parts of s'-di(α,α'-methyl-α"-acetic acid) trithiocarbonate (RAFT reagent), heated to 70°C for reflux reaction for 8 hours, after the reaction, at 60°C and 800Pa Distilled under reduced pressure for 2 hours to remove the solvent ethyl acetate to obtain the interpolymer A (measured weight average molecular weight Mw=29500);

[0046] B. Put 100 parts of polymer A into a stirred vacuum distillation reactor, add 30 parts of ethanolamine, 2.0 parts of catalyst DOO1 cationic resin, and conduct vacuum distillation reaction at 80°C for 8 hours, increase the vacuum distillation temperature to 140°C and continue to reduce the pressure Distill 4h, filter out catalyst ...

Embodiment 2

[0049] The lubricating oil antiwear agent is specifically prepared according to the following steps:

[0050] A. In terms of parts by mass, put 100 parts of n-butyl acrylate, 1.0 parts of initiator azobisisobutyronitrile AIBN and 100 parts of ethyl acetate into the reaction kettle with agitator and condenser, and put s , 2.0 parts of s'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate (RAFT reagent), heated to 75°C for reflux reaction for 8h, after the reaction, at 65°C and 1000Pa Distilled under reduced pressure for 2.5h to remove the solvent ethyl acetate to obtain polymer A (measured weight average molecular weight Mw=15000);

[0051] B. Put 100 parts of polymer A into a stirred vacuum distillation reaction kettle, add 30 parts of ethanolamine, 2.0 parts of catalyst DOO1 cationic resin, and react under vacuum distillation at 95°C for 6h, increase the vacuum distillation temperature to 150°C and continue to reduce Pressure distillation 3h, filter out catalyst cationic resin...

Embodiment 3

[0054] The lubricating oil antiwear agent is specifically prepared according to the following steps:

[0055] A. In terms of parts by mass, put 100 parts of n-butyl acrylate, 0.8 parts of initiator azobisisobutyronitrile AIBN and 90 parts of ethyl acetate into the reaction kettle with agitator and condenser, and put s , 1.8 parts of s'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate (RAFT reagent), heated to 72°C for reflux reaction for 9h, after the reaction, control the temperature at 62.5°C and vacuum pressure Under the condition of 900Pa, the solvent ethyl acetate was removed by distillation under reduced pressure for 2h to obtain block polymer A (the weight average molecular weight Mw=22700 was determined by molecular permeation gel chromatography);

[0056] B. Put 100 parts of polymer A into a stirred vacuum distillation reaction kettle, add 30 parts of ethanolamine, 2.0 parts of catalyst DOO1 cationic resin, react under vacuum distillation at 90°C for 7h, increase the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com