A kind of anti-erosion coating for wind power blade leading edge and preparation method thereof

A wind turbine blade and anti-erosion technology, applied in coatings, wind power generation, anti-corrosion coatings, etc., can solve the problems of increased maintenance costs, damage to the integrity of wind turbine blades, reduced aerodynamic performance and operational reliability, and improved adhesion. , High anti-corrosion performance and adhesion, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The above-mentioned preparation method of the anti-erosion coating for the leading edge of the wind turbine blade comprises the following steps:

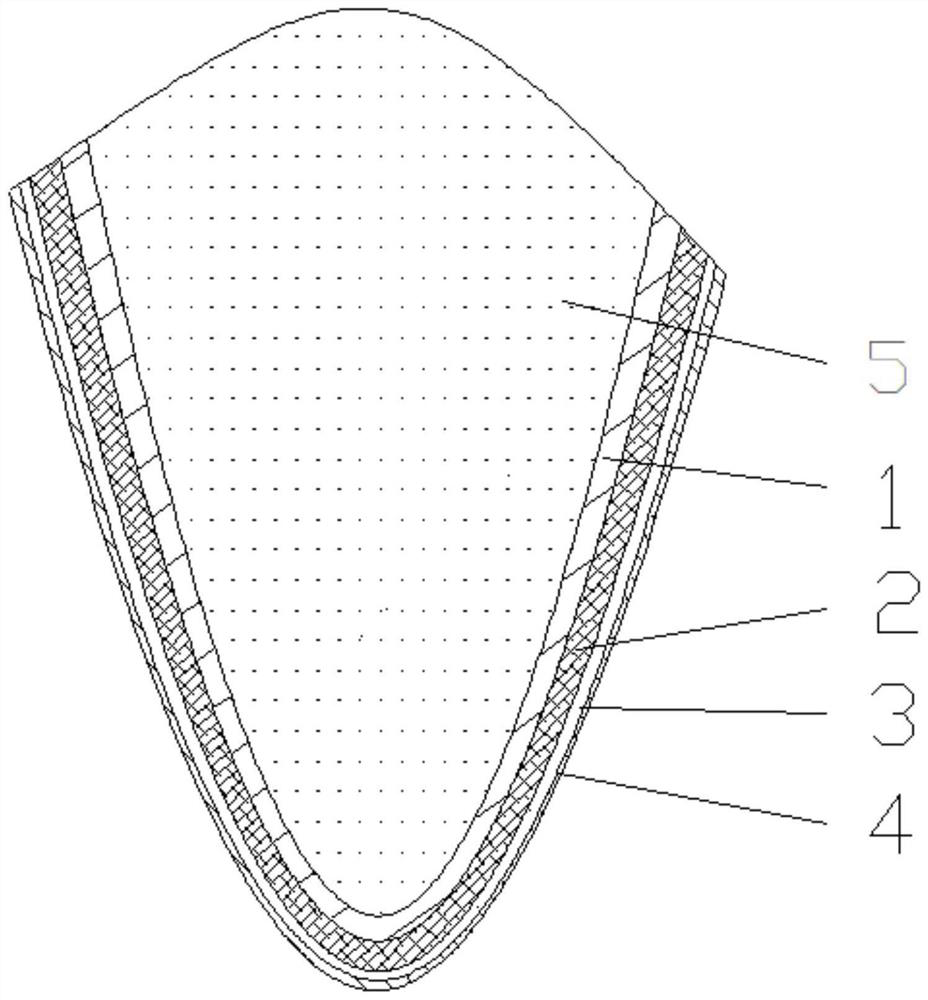

[0053] 1) Prepare the substrate 5, pre-treat the surface of the leading edge of the blade, and use sandpaper to polish it. After completion, use compressed air to blow for 5-10 minutes, decontamination, oil, and moisture, and check the surface quality. There should be no obvious defects on the surface. Defects such as meat, cracks and pits.

[0054] 2) coating the bottom layer 1, the above-mentioned epoxy coating is evenly stirred, and evenly coated on the surface of the substrate 5 to obtain the bottom layer 1, the coating method of spraying can be used, and the temperature of the surface of the substrate 5 during the coating process is not lower than 10 ℃, the thickness of the bottom layer 1 ranges from 100 to 150um. After curing, it is properly repaired and polished.

[0055] 3) Paint the intermediate layer 2, control the...

Embodiment 1

[0059] The bottom layer 1 is a two-component solvent-based epoxy coating that can be cured at room temperature.

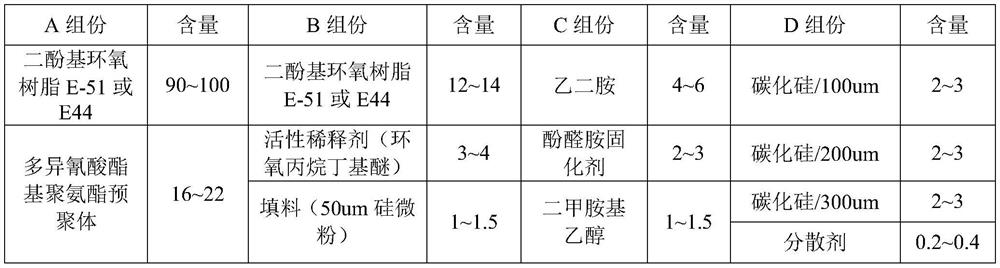

[0060] The intermediate layer 2 is an anti-corrosion coating, which is a silicon carbide-reinforced polyurethane-modified epoxy coating, and is composed of components A, B, C and D. The specific proportions are as follows shown:

[0061]

[0062] Component A, Component B, Component C and Component D are proportioned according to the above-mentioned quality. The proportioning sequence is: firstly prepare Component A, and then add the homogeneous mixture of Component B and Component C to Group A Finally, add component D and mix well.

[0063] Described leveling layer 3 is made of B component, C component, E component and F component, and the proportion is as shown in the following table:

[0064]

[0065] Component B, Component C, Component E and Component F are proportioned according to the above-mentioned quality. The order of proportioning is: Mix Componen...

Embodiment 2

[0074] Compared with Example 1, Example 2 mainly changed the epoxy resin E51 in components A and B to epoxy resin E44, the proportions of other components were unchanged, and the coating process was the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com