Weathering resistant steel with low yield ratio and preparation method thereof

A low yield ratio, weathering steel technology, applied in the field of iron and steel smelting, can solve the problems of high corrosion resistance and toughness of weathering steel, low chromium content and high phosphorus content in weathering steel, and achieve excellent comprehensive product performance. The effect of high qualified product rate and high product qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

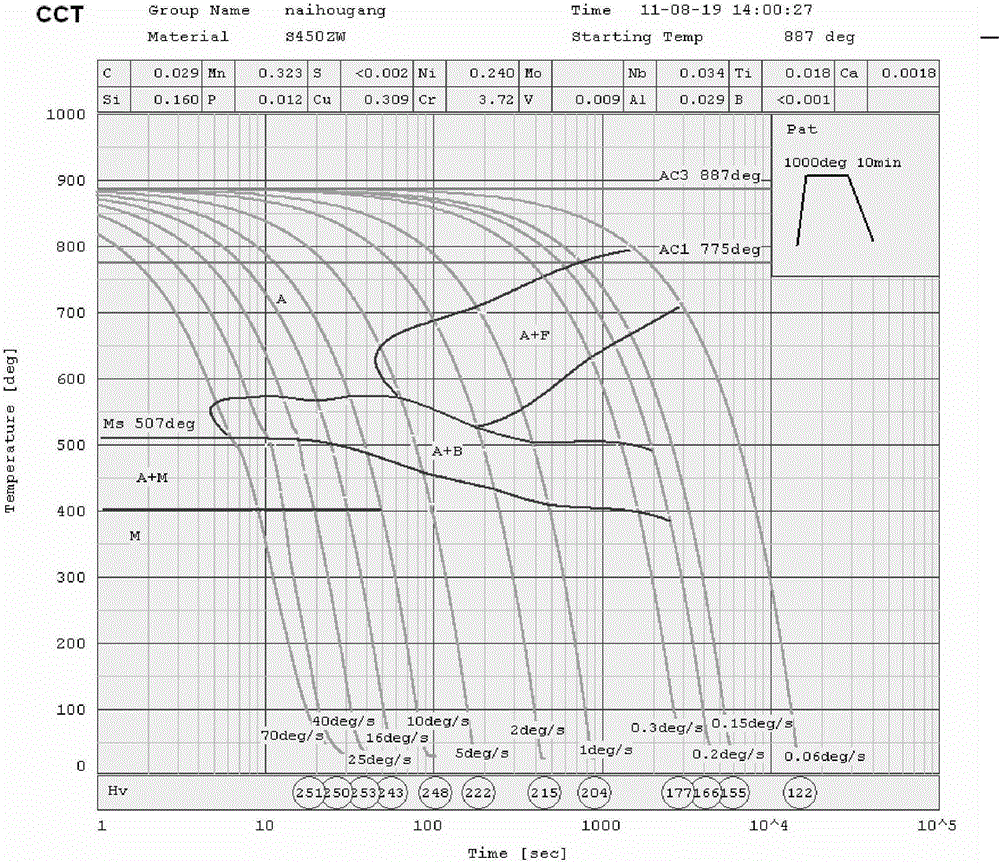

[0025] The preparation method of the above-mentioned low yield ratio weathering steel mainly includes the following steps: billet → hot rolling → laminar cooling → coiling;

[0026] Wherein, the start rolling temperature of the finish rolling in the hot rolling step is 950-995°C, the finish rolling temperature in the hot rolling step is 830-855°C, and the rolling speed in the hot rolling step is 2-10m / s; The proportion of water in the tube is 45-55%, the proportion of water in the lower header is 55-65%, the average cooling rate of the steel plate in the cooling step is 5-20°C / s; the coiling temperature is 560-596°C.

[0027] Further, as a more preferred technical solution, in the preparation method of the above-mentioned low yield ratio weathering steel, the starting temperature of the finish rolling in the hot rolling step is 975°C, the finishing rolling temperature in the hot rolling step is 845°C, and the hot rolling step The rolling speed in the step is 6.2m / s; the water ...

Embodiment 1

[0039] The weight percent of the chemical composition of the billet is: C: 0.04%, Si: 0.30%, Mn: 0.75%, P: 0.015%, S: 0.007%, Cr: 3.35%, Ni: 0.15%, Cu: 0.30%, Ti : 0.02%, the rest is Fe and unavoidable impurities.

[0040] The starting temperature of finish rolling in the hot rolling step is 975°C, the finish rolling temperature in the hot rolling step is 845°C; the rolling speed in the hot rolling step is 6.2m / s; the water volume ratio of laminar flow cooling in the cooling step is 50% , the proportion of water in the lower header is 60%; the average cooling rate of the steel plate in the cooling step is 12.5°C / s; the temperature in the coiling step is 580°C.

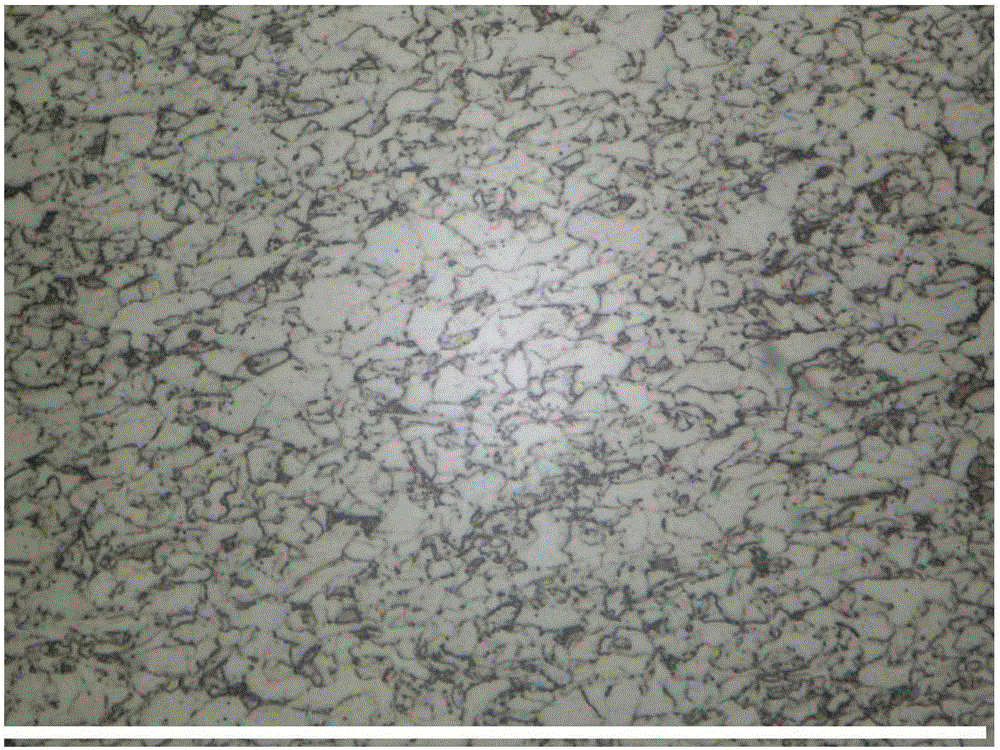

[0041] The low yield strength ratio weathering steel mechanical properties Rel: 523MPa, Rm: 715MPa, yield ratio 0.73, A%: 27% of the low yield strength ratio weathering steel produced by this method; Low temperature impact performance (-40 ℃): 185J, weather resistance performance (relative corrosion rate): 28%.

Embodiment 2

[0043] The weight percent of the chemical composition of the billet is: C: 0.031%, Si: 0.11%, Mn: 0.52%, P: 0.012%, S: 0.006%, Cr: 3.05%, Ni: 0.12%, Cu: 0.21%, Ti : 0.011%, the rest is Fe and unavoidable impurities.

[0044] The starting temperature of finish rolling in the hot rolling step is 952°C, the finish rolling temperature in the hot rolling step is 831°C; the rolling speed in the hot rolling step is 2.1m / s; the water volume ratio of the laminar cooling upper header in the cooling step is 45% , the proportion of water in the lower header is 55%; the average cooling rate of the steel plate in the cooling step is 5.2°C / s; the temperature in the coiling step is 563°C.

[0045] The low yield strength ratio weathering steel mechanical properties Rel: 505MPa, Rm: 708MPa produced by this method, yield strength ratio 0.71, A%: 27%; Low temperature impact performance (-40 ℃): 196J, weather resistance performance (relative corrosion rate): 29.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com