Abrasion-resistant coating for front edge of wind power blade and preparation method of abrasion-resistant coating

An anti-corrosion technology for wind turbine blades, applied in coatings, wind power generation, anti-corrosion coatings, etc., can solve problems such as increased maintenance costs, damage to the integrity of wind turbine blades, reduced aerodynamic performance and operational reliability, and achieves improved adhesion , high anti-corrosion performance and adhesion, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the above-mentioned anti-corrosion coating for the leading edge of wind turbine blades comprises the following steps:

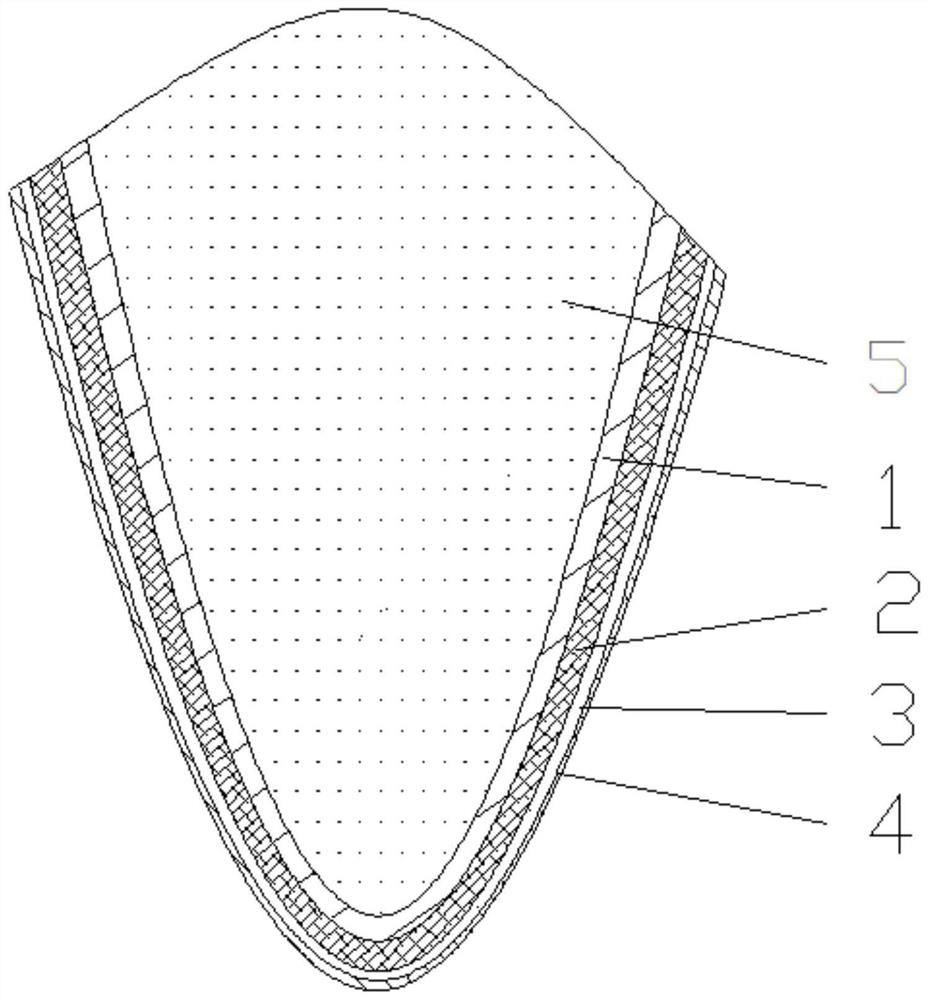

[0053] 1) Prepare the substrate 5. Pre-treat the surface of the leading edge of the blade, which can be polished with sandpaper. After completion, use compressed air to blow for 5 to 10 minutes, decontaminate, degrease and dehumidify, and check the surface quality. There must be no obvious defects on the surface. Defects such as meat, cracks and pits.

[0054] 2) To coat the bottom layer 1, the above-mentioned epoxy paint is evenly stirred, and evenly coated on the surface of the substrate 5 to obtain the bottom layer 1. The coating method of spraying can be used, and the temperature of the surface of the substrate 5 during the coating process is not lower than 10 ℃, the thickness of the bottom layer 1 ranges from 100 to 150um, and it should be properly repaired and polished after curing.

[0055] 3) Coating the middle layer ...

Embodiment 1

[0059] The bottom layer 1 is a two-component solvent-based epoxy coating cured at room temperature.

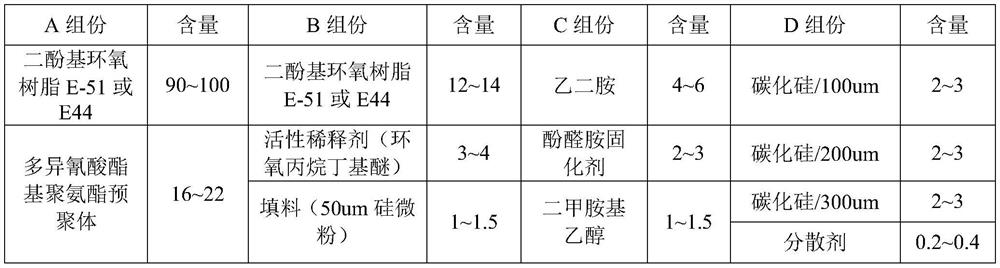

[0060] The middle layer 2 is an anti-corrosion coating, which is a silicon carbide-reinforced polyurethane-modified epoxy coating, and is composed of components A, B, C and D, and the specific ratio is as shown in the following table Shown:

[0061]

[0062] The dosages of components A, B, C and D are mixed according to the above mass, and the proportioning sequence is as follows: first prepare component A, and then add the uniform mixture of components B and C to group A part, and finally add component D and mix well.

[0063] The leveling layer 3 is made of components B, C, E and F, and the proportioning ratio is shown in the following table:

[0064]

[0065] The dosages of components B, C, E and F are mixed according to the above mass, and the proportioning sequence is: mix components B and C evenly, then add component E, and finally add component F The components...

Embodiment 2

[0074] Compared with Example 1, Example 2 mainly changes the epoxy resin E51 in components A and B to epoxy resin E44, the ratio of other components remains unchanged, and the coating process is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com