Concentrated solution for compatible hydraulic support and preparation method of concentrated solution

A hydraulic support and compatible technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of cumbersome replacement work, affecting the downhole environment, waste of resources, etc., achieving good stability, solving emulsion replacement, and reliable liquid supply. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

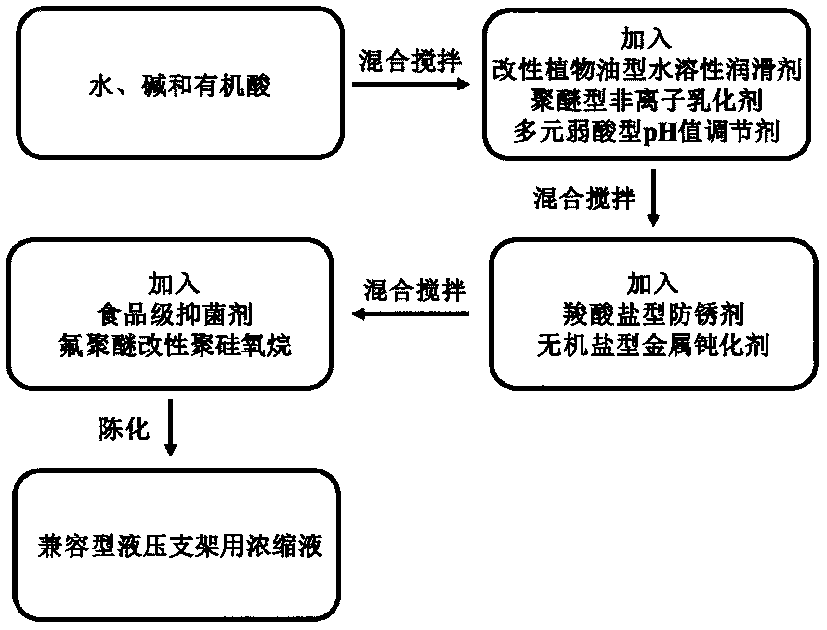

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a concentrated solution for a compatible hydraulic support, which includes the following steps:

[0031] a. Mix and stir water, alkali and organic acid to obtain a chelating dispersant containing nitrogen atoms;

[0032] b. Add modified olive oil water-soluble lubricant, polyether type nonionic emulsifier, polybasic weak acid type pH regulator and water to the chelating dispersant containing nitrogen atoms in the step a, mix and stir, A dispersion mixture was obtained.

[0033] c. Add carboxylate-type antirust agent and inorganic salt-type metal passivator to the dispersed mixed solution in step b, mix and stir to obtain antirust mixed solution.

[0034] d. Add bacteriostatic agent and fluoropolyether-modified polysiloxane to the antirust mixture in step c, mix, stir and age to obtain a concentrated solution for compatible hydraulic supports.

[0035] According to the p...

Embodiment 1

[0042] Water, monoethanolamine and polyacrylic acid (average molecular weight 20,000) were mixed according to the mass ratio of 11:3:2, the temperature was 100°C, the stirring time was 120min, and the rotation speed was 60r / min to obtain a chelating dispersant containing nitrogen atoms.

[0043] Mix caprylic acid, azelaic acid, ternary polycarboxylic acid and monoethanolamine in a mass ratio of 3:5:3:4, stir at 80°C for 60min, and rotate at 60r / min to obtain a carboxylate-type rust inhibitor.

[0044] Water-soluble sodium molybdate, sodium silicate and sodium tetraborate are mixed in a mass ratio of 5:3:6 to obtain an inorganic salt type metal passivator.

[0045] The mass percent content of each raw material in the concentrated liquid for compatible hydraulic support is: 4% of modified olive oil water-soluble lubricant, 2% of polyether type nonionic emulsifier, 5% of chelating dispersant containing nitrogen atoms, Multivariate weak acid pH regulator 2%, carboxylate type rust ...

Embodiment 2

[0049] Mix water, diethanolamine and polymethacrylic acid (average molecular weight 40,000) according to the mass ratio of 9:2:2, the temperature is 90°C, the stirring time is 90min, and the rotation speed is 90r / min to obtain a chelate dispersion containing nitrogen atoms. agent.

[0050] Mix nonanoic acid, azelaic acid, ternary polycarboxylic acid and diethanolamine in a mass ratio of 6:10:5:8, stir at 100°C for 90 minutes, and rotate at 90 r / min to obtain a carboxylate-type rust inhibitor .

[0051] Mix water-soluble sodium molybdate, sodium silicate and sodium tetraborate in a mass ratio of 1:1:2 to obtain an inorganic salt type metal passivator.

[0052] The mass percent content of each raw material in the concentrated liquid for compatible hydraulic support is: 20% of modified olive oil water-soluble lubricant, 8% of polyether type nonionic emulsifier, 15% of chelating dispersant containing nitrogen atoms, Multivariate weak acid pH adjuster 8%, carboxylate type rust in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com