Non-sulphur and phosphorus antiwear and friction reducing multifunctional additive agent and preparation method

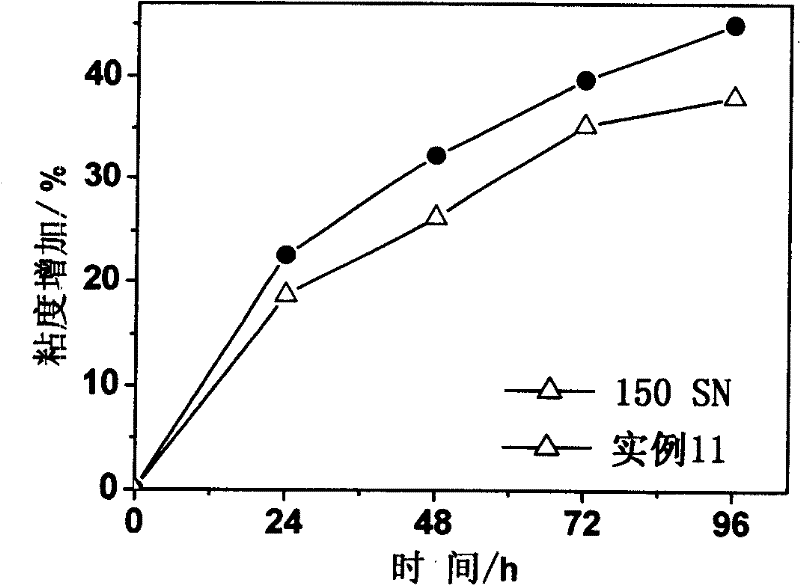

A multi-functional additive technology, applied in the field of lubricating oil, can solve the problems of reducing extreme pressure, anti-wear and anti-oxidation properties of oil products, and achieve the effects of increasing the initial oxidation temperature, improving high-temperature anti-oxidation properties, and inhibiting the increase in viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Synthesis of friction modifiers. Add 0.2mol oleic acid and 0.2mol triethanolamine into the reaction flask, then 4.5g dibutylamine, stir, and heat to 120°C, react for 3 hours to synthesize an intermediate, then add 0.05mol dibutyltin laurate, 0.1 The mixture of mol tetraisopropyl titanate and 0.025mol bismuth oxide was stirred continuously and reacted at 180° C. for 6 hours to finally obtain a friction modifier product.

[0026] Add friction modifier 45%, oleic acid diethanolamide borate 45%, 2,6-di-tert-butyl p-cresol 3%, dienyl succinimide 6%, dodecenyl butanedi 1% acid was mixed sequentially, and the mixture was heated up to 50° C. under stirring, and stirred evenly to obtain the anti-wear and friction-reducing multifunctional nonthion phosphorus additive of the present invention.

Embodiment 2

[0028] 50% of the friction modifier prepared in Example 1, 40% of oleic acid diethanolamide borate, 3% of methylene-bis(dibutyldithiocarbamate), 2% of calcium alkyl salicylate , 4% of dienyl succinimide and 1% of dodecenyl succinic acid are mixed successively, and the mixture is heated up to 50-60°C under stirring, and stirred evenly to obtain the anti-wear and friction-reducing nonthion phosphorus of the present invention Multifunctional additive.

Embodiment 3

[0030] 55% of the friction modifier prepared in Example 1, 35% of borate (T 361), 3% of diisooctyldiphenylamine, 6% of calcium alkyl salicylate, and 1% of dodecenylsuccinic acid Mixing, raising the temperature of the mixture to 50-60° C. under stirring, and stirring evenly to obtain the nonthion phosphorus anti-wear and friction-reducing multifunctional additive of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com