A kind of preparation method of copper-silver composite powder and conductive adhesive

A technology of conductive adhesive and composite powder, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of low utilization rate of copper and silver reagents, serious agglomeration between particles, and silver waste, and achieve excellent conductivity and Oxidation resistance, increased initial oxidation temperature, and stable service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of copper-silver composite powder of the present invention comprises the following steps:

[0032] (1) Put a graphite crucible with 400g of silver ingot and 3600g of copper plate into the Hermiga gas atomization device manufactured by British PSI company, heat it from room temperature to 1150°C at a rate of 50°C / min, and melt to obtain a uniform mixed alloy For the melt, use high-pressure nitrogen atomization to atomize the mixed alloy melt to obtain copper-silver alloy powder with a silver content of 10% (with a particle size of 120 microns or less).

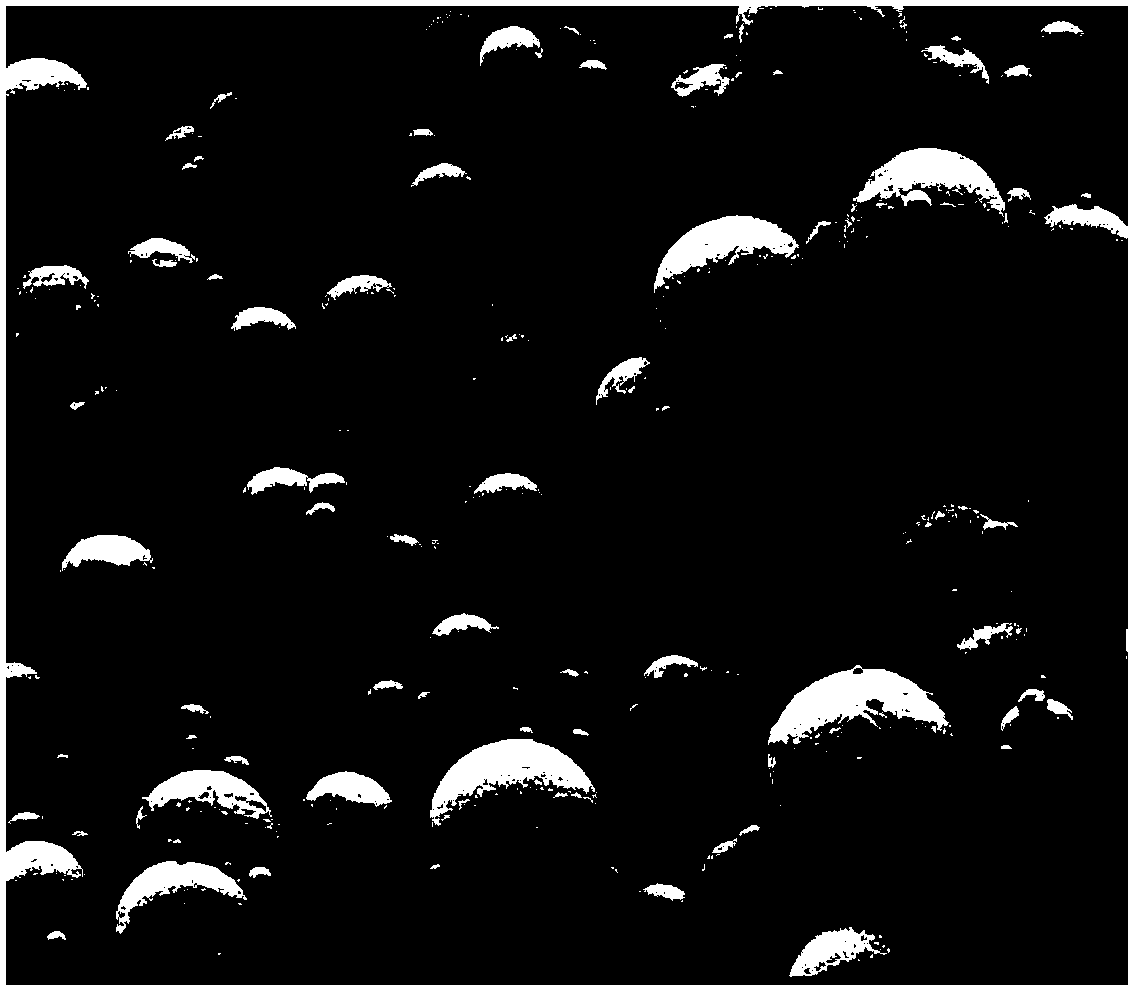

[0033] (2) First sieve the copper-silver alloy powder obtained in step (1) to get -100 mesh powder, and then use 600 mesh and 800 mesh standard sieves to obtain copper-silver alloy powder with a particle size distribution range of 10 to 25 μm, such as figure 1 Shown is a nearly spherical powder.

[0034] (3) Weigh 20g of the copper-silver alloy powder sieved in step (2) and put it into a well-sealed...

Embodiment 2

[0037] A preparation method of copper-silver composite powder of the present invention comprises the following steps:

[0038] (1) Put a graphite crucible with 35g of silver ingot and 380g of copper plate into the Hermiga gas atomization device manufactured by British PSI company, heat it from room temperature to 1200°C at a rate of 50°C / min, and melt to obtain a uniform alloy melt The solution was atomized with high-pressure nitrogen gas to obtain copper-silver alloy powder with a silver content of 8.43% (with a particle size of 120 microns or less).

[0039](2) Sieve the copper-silver alloy powder obtained in step (1) to obtain -100-mesh powder, and then use 600-mesh and 800-mesh standard sieves to obtain copper-silver alloy powder with a particle size distribution range of 10-25 μm.

[0040] (3) Weigh 10g of the copper-silver alloy powder obtained in step (2) and put it into a well-sealed furnace, then use an electric oil pump to pump air until the vacuum in the furnace rea...

Embodiment 3

[0046] The preparation method of copper-silver composite powder of the present invention comprises the following steps:

[0047] (1) The seven silver ingots and copper plates are respectively 0.1g and 9.9g, 0.4g and 9.6g, 0.6g and 9.4g, 0.8g and 9.2g, 1.0g and 9.0g, 1.2g and 8.8g, The 1.4g and 8.6g graphite crucibles were put into the Hermiga gas atomization device manufactured by British PSI company, heated from room temperature to 1200°C at a rate of 50°C / min, and melted to obtain a homogeneous alloy melt, which was formed sequentially by high-pressure nitrogen atomization. Copper-silver alloy powders with silver mass content of 1%, 4%, 6%, 8%, 10%, 12% and 14% were obtained.

[0048] (2) Sieve the pure copper powder and the copper-silver alloy powder obtained in step (1) to obtain -100 mesh powder, and then use 600 mesh and 800 mesh standard sieves to obtain copper-silver alloy powder with a particle size distribution range of 10-25 μm .

[0049] (3) Weigh the 8 powders o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com