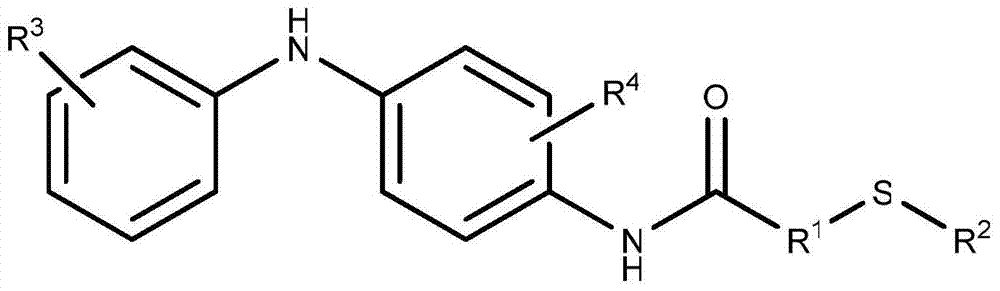

Antioxidant of n‑(4‑anilinophenyl)‑amidosulfide compounds

An anilino phenyl compound technology is applied in the field of anti-oxidant additives for lubricating oil, which can solve the problems of oxidative failure of ester lubricating oil, affecting the safe use of equipment, etc., so as to improve the initial oxidation temperature, improve service performance, and reduce oxidative deterioration. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

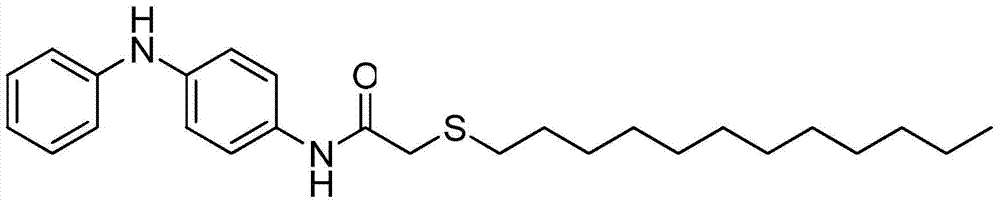

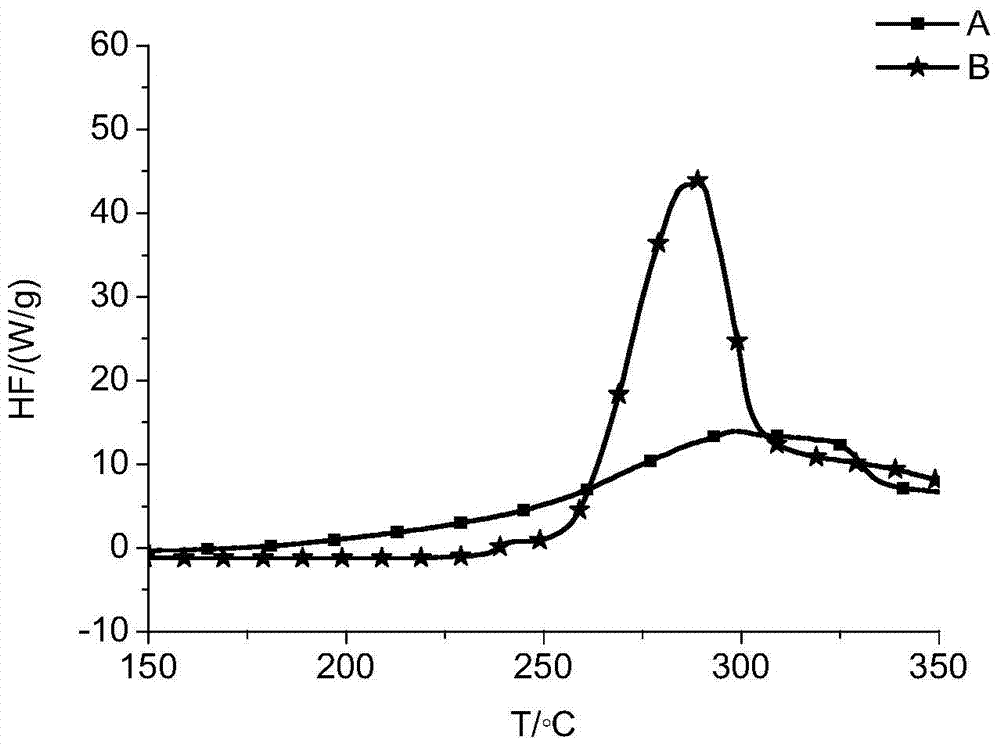

[0037] Synthetic N-(4-anilinophenyl)-amido-methylene dodecyl sulfide (such as figure 2 ), as a lubricating oil antioxidant additive, dissolved in the lubricating oil base oil trimethylolpropane oleate with a concentration of 1%, and using differential scanning calorimetry (DSC) to detect this base oil and the antioxidant According to the initial oxidation temperature and oxidation induction period of the base oil of the agent, the high temperature oxidation resistance of the antioxidant can be judged according to the initial oxidation temperature, and the stability of the antioxidant can be judged according to the length of the oxidation induction period.

[0038] The DSC-Q10 differential scanning calorimeter was used for testing. Dynamic DSC test conditions: nitrogen flow rate 30mL / min, oxygen flow rate 20mL / min, heating rate 20°C / min, record data at 100-400°C. Nitrogen is introduced at the beginning of the test, and when the temperature reaches the set temperature of 100°C,...

Embodiment 2

[0042] Synthetic N-(4-anilinophenyl)-amido-methylene nonyl sulfide (such as Figure 4 ), as a lubricating oil antioxidant additive, dissolved in the lubricating base oil trimethylolpropane oleate with its 1% concentration, and utilizes dynamic DSC to measure the initial oxidation temperature in the specific lubricating base oil wherein. Test apparatus and test condition are consistent with embodiment 1. The test results of dynamic DSC are as follows Figure 5, the results show that after the addition of N-(4-anilinophenyl)-amido-methylenenonyl sulfide, the initial oxidation temperature of the lubricating oil is 272.86°C, which effectively improves the oxidation resistance of the lubricating oil Performance (Under the same test conditions, the initial oxidation temperature of the lubricating base oil trimethylolpropane oleate is 233.65°C).

[0043] Static DSC was used to measure the oxidation induction time of lubricating oil containing 1% N-(4-anilinophenyl)-amido-methylenen...

Embodiment 3

[0045] Figure 6 It is the dynamic DSC curve of lubricating base oil trimellitate and lubricating oil containing 1% N-(4-anilinophenyl)-amido-methylene nonyl sulfide. Test apparatus and test condition are consistent with embodiment 1,2. Dynamic DSC test results show that: the initial oxidation temperature of trimellitate is 243.61 ° C, after adding 1% concentration of N-(4-anilinophenyl)-amido-methylene nonyl sulfide, the lubricating The initial oxidation temperature of the oil is 285.27°C, which effectively improves the oxidation resistance of the lubricating oil.

[0046] Determination of lubricating oil containing lubricating base oil trimellitate and 1% N-(4-anilinophenyl)-amido-methylene nonyl sulfide + trimellitate at 230°C by static DSC Oxidation induction time at constant temperature. Static DSC oxidation reaction test conditions: nitrogen flow rate 30mL / min, heating rate 20°C / min, when the temperature rises to 230°C, switch to oxygen, oxygen flow rate 20°C / min, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com