A kind of polyethylene sound-absorbing composite material for building drainage pipeline and preparation method thereof

A technology for building drainage and composite materials, which is applied in the field of polyethylene sound-absorbing composite materials for building drainage pipes and its preparation, can solve problems such as failing to meet environmental protection requirements, achieve high oxidation induction time, simple and easy-to-obtain raw materials, and improve surface activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

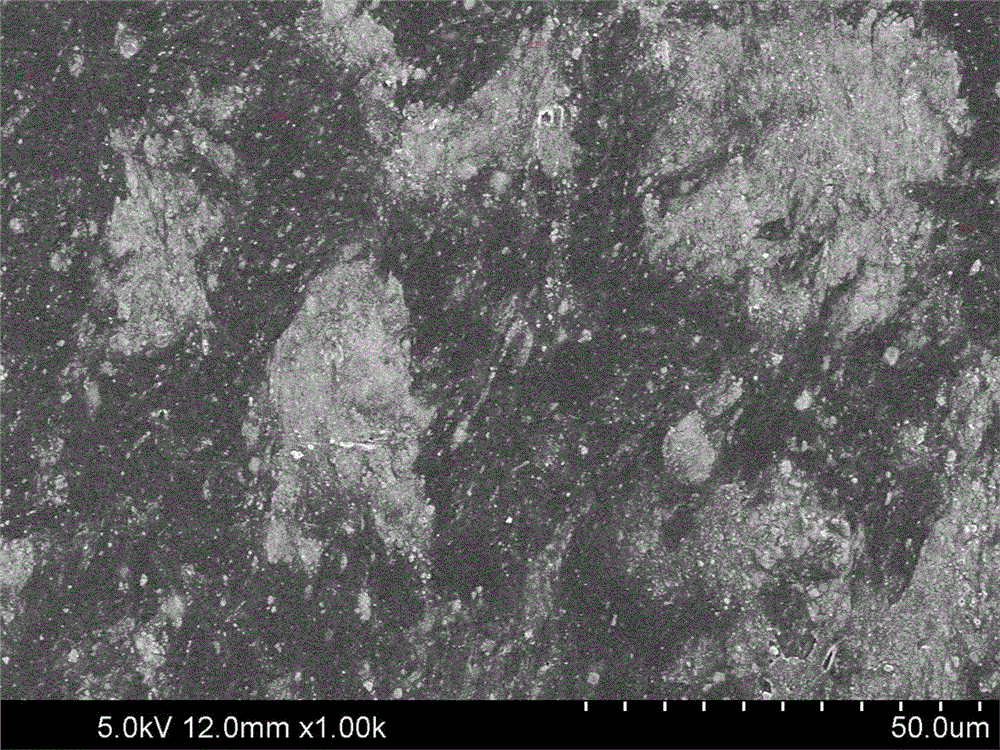

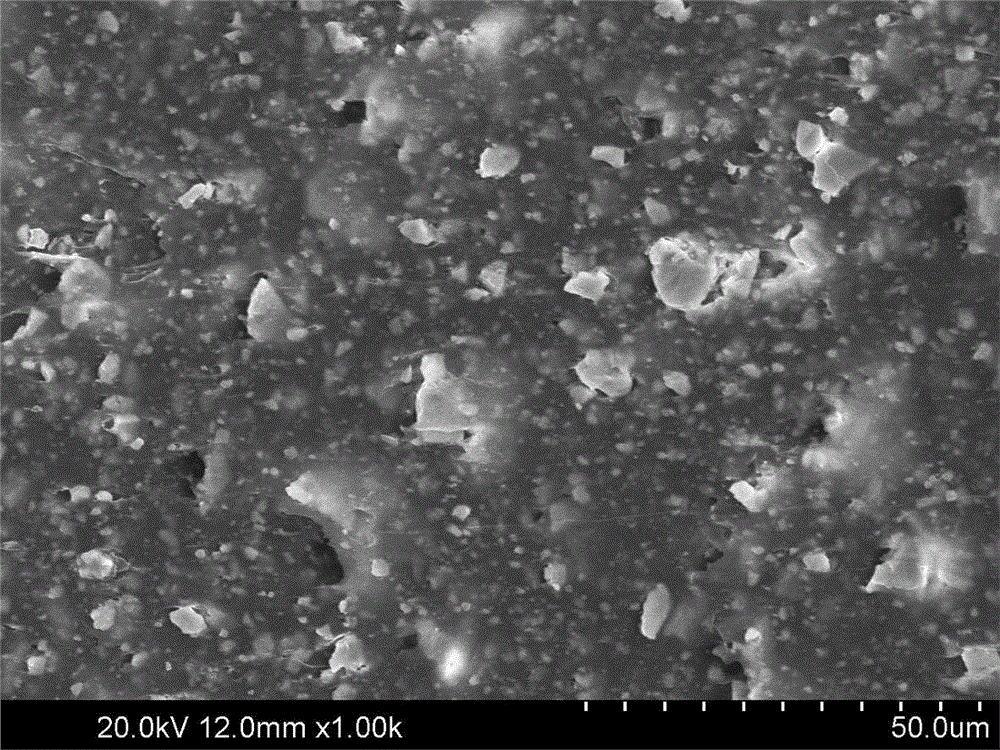

Image

Examples

Embodiment 1

[0031] (1) Formula: 40 parts by weight of high-density polyethylene, 0.015 parts by weight of dicumyl peroxide, 0.8 parts by weight of vinyltrimethoxysilane, 50 parts by weight of activated nano-scale barium sulfate, activated 10 parts by weight of 1200 mesh barium sulfate, 2 parts by weight of polyethylene wax, 4 parts by weight of titanium dioxide, 0.3 parts by weight of antioxidant 1010, 0.3 parts by weight of antioxidant 168, 2 parts by weight of carbon black number.

[0032] (2) Preparation process: weigh the above formula and put it into a high-speed mixer, stir it at 25°C for 5 minutes, and discharge it for use. Add the mixed material into the extruder to granulate. The process conditions of the extruder:

[0033] The length-to-diameter ratio of the extruder is L / D=44:1, the number of heating sections of the extruder is 12 sections, and a vacuum extraction port is opened in the 9th heating section, and the processing temperature is gradually increased from the fe...

Embodiment 2

[0037] (1) Formula: 30 parts by weight of high-density polyethylene, 0.02 parts by weight of a mixture of di-tert-butane peroxide and 1,3-di-tert-butyl peroxide in a weight ratio of 1:1, dimethyl 0.8 parts by weight of vinyl ethoxysilane, 50 parts by weight of nano-scale barium sulfate after activation treatment, 20 parts by weight of 1200 mesh barium sulfate after activation treatment, 2 parts by weight of polyethylene wax, 4 parts by weight of titanium dioxide Number, antioxidant 1010 0.3 parts by weight, antioxidant 168 0.3 parts by weight, carbon black 2 parts by weight.

[0038] (2) Preparation process: weigh the above formula and put it into a high-speed mixer, stir it at 25°C for 5 minutes, and discharge it for use. Add the mixed material into the extruder to granulate. The process conditions of the extruder:

[0039] The length-to-diameter ratio of the extruder is L / D=44:1, the number of heating sections of the extruder is 12 sections, and a vacuum extraction po...

Embodiment 3

[0041] (1) Formula: 30 parts by weight of high-density polyethylene, 0.01 parts by weight of 2,5-dimethyl-2,5 bis(tert-butylperoxy)hexyne, methylvinyldiethoxysilane 0.5 parts by weight, 40 parts by weight of nano-scale barium sulfate that activation has been processed, 20 parts by weight of 1200 mesh barium sulfate that activation has been processed, 2 parts by weight of polyethylene wax, 4 parts by weight of titanium dioxide, antioxidant 168 0.3 parts by weight, carbon black 2 parts by weight.

[0042] (2) Preparation process: weigh the above formula and put it into a high-speed mixer, stir it at 25°C for 5 minutes, and discharge it for use. Add the mixed material into the extruder to granulate. The process conditions of the extruder:

[0043] The length-to-diameter ratio of the extruder is L / D=44:1, the number of heating sections of the extruder is 12 sections, and a vacuum extraction port is opened in the 9th heating section, and the processing temperature is gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com