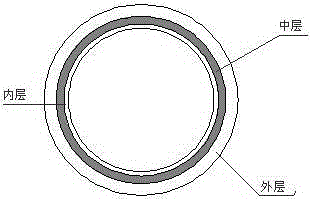

A method for manufacturing a three-resistance light-blocking composite pipe

A composite pipe material and manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of not greatly improving the service life, poor overall performance of wear-resistant materials, pulverization and mechanical property damage, etc. problems, to achieve the effects of improving mechanical properties and aging resistance, prolonging the oxidation induction time, and reducing the coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 200ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0035] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 100ml, nucleating agent DBS 12.5kg;

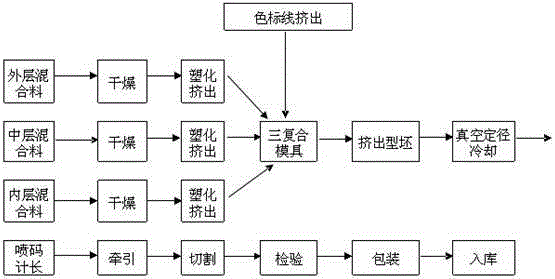

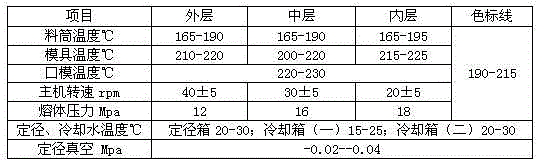

[0036] 3. Pipe preparation: The outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 4.5 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 2.5 parts of nucleating agent masterbatch, and 3 parts of white masterbatch ;The middle layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 2 parts of gray masterbatch, 4.5 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP -R100 parts, 2 parts of nano-silver ion composite titanium dioxide antibacterial maste...

Embodiment 2

[0041] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 200ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0042] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 100ml, nucleating agent DBS 12.5kg;

[0043] 3. Preparation of pipe material: The outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 5.5 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 4 parts of nucleating agent masterbatch, and 2 parts of white masterbatch ;The middle layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 3 parts of gray masterbatch, 4 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP -R100 parts, 2 parts of nano-silver ion composite titanium dioxide antibacteri...

Embodiment 3

[0048] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 300ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0049] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 200ml, nucleating agent DBS 12.5kg;

[0050] 3. Preparation of pipe material: the outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 5.4 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 4 parts of nucleating agent masterbatch, and 3 parts of white masterbatch ;The middle layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 3 parts of gray masterbatch, 4.5 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP -R100 parts, 2 parts of nano-silver ion composite titanium dioxide antibacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com