A preparation method and product of seabuckthorn seed oil microcapsules and its application in seabuckthorn chewable tablets

A technology of seabuckthorn seed oil and microcapsules, which is applied in the fields of application, food forming, and confectionery industry, etc. It can solve the problems of embedding rate of seabuckthorn seed oil microcapsules, low oil load, inconvenient carrying and eating, and microcapsule dissolution Insufficient sex and other problems, to achieve the effect of good digestion and absorption, less loss of nutrients, stable and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

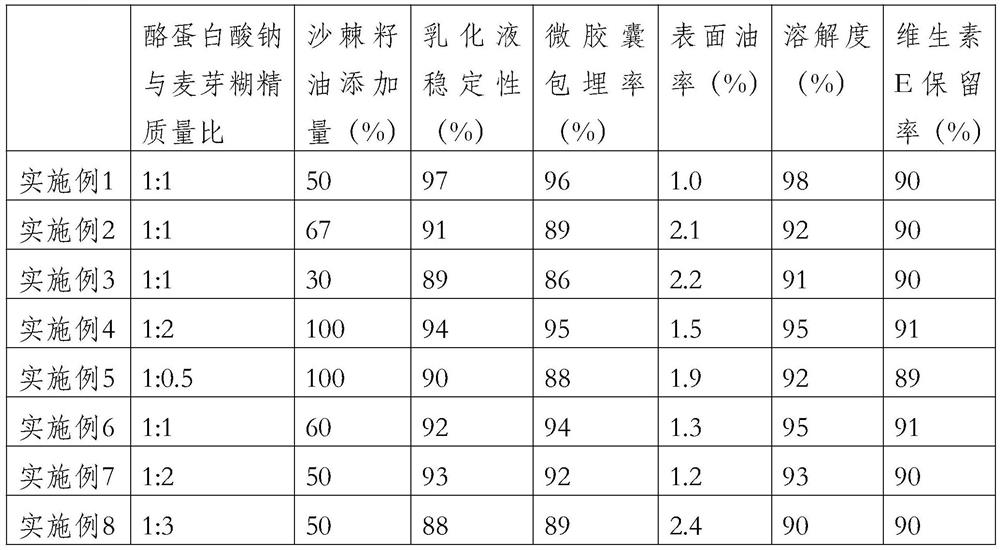

Embodiment 1

[0026] A preparation method of sea buckthorn seed oil microcapsules, comprising the following steps:

[0027] (1) Using sodium caseinate and maltodextrin as wall materials, according to the ratio of sodium caseinate: maltodextrin (w:w)=1:1, add an appropriate amount of distilled water, wall material: distilled water (w:w) =1:6, obtain the wall material solution;

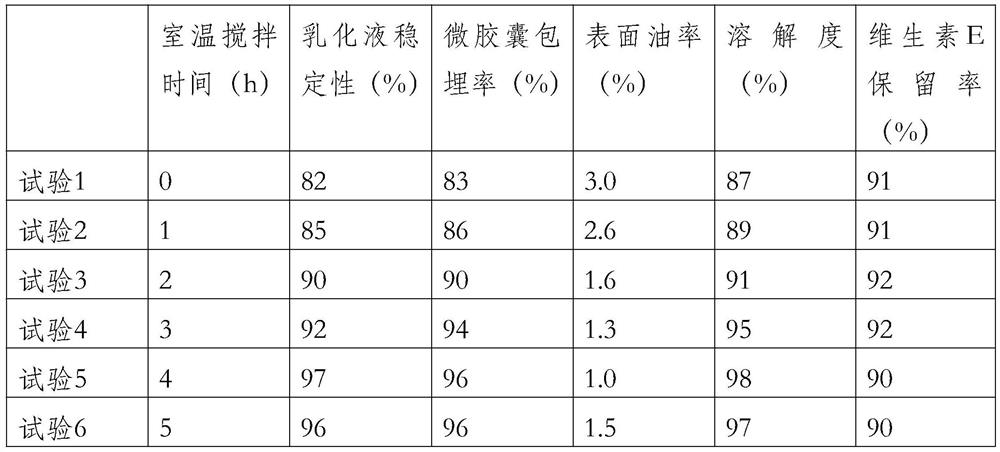

[0028] (2) After dissolving the wall material solution in (1) in hot water at 50-60° C. for 30 minutes, it is then stirred at room temperature for 4 hours to fully dissolve, wherein the stirring rate is 750 r / min;

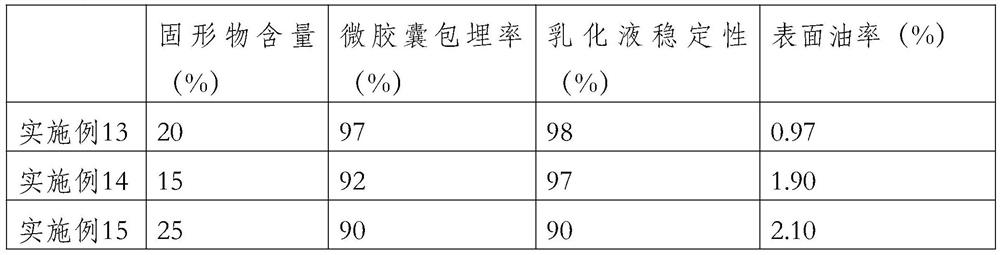

[0029] (3) adding the sea buckthorn seed oil with a mass of 50% of the wall material to the wall material solution obtained in step (2), shearing for 8 minutes at a speed of 20000 r / min, to obtain the initial sea buckthorn seed oil with a solid content of 20% lotion;

[0030] (4) homogenizing the primary emulsion obtained in step (3) under a pressure of 30 to 40 MPa twice to obtain a seabuckthorn seed o...

Embodiment 2

[0033] A preparation method of sea buckthorn seed oil microcapsules, comprising the following steps:

[0034] (1) Using sodium caseinate and maltodextrin as wall materials, according to the ratio of sodium caseinate: maltodextrin (w:w)=1:1, add an appropriate amount of distilled water, wall material: distilled water (w:w) =3:20, obtain the wall material solution;

[0035] (2) After dissolving the wall material solution in (1) in hot water at 50 to 60°C for 30 minutes, it is then stirred at room temperature for 4 hours to fully dissolve, wherein the stirring rate is 750 r / min;

[0036] (3) adding the sea buckthorn seed oil with a mass of 67% of the wall material to the wall material solution obtained in step (2), shearing for 8 minutes at a speed of 20000 r / min, to obtain the initial sea buckthorn seed oil with a solid content of 20% lotion;

[0037] (4) homogenizing the primary emulsion obtained in step (3) under a pressure of 30 to 40 MPa twice to obtain a seabuckthorn seed...

Embodiment 3

[0040] A preparation method of sea buckthorn seed oil microcapsules, comprising the following steps:

[0041] (1) Using sodium caseinate and maltodextrin as wall materials, according to the ratio of sodium caseinate: maltodextrin (w:w)=1:1, add an appropriate amount of distilled water, wall material: distilled water (w:w) =3:16, obtain the wall material solution;

[0042] (2) After dissolving the wall material solution in (1) in hot water at 50 to 60°C for 30 minutes, it is then stirred at room temperature for 4 hours to fully dissolve, wherein the stirring rate is 750 r / min;

[0043] (3) adding the sea buckthorn seed oil with a mass of 30% of the wall material to the wall material solution obtained in step (2), shearing for 8 minutes at a speed of 20000 r / min, to obtain the initial sea buckthorn seed oil with a solid content of 20% lotion;

[0044] (4) homogenizing the primary emulsion obtained in step (3) under a pressure of 30 to 40 MPa twice to obtain a seabuckthorn seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com