Antioxidant additive composite

A composition and additive technology, applied in the field of lubricating oil, can solve the problem of not finding additive formula and other problems, and achieve the effects of highlighting high temperature antioxidant performance, improving antioxidant performance, and improving high temperature antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

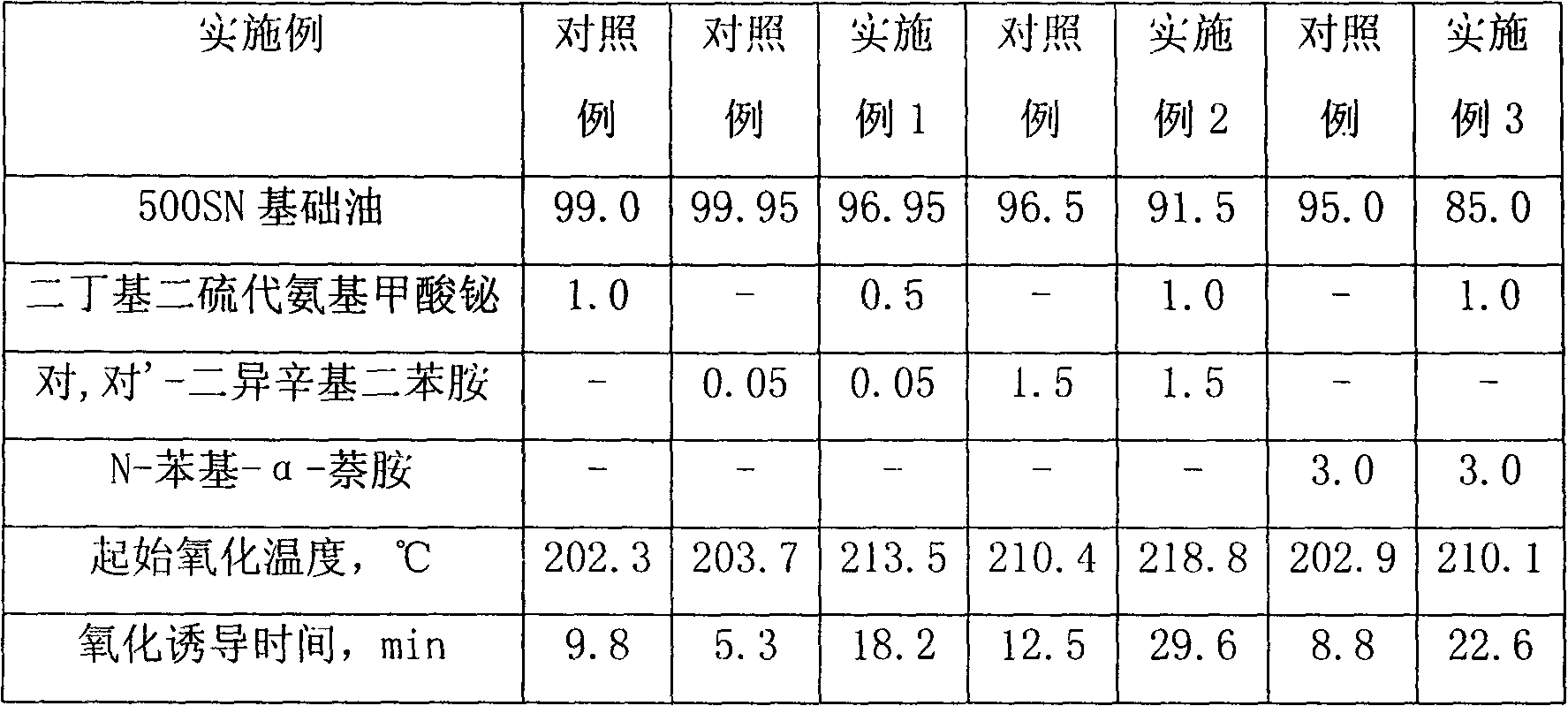

Embodiment 1-3

[0014] Dibutyl bismuth dithiocarbamate, p-, p-diisooctyl diphenylamine (trade name TZ516) and N-phenyl-α-naphthylamine (trade name T531) of different weight percent concentrations were added successively Into 500SN (commercially available) base oil, after heating and dissolving, obtain embodiment 1-3 and evaluate its oxidation resistance. The anti-oxidation performance of the oil is evaluated by differential scanning calorimetry (DSC) experiment, the test conditions: the weight of the test oil sample is 2.00mg, and the oxygen flow rate is 120mL min -1 , in the dynamic oxidation test, the heating rate is 10°C min -1 , in the static oxidation test, the temperature is 180°C. The results of the oxidation experiments are shown in Table 1. As can be seen from the results in the table, bismuth dibutyldithiocarbamate of the present invention and p-'-diisooctyldiphenylamine and N-phenyl-α-naphthylamine have all shown good high temperature oxidation resistance synergistic performance...

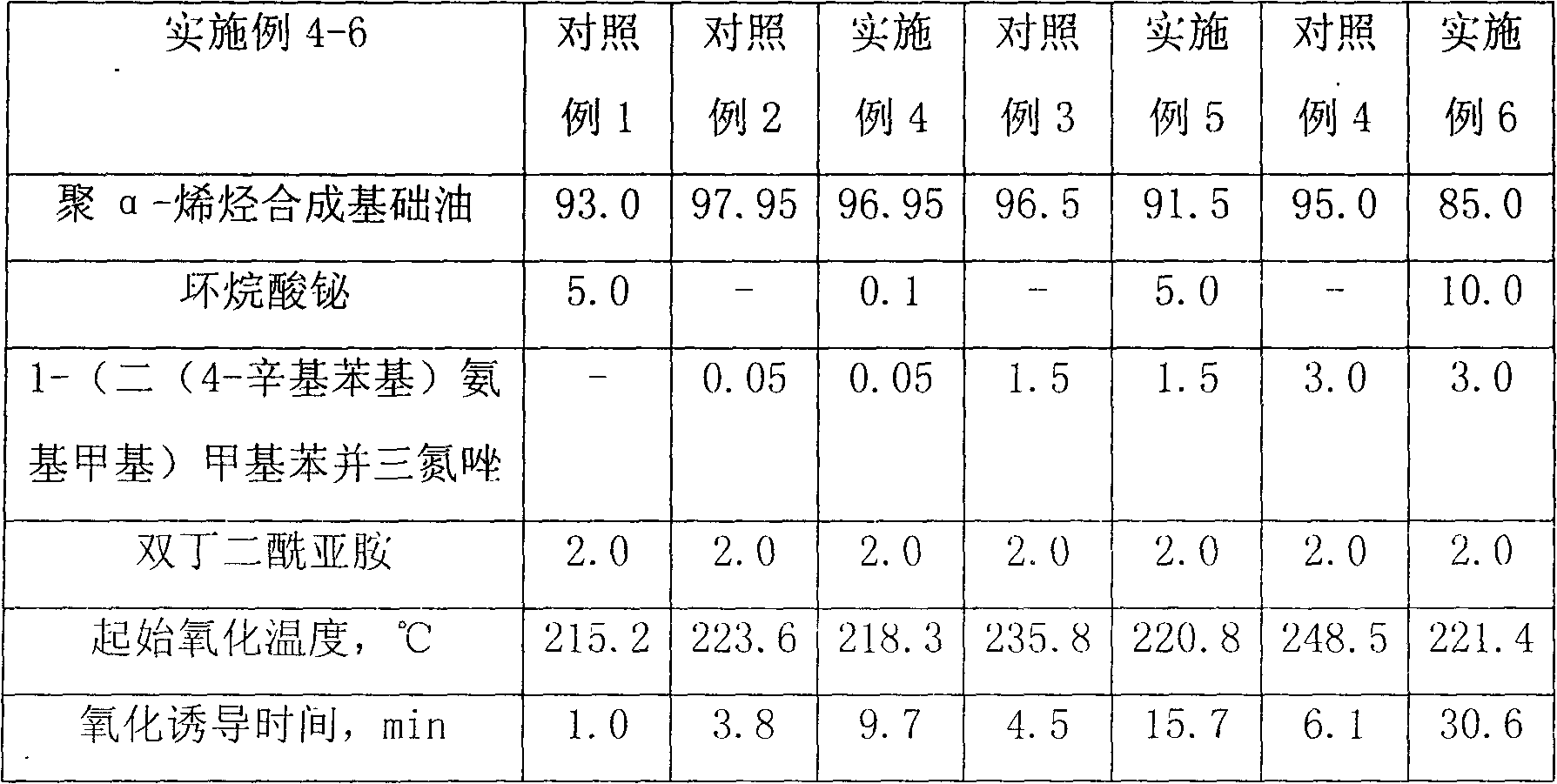

Embodiment 4-6

[0018] With the bismuth naphthenate of different weight percentage concentration, 1-(bis(4-octylphenyl) aminomethyl) methyl benzotriazole (trade mark Produced by U.S. R.T.Vanderbilt Company) and 2.0% bis-succinimide (trade name T152) successively join in polyalpha-olefin synthetic base oil (commercially available), after heating and dissolving, obtain embodiment 4-6, evaluate its Antioxidant properties. The anti-oxidation performance of the oil is evaluated by differential scanning calorimetry (DSC) experiment, the test conditions: the weight of the test oil sample is 1.00mg, and the oxygen flow rate is 60mL min -1 , in the dynamic oxidation test, the heating rate is 10°C min -1 . In the static oxidation test, the temperature was 200°C. The results of the oxidation experiments are shown in Table 2. It can be seen from the results in the table that the bismuth naphthenate of the present invention and 1-(bis(4-octylphenyl)aminomethyl)methylbenzotriazole have outstanding hig...

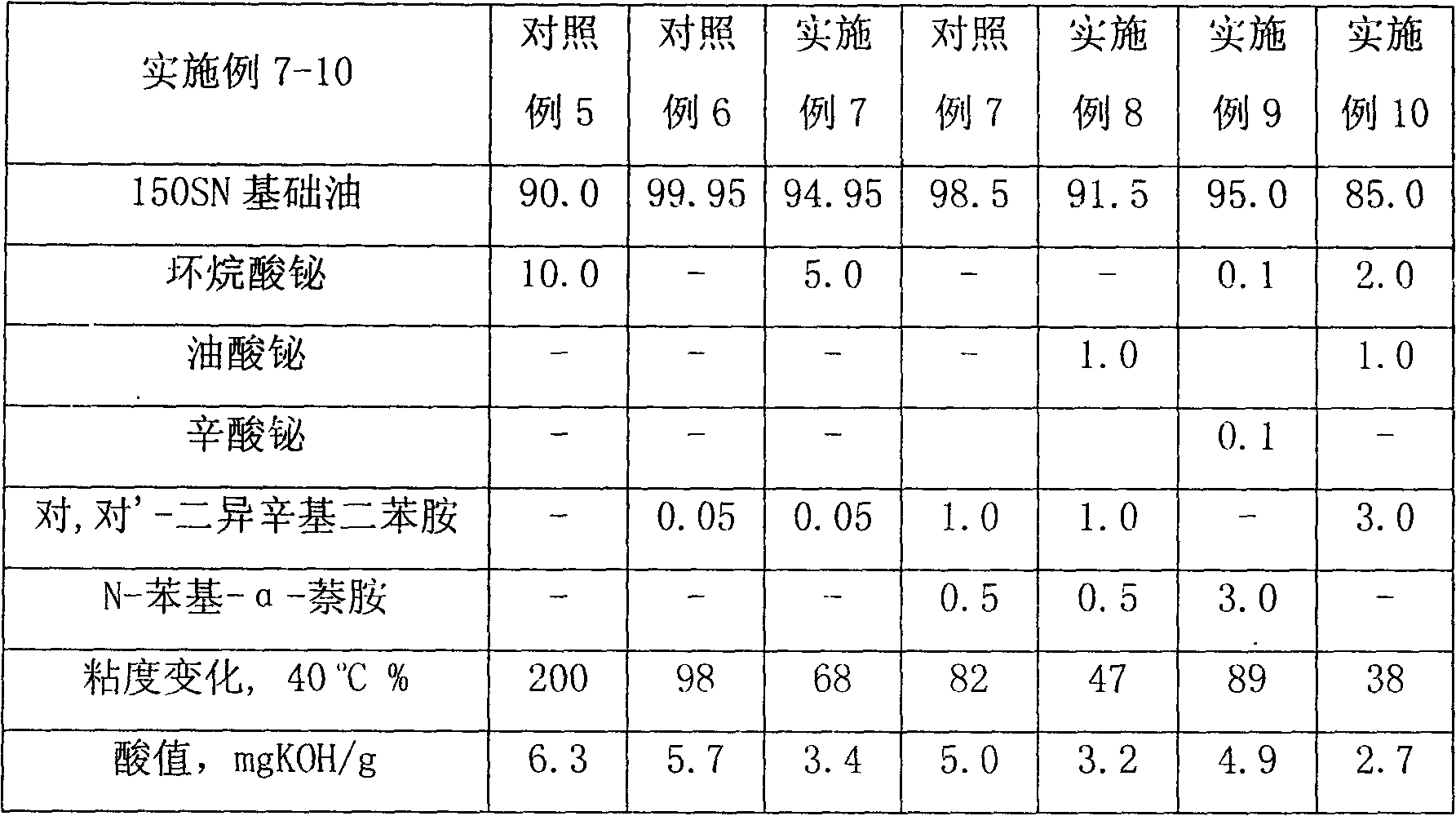

Embodiment 7-10

[0022] Add bismuth naphthenate, bismuth oleate, bismuth octoate, p-, p-diisooctyldiphenylamine and N-phenyl-α-naphthylamine (trade name T531) of different weight percent concentrations to 150SN (market (sold) in the base oil, obtain embodiment 7-10 after heating and dissolving, evaluate its oxidation resistance. The anti-oxidation performance of the oil is evaluated by the thermal oil oxidation test, the test conditions: the weight of the test oil sample is 25g, and the air flow rate is 10L h -1 , the oil temperature is 160°C, and the test time is 72. The viscosity change and acid value of the oxidized oil sample at 40°C were used as the evaluation index of oxidation stability. The smaller the viscosity increase value and the smaller the acid value, the better the oxidation stability. The experimental results are shown in Table 3.

[0023] table 3

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com