A flame retardant high heat dissipation modified polypropylene power pipe and its preparation method

A polypropylene, high heat dissipation technology, applied in the field of flame retardant and high heat dissipation modified polypropylene power pipe and its preparation, can solve the problems of shortening the service life of the cable insulation layer, aging cracks, safety accidents, etc., and achieves a simple preparation process, Long service life and easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

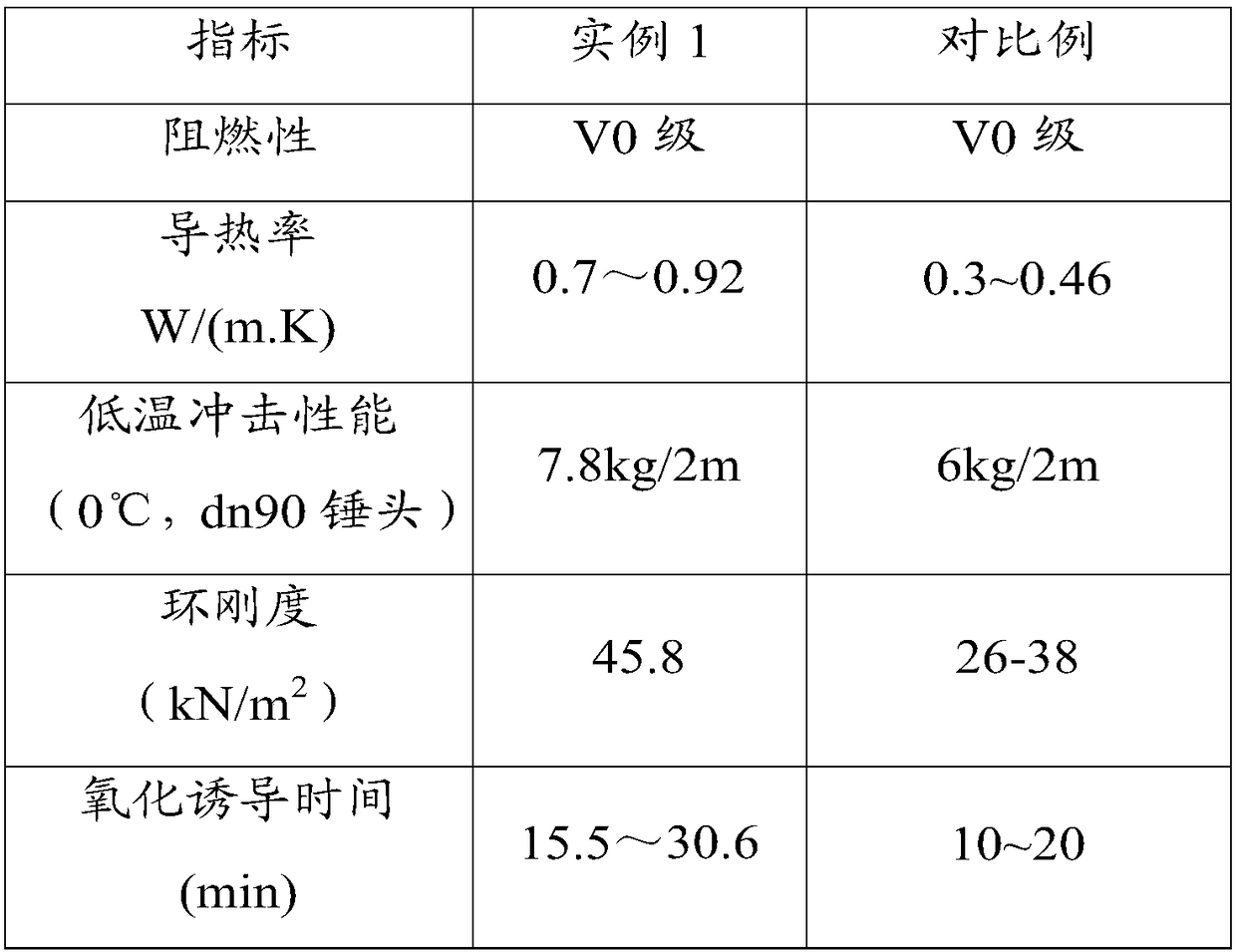

Embodiment 1

[0040] This embodiment provides a kind of modified polypropylene, which is mainly made of the raw materials of the following components in parts by weight:

[0041]750 parts of polypropylene, 5 parts of diamond powder, 5 parts of graphene, 5 parts of silver powder, 10 parts of aluminum nitride powder, 1 part of oxidized polyethylene wax, 10 parts of ethylene-propylene copolymer, 10 parts of ethylene-vinyl acetate copolymer, 10 parts of EPDM rubber (Kunlun J4045), 50 parts of heat-resistant polyethylene, 5 parts of antioxidant 1076, 30 parts of aluminum oxide, 80 parts of ammonium octamolybdate, 10 parts of mica, 5 parts of aluminum titanium coupling agent 50 parts, 50 parts of chlorinated polypropylene, 6 parts of iron red pigment.

[0042] The above-mentioned modified polypropylene pipe is made by the following method:

[0043] Step 1. First, weigh the heat-resistant polyethylene, diamond powder, graphene, silver powder, aluminum nitride powder, and oxidized polyethylene wax...

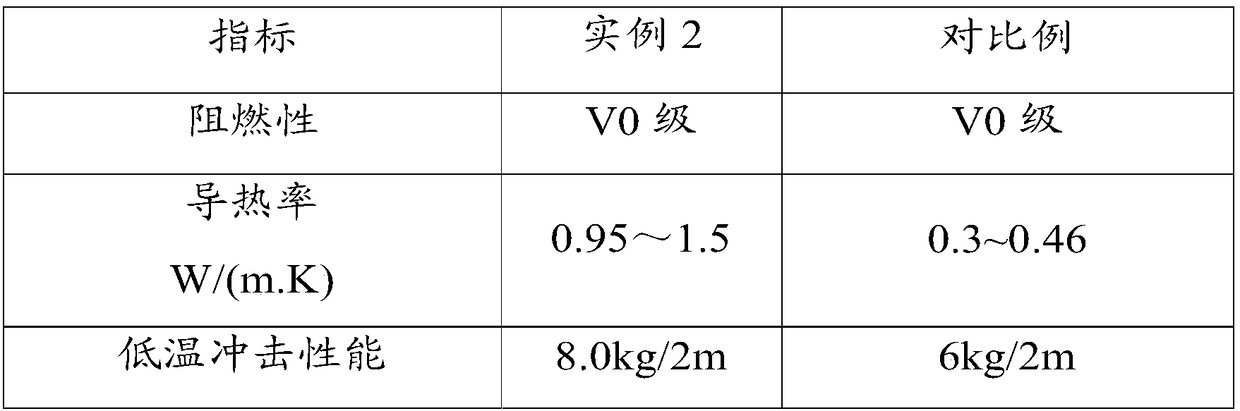

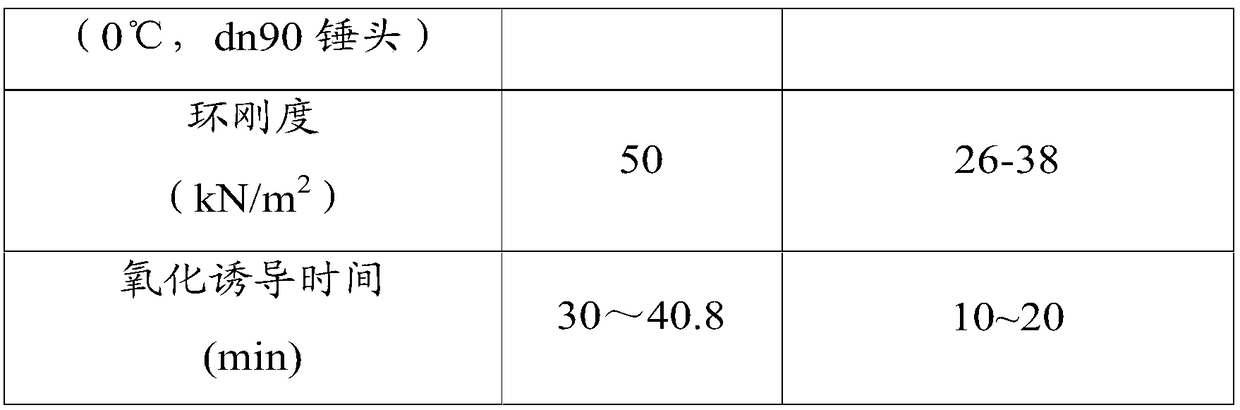

Embodiment 2

[0061] This embodiment provides a modified polypropylene, which is mainly made of the raw materials of the following components:

[0062] In parts by weight, 850 parts of polypropylene, 150 parts of diamond powder, 50 parts of graphene, 40 parts of silver powder, 90 parts of aluminum nitride powder, 5 parts of oxidized polyethylene wax, 100 parts of ethylene-propylene copolymer, ethylene-vinyl acetate 50 parts of copolymer, 40 parts of EPDM rubber, 100 parts of heat-resistant polyethylene, 15 parts of antioxidant 168, 40 parts of red phosphorus, 85 parts of aluminum hydroxide, 50 parts of calcium carbonate, 20 parts of aluminate coupling agent 100 parts of chlorinated polypropylene, 10 parts of iron red pigment.

[0063] The above-mentioned modified polypropylene is made by the following method:

[0064] Step 1. First, weigh heat-resistant polyethylene, diamond powder, graphene, silver powder, aluminum nitride powder, and oxidized polyethylene wax according to their weight, a...

Embodiment 3

[0082] This embodiment provides a modified polypropylene, which is mainly made of the raw materials of the following components:

[0083] In parts by weight, 1000 parts of polypropylene, 200 parts of diamond powder, 100 parts of graphene, 80 parts of silver powder, 180 parts of aluminum nitride powder, 10 parts of oxidized polyethylene wax, 100 parts of ethylene-propylene copolymer, ethylene-vinyl acetate 100 parts of copolymer, 80 parts of EPDM rubber, 150 parts of heat-resistant polyethylene, 60 parts of magnesium hydroxide, 100 parts of ammonium octamolybdate, 100 parts of whiskers, 30 parts of silane coupling agent, 12 parts of antioxidant 1010, 150 parts of chlorinated polypropylene, 9 parts of iron red pigment.

[0084] The above-mentioned modified polypropylene is made by the following method:

[0085] Step 1. First, weigh heat-resistant polyethylene, diamond powder, graphene, silver powder, aluminum nitride powder, and oxidized polyethylene according to weight, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com