Special high-density polyethylene resin for pressure-resistant pipes and preparation method of special high-density polyethylene resin

A technology of high-density polyethylene and polyethylene resin, which is applied in the field of high-density polyethylene resin for pressure-resistant pipes and its preparation, can solve problems such as the difficulty of pressure-resistant performance to meet the requirements, and achieve the increase of nominal strain at tensile fracture and tensile strength. The effect of increasing tensile yield stress and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

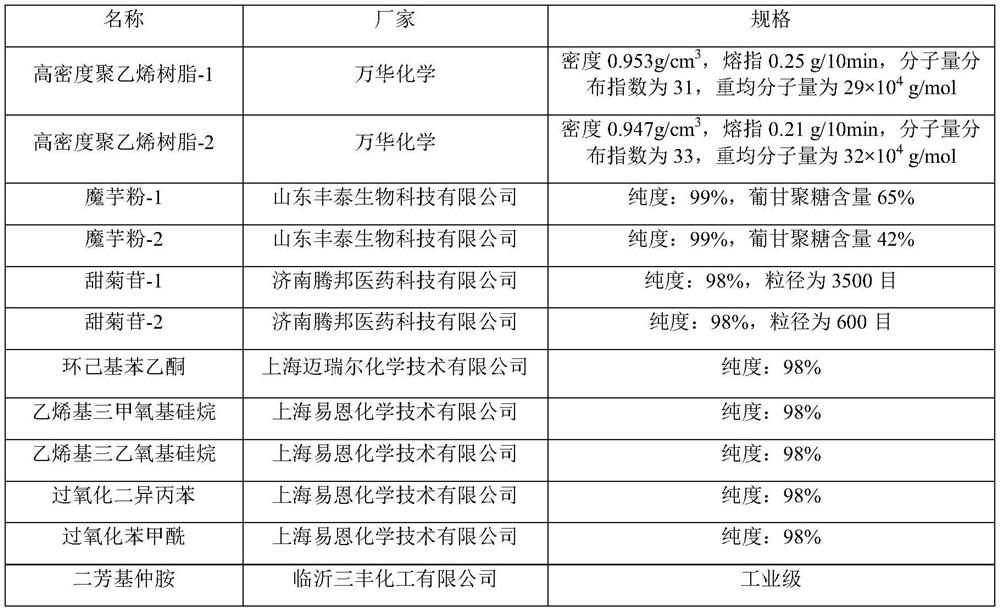

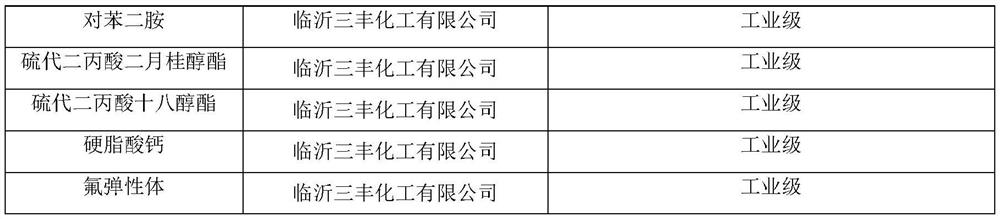

Method used

Image

Examples

Embodiment 1

[0038] The raw material of the special high-density polyethylene resin for pressure-resistant pipes of the present embodiment includes the following quality components: 70kg high-density polyethylene resin-1, 10kg konjac flour-1, 5kg stevioside-1, 5kg cyclohexyl acetophenone, 0.3 kg vinyltrimethoxysilane, 0.3kg dicumyl peroxide, 0.10kg diaryl secondary amine, 0.10kg dilauryl thiodipropionate, 0.08kg calcium stearate, 0.02kg fluoroelastomer.

[0039] Its preparation method includes the following steps: take each raw material according to the selected quality and add it to a high-speed mixer for 50r / min and mix it uniformly for 2 hours, then add the uniformly mixed material into a special extruder to extrude and granulate, and the temperature of the extruder is 180 ℃, the screw speed is 150r / min, and the high-density polyethylene resin, which is a special material for pressure-resistant pipes, is obtained.

Embodiment 2

[0041] The raw material of the special high-density polyethylene resin for pressure-resistant pipes of the present embodiment includes the following quality components: 80kg high-density polyethylene resin-1, 15kg konjac flour-1, 10kg stevioside-1, 8kg cyclohexyl acetophenone, 0.6 kg vinyltrimethoxysilane, 0.6kg dicumyl peroxide, 0.16kg diaryl secondary amine, 0.15kg dilauryl thiodipropionate, 0.13kg calcium stearate, 0.03kg fluoroelastomer.

[0042] Its preparation method comprises the following steps: taking each raw material according to the selected quality and adding it into a high-speed mixer at 50r / min for uniform mixing for 2 hours, adding the uniformly mixed material into a special extruder for extruding and granulating, and the temperature of the extruder is 200 ℃, the screw speed is 120r / min, and the high-density polyethylene resin, which is a special material for pressure-resistant pipes, is obtained.

Embodiment 3

[0044] The raw material of the special high-density polyethylene resin for pressure-resistant pipes of the present embodiment includes the following quality components: 75kg high-density polyethylene resin-1, 13kg konjac flour-1, 8kg stevioside-1, 7kg cyclohexyl acetophenone, 0.5 kg vinyltriethoxysilane, 0.4kg bis-tert-butylperoxycumene, 0.12kg ketone-amine condensation product, 0.12kg dilauryl thiodipropionate, 0.10kg calcium stearate, 0.02 kg fluoroelastomer.

[0045] Its preparation method comprises the following steps: taking each raw material according to the selected quality and adding it into a high-speed mixer at 50r / min for uniform mixing for 2 hours, adding the uniformly mixed material into a special extruder for extruding and granulating, and the temperature of the extruder is 200 ℃, the screw speed is 120r / min, and the high-density polyethylene resin, which is a special material for pressure-resistant pipes, is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com