Method and roasting device for roasting and making lithium salt by taking spontaneous combustion of lithium ore as heat source

A lithium ore and roasting technology, which is applied in the direction of improving process efficiency, can solve problems such as unstable production, increased loss of lithium ore powder, and aggravated kiln knotting, so as to facilitate extrusion molding, improve comprehensive yield, Ease of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

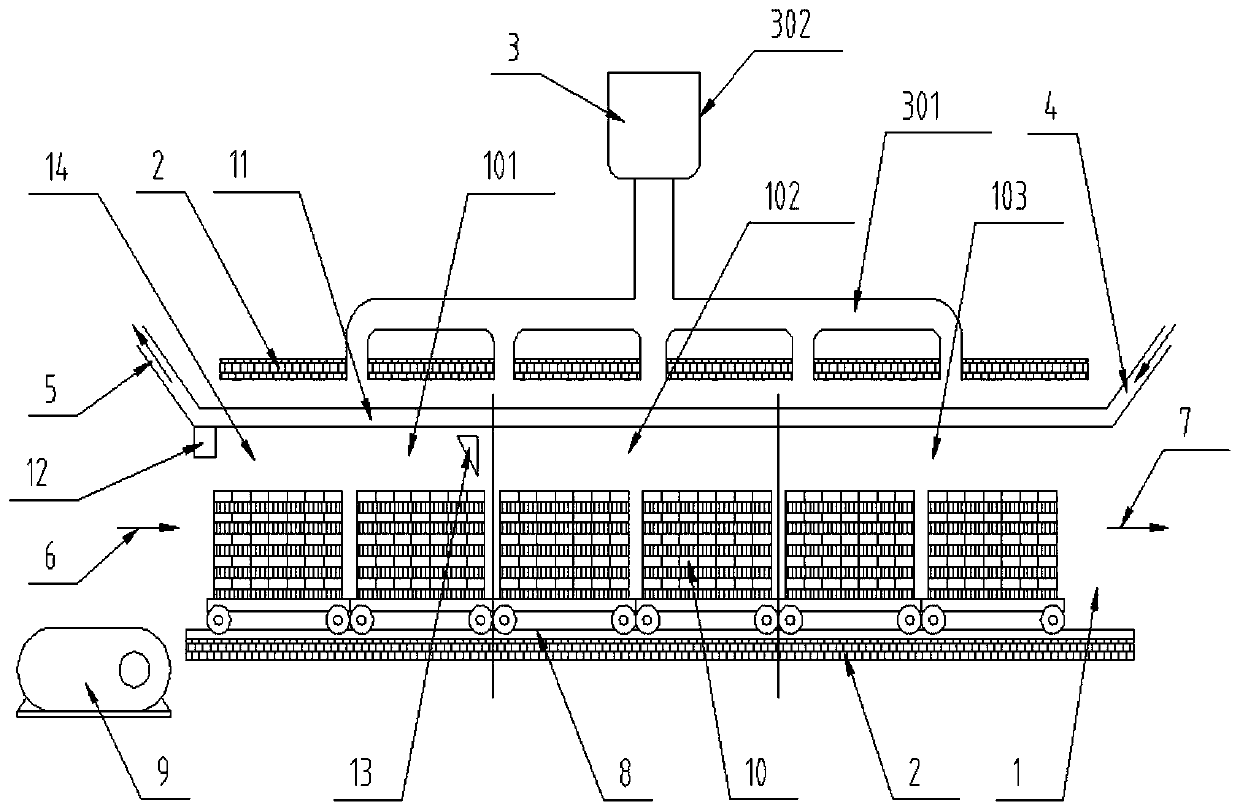

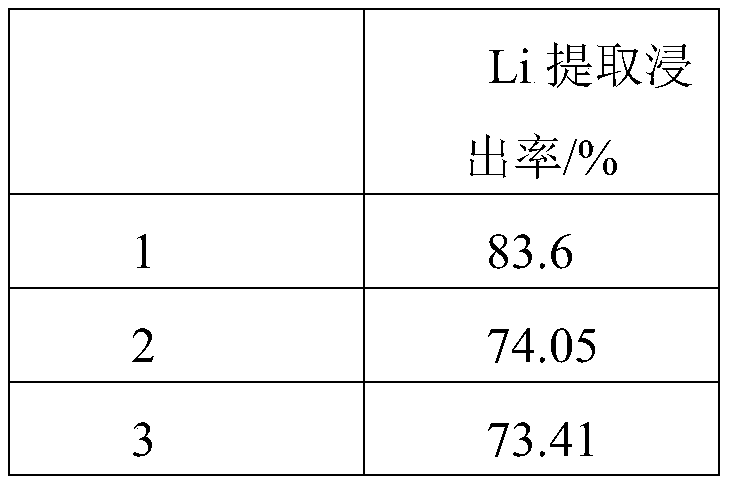

[0036] The specific technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. In the examples, the components involved are in parts by mass or in mass ratio, and the concentrations involved are all mass concentrations.

[0037] The invention discloses a method for roasting lithium salts by using lithium ore spontaneous combustion as a heat source, using lithium ore as a raw material, and using lithium ore and roasting auxiliary materials as self-fuel for roasting. The method is characterized in that it includes the following method steps:

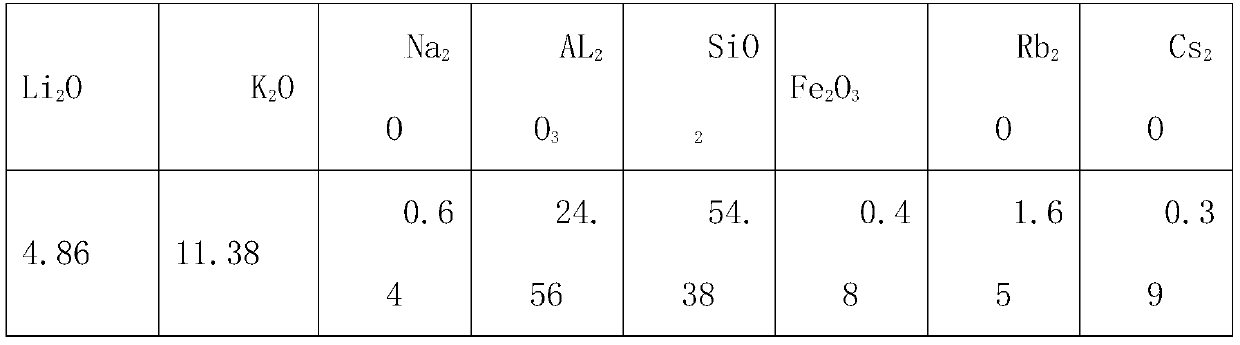

[0038] 1) crushing, crushing the lithium ore to 85-150 mesh, which is lithium ore crushed material; the lithium ore crushed material can be lepidolite powder or spodumene powder or lithium china stone powder or lithium feldspar powder;

[0039] 2) Prepare the roasting formula mixture, stir and mix the lithium ore scrap, compound salt, combustibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com