Hollow titanium dioxide microsphere based on gel sphere precursor and preparation method of hollow titanium dioxide microsphere

A microsphere, hollow technology, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of low preparation cost, improved photocatalytic efficiency, and improved photocatalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

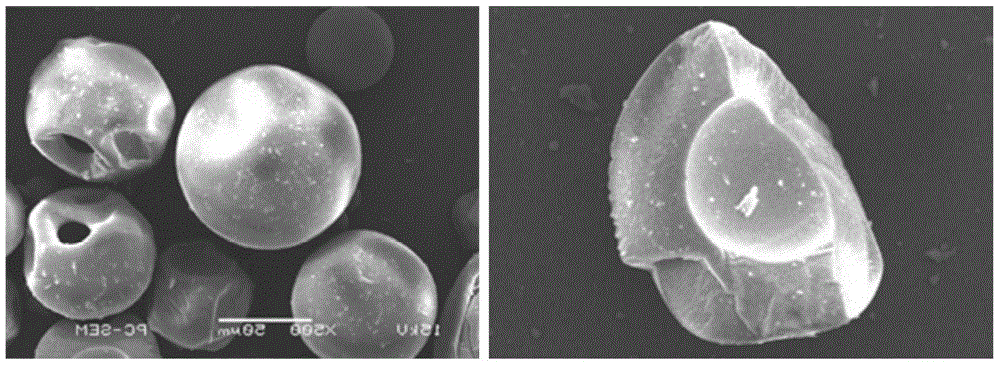

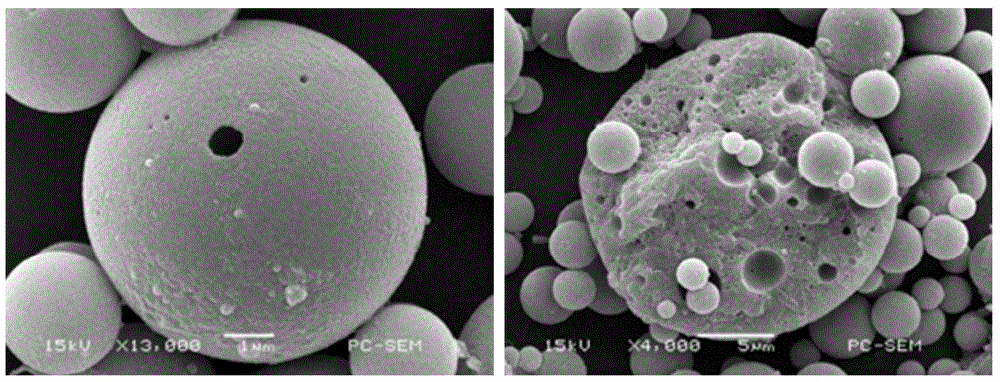

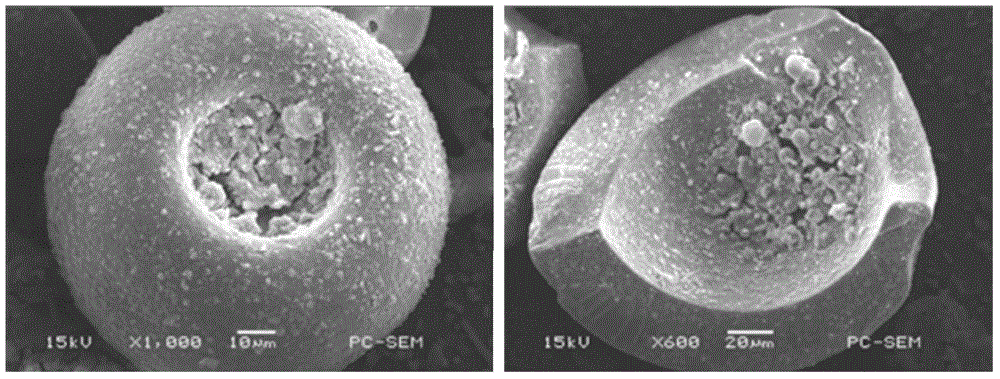

Image

Examples

Embodiment 1

[0031] 1. Preparation of starch solution

[0032] Dissolve 1.18g of starch in 40mL of deionized water at 90°C, and then naturally cool to room temperature;

[0033] 2. Complexation of tetra-n-butyl titanate

[0034]Add 1 mL of acetylacetone to 2.5 mL of tetra-n-butyl titanate, stir and react for 0.5 h to obtain a complex of tetra-n-butyl titanate;

[0035] 3. Preparation of dispersed system

[0036] In the case of stirring, the tetra-n-butyl titanate complex obtained in step 2 is added to the starch solution obtained in step 1, and stirred evenly to obtain a milky yellow dispersion system;

[0037] 4. Hydrothermal treatment

[0038] Transfer the milky yellow dispersion system obtained in step 3 into a high-pressure reaction kettle with a polytetrafluoroethylene inner cup, and conduct a hydrothermal reaction at 150°C for 10 hours. After the reaction product is sequentially washed with deionized water and ethanol, the Dry at 100°C for 2h to obtain hollow TiO 2 Microspheres....

Embodiment 2

[0041] 1. Preparation of starch solution

[0042] Dissolve 1.18g of starch in 40mL of 90°C deionized water, then cool naturally to room temperature (25°C) to obtain a starch solution, then add 3.6mg of dodecylbenzenesulfonic acid to the starch solution, and stir evenly;

[0043] 2. Complexation of tetra-n-butyl titanate

[0044] Add 1 mL of acetylacetone to 2.5 mL of tetra-n-butyl titanate, stir and react for 0.5 h to obtain a complex of tetra-n-butyl titanate;

[0045] 3. Preparation of dispersed system

[0046] In the case of stirring, the tetra-n-butyl titanate complex obtained in step 2 is added to the starch solution obtained in step 1, and stirred evenly to obtain a milky yellow dispersion system;

[0047] 4. Hydrothermal treatment

[0048] Transfer the milky yellow dispersion system obtained in step 3 into a high-pressure reaction kettle with a polytetrafluoroethylene inner cup, and conduct a hydrothermal reaction at 150°C for 10 hours. After the reaction product is ...

Embodiment 3

[0053] 1. Preparation of starch solution

[0054] Dissolve 7.1g of starch in 40mL of 90°C deionized water, then cool naturally to room temperature (25°C) to obtain a starch solution, then add 3.6mg of dodecylbenzenesulfonic acid to the starch solution, and stir evenly;

[0055] 2. Complexation of tetra-n-butyl titanate

[0056] Add 1 mL of acetylacetone to 2.5 mL of tetra-n-butyl titanate, stir and react for 0.5 h to obtain a complex of tetra-n-butyl titanate;

[0057] 3. Preparation of dispersed system

[0058] In the case of stirring, the tetra-n-butyl titanate complex obtained in step 2 is added to the starch solution obtained in step 1, and stirred evenly to obtain a milky yellow dispersion system;

[0059] 4. Hydrothermal treatment

[0060] Transfer the milky yellow dispersion system obtained in step 3 into a high-pressure reaction kettle with a polytetrafluoroethylene inner cup, and conduct a hydrothermal reaction at 150°C for 10 hours. After the reaction product is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com