Apparatus for preventing carbon corrosion at cathod in fuel cell

A fuel cell cathode and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve problems such as inconvenience, adverse effects on fuel cell durability performance, and gas burner safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

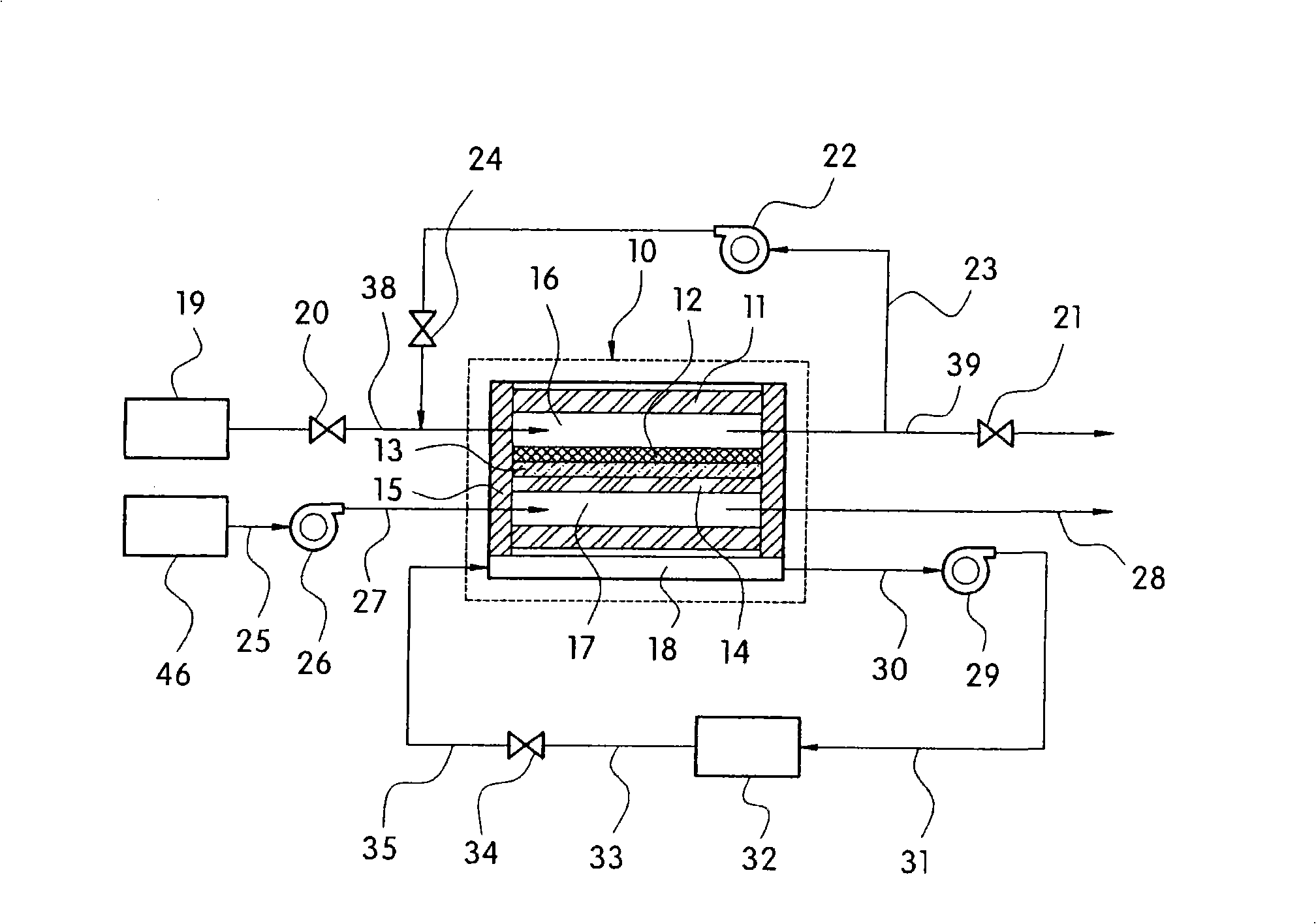

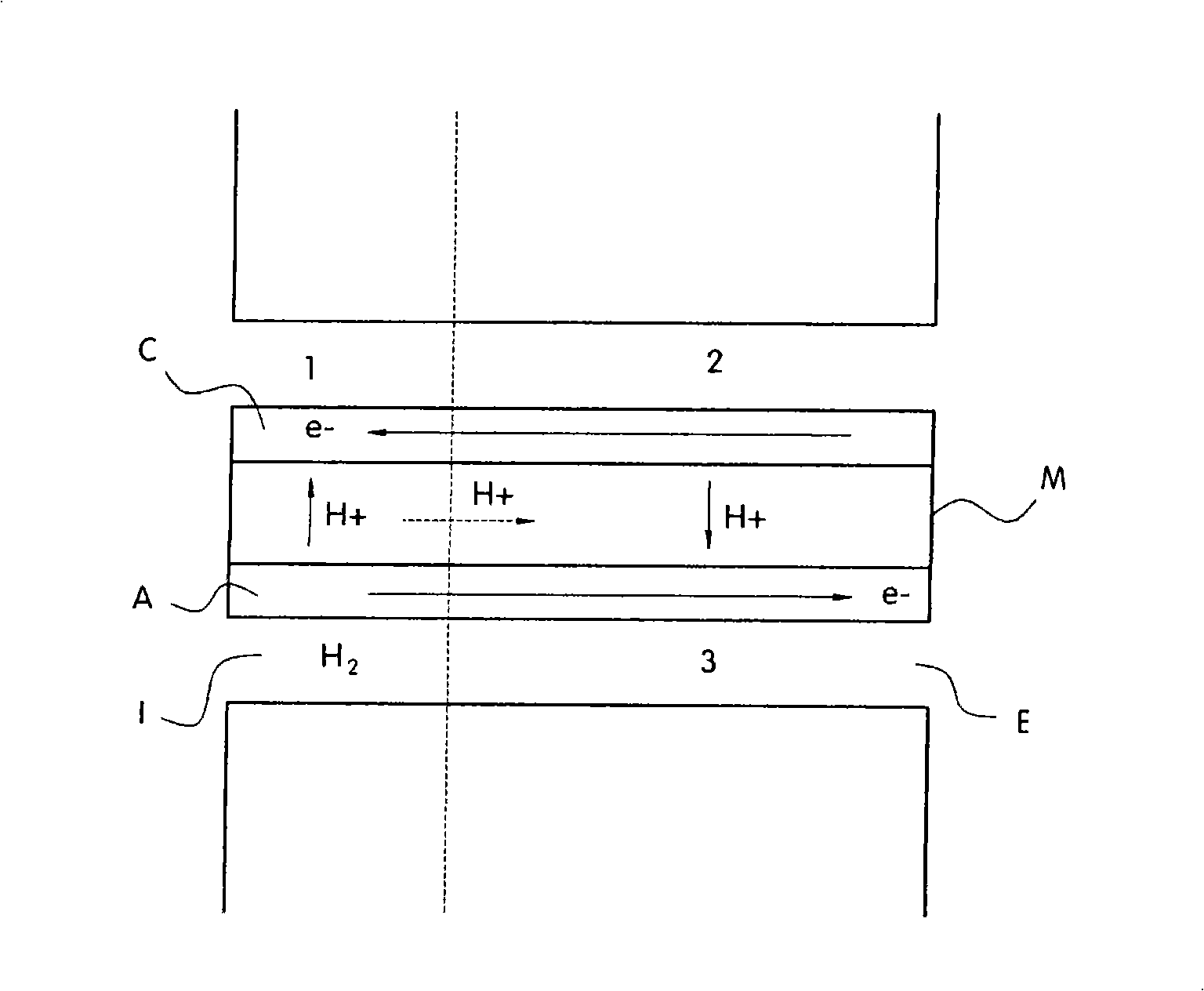

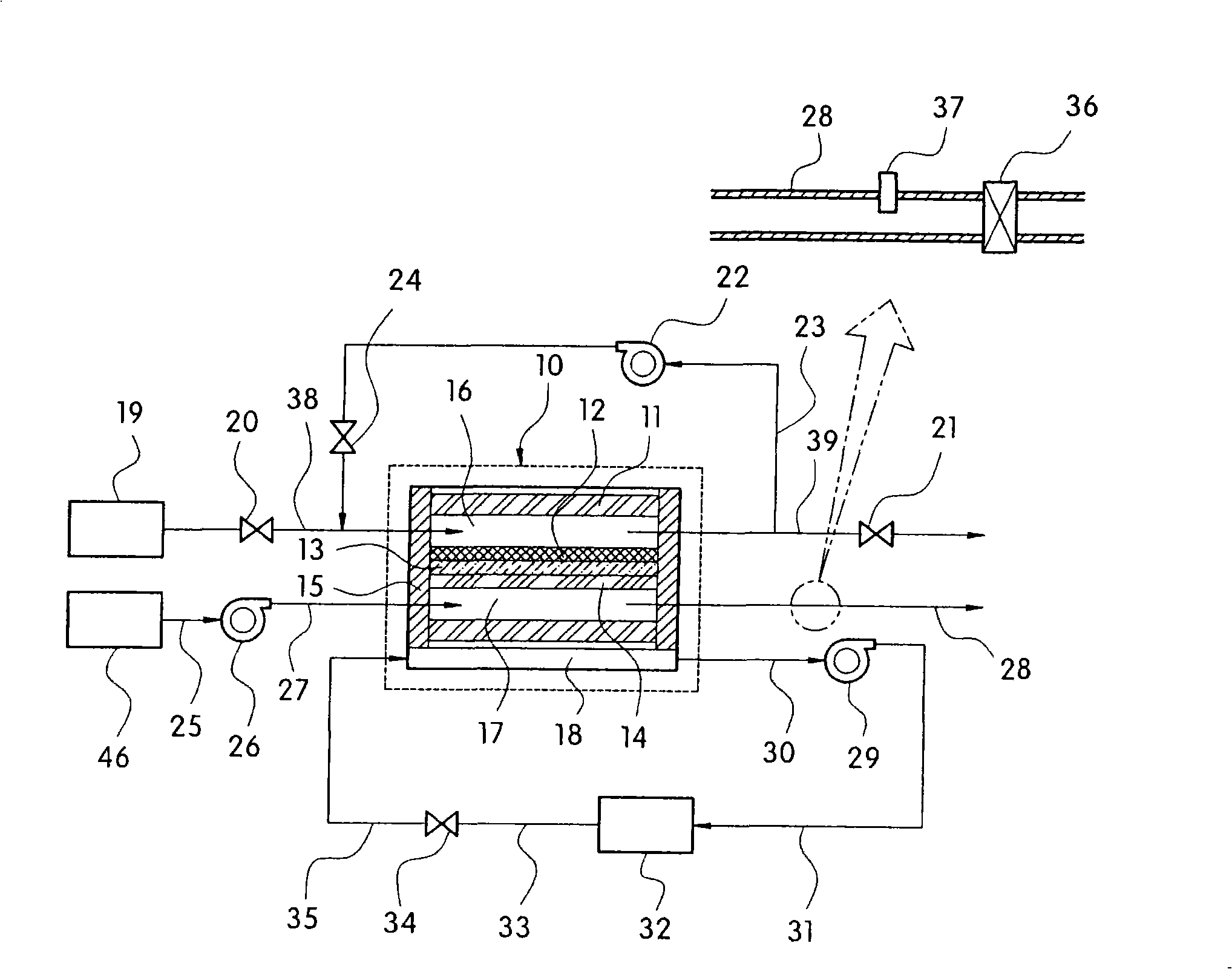

[0069] Reference is now made in detail to specific embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like elements are designated by like reference numerals throughout. Embodiments are described below, by referring to the appended Figure 3-7 to explain the present invention.

[0070] As mentioned above, the existing technology has the following problems: 1) complex structure (resistance, hydrogen burner in hydrogen recirculation line, nitrogen tank, etc.); 2) complex startup / shutdown process takes too much time; 3) Reduced performance stability due to air flow into the anode during startup / shutdown using additional devices; and 4) reduced stability due to contamination of the fuel cell due to exposure of hydrogen off-gas and air off-gas to air.

[0071] For example, moisture in fuel cells can evaporate under dry atmospheric conditions, and humidification water in MEAs is evaporated, resulting in reduced performance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com