Start-stop method of high-temperature proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as difficult nitrogen gas sources, and achieve the effect of alleviating the problem of cathode carbon corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Experiments were carried out using a high-temperature proton exchange membrane fuel cell based on a phosphoric acid-doped poly(4,4'-diphenyl ether-5,5'-dibenzimidazole) high-temperature electrolyte membrane. The anode of the battery is a gas diffusion electrode loaded with 60% Pt / C electrocatalyst, and the cathode is a gas diffusion electrode loaded with a metal atomic ratio of 1:3 PtCr / C electrocatalyst.

[0019] Start-up operation: After the temperature of the fuel cell rises to 70°C, the anode is fed with H 2 , the feed rate corresponds to 200mA / cm 2 The stoichiometric ratio is 1.3 times. After 20s, the cathode is fed with air. When the temperature rises to 105°C, the current is applied for discharge. After the temperature rises to 160°C, the current is discharged at 200mA / cm 2 Next discharge test.

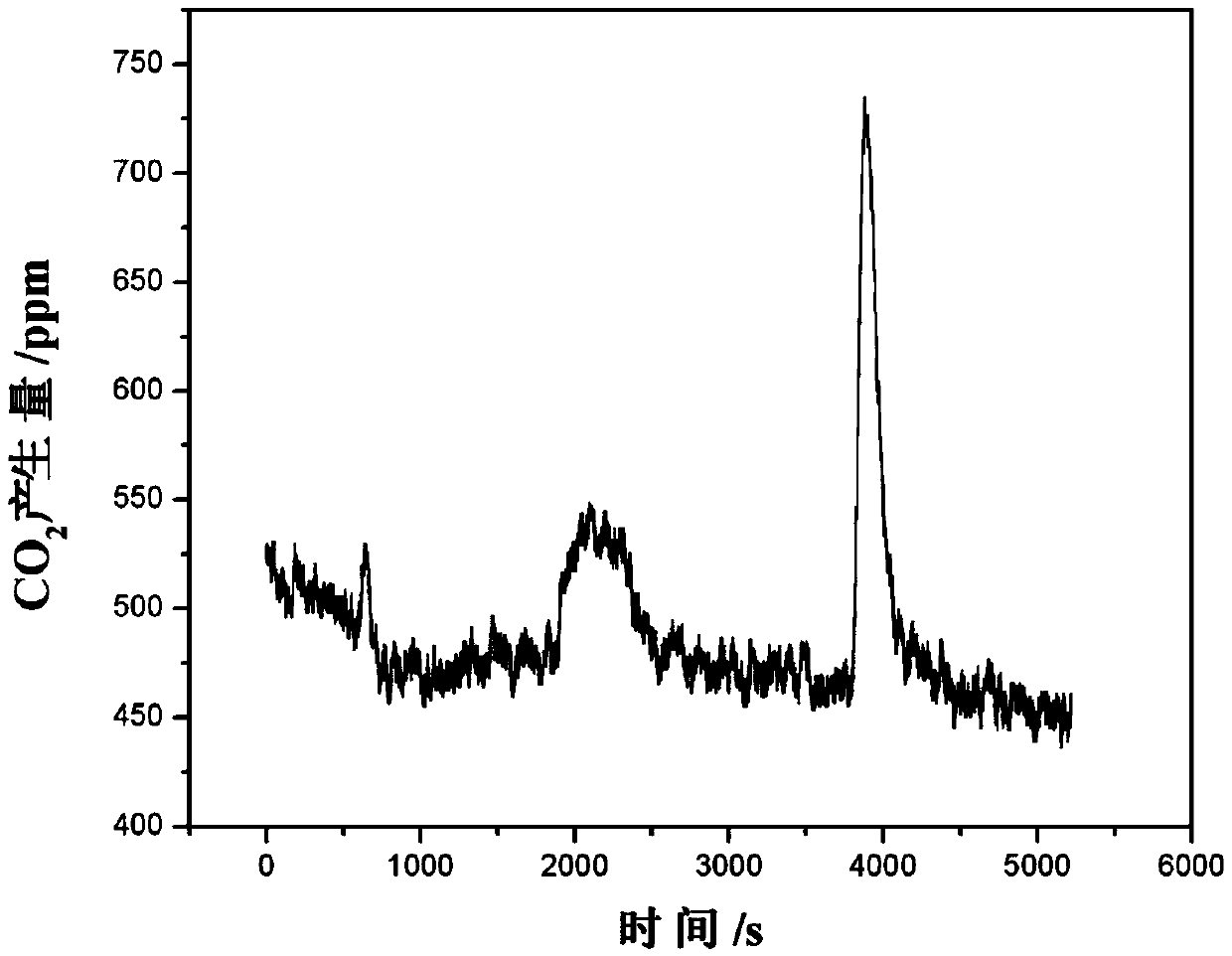

[0020] Shutdown operation: reduce the discharge current density to 150mA / cm 2 , at this time, the discharge voltage of the single cell is 0.7V. As the temperature dec...

Embodiment 2

[0023] Experiments were carried out using a high-temperature proton exchange membrane fuel cell based on a phosphoric acid-doped poly(2,5-benzimidazole) high-temperature electrolyte membrane. The anode of the battery is a gas diffusion electrode loaded with PtNi / C electrocatalyst, and the cathode is a gas diffusion electrode loaded with PtCr / C electrocatalyst.

[0024] Start-up operation: After the temperature of the fuel cell rises to 90°C, the anode is fed with H 2 and CO mixed gas, where the volume content of CO is 1%, and the feed amount corresponds to 200mA / cm 2 The stoichiometric ratio is 1.5 times, after 30s, the cathode is fed with air, when the temperature rises to 110°C, the current is applied to discharge, and when the temperature rises to 160°C, the discharge starts at 300mA / cm 2 Next discharge test.

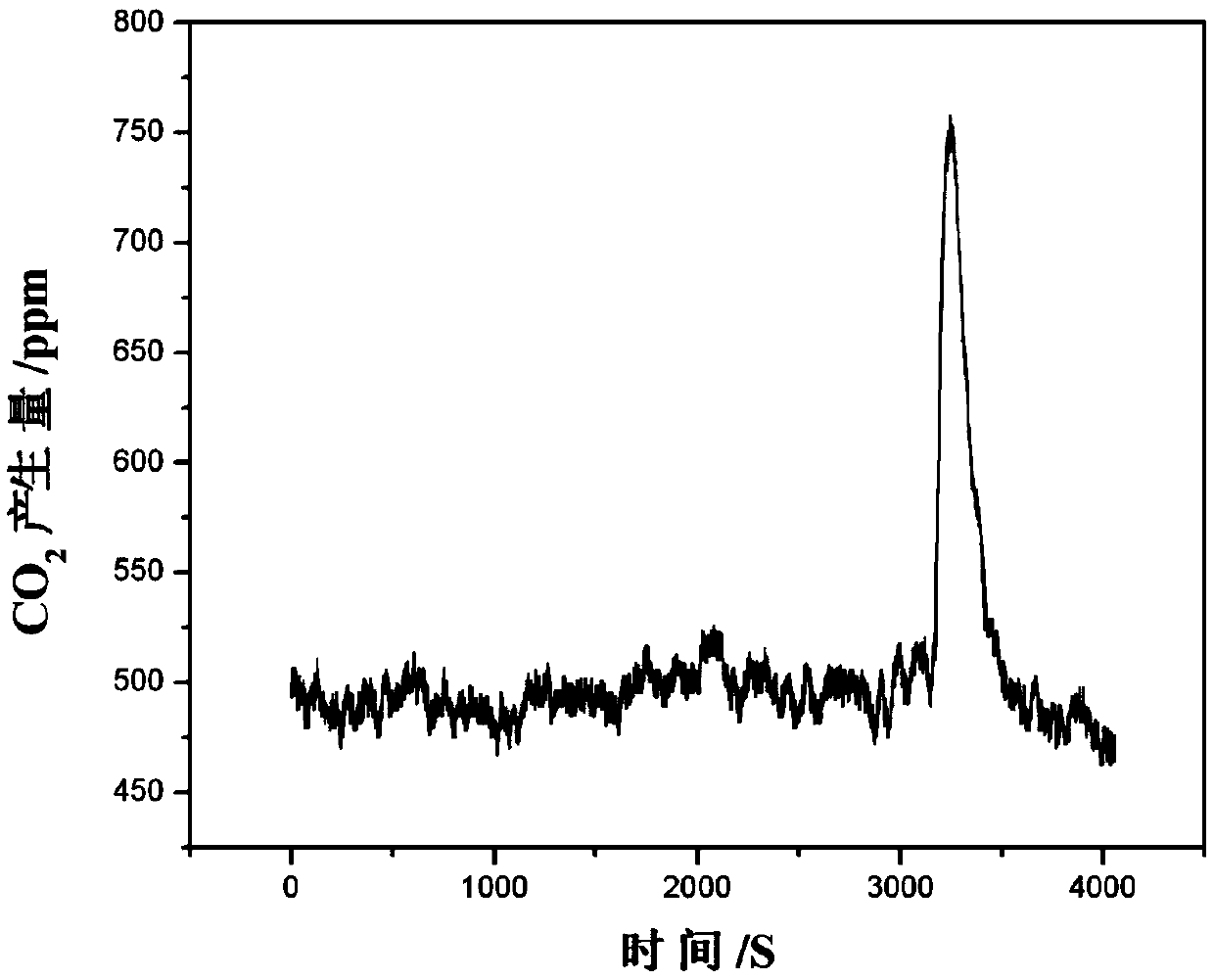

[0025] Shutdown operation: reduce the discharge current density to 100mA / cm 2 At this time, the average discharge voltage of a single battery is 0.73V. As the tem...

Embodiment 3

[0028] Experiments were carried out using a high-temperature proton exchange membrane fuel cell based on a phosphoric acid-doped poly(2,2'-m-tolyl-5,5'-bibenzimidazole) high-temperature electrolyte membrane. The anode of the battery is a gas diffusion electrode loaded with PtRu / C electrocatalyst, and the cathode is a gas diffusion electrode loaded with PtW / C electrocatalyst.

[0029] Start-up operation: After the temperature of the fuel cell rises to 100°C, the anode is fed with H 2and CO mixed gas, where the volume content of CO is 10%, and the feed amount corresponds to 200mA / cm 2 The stoichiometric ratio is 1.7 times, after 10s, the cathode is fed with air, and when the temperature rises to 125°C, the current is applied to discharge, and when the temperature rises to 160°C, the discharge starts at 300mA / cm 2 Next discharge test.

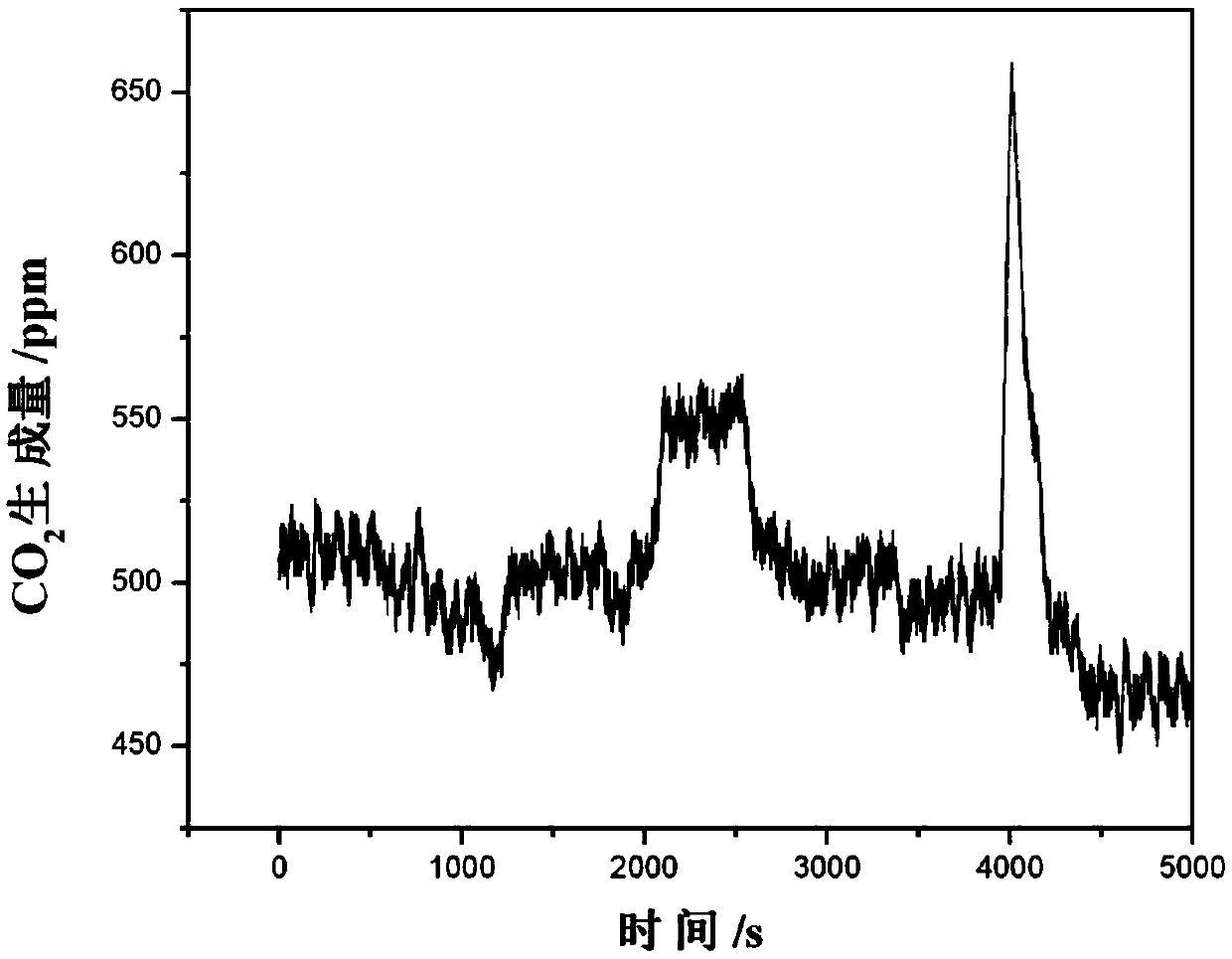

[0030] Shutdown operation: reduce the discharge current density to 200mA / cm 2 At this time, the average discharge voltage of a single battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com