An online detection method for carbon corrosion in membrane electrodes

A detection method and membrane electrode technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large error, high price, and large impact, and achieve the effects of high accuracy, good repeatability, and intuitive testing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

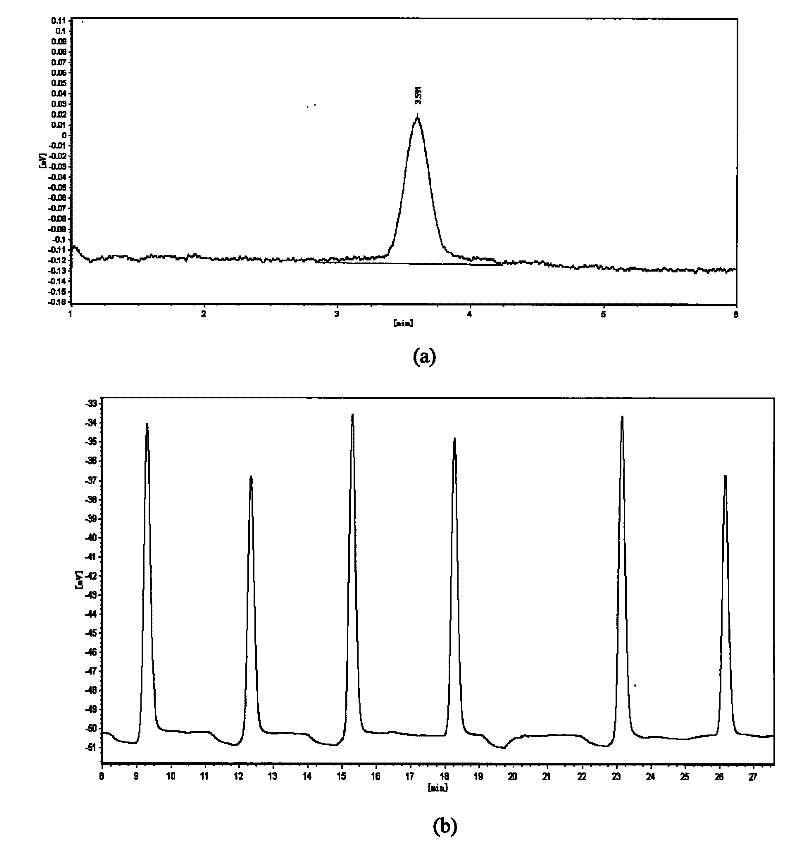

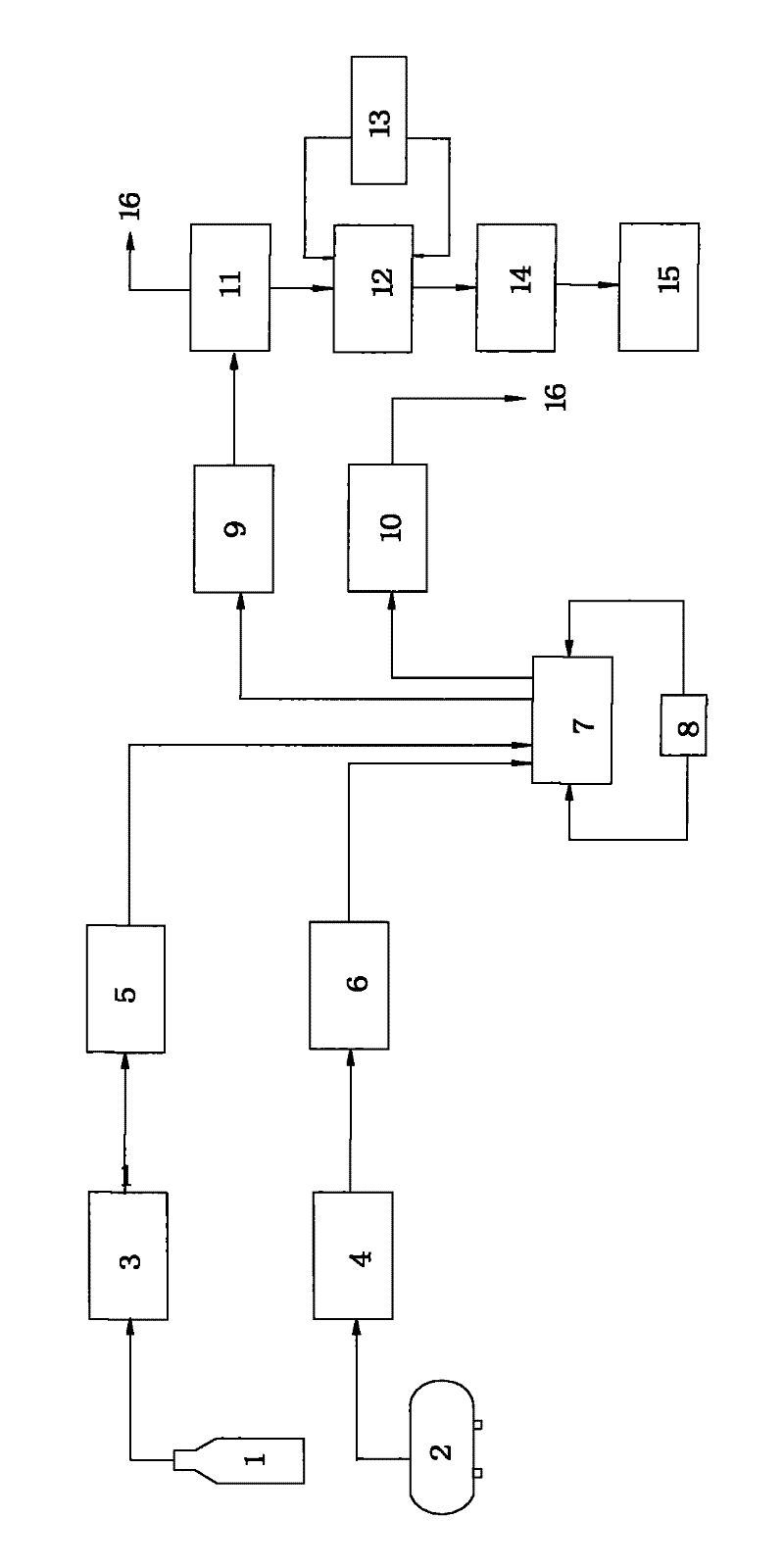

[0025] The tail gas of the anode outlet of the fuel cell in normal operation is passed into the three-way solenoid valve, one port of the three-way valve is connected with the tail gas of the cathode outlet, the second port is connected with the atmosphere, and the third port is connected with the gas inlet reformer After the exhaust gas at the cathode outlet is diverted by the three-way valve, the exhaust gas can be collected at any time; the exhaust gas can realize CO x The methanation of X = 1 or 2; the temperature of the reformer is 300°C, and the catalyst for the reformer is 5% to 30% Ru-Al 2 o 3 , the converted gas flowing out from the gas outlet of the gas reformer enters the gas chromatograph through the six-way valve automatic sampling device for detection, and the gas chromatograph adopts a carbon molecular sieve chromatographic column. By mixing with standard gas (CO or CO 2 ) chromatographic peak area comparison, calculate the amount of gas produced by carbon car...

Embodiment 2

[0038] Assemble a freshly pressed MEA into a single-cell test device, and inject hydrogen and oxygen into both sides of the device to make the fuel cell run normally; battery conditions: outlet backup pressure 28psig, battery temperature 75°C, dew point humidification temperature 70°C, Reaction gas pipeline temperature 85°C, St-H 2 : 1.5, St-Air: 2.5. Start-Stop test procedure: Start: 1min, Stop: 1min, and so on.

[0039] The tail gas on the hydrogen side is connected to the plane three-way valve to realize the collection of tail gas at any time; then the collected tail gas is passed into the gas reformer, the temperature of the reformer is 350°C, and the catalyst for the reformer is Ni-Al 2 o 3 Realize CO x -CH x Transformation; the transformed gas is connected to a six-way valve automatic sampling device, and enters a gas chromatograph for detection. The gas chromatograph uses a carbon molecular sieve chromatographic column. By comparing with the standard gas, calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com