All metal leave N place armor joint form with joint fill retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

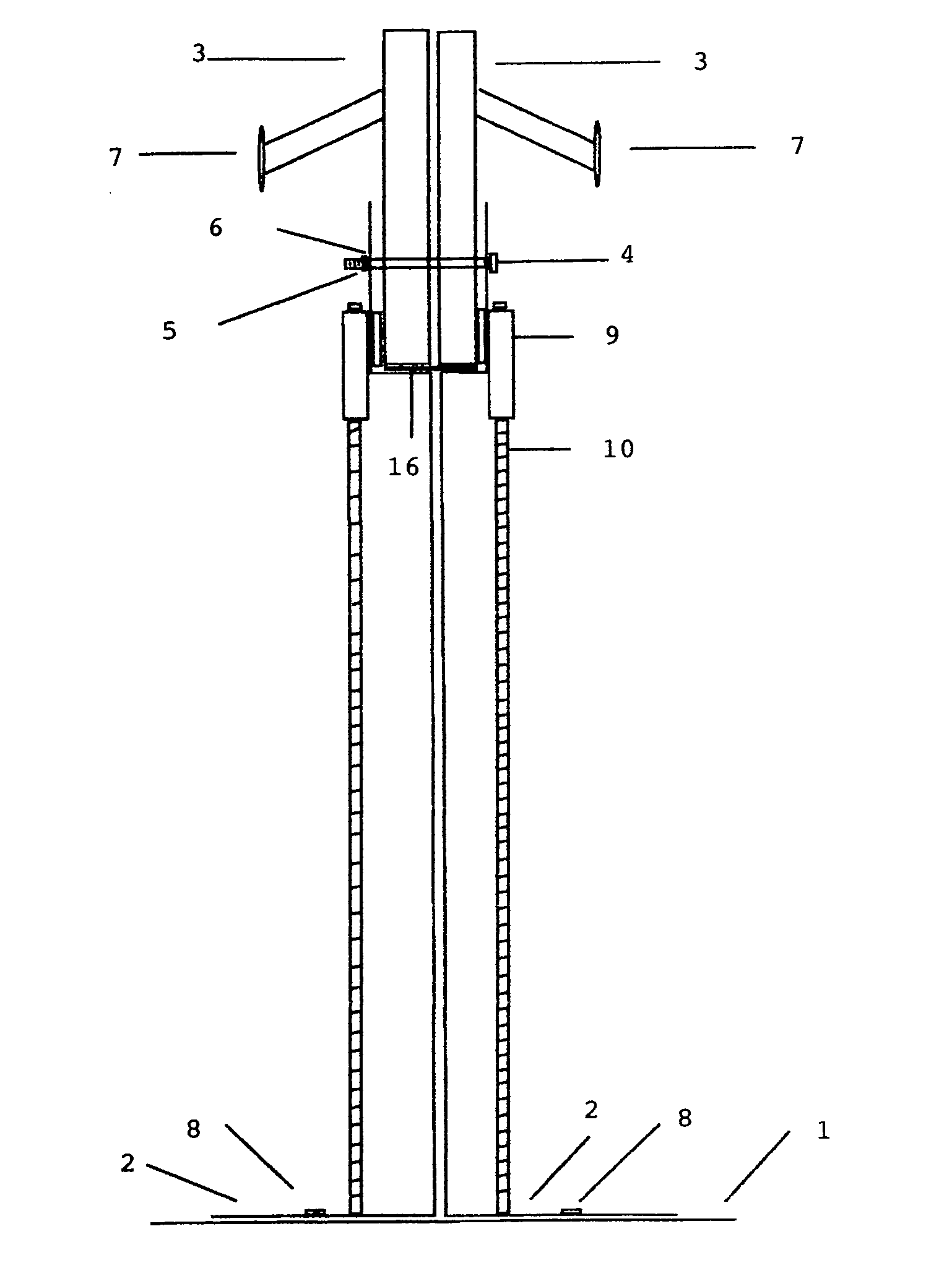

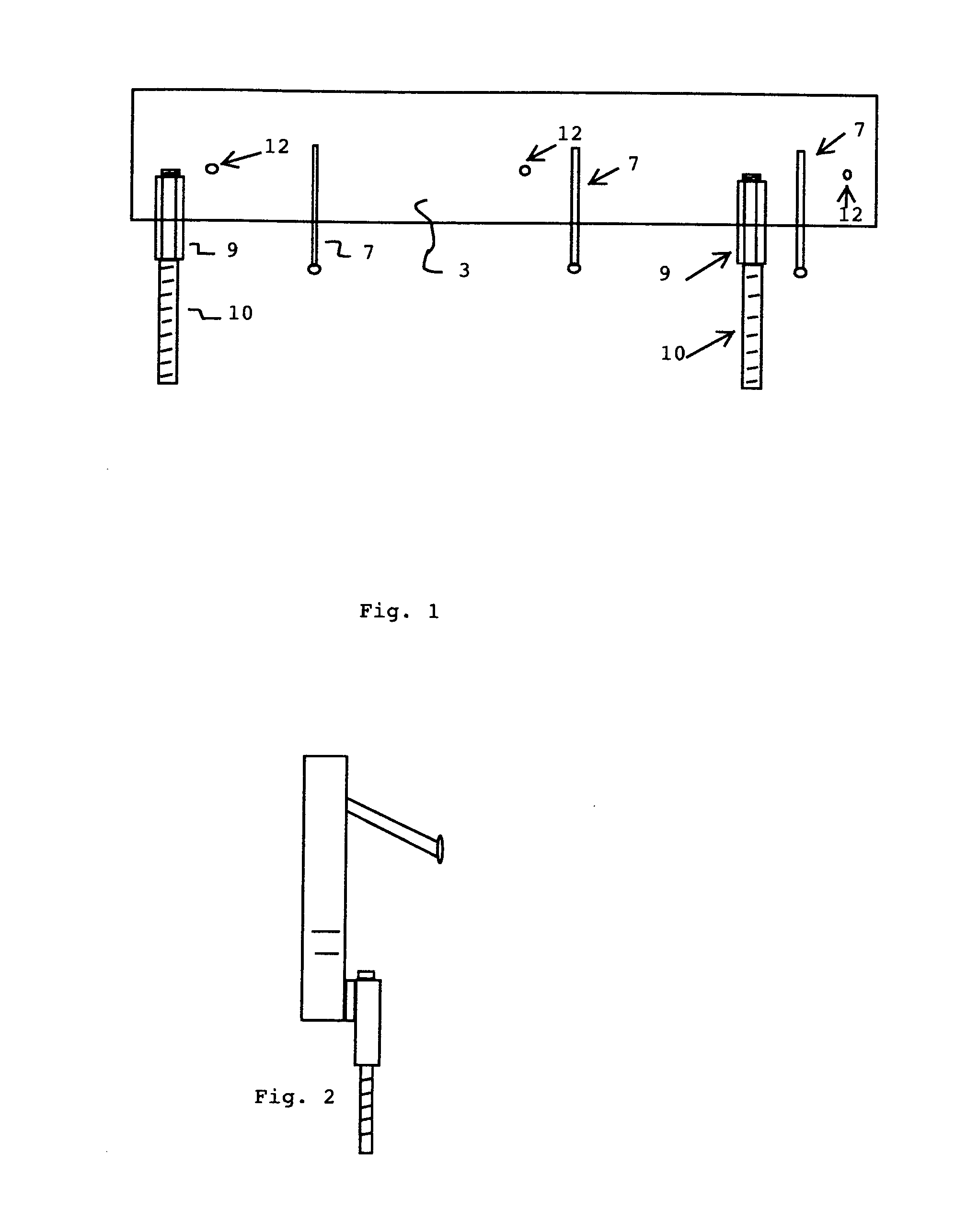

[0020]Referring to the drawing FIG. 5 this designates the metal base piece 1 to which will provide a support base for stabilization and to which the piece 2 as depicted in FIG. 3 shall be attached. This is accomplished by use of piece 8, a self tapping, self drilling screw, or rivet. Pieces 3 are then attached to piece 2 using neoprene bolts, nuts and washers, pieces 4, 5, 6, as depicted on FIG. 5, by inserting 4 thru the holes 12 in the pieces 7 and holes 13 in piece 2 as depicted FIG. 2 and FIG. 4. The neoprene bolts are designed to comprise during the concrete curing process and allow the armor joints to separate as the concrete floor cures. Pieces 5 and 6 are then used to secure pieces 7 to piece 2.

[0021]Pieces 3 is a fabricated assembly by attaching a stub, piece 7 at 30 degrees as depicted on FIG. 1. by welding. Piece 9 is a threaded coupling which is also attached by welding. Piece 10 is a threaded bolt which is threaded thru piece 8 and provides an adjustment mechanism for h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

| Stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com