Down filler processing method

A processing method and stuffing technology, which is applied in the direction of sewing tools, garments, coats, etc., to achieve the effect of easier handling, less drilling and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

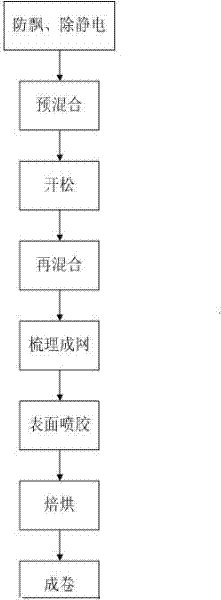

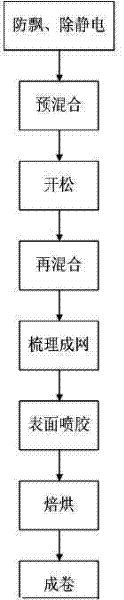

Method used

Image

Examples

Embodiment 1

[0029] Spray anti-floating agent on the raw material of duck down for anti-floating treatment; then add the raw material of duck down with anti-floating treatment to the static electricity removal machine to remove the static electricity of the raw material of duck down; select 20% of raw material of duck down, 65% of imitation down fiber, and 15% of 4080 low temperature After the fibers are pre-mixed, they are opened twice, and finally mixed to form a mixed raw material; the mixed raw material is sent to a carding machine to be carded into a mesh; glue is sprayed on the surface of the mesh, and sent to an oven for baking at a temperature of 130°C ~160℃, advance speed is 2~3m / min; finally roll.

Embodiment 2

[0031] Spray anti-floating agent on the mixed down raw material of duck down and goose down to carry out anti-floating treatment; then add the anti-floating raw material to the anti-static machine to remove the static electricity of the down material; select 30% of the down material and 60% of the imitation down fiber, 10% 4080 low-temperature fiber is pre-mixed, then opened twice, and finally mixed to form a mixed raw material; the mixed raw material is sent to a carding machine to be carded into a web; glue is sprayed on the surface of the mesh, sent to an oven, and baked. The temperature is 130 ℃ ~ 160 ℃, the forward speed is 2 ~ 3m / min; finally roll.

Embodiment 3

[0033] Spray anti-floating agent on the raw material of duck down for anti-floating treatment; then add the raw material of duck down with anti-floating treatment to the static electricity removal machine to remove the static electricity of the raw material of duck down; select 40% of raw material of duck down, 50% of imitation down fiber, and 10% of 4080 low temperature After the fibers are pre-mixed, they are opened twice, and finally mixed to form a mixed raw material; the mixed raw material is sent to a carding machine to be carded into a mesh; glue is sprayed on the surface of the mesh, and sent to an oven for baking at a temperature of 130°C ~160℃, advance speed is 2~3m / min; finally roll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com