Device for determining the filling level of a filling product in a filling product reservoir

A filling level and reservoir technology, applied in the direction of measuring devices, distribution devices, lubrication indicator devices, etc., can solve the problems of unsuitable filling devices and inability to provide hygienic design, and achieve reliable measurement, flexible installation, and temperature compensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments are described with reference to the accompanying drawings. Here, the same, similar or equivalent elements in different drawings are attached with the same reference numerals, and repeated descriptions of these elements are partially omitted to avoid redundancy.

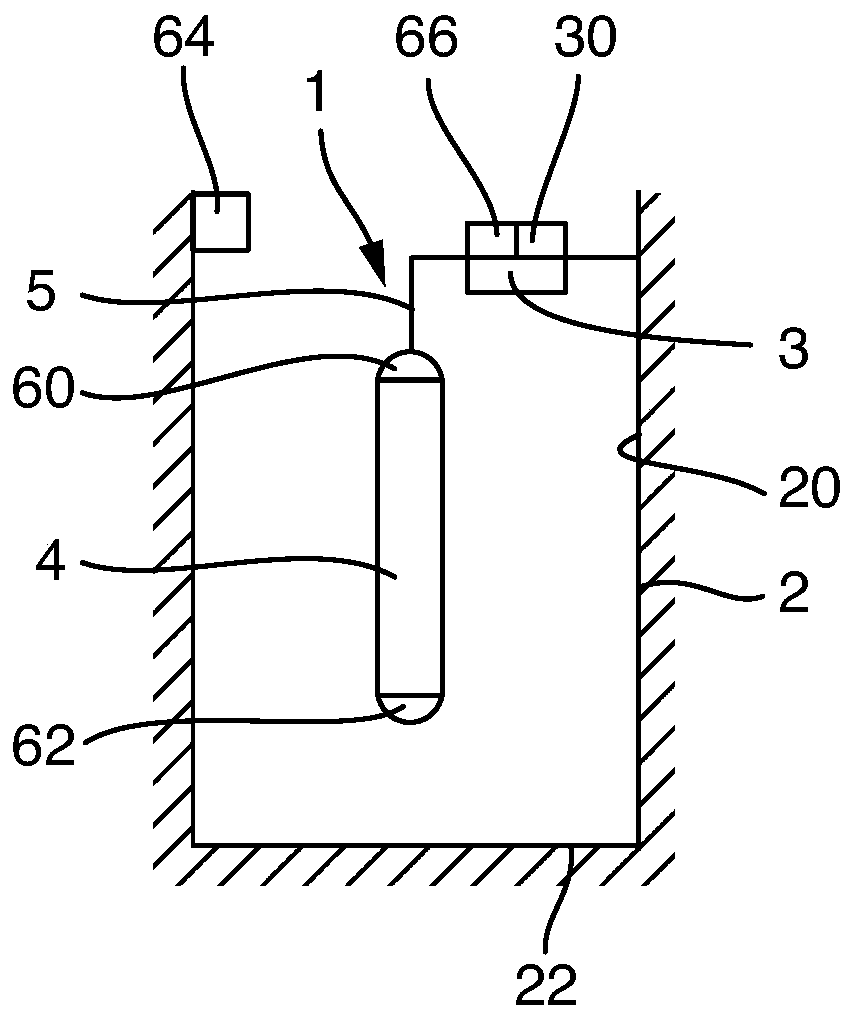

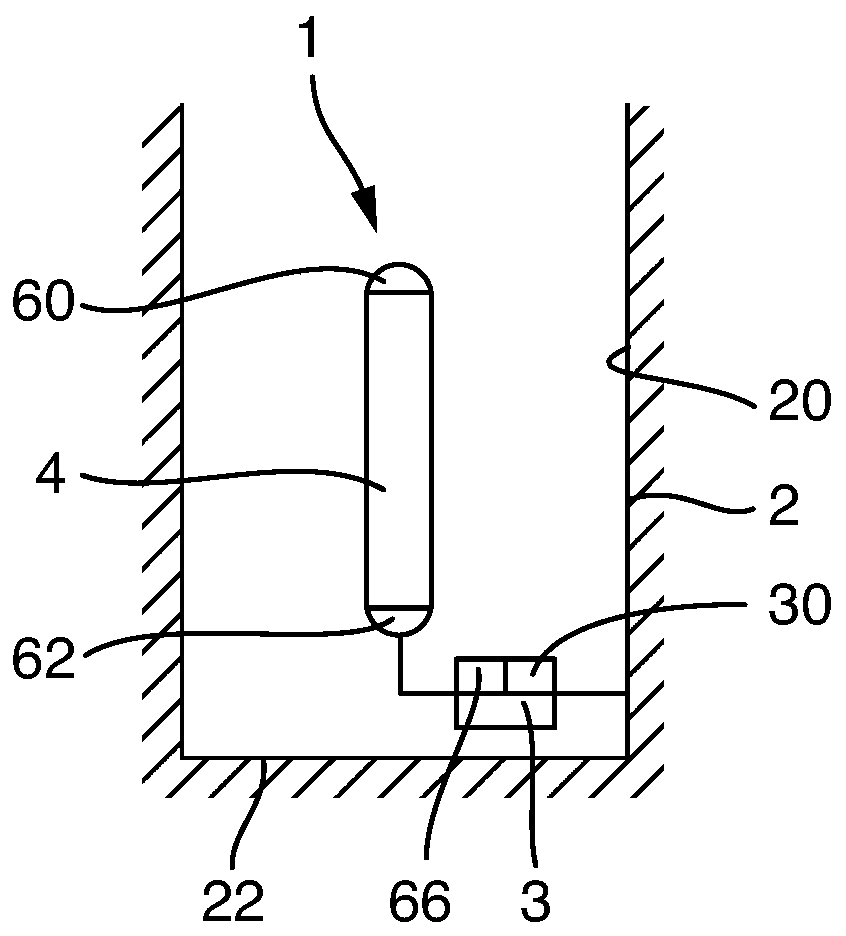

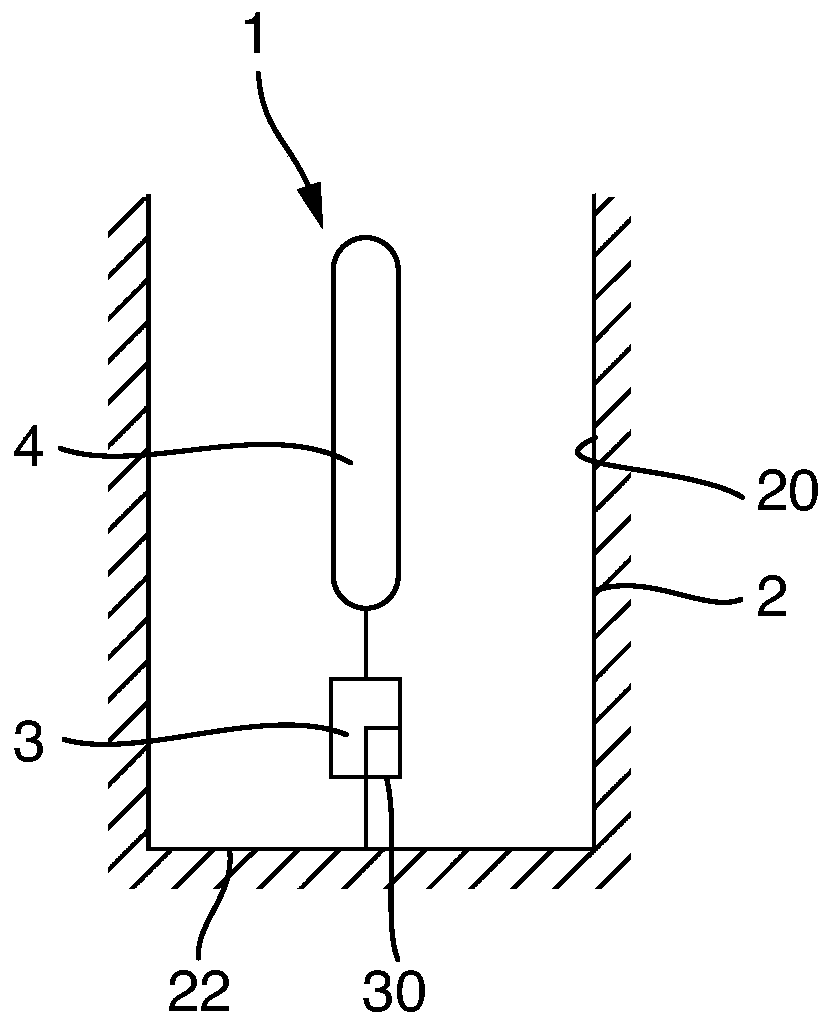

[0039] exist figure 1 A schematic and exemplary sectional view of a filling product reservoir 2 is shown in , in which a device 1 for determining the filling level of a filling product not shown here is arranged. The filling product reservoir 2 may be, for example, a feed tank of a filling product filling plant, in which the filling product is temporarily stored before being fed to a corresponding filling valve for filling the container to be filled. The filling product container 2 can also be an attached filling product box in the filling product filling plant. Furthermore, the filling product reservoir 2 can also be arranged in the filling product filling installation in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com