Sintering-free raw material ball filler for rural sewage treatment system, and preparation and maintenance method of sintering-free raw material ball filler

A technology for treating system and rural sewage, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable waste treatment, etc. It can solve the problems of easy glaze on the filler surface, limit the amount of microbial adhesion, and energy consumption of inorganic fillers Large and other problems, to achieve the effect of resource utilization, increase the amount of active microbial film formation, and reduce the weight of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

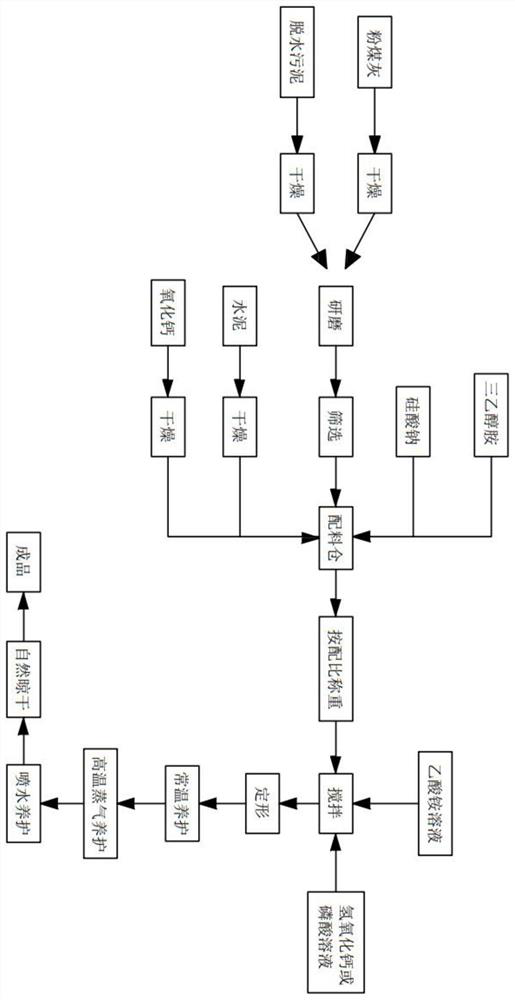

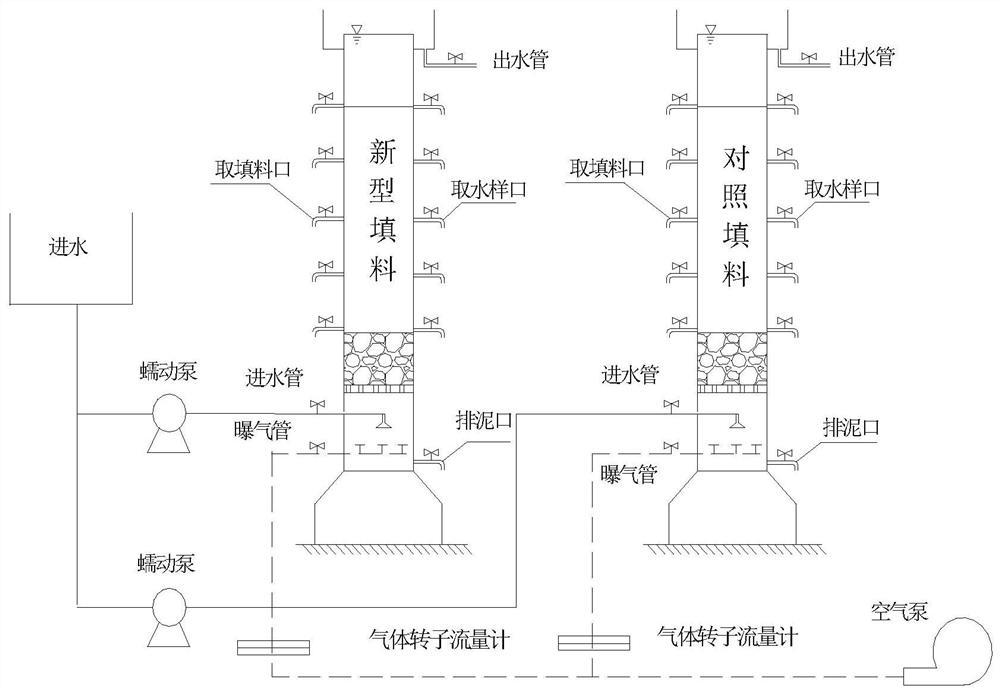

Method used

Image

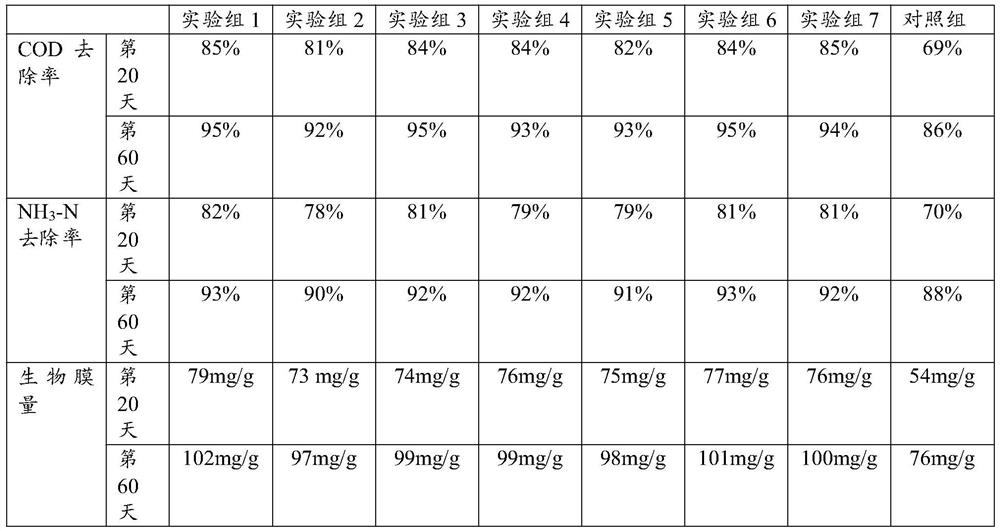

Examples

Embodiment 1

[0077] This embodiment discloses a sinter-free raw meal ball filler for a rural sewage treatment system, which includes the following raw materials in weight ratio: 55% of fly ash, 15% of dewatered sludge, 20% of cement, 5% of calcium oxide, 2% of ammonium acetate, Sodium silicate 3%, triethanolamine 0.05%.

[0078] In order to further optimize the above technical scheme, SiO in fly ash 2 and Al 2 o 3 The mass content of the fly ash is 52-55% and 28-32%, respectively, and the moisture content of the fly ash is less than 2%;

[0079] In order to further optimize the above technical scheme, SiO in dewatered sludge 2 and Al 2 o 3 The mass content of the dewatered sludge is 15-18% and 5-8%, respectively, and the moisture content of the dewatered sludge is less than 5%;

[0080] In order to further optimize the above technical scheme, SiO in cement 2 and Al 2 o 3 The mass content of cement is 20-25% and 6-8% respectively; the moisture content of cement is less than 2%;

...

Embodiment 2

[0106] This embodiment discloses a sinter-free raw meal ball filler for a rural sewage treatment system, which includes the following raw materials in weight ratio: 50% of fly ash, 10% of dewatered sludge, 25% of cement, 8% of calcium oxide, 2% of ammonium acetate, Sodium silicate 5%, triethanolamine 0.04%.

[0107] And the difference with the preparation method of a kind of sintering-free raw meal spherical filler for rural sewage treatment system disclosed in Example 1 is that in S3, the stirring is carried out by using a vertical shaft planetary mixer, the mixer speed is 550r / min, and the mixing time is 4min. And to adjust the pH value is to add 7wt% calcium hydroxide solution.

[0108] A curing method is provided on the basis of the raw meal ball filler prepared above, which specifically includes:

[0109] 1) Curing at room temperature

[0110] First cured the raw ball filler at 20°C for 12 hours;

[0111] 2) High temperature steam curing

[0112] Then carry out high-t...

Embodiment 3

[0120] This embodiment discloses a sinter-free raw meal ball filler for a rural sewage treatment system, which includes the following raw materials in weight ratio: 60% of fly ash, 10% of dewatered sludge, 20% of cement, 6% of calcium oxide, 1% of ammonium acetate, Sodium silicate 3%, triethanolamine 0.06%.

[0121] And the difference with the preparation method of sintering-free raw meal ball filler disclosed in a kind of rural sewage treatment system disclosed in embodiment 1 is:

[0122] In S2, wherein the ammonium acetate is configured as a solution with a concentration of 1wt% for subsequent use;

[0123] In S3, stirring is carried out by using a vertical shaft planetary mixer, the mixer speed is 550r / min, the stirring time is 3min, and the pH value is adjusted to 7.8, and 10wt% calcium hydroxide solution is added to adjust the water content to 16%.

[0124] A curing method is provided on the basis of the raw meal ball filler prepared above, which specifically includes: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com