Patents

Literature

74 results about "Induction sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction sealing is the process of bonding thermoplastic materials by induction heating. This involves controlled heating an electrically conducting object (usually aluminum foil) by electromagnetic induction, through heat generated in the object by eddy currents.

Induction sealing

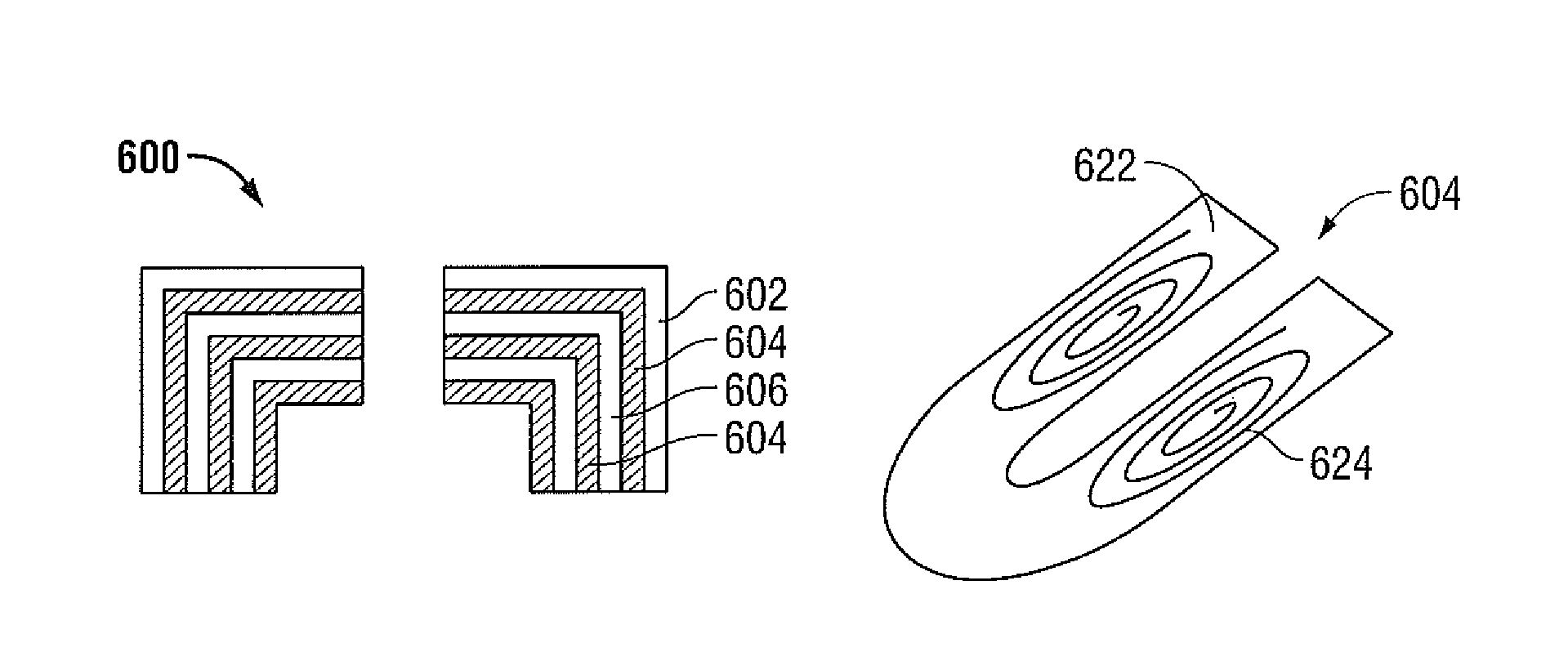

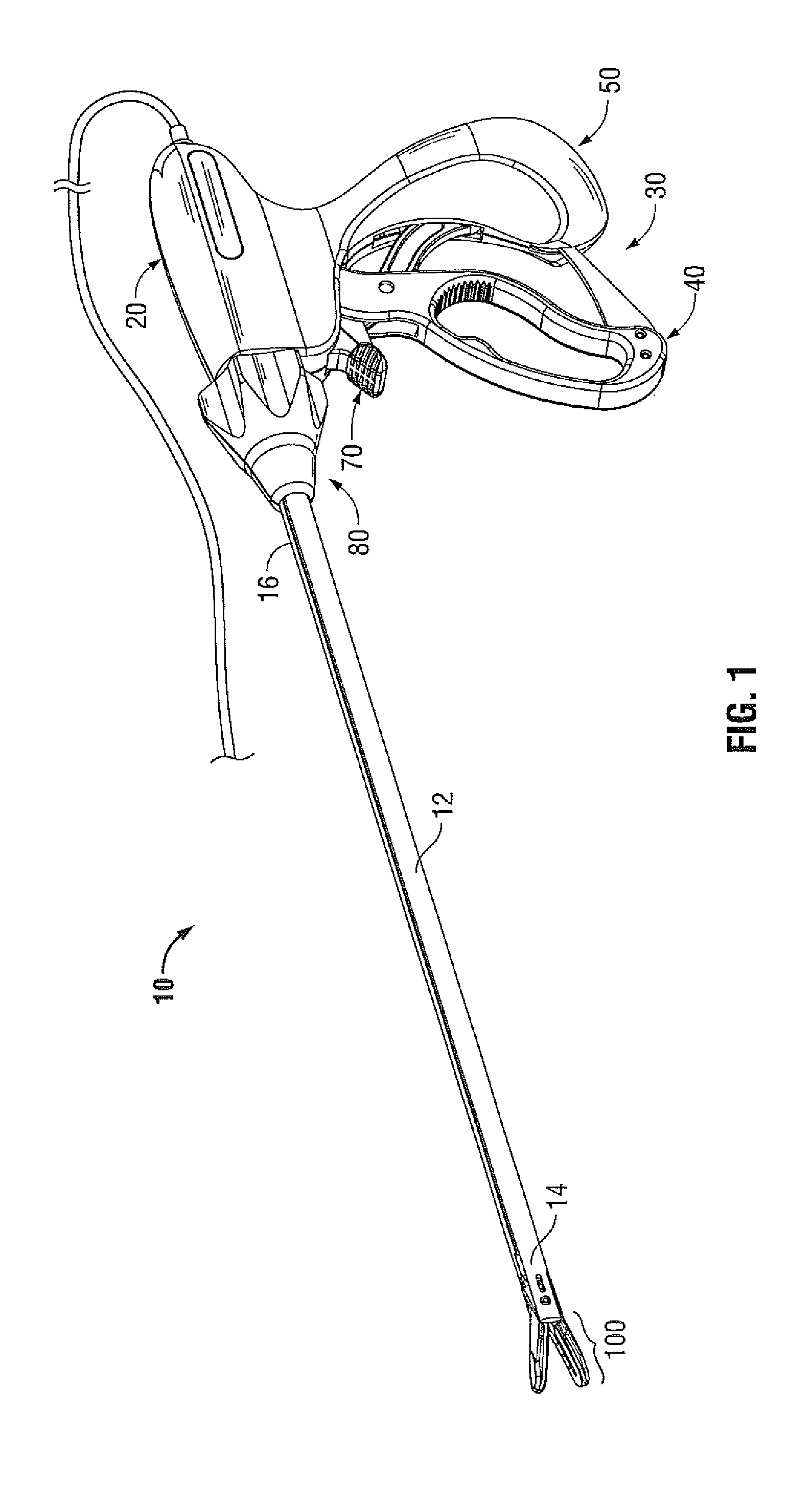

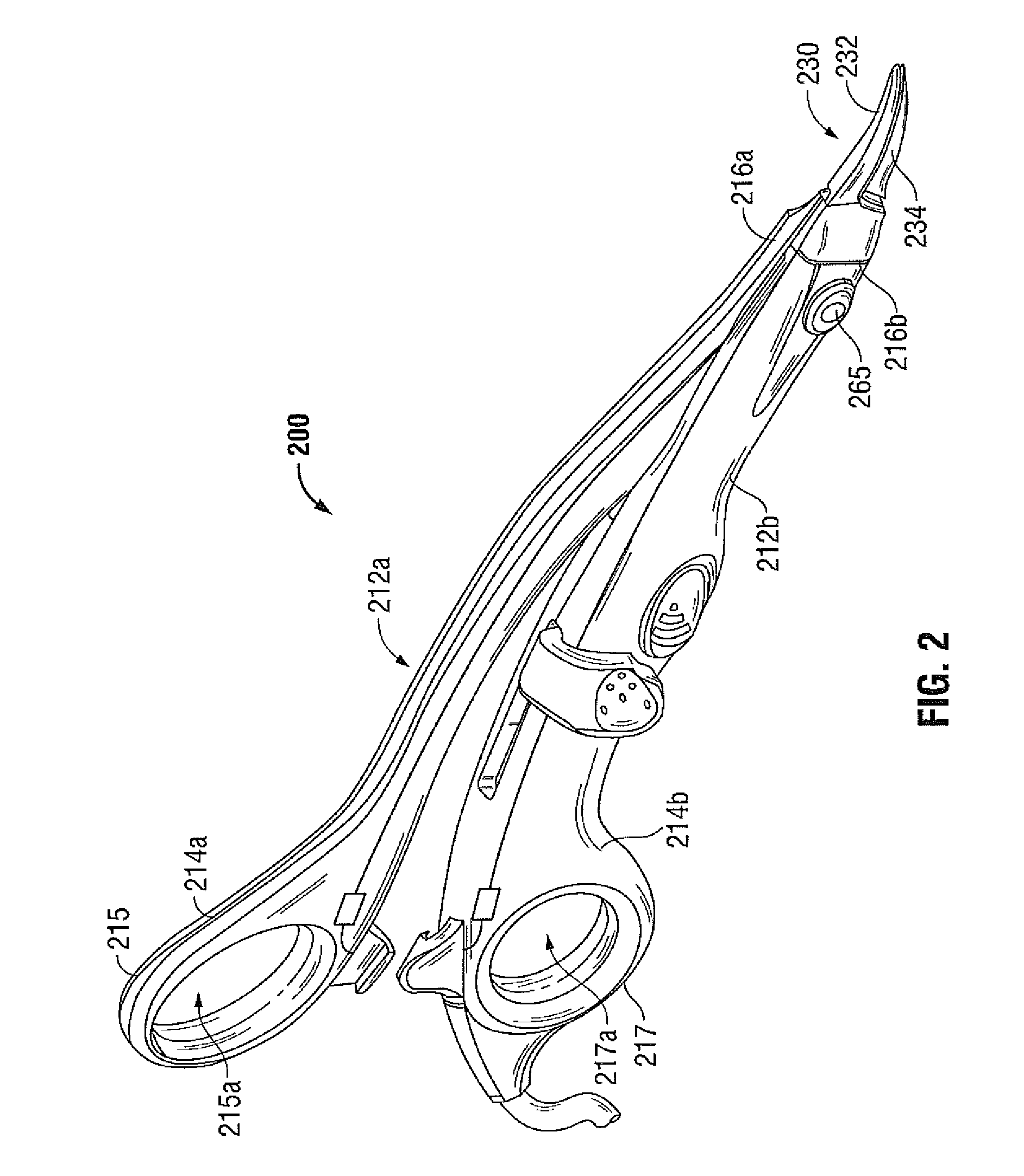

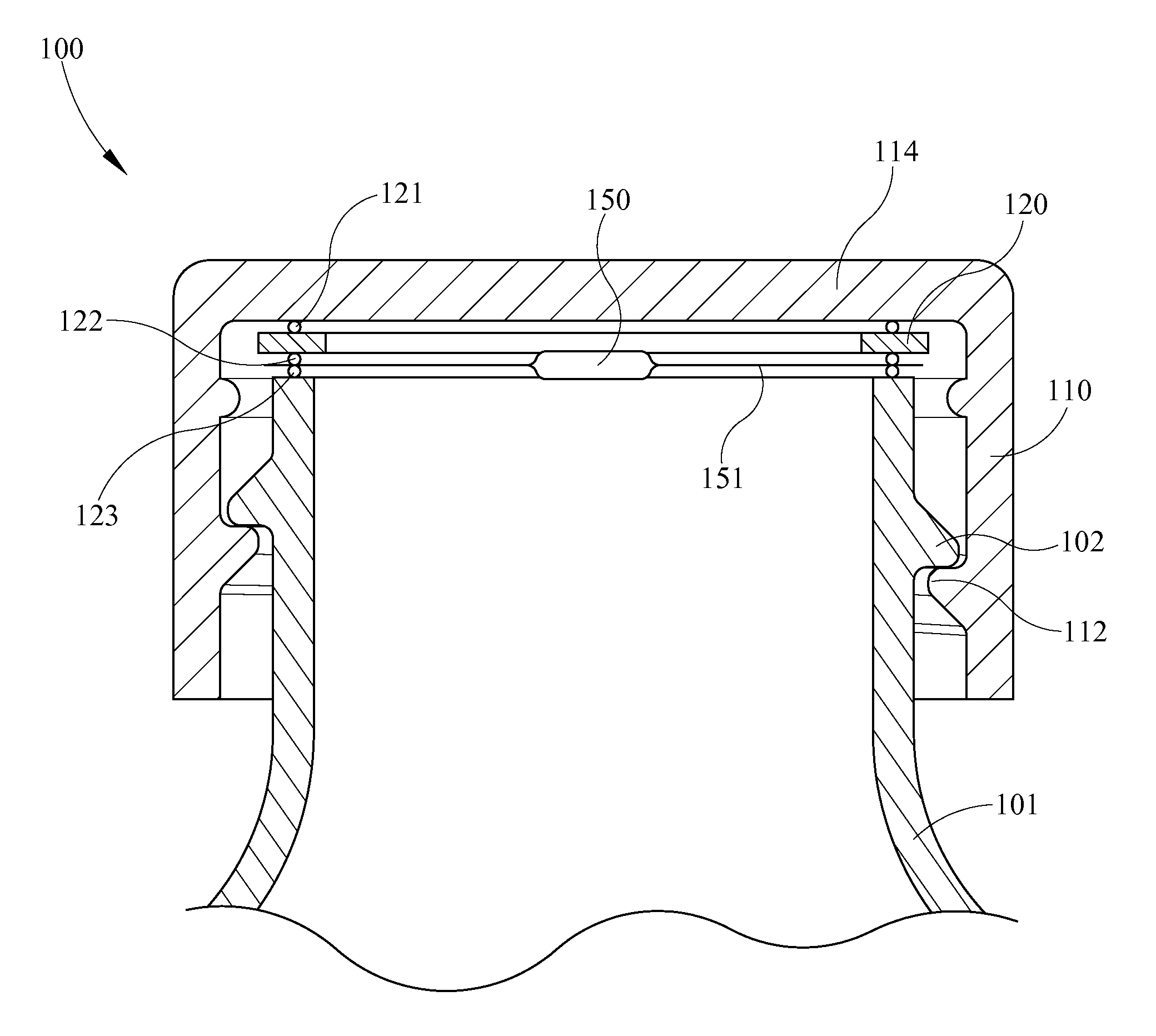

An end effector assembly for use with an electrosurgical instrument is provided. The end effector assembly has a first jaw member having a support base and a sealing plate formed from a ferrous material. The end effector assembly also has a second jaw member including a support base, an electrical jaw lead and a sealing plate coupled to the electrical jaw lead. The sealing plate includes a first layer formed from a non-stick material and a second layer having a coil formed thereon.

Owner:TYCO HEALTHCARE GRP LP

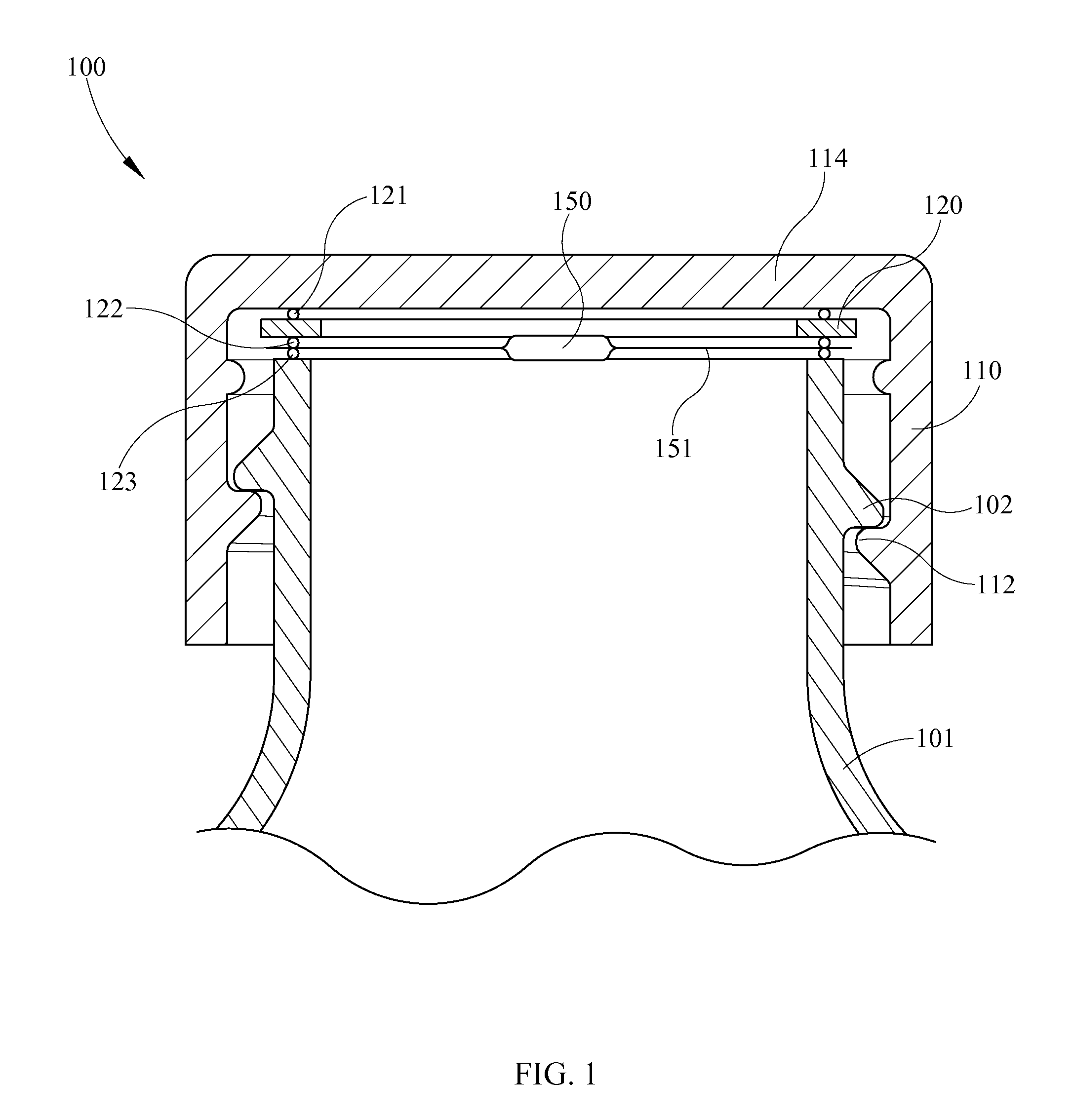

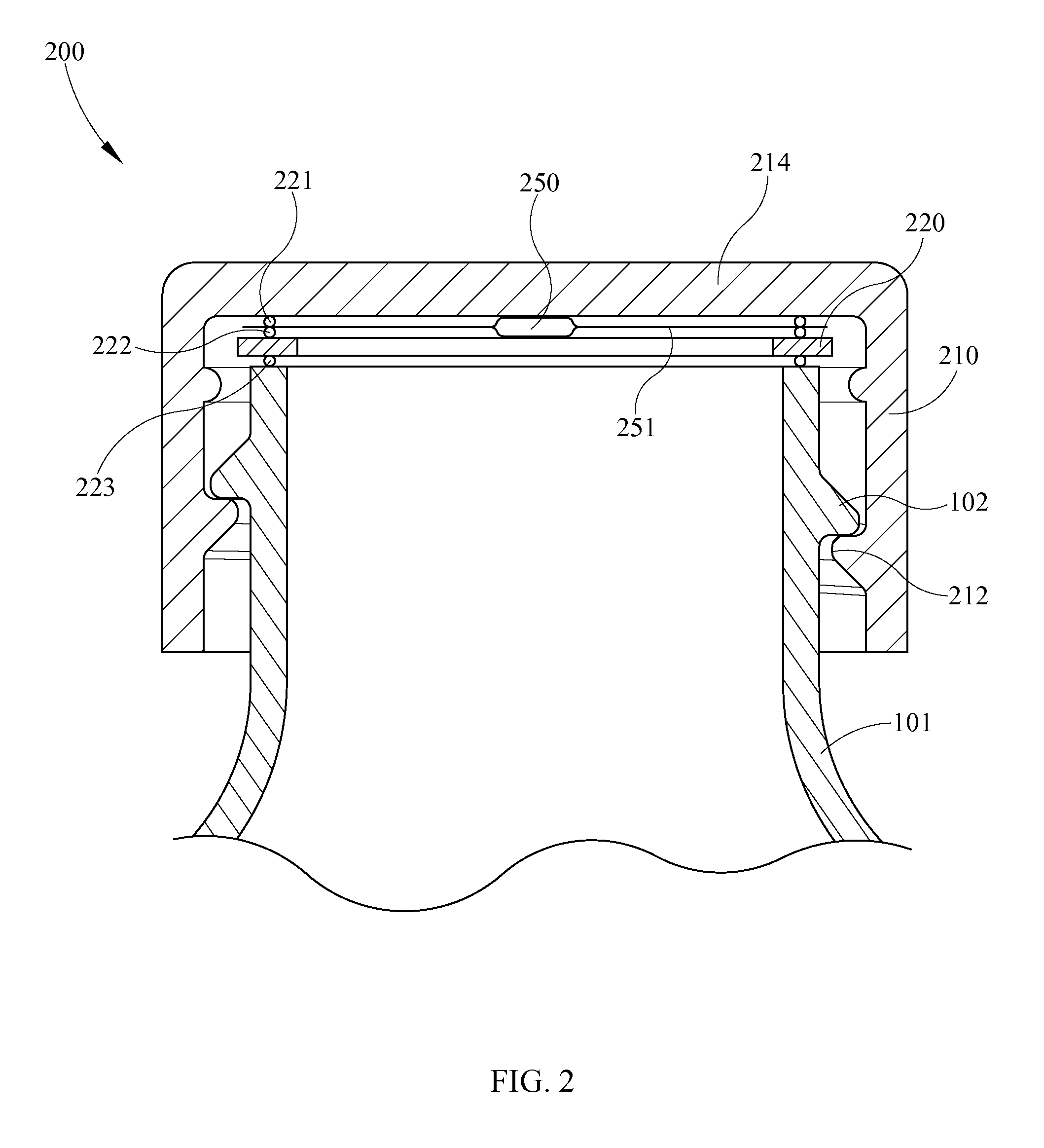

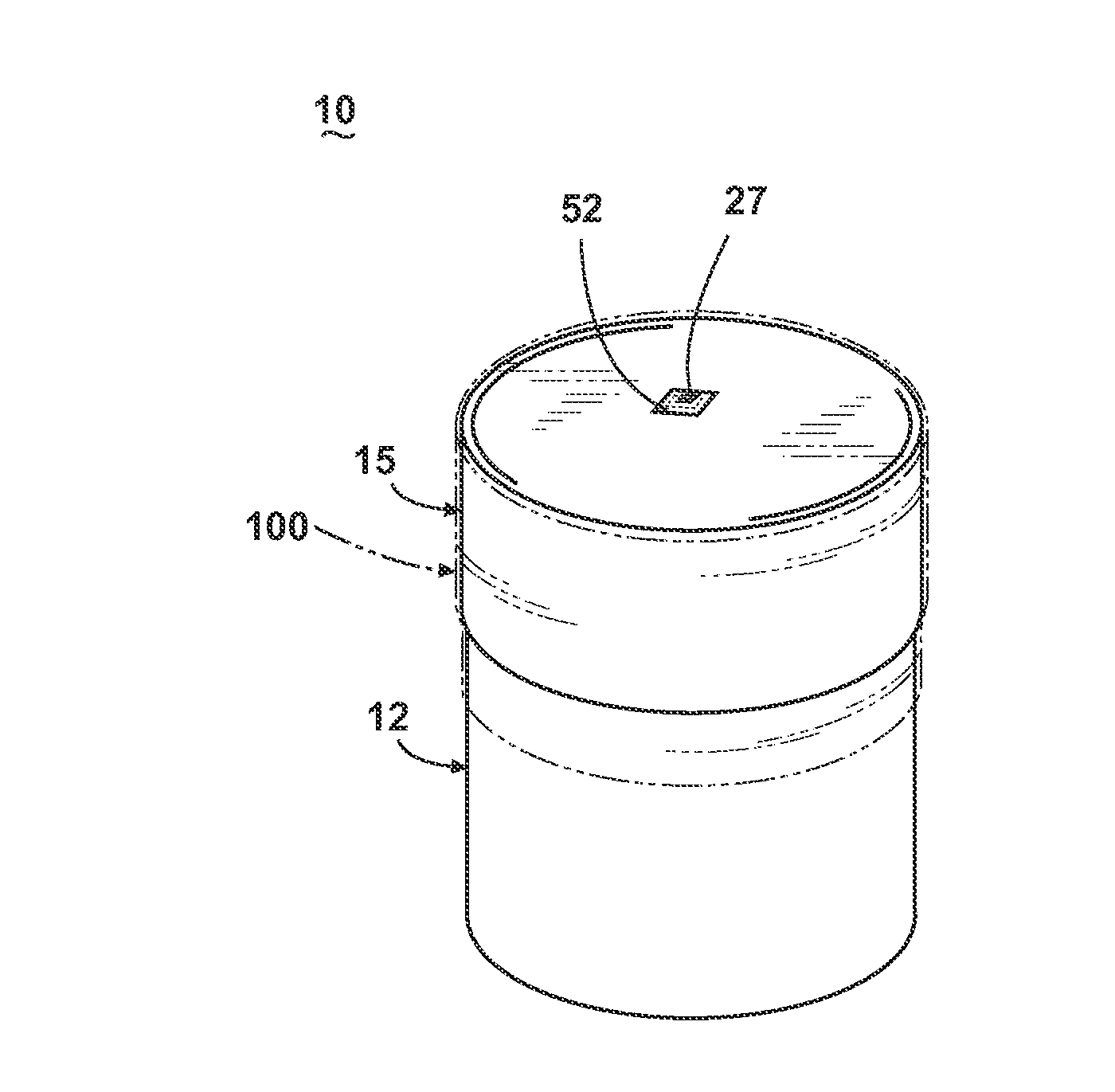

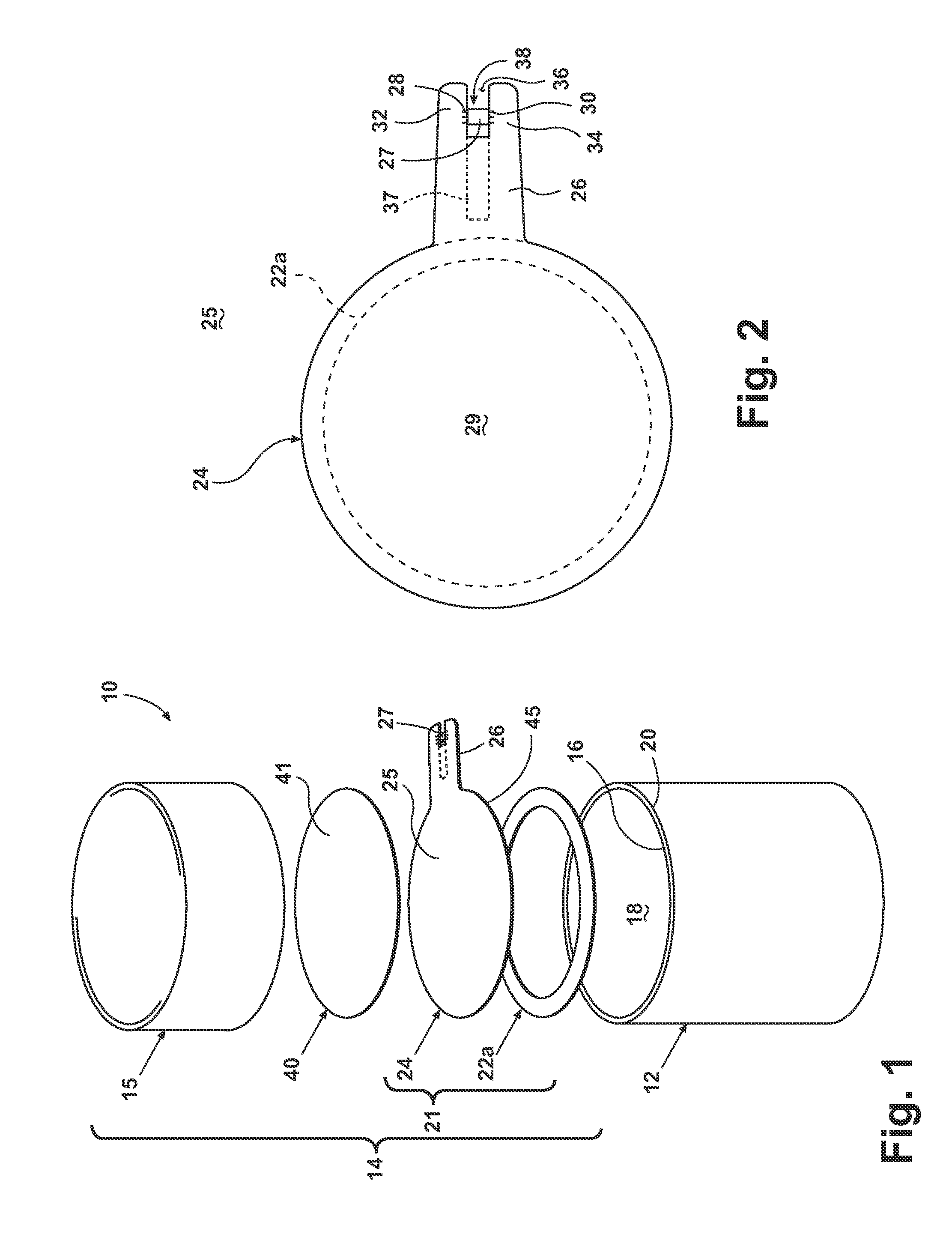

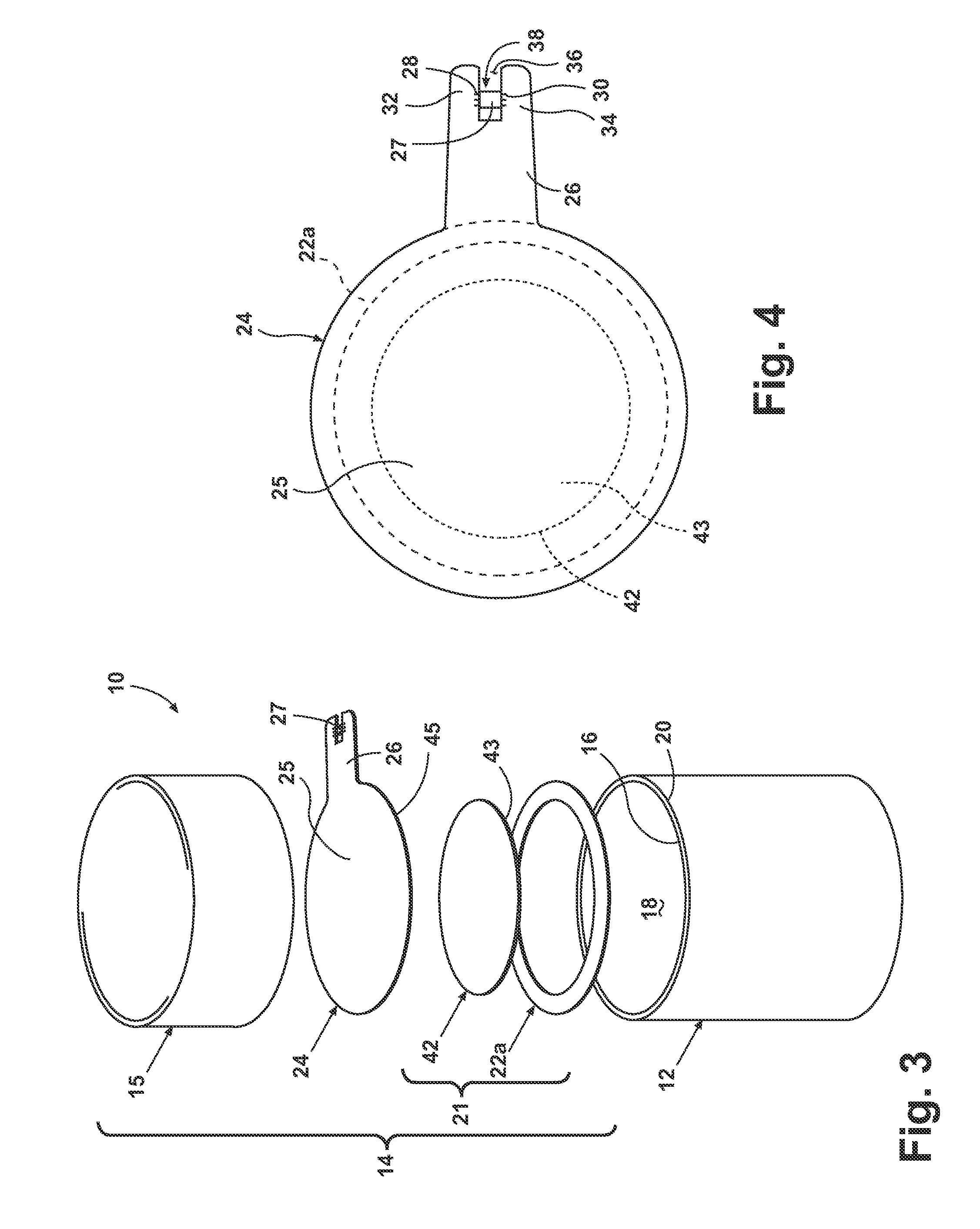

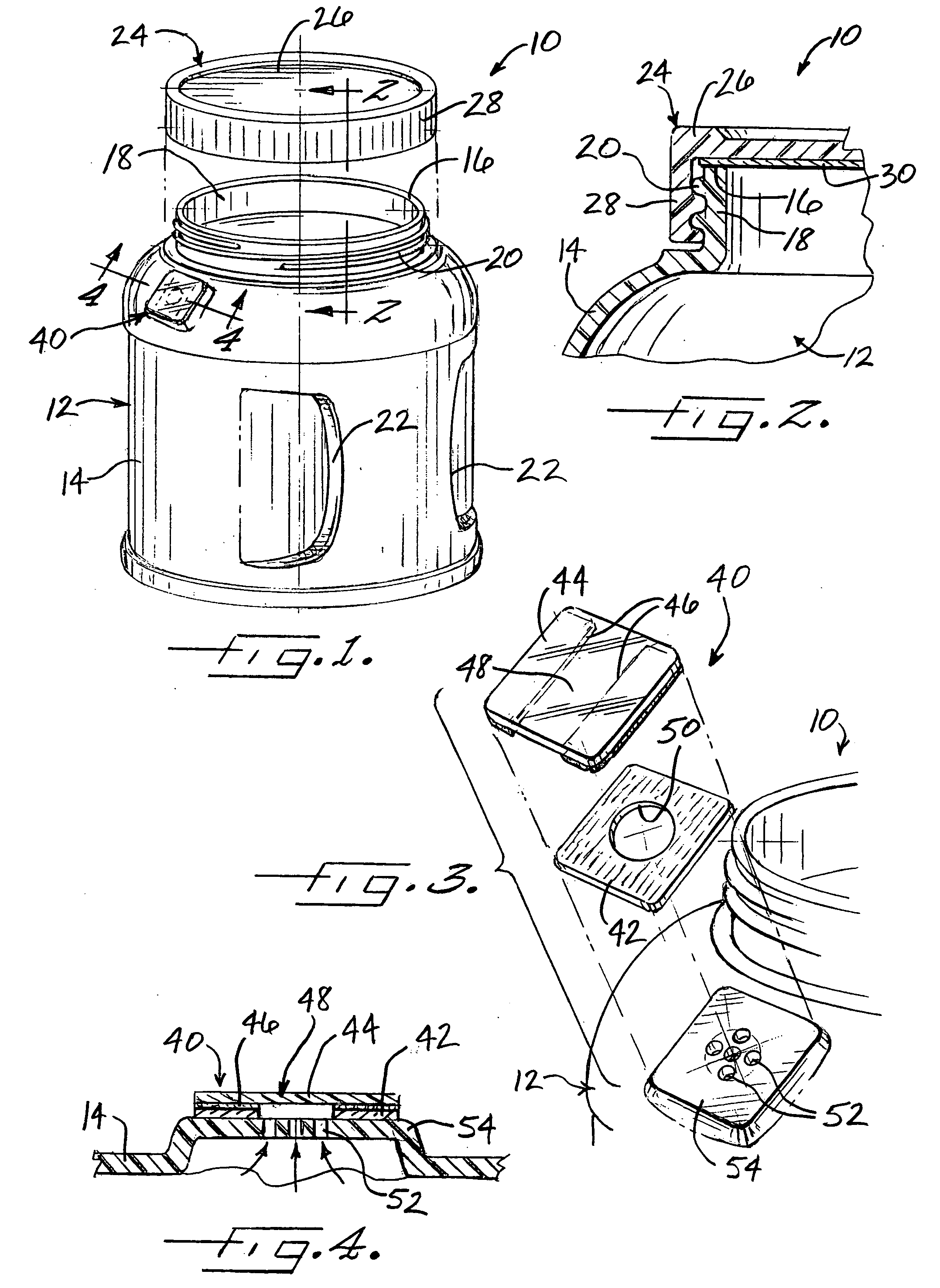

Closure having RFID and foil

InactiveUS7973664B1Increase temperatureContainer decorationsLevel indicationsEngineeringInduction sealing

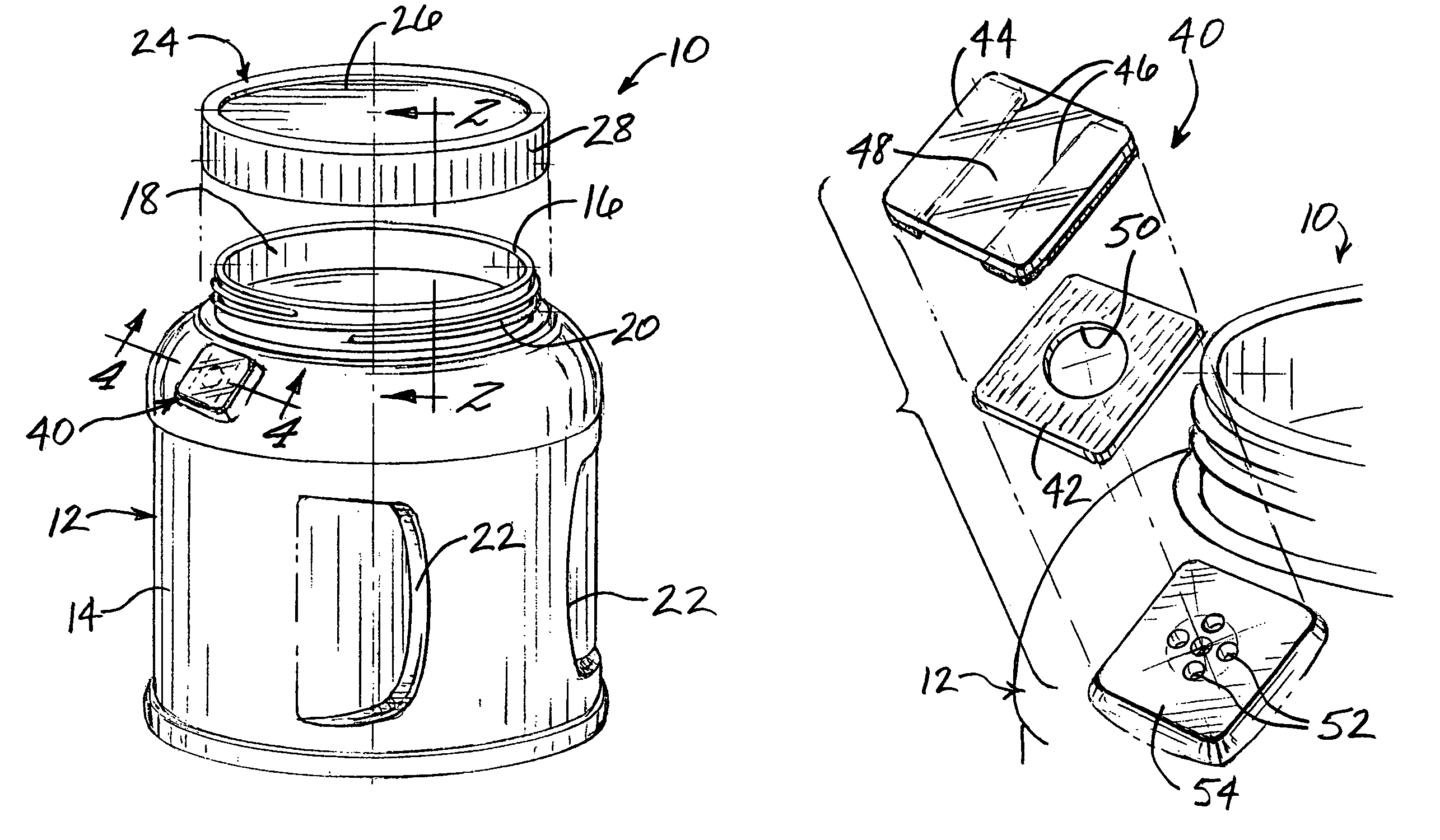

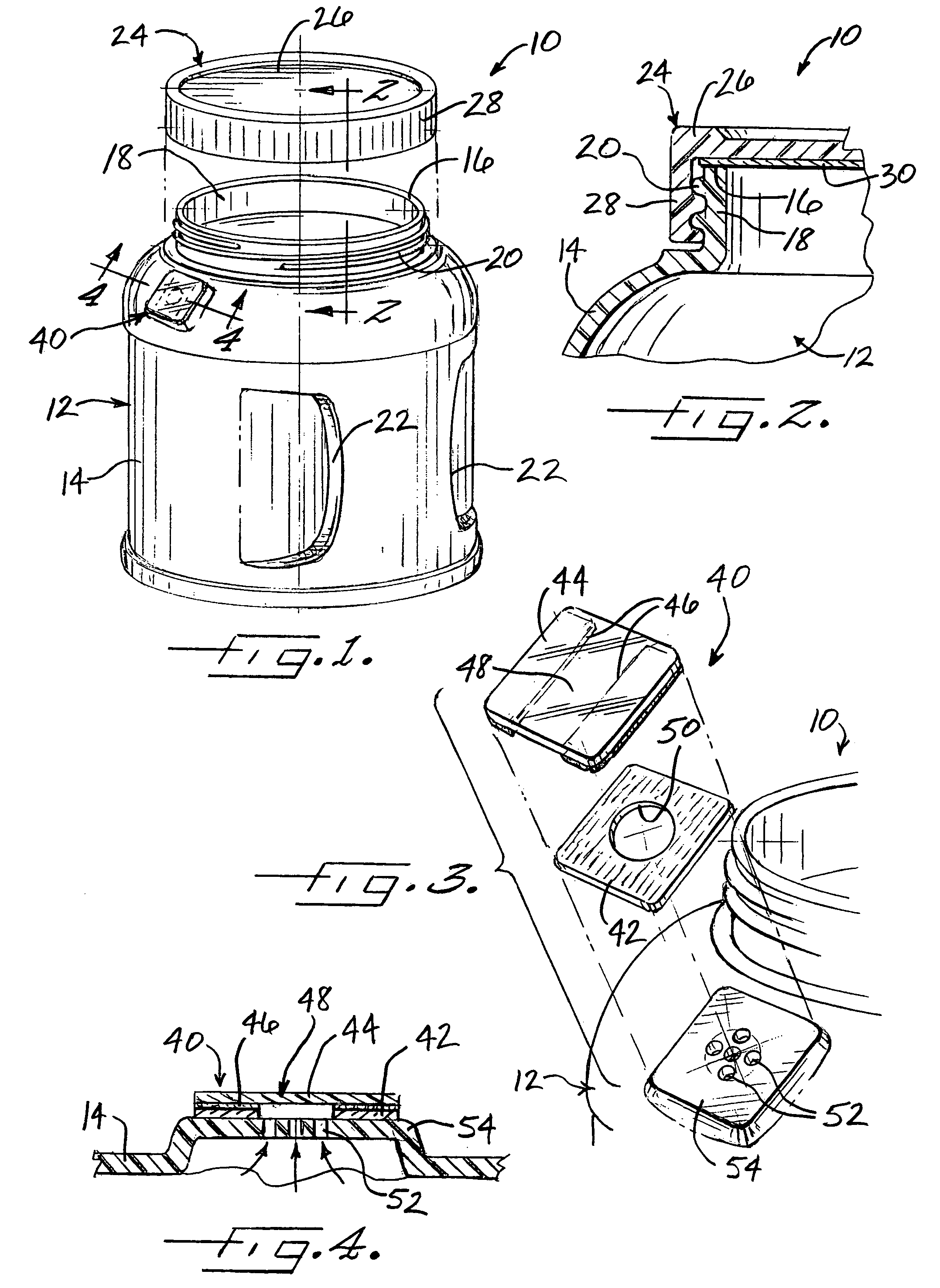

A closure comprising a top wall with an annular side wall depending there from. An induction foil is proximate an inner surface of the top wall and may have a ring or circular configuration. An RFID device is affixed or is integral with the closure a minimum distance from and / or orientation with the induction foil as to prevent damage to the RFID device during an induction sealing process and to reduce adverse operational effects of the RFID from the foil. The RFID may be active or passive and may be proximate or integral with the top wall or integral with the side wall of the closure. The RFID may be contained within a film wherein a portion of the film is inductively sealed to the closure.

Owner:BPREX HEALTHCARE PACKAGING INC

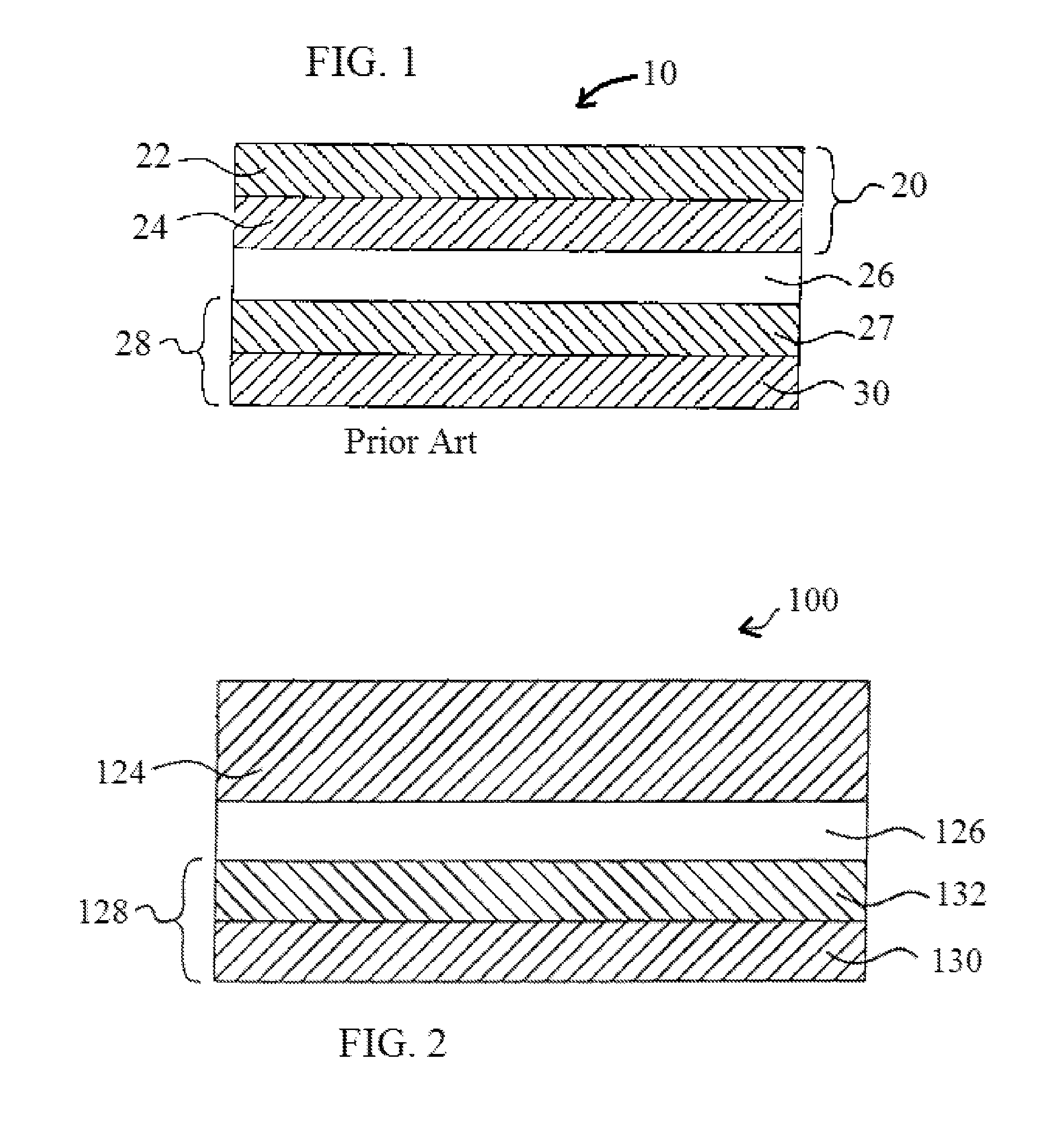

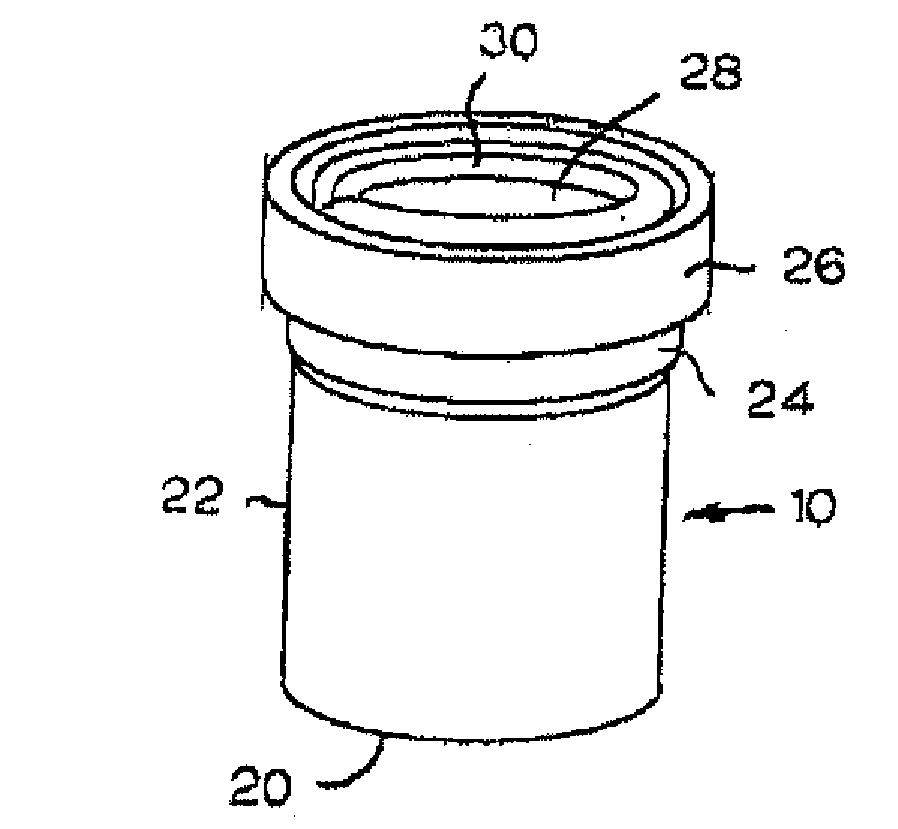

Synthetic two-piece induction seal products

ActiveUS7850033B2Efficient and cost-effectiveSafe and cleanCapsClosure using stoppersWaxSynthetic materials

A two-piece induction seal for use in creating clean, safe, and secure inner seals on containers having a monolayer plastic formed from synthetic fibers with stable pore dimensions for fluid permeability while retaining dimensional stability for compression. An inductive innerseal membrane is provided having a first side and a second side thereof, with an adhesive layer at the first side of the membrane. The second side of the membrane is detachably bound to the synthetic material with a wax layer. The synthetic material is further suitable for absorbing substantially all of said wax layer when said wax layer is in liquid form.

Owner:SELIG SEALING PROD INC

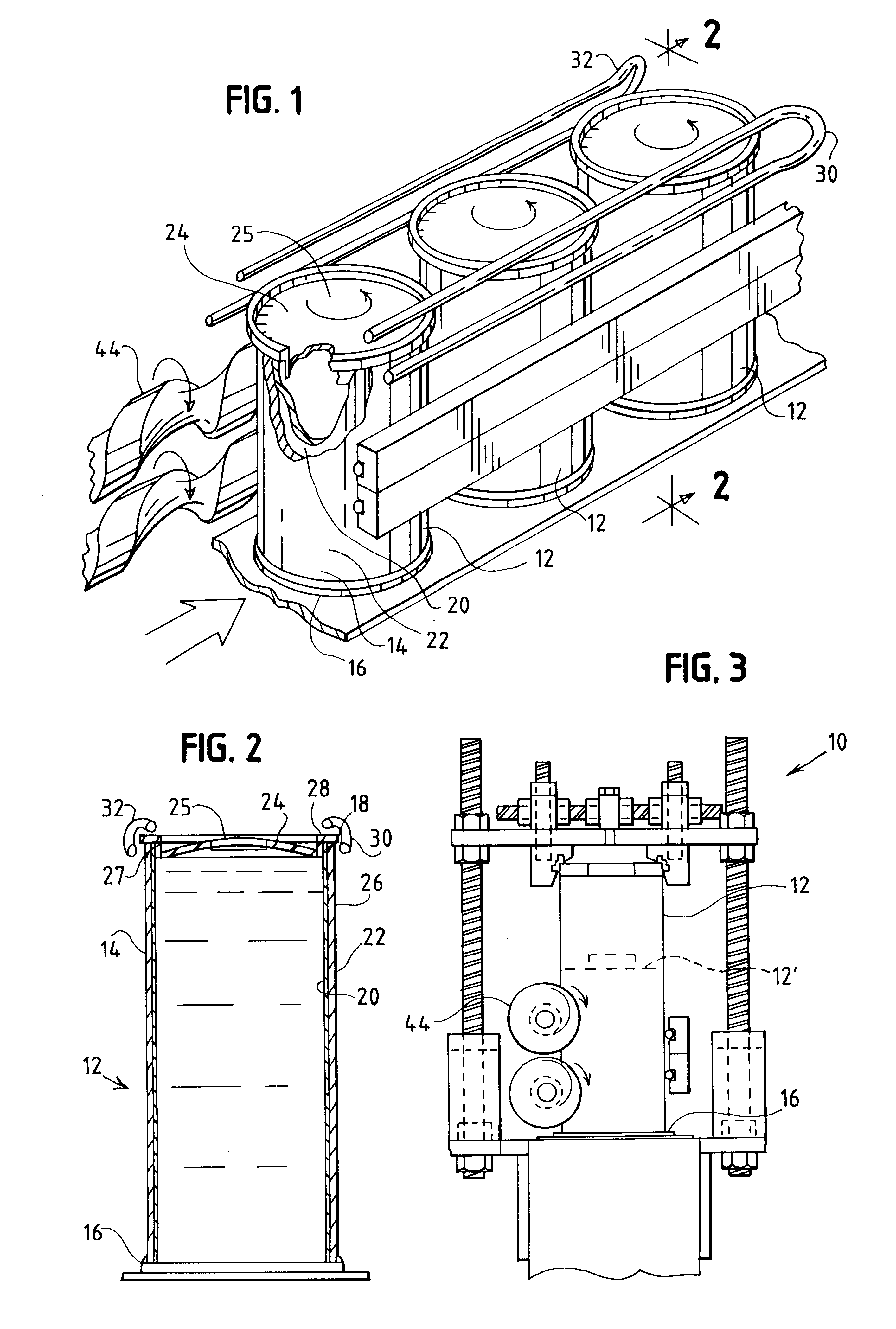

Induction foil cap sealer

InactiveUS20020020144A1Opening closed containersBottle/container closureLitz wireElectromagnetic field

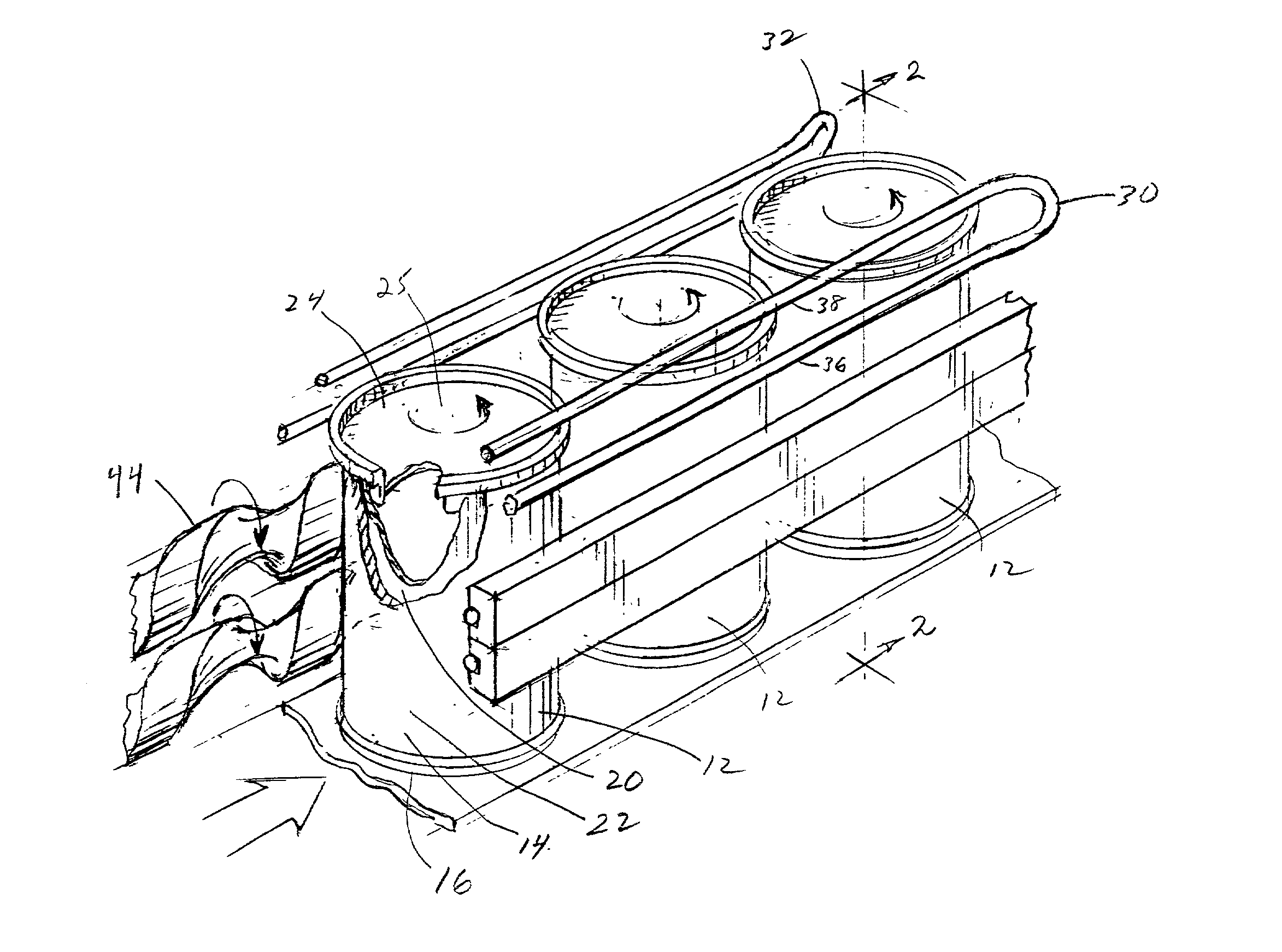

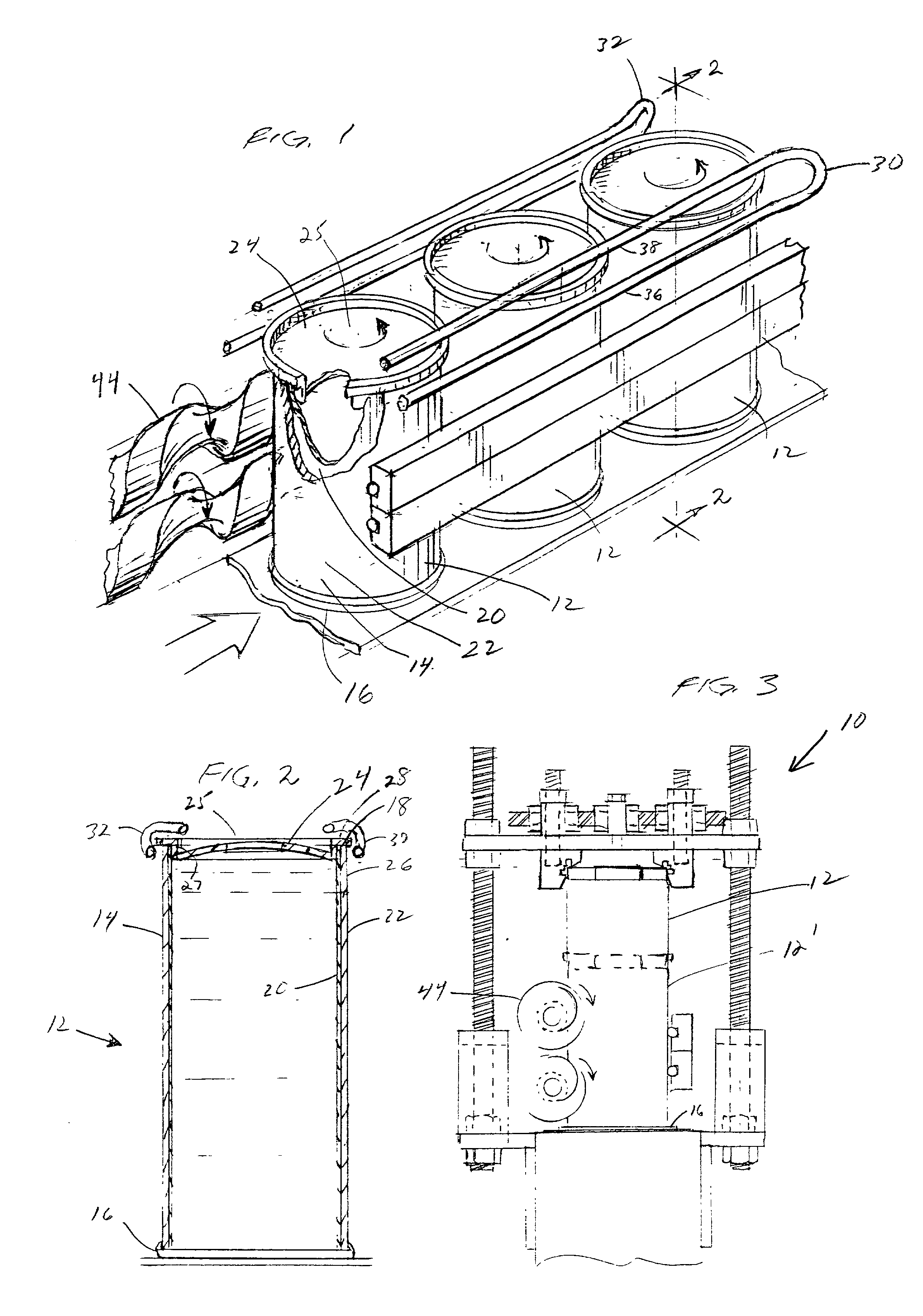

An sealing system includes a frame, a ferrite core disposed within the frame, and a litz wire coil disposed proximate to the ferrite core for producing an electromagnetic field within the ferrite core, where the ferrite core and litz wire coil are adapted to direct the electromagnetic field toward a foil to seal an opening of a container with the foil. The sealing head is air cooled within the induction sealing unit.

Owner:AUTO KAPS

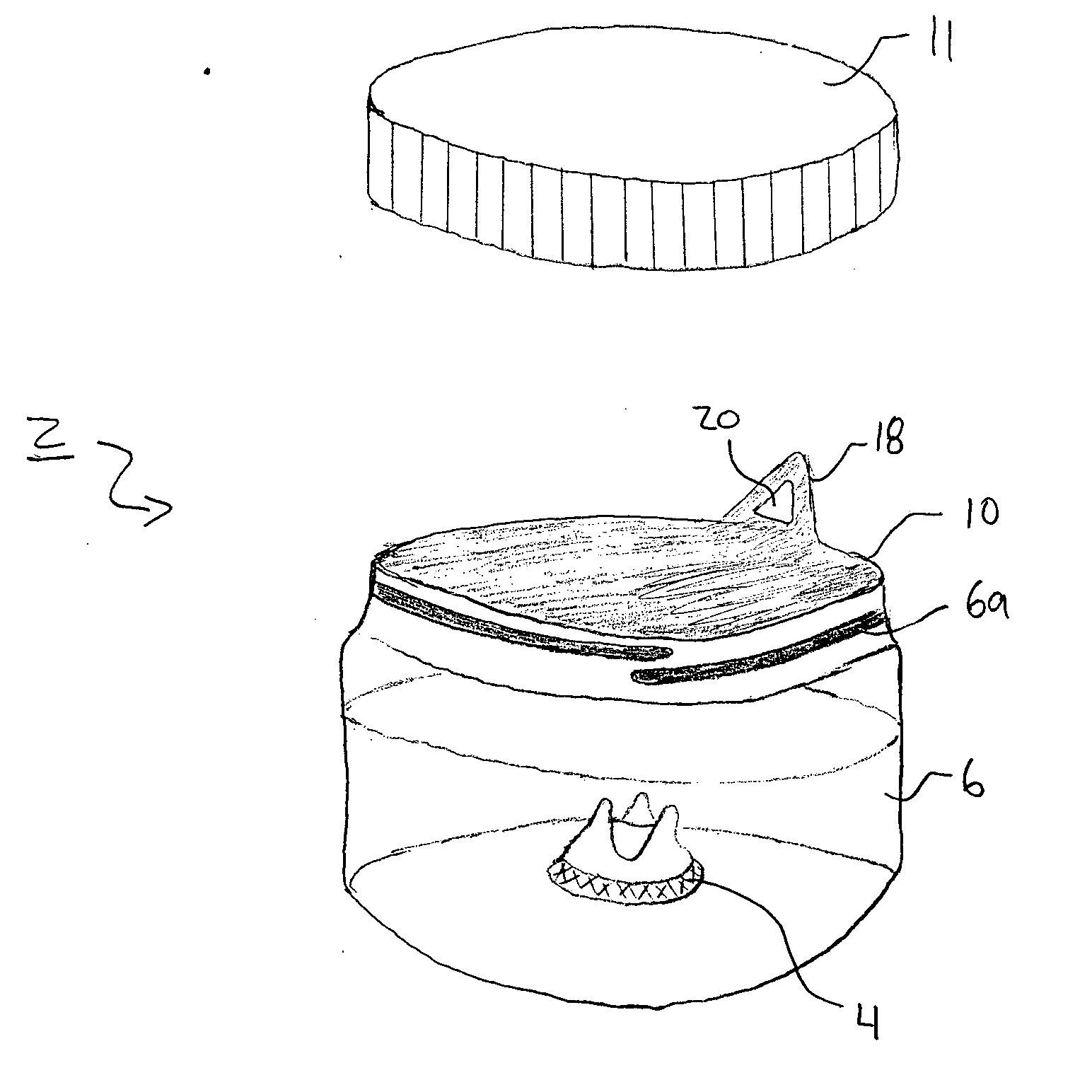

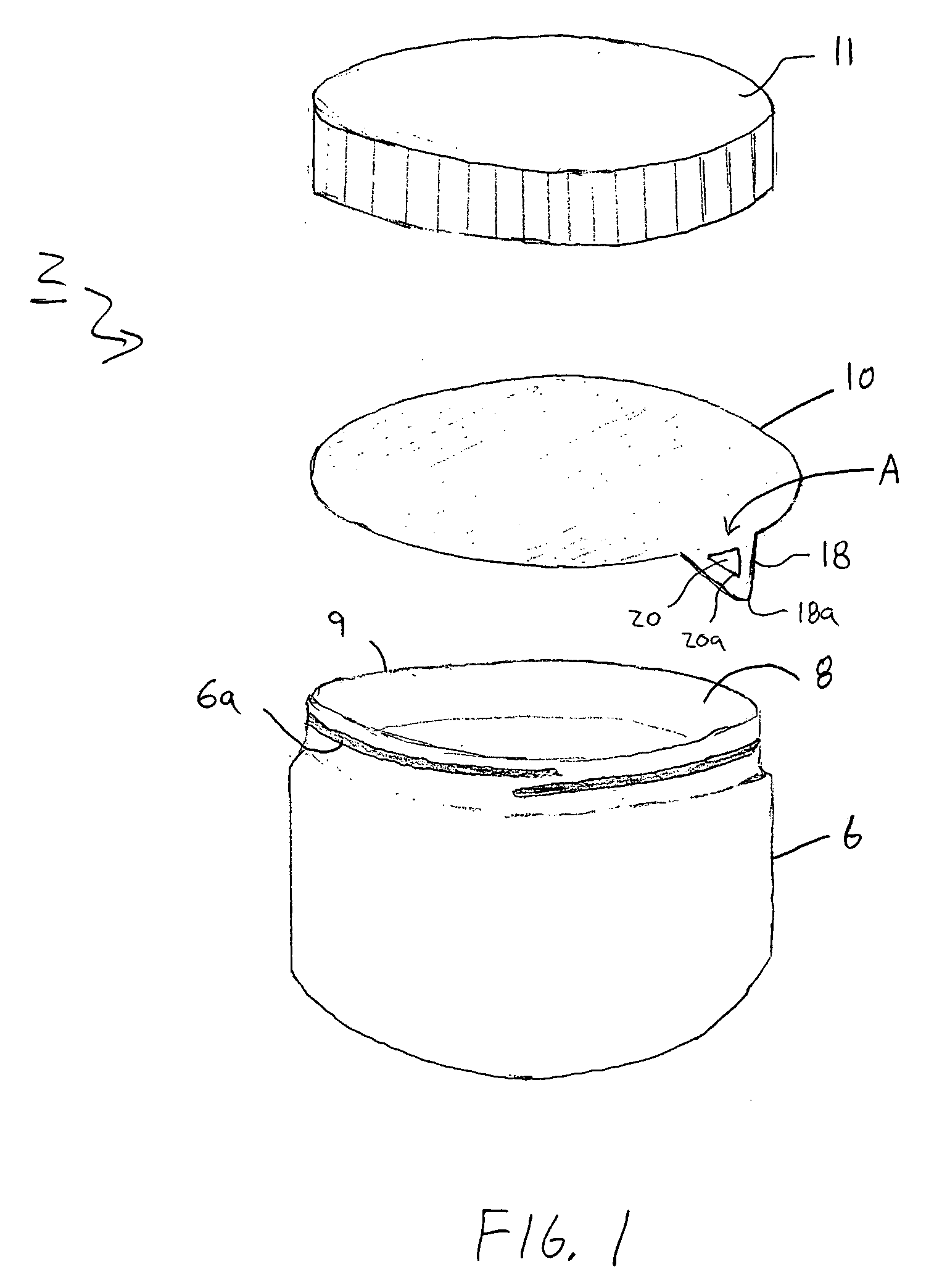

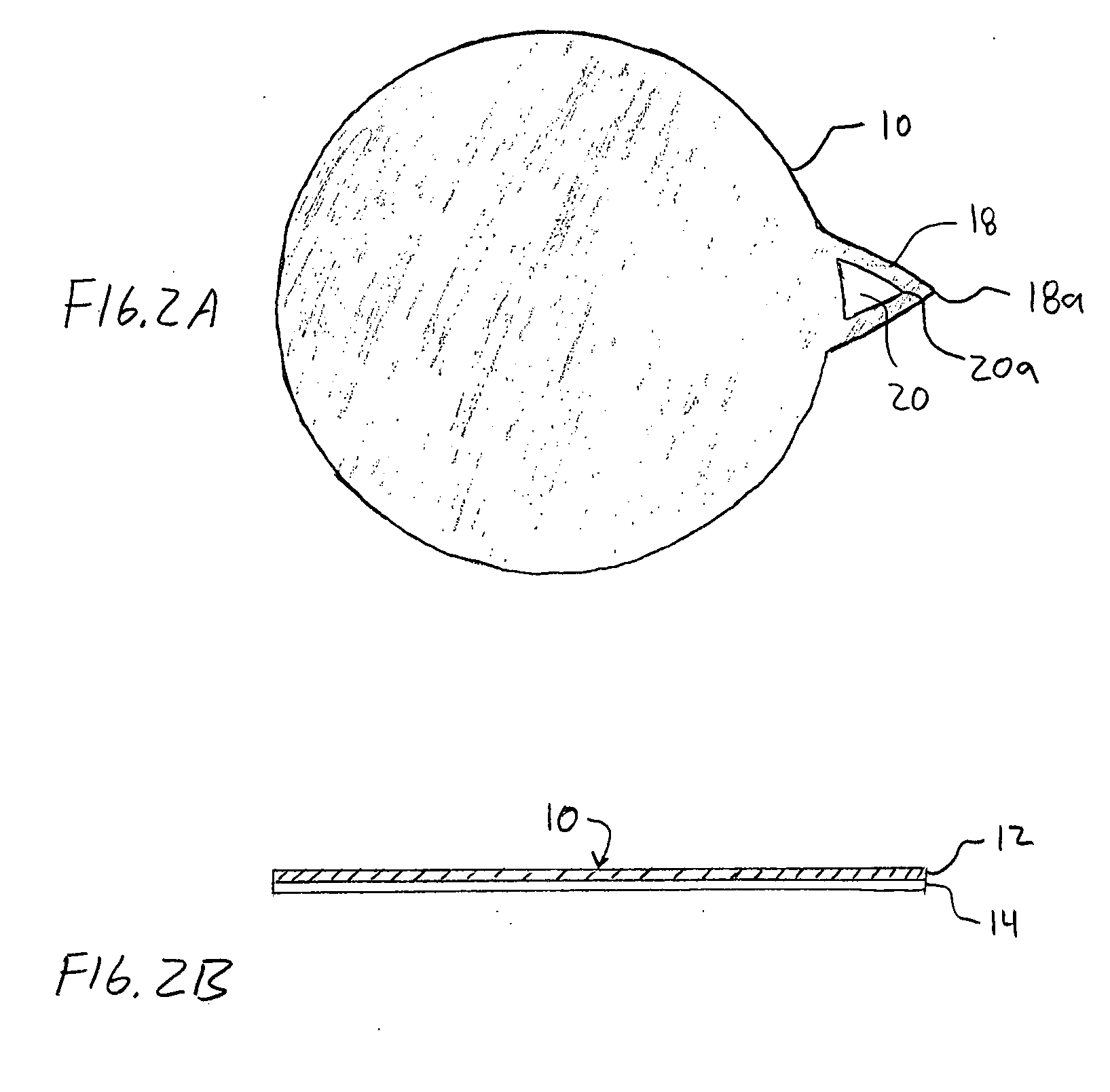

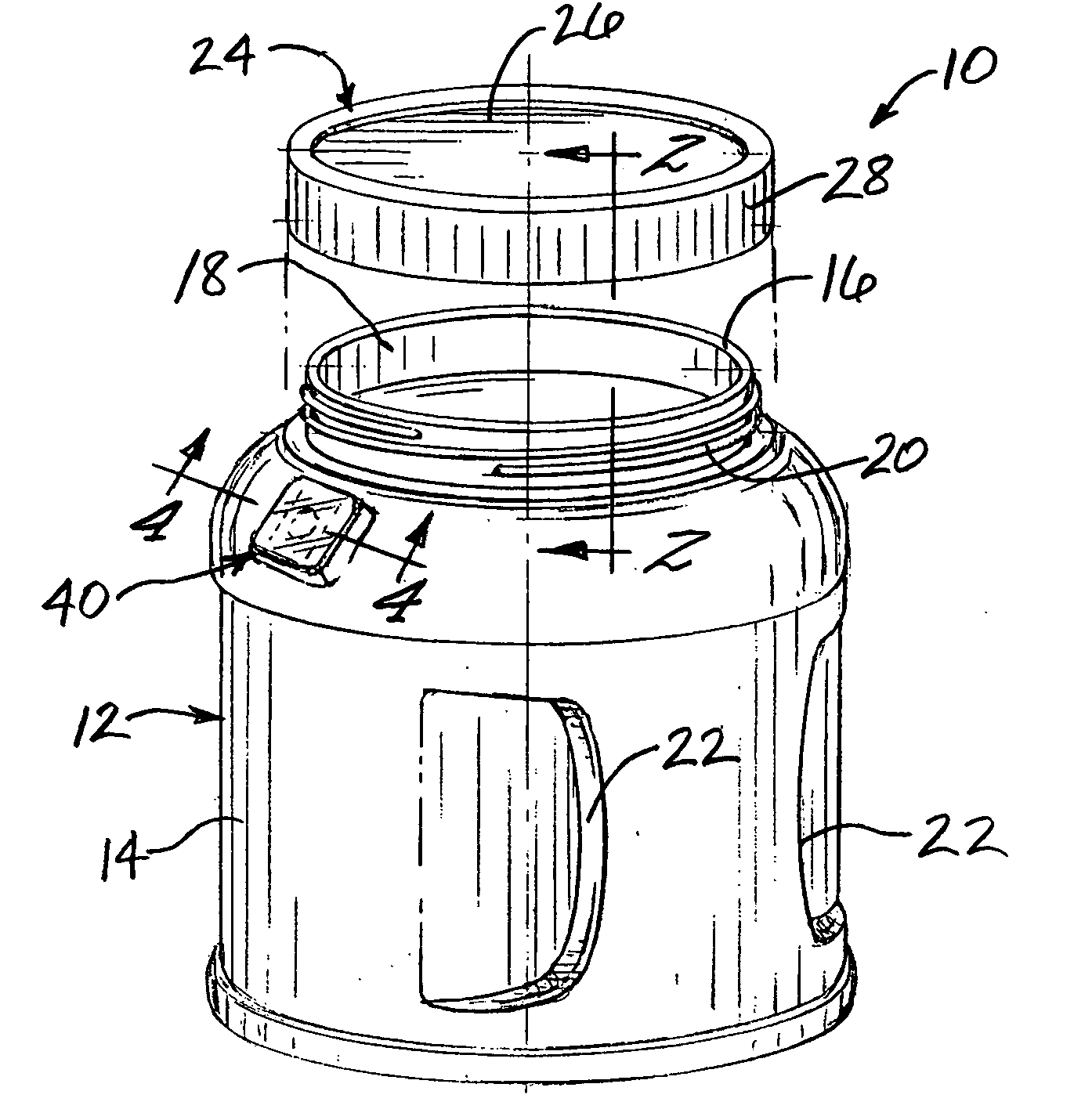

Apparatus for storing biological prostheses

An apparatus for storing a bioprosthetic device includes a container for receiving the bioprosthetic device within an opening in the container. The storage apparatus includes an induction seal having a foil layer and a heat seal layer for sealing the opening of the container. A pull tab is located on the induction seal and includes an aperture therein that facilitates bonding the induction seal to the container and / or otherwise sealing the container. A substantially hermetic seal is created by the induction seal. The apparatus may be opened with relative ease by pulling on the pull tab. The apparatus also reduces the risk of spillage of sterilant solution upon opening.

Owner:ARBOR SURGICAL TECH

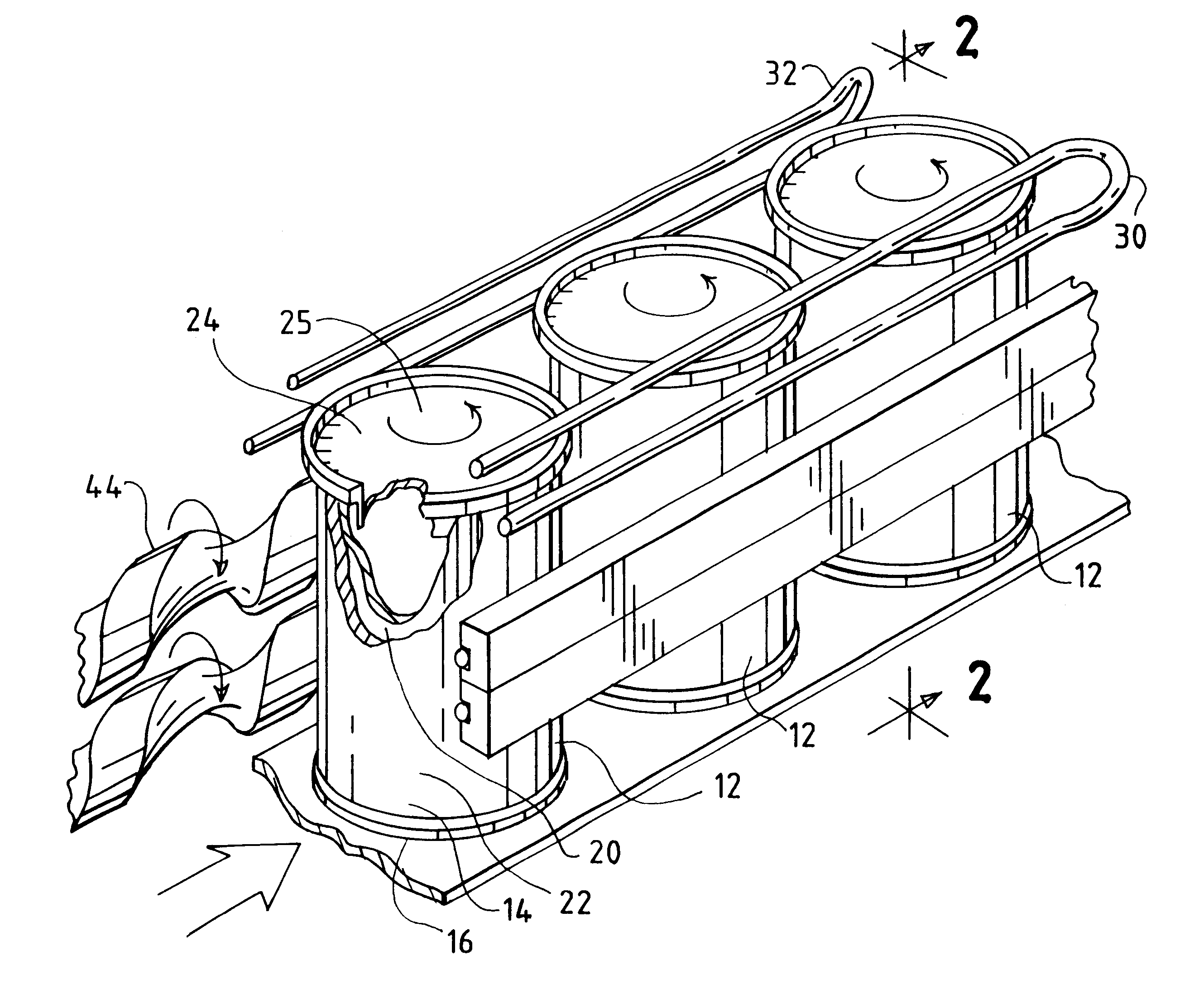

Method for induction sealing a plastic part to a composite container

A method for induction sealing a plastic part to a composite container using a pair of linear coils electrically connected to low frequency generators. The linear coils produce overlapping electromagnetic fields on either side of the container. Rotating the container assures even heating of the polyethylene liner and plastic part. The method produces a reliable seal between the liner and plastic part and can be used at high production speeds.

Owner:SONOCO DEV INC

Slotted induction heater

InactiveUS6412252B1Little room for errorGain of the LCR circuit is greatly reducedCoil arrangementsControl devices for conveyorsLitz wireInduction heater

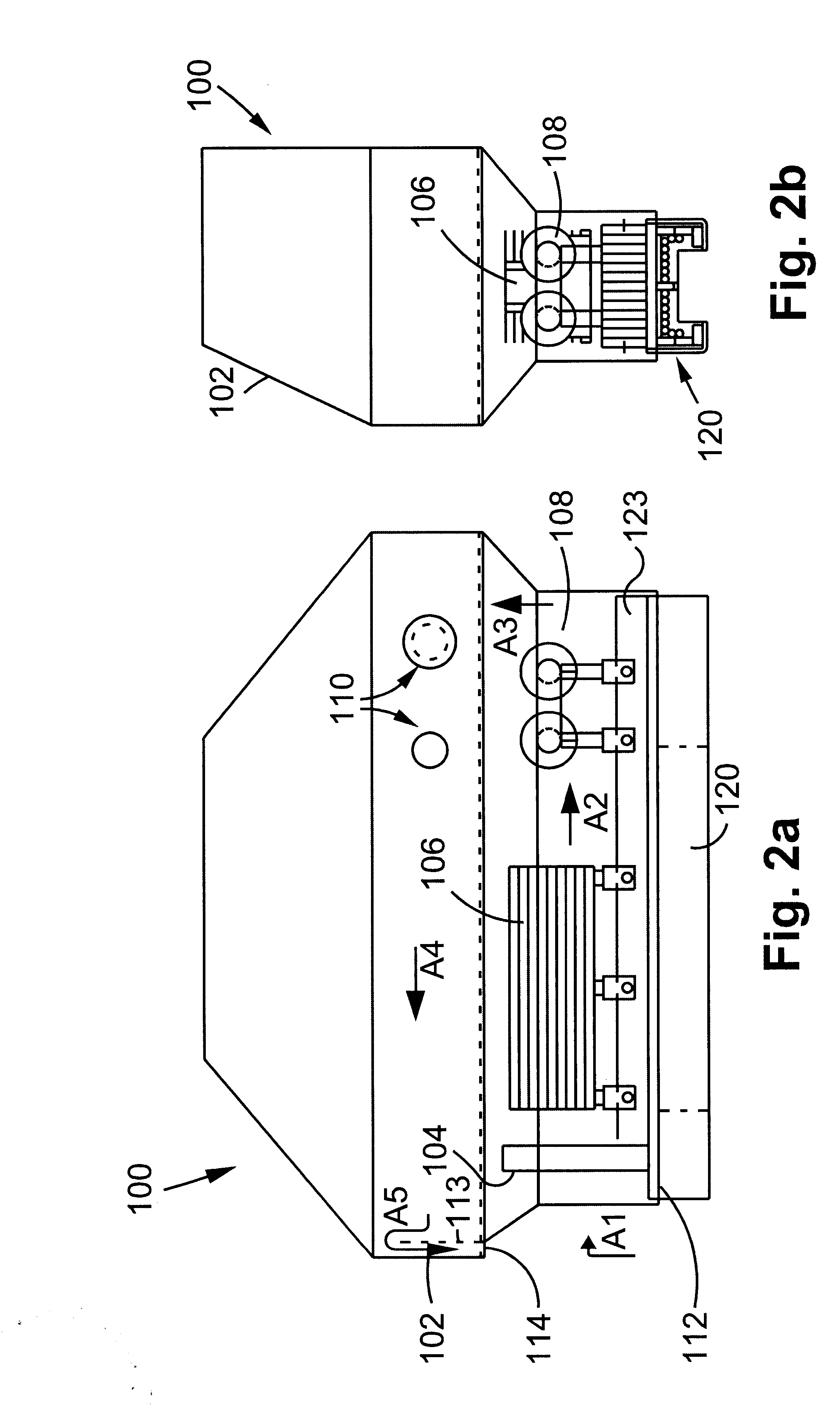

An induction sealing conveyor system includes an induction sealing unit coupled to an adjustment mechanism which adjustably positions the induction sealing unit with respect to a conveyor which moves a container to be sealed near a sealing head of the induction sealing unit. The sealing head includes ferrite cores and a litz wire coil formed on the ferrite cores which produces an electromagnetic field for hermetically sealing the container. The sealing head is entirely air cooled within the induction sealing unit.

Owner:AUTO KAPS +1

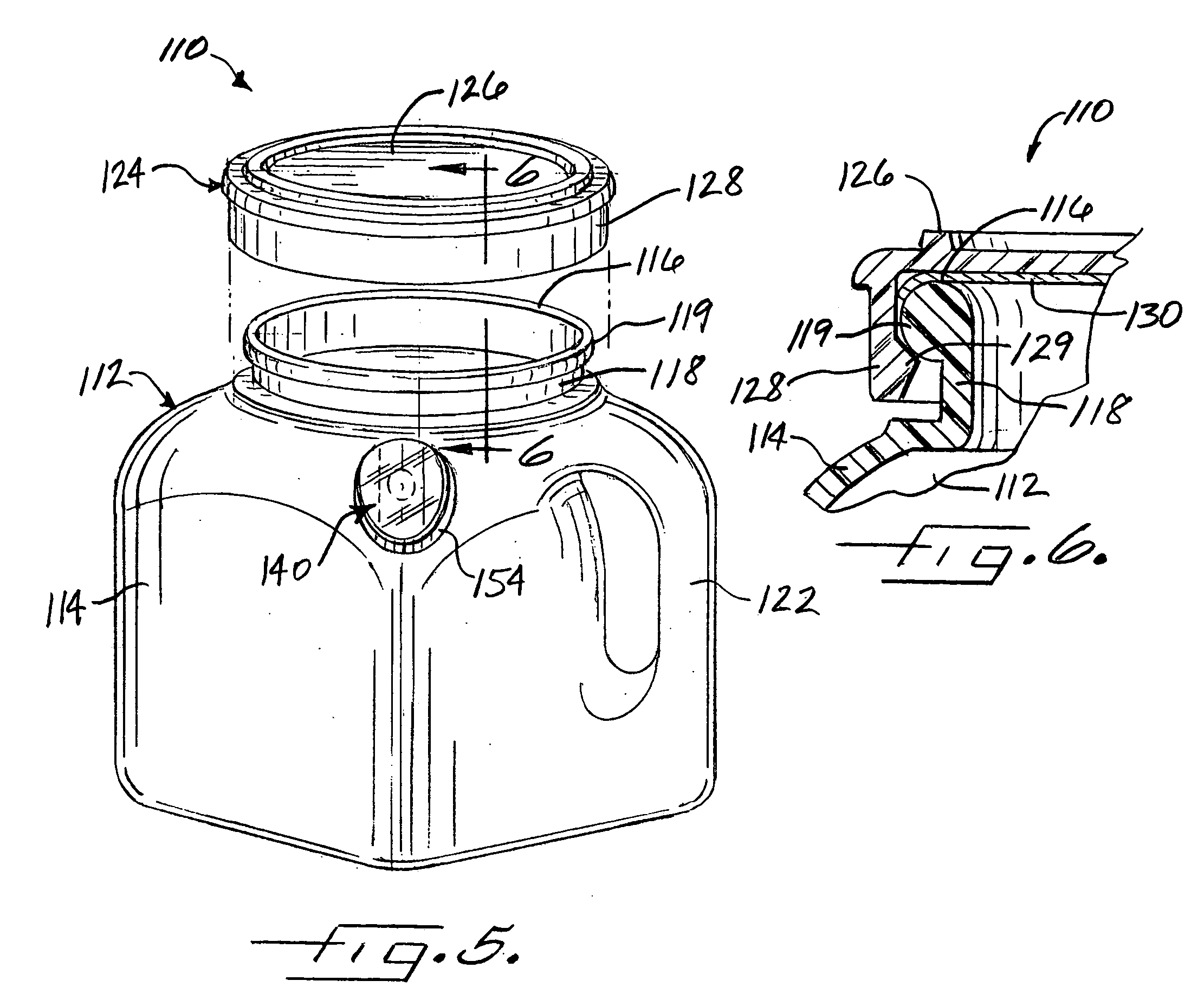

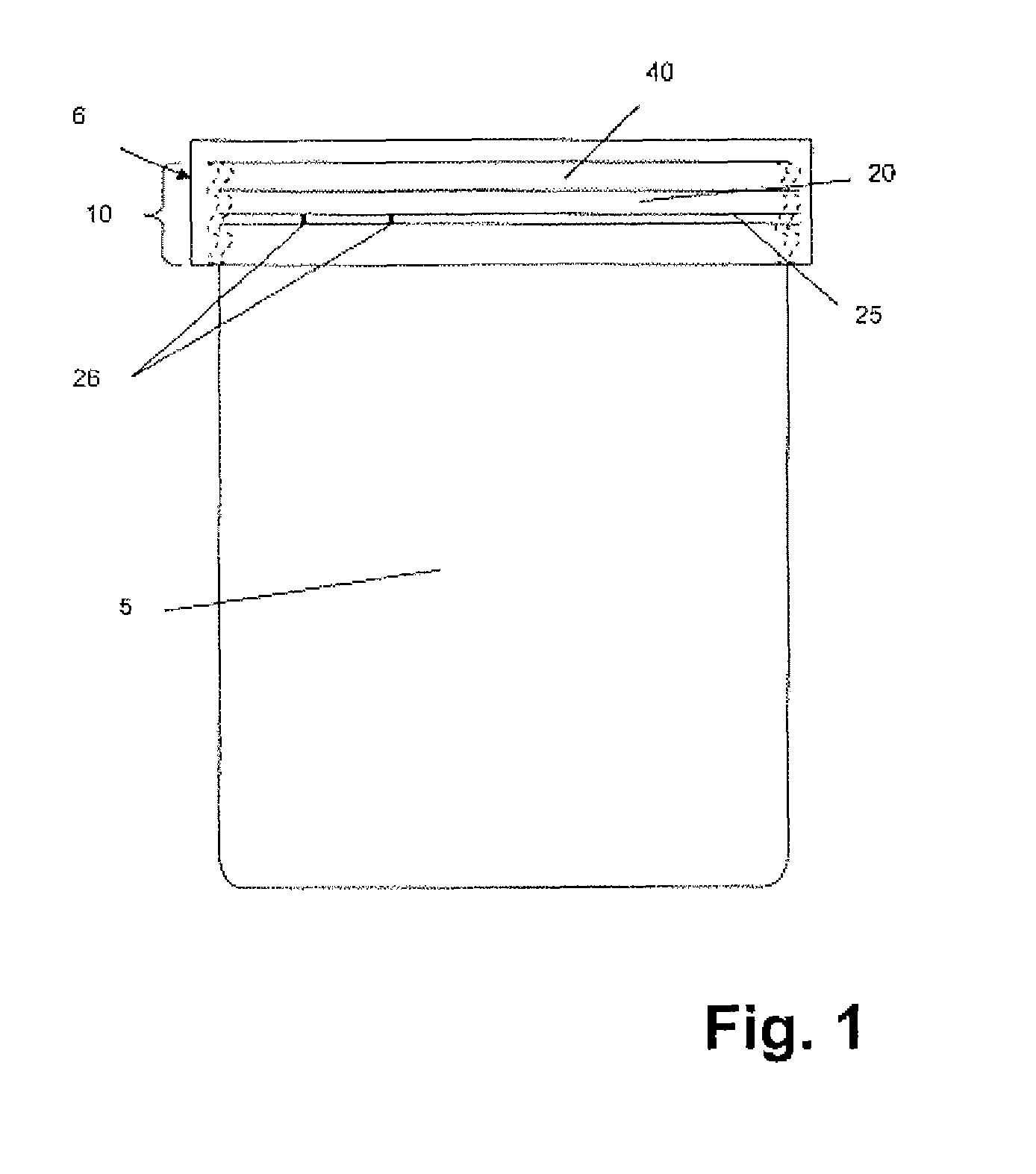

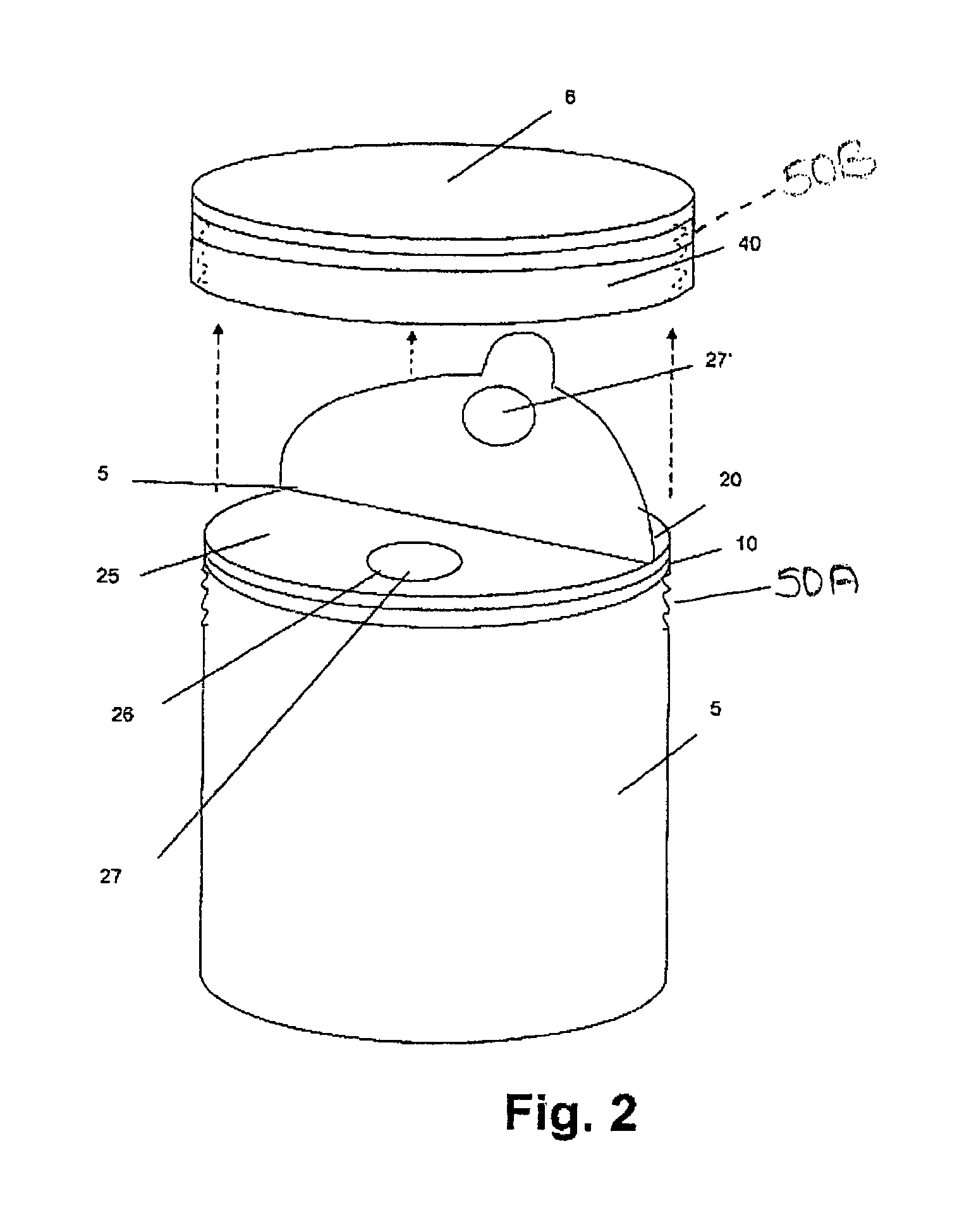

Container with gas release feature

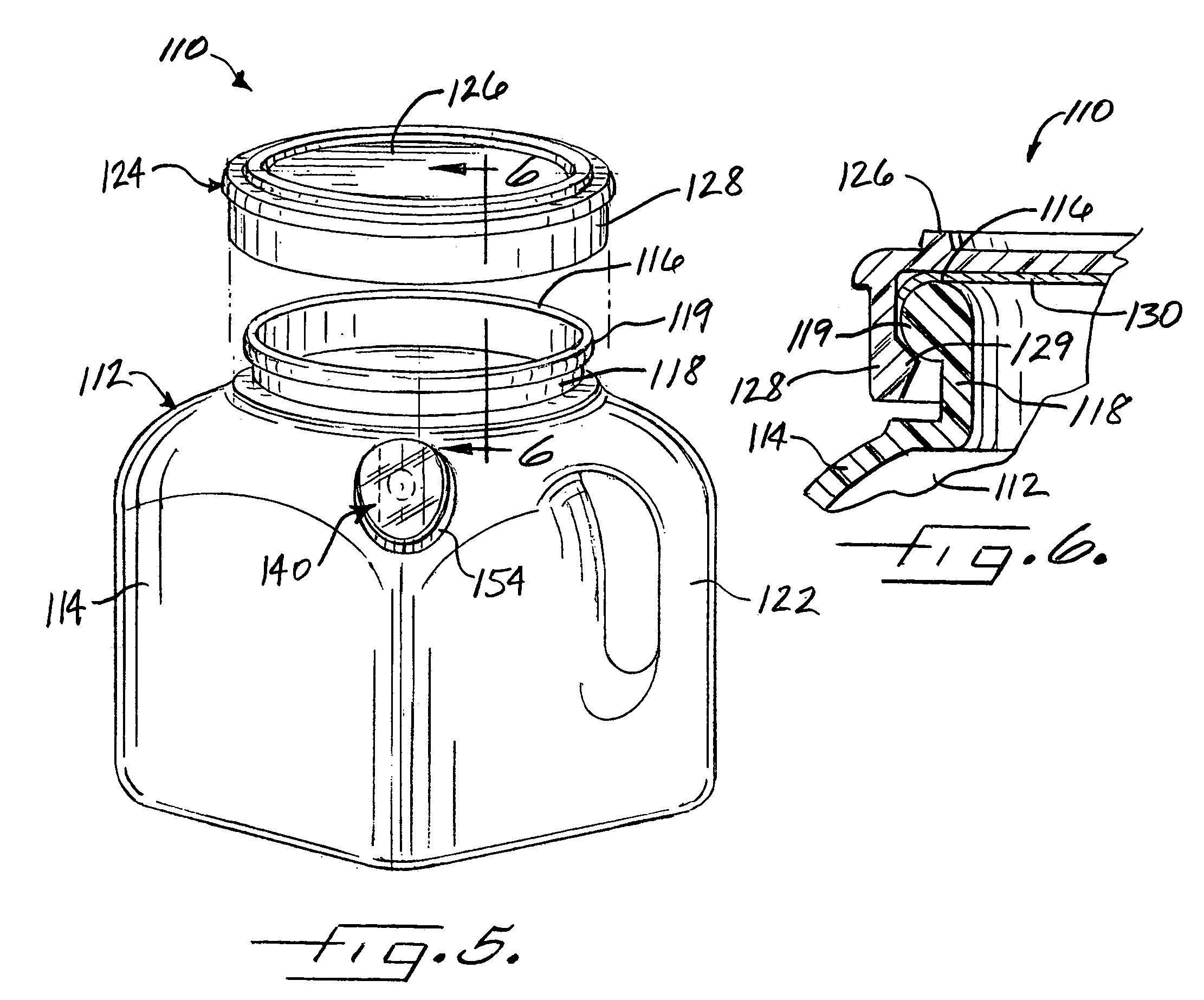

A gas release container comprises a container body having a bottom wall and a side wall extending upwardly from the bottom wall and terminating at an upper edge, a removable closure affixed to the upper edge in a substantially gas-tight manner, and a gas release valve in a wall of the container body and operable to release gas from the container when the pressure differential between the interior and the exterior of the container is sufficient to open the valve. The removable closure can include a flexible gas-barrier membrane sealed to the upper edge of the container body. A lower surface of the membrane and the upper edge of the side wall comprise heat-sealable polymer materials, and the membrane is heat-sealed to the upper edge, preferably by induction sealing. The closure can include an overcap.

Owner:SONOCO DEV INC

Container seal with radio frequency identification tag, and method of making same

ActiveUS20120217244A1Minimize migrationCapsContainer decorationsElectromagnetic interferenceEngineering

A container defines an interior volume, an opening into the interior volume, and a sealing surface bordering the opening. A closure assembly may be attachable over the opening and includes at least one of an induction seal liner, an inner seal, and a sealable film. A radio frequency identification tag includes a microprocessor and an antenna for receiving, storing, and transmitting selected digitized information. The induction seal liner, inner seal, and sealable film minimizes migration of fluids between the interior volume and the container exterior when the closure assembly may be engaged with the sealing surface. The radio frequency identification tag may be included in the closure assembly, or within the interior volume, or on the container exterior, or may be incorporated into the induction seal liner, inner seal, or sealable film, without the closure assembly electromagnetically interfering with the receiving, storing, or transmitting of digitized information.

Owner:EAGILE

Container with gas release feature

A gas release container comprises a container body having a bottom wall and a side wall extending upwardly from the bottom wall and terminating at an upper edge, a removable closure affixed to the upper edge in a substantially gas-tight manner, and a gas release valve in a wall of the container body and operable to release gas from the container when the pressure differential between the interior and the exterior of the container is sufficient to open the valve. The removable closure can include a flexible gas-barrier membrane sealed to the upper edge of the container body. A lower surface of the membrane and the upper edge of the side wall comprise heat-sealable polymer materials, and the membrane is heat-sealed to the upper edge, preferably by induction sealing. The closure can include an overcap.

Owner:SONOCO DEV INC

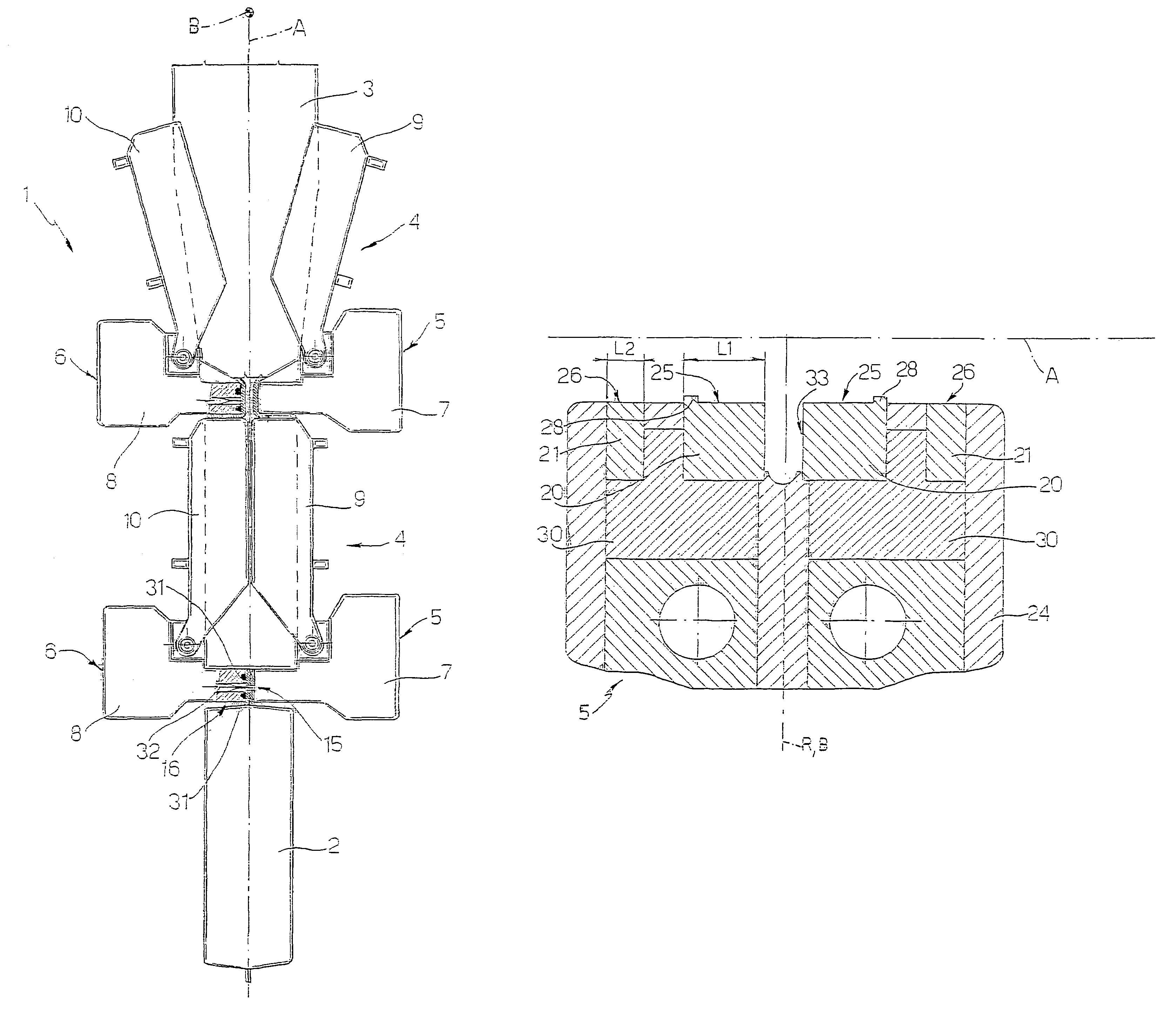

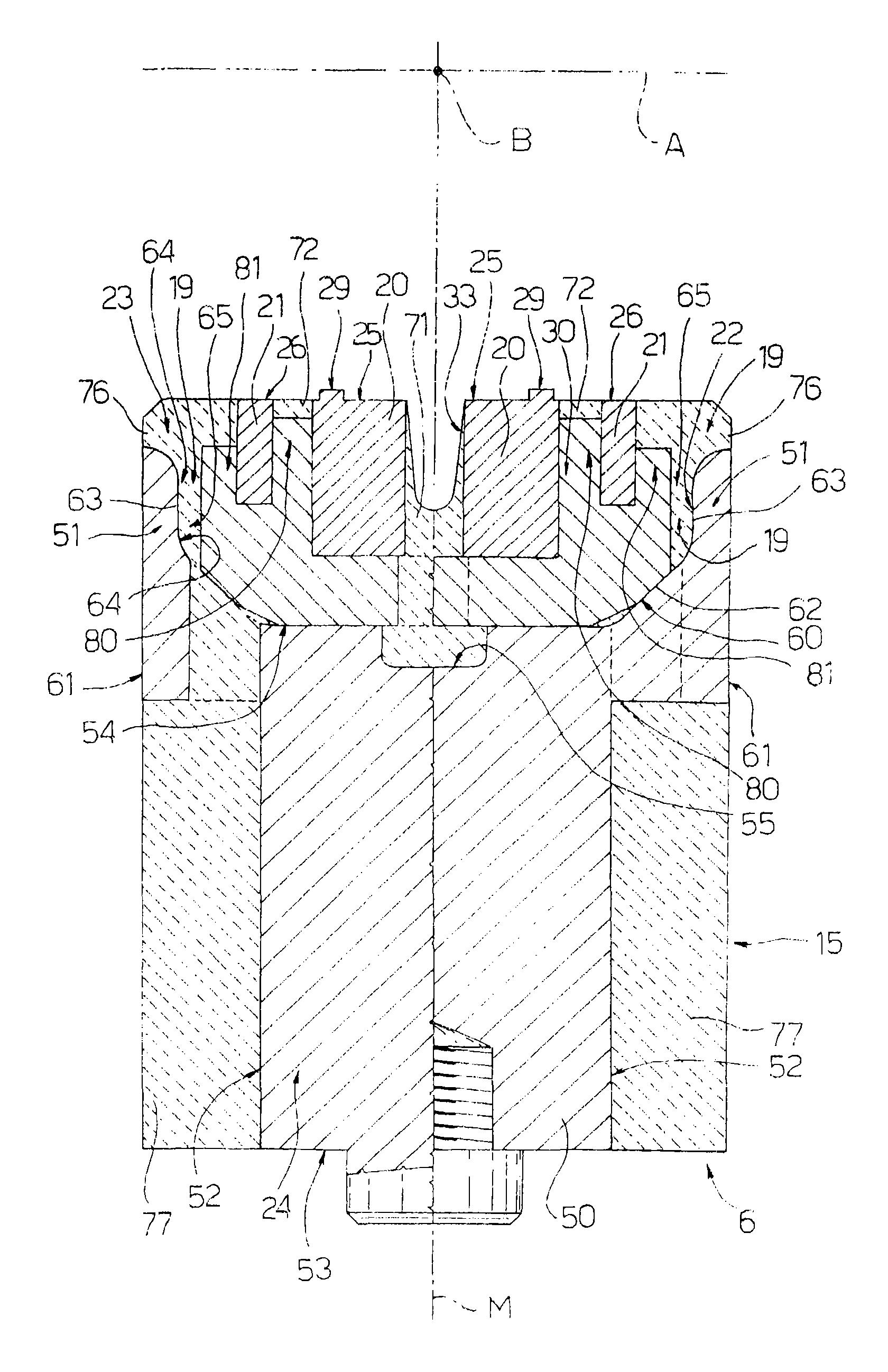

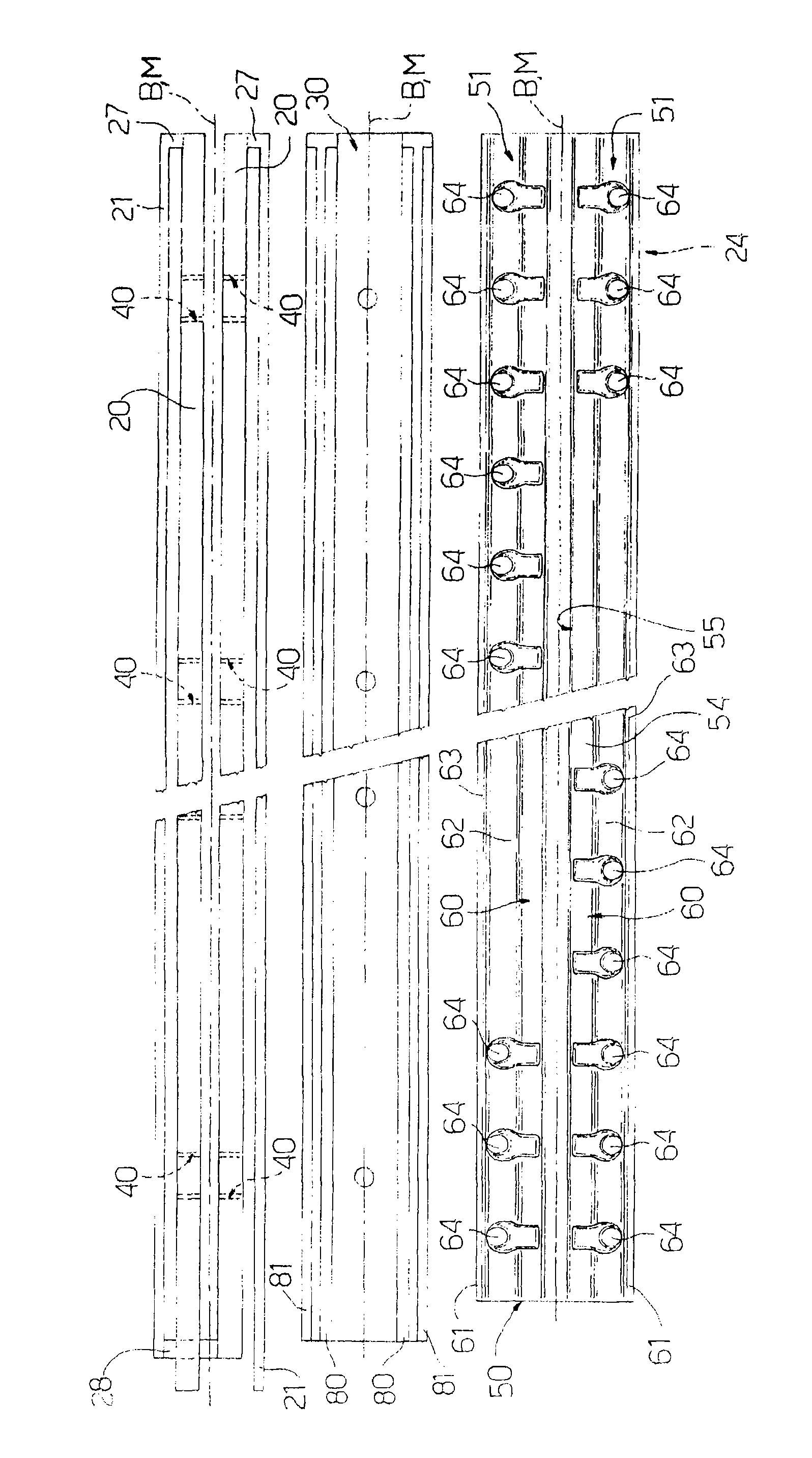

Induction sealing device for heat sealing packaging material

InactiveUS7059100B2Drawback can be obviatedImproved transverse sealingLamination ancillary operationsControlling laminationEngineeringActive surface

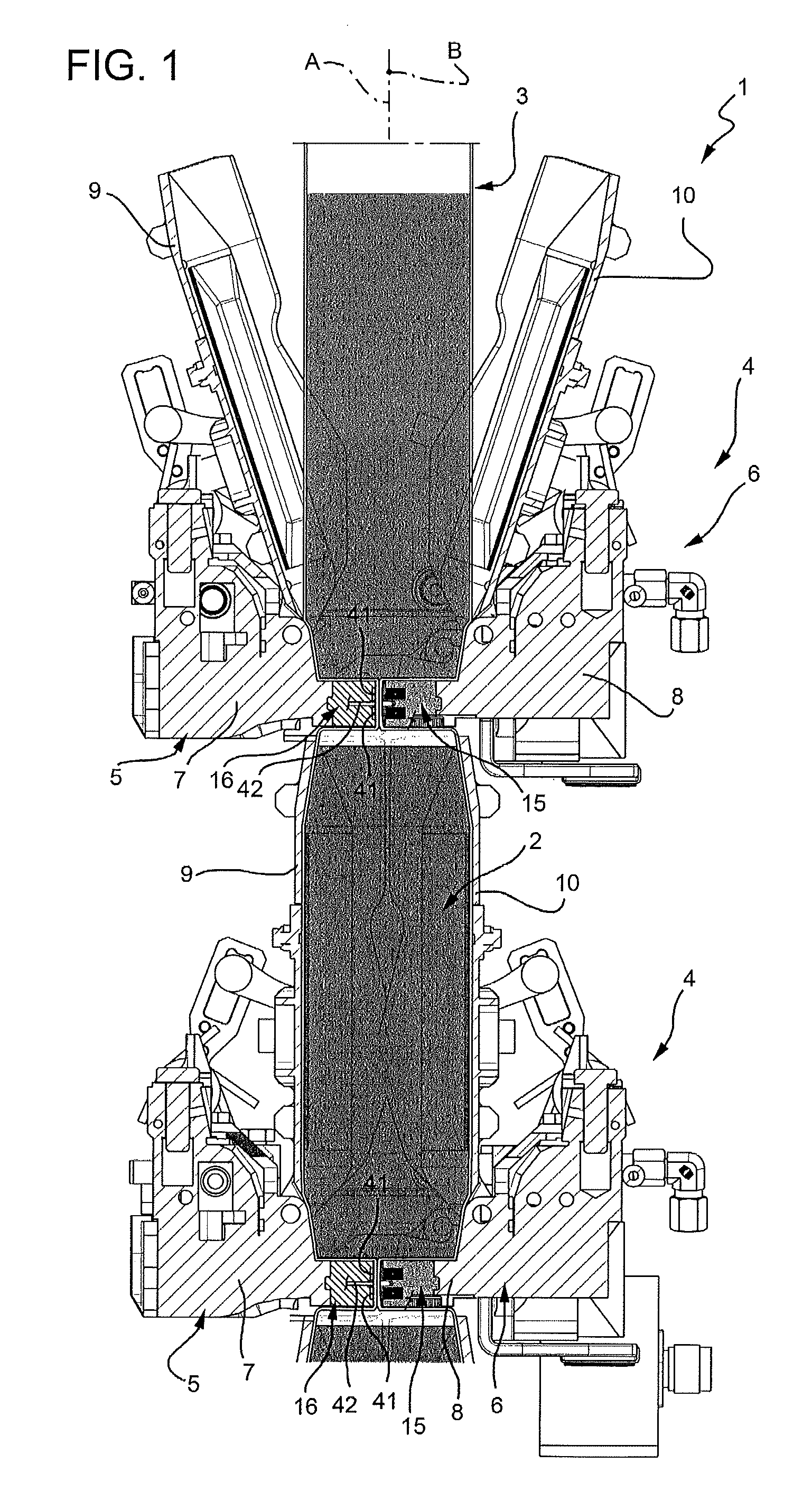

There is described an induction sealing device for heat sealing packaging material for producing sealed packages of pourable food product and fed in a first direction. The sealing device has induction means interacting with the packaging material by means of a pair of first active surfaces and a pair of second active surfaces interposed between the first active surfaces in the first direction; and the second active surfaces have, in the first direction, a width greater than the width of the first active surfaces at least along most of the length of the first and second active surfaces in a second direction perpendicular to the first direction.

Owner:TETRA LAVAL HLDG & FINANCE SA

Method for induction sealing a plastic part to a composite container

A method for induction sealing a plastic part to a composite container using a pair of linear coils electrically connected to low frequency generators. The linear coils produce overlapping electromagnetic fields on either side of the container. Rotating the container assures even heating of the polyethylene liner and plastic part. The method produces a reliable seal between the liner and plastic part and can be used at high production speeds.

Owner:SONOCO DEV INC

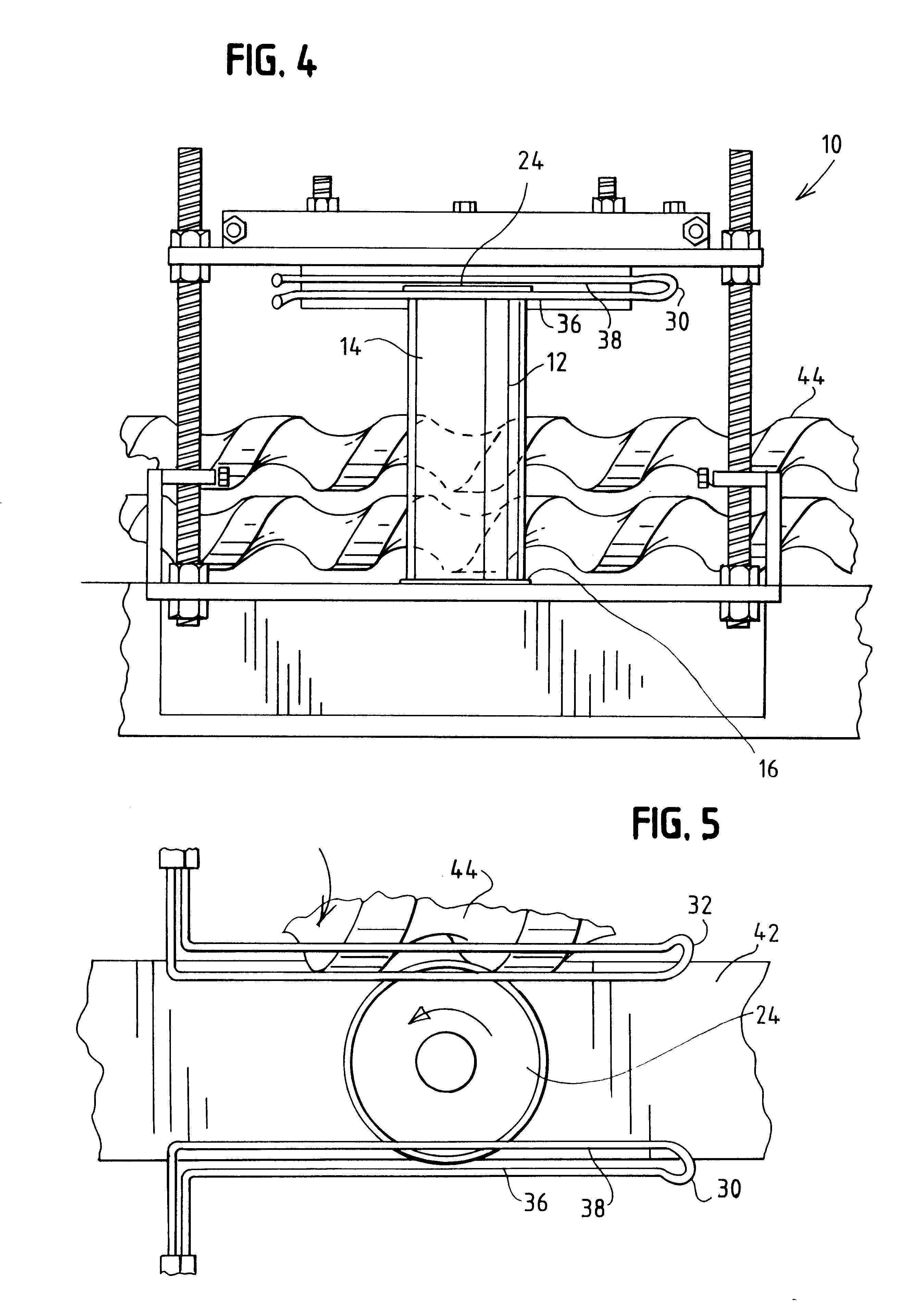

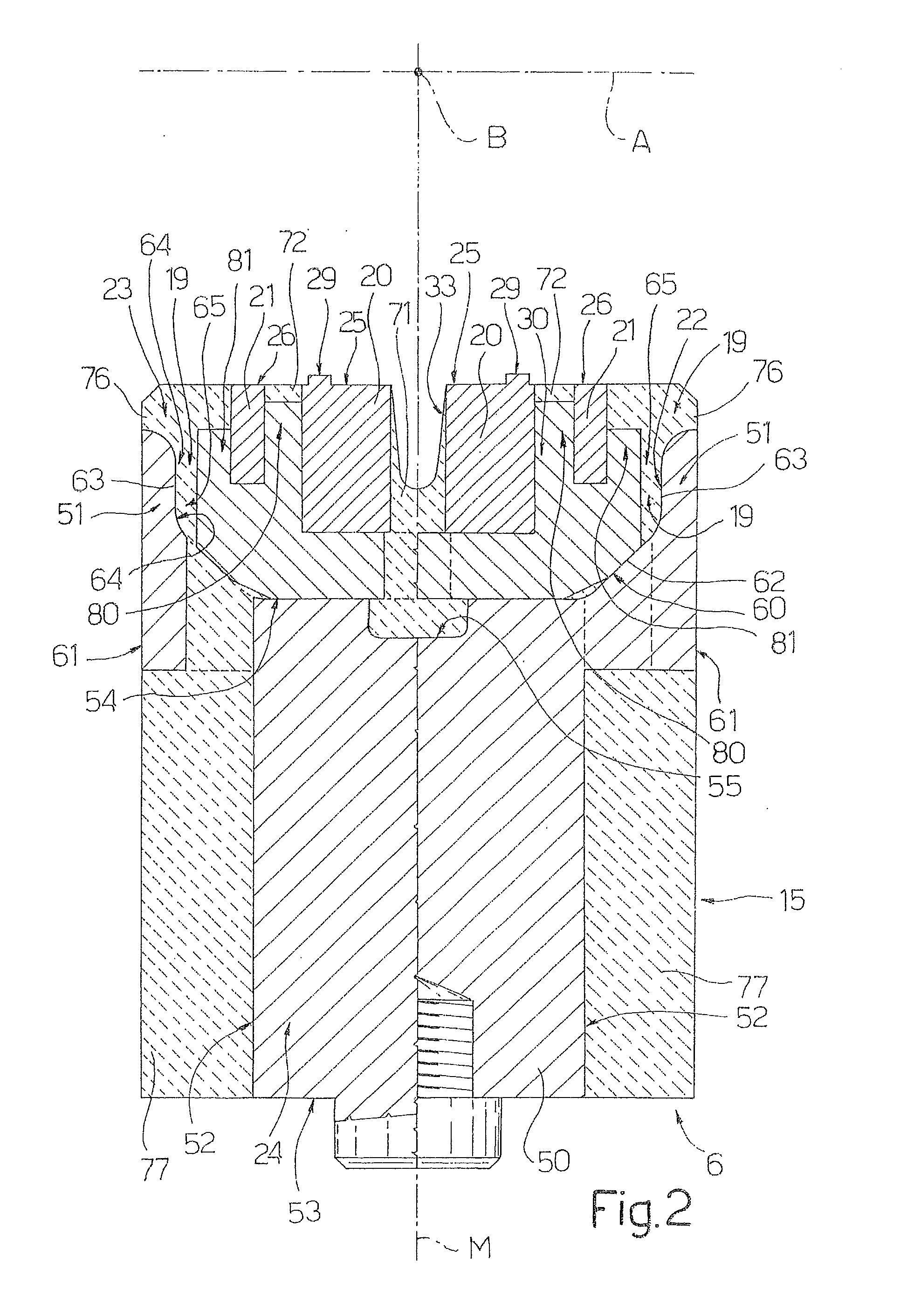

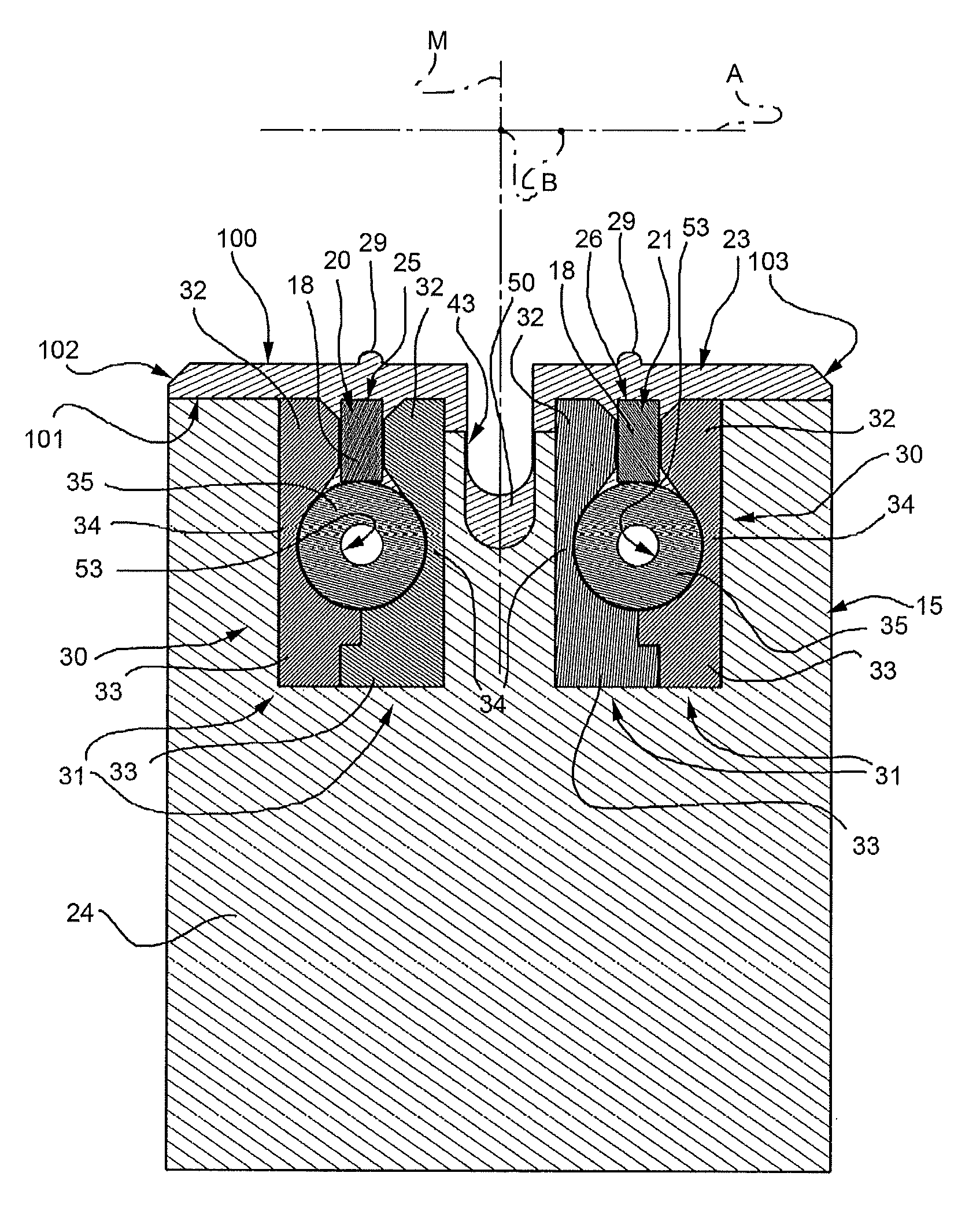

Induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products

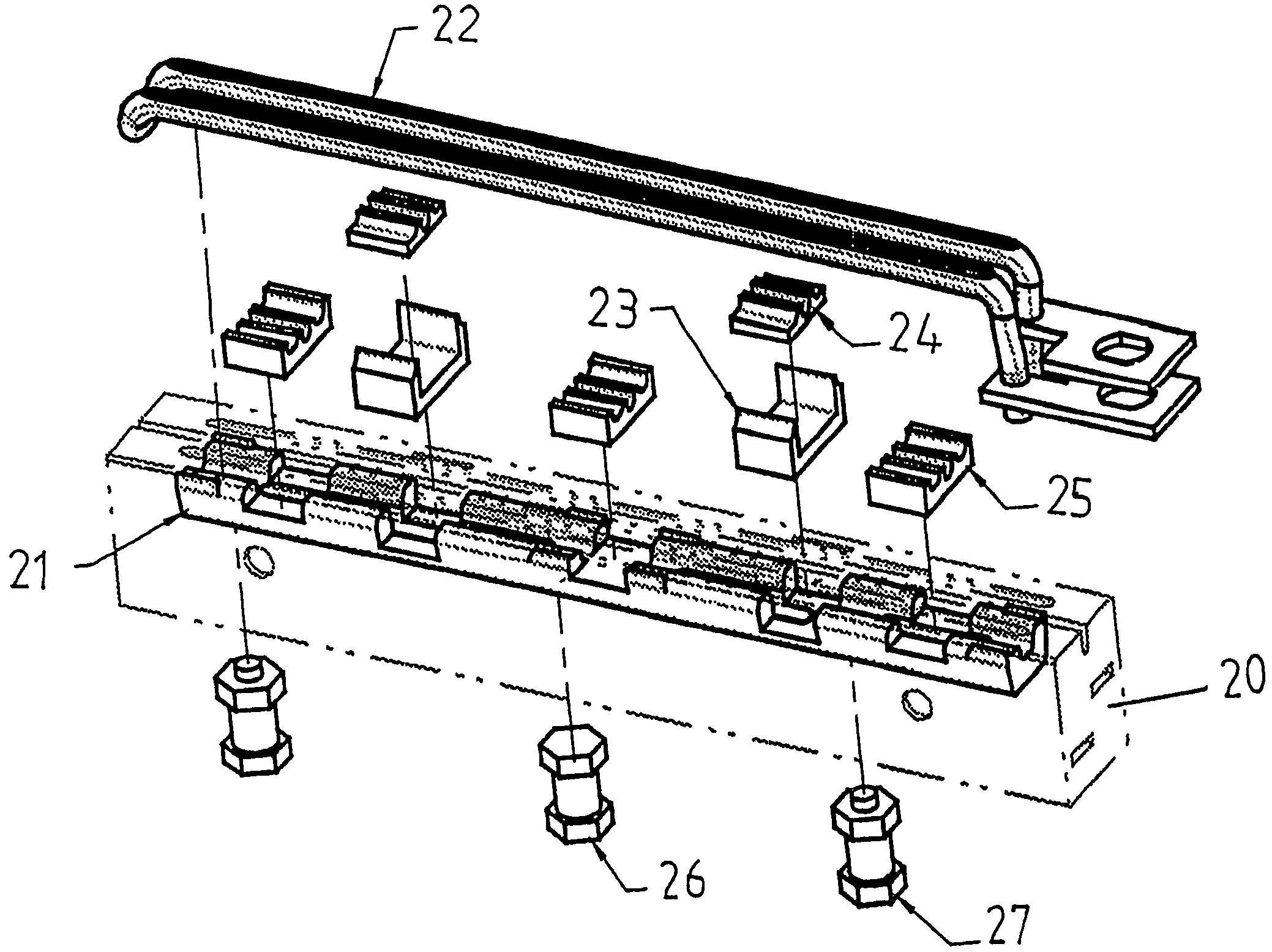

ActiveUS20100180545A1Straightforward and low-costWrapper twisting/gatheringDomestic articlesPlastic materialsHeat conducting

An induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products and fed in a first direction, the sealing device having an inductor device which interacts with the packaging material by at least one active surface; a supporting body made of heat-conducting material and housing the inductor device; an insert made of magnetic flux-concentrating material and housed in the supporting body; and a member made of plastic material, and having at least a first portion interposed, in the first direction, between the supporting body and the insert so as to be at least partly surrounded by the supporting body.

Owner:TETRA LAVAL HLDG & FINANCE SA

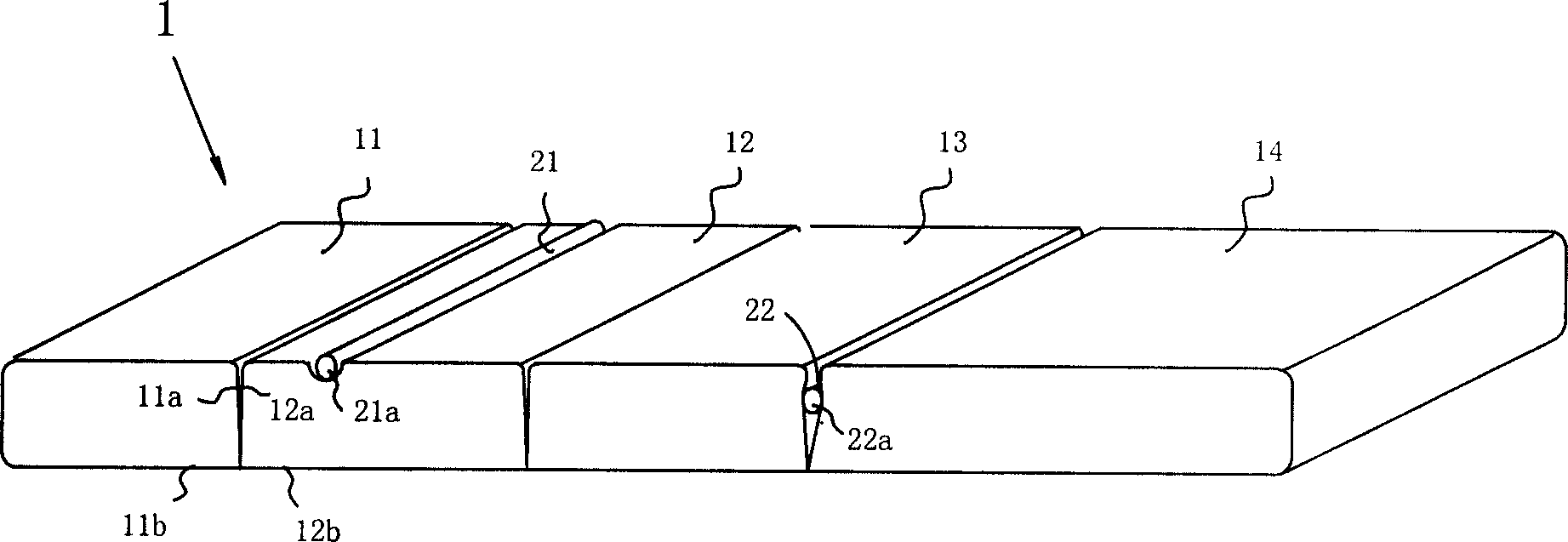

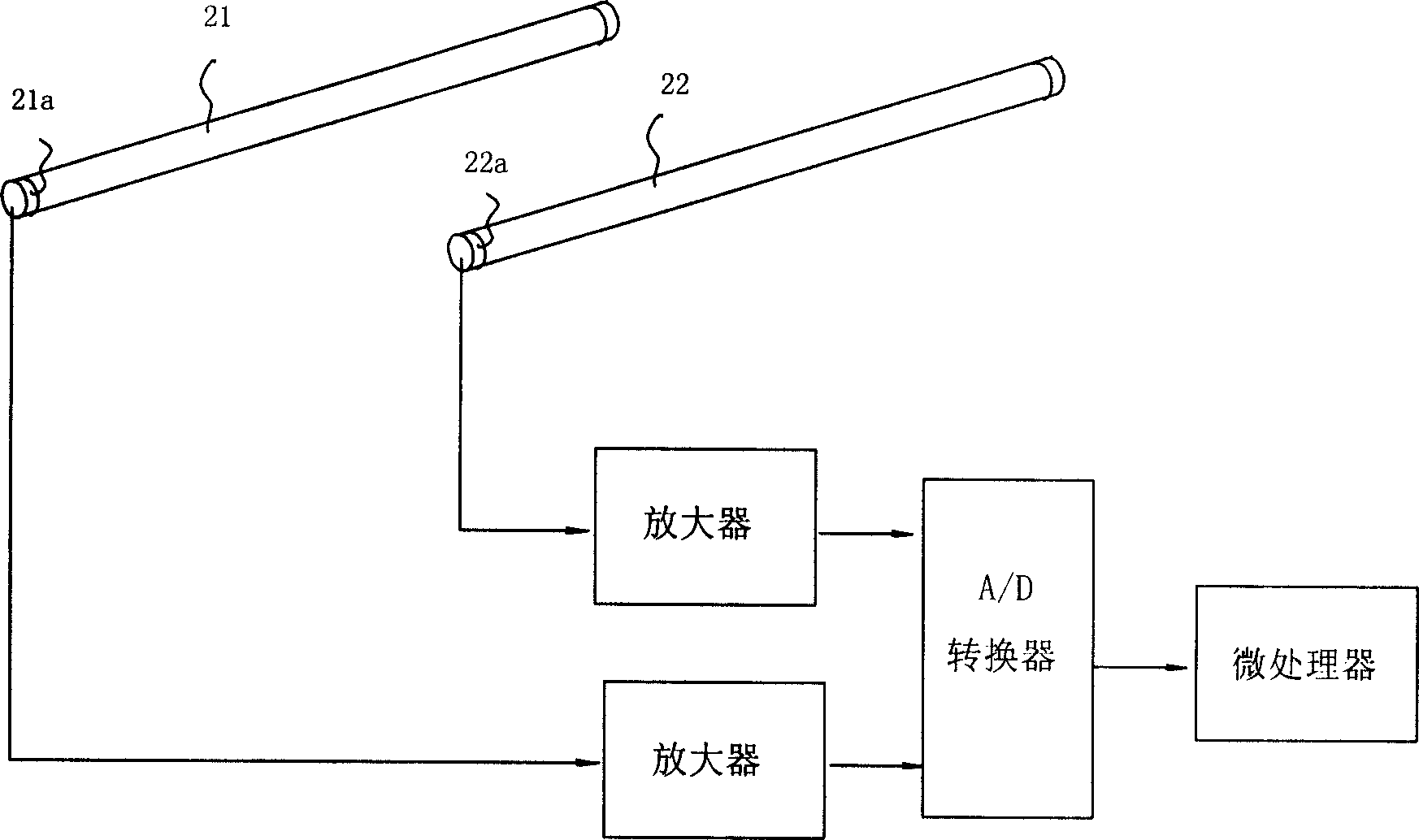

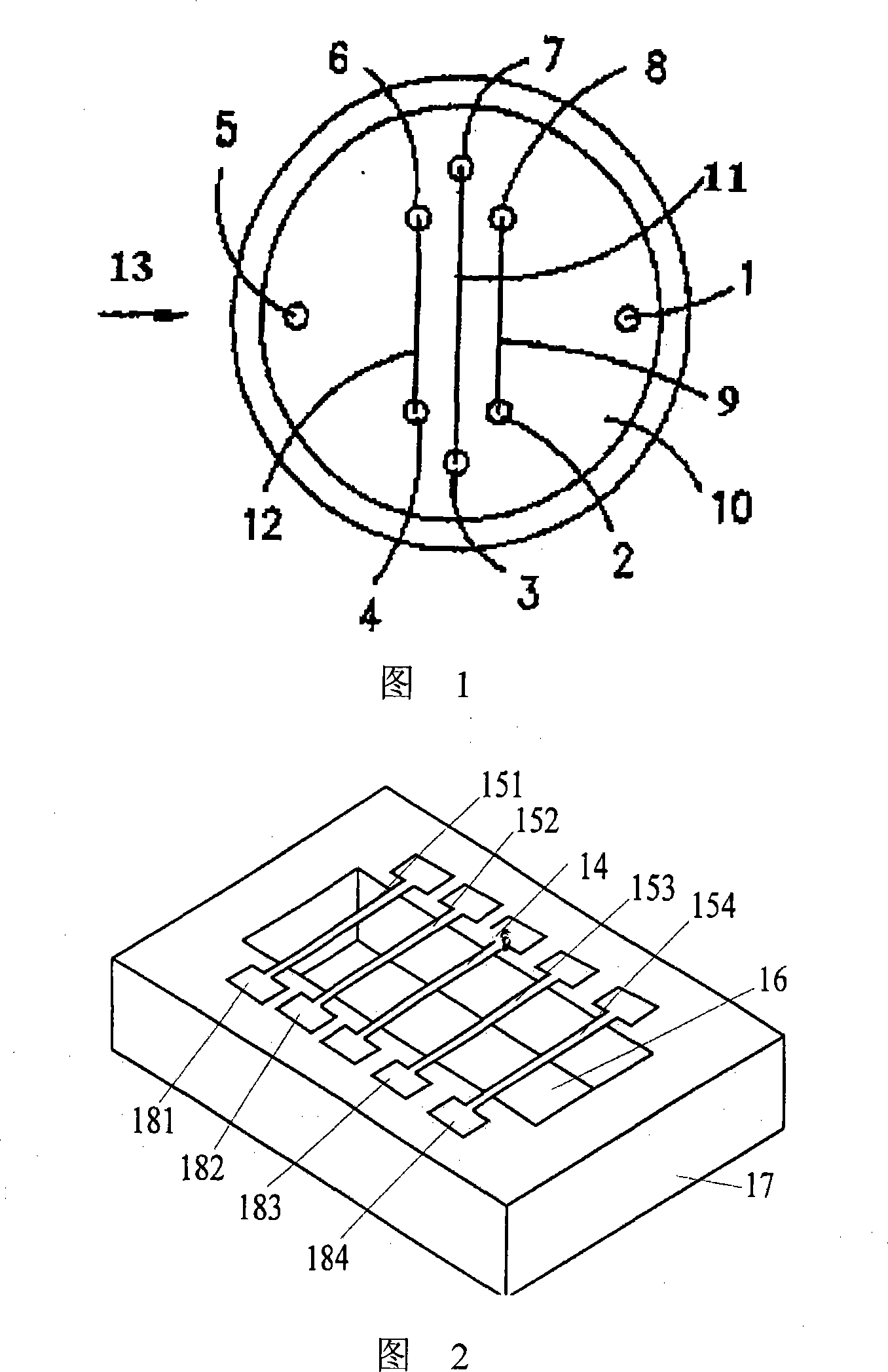

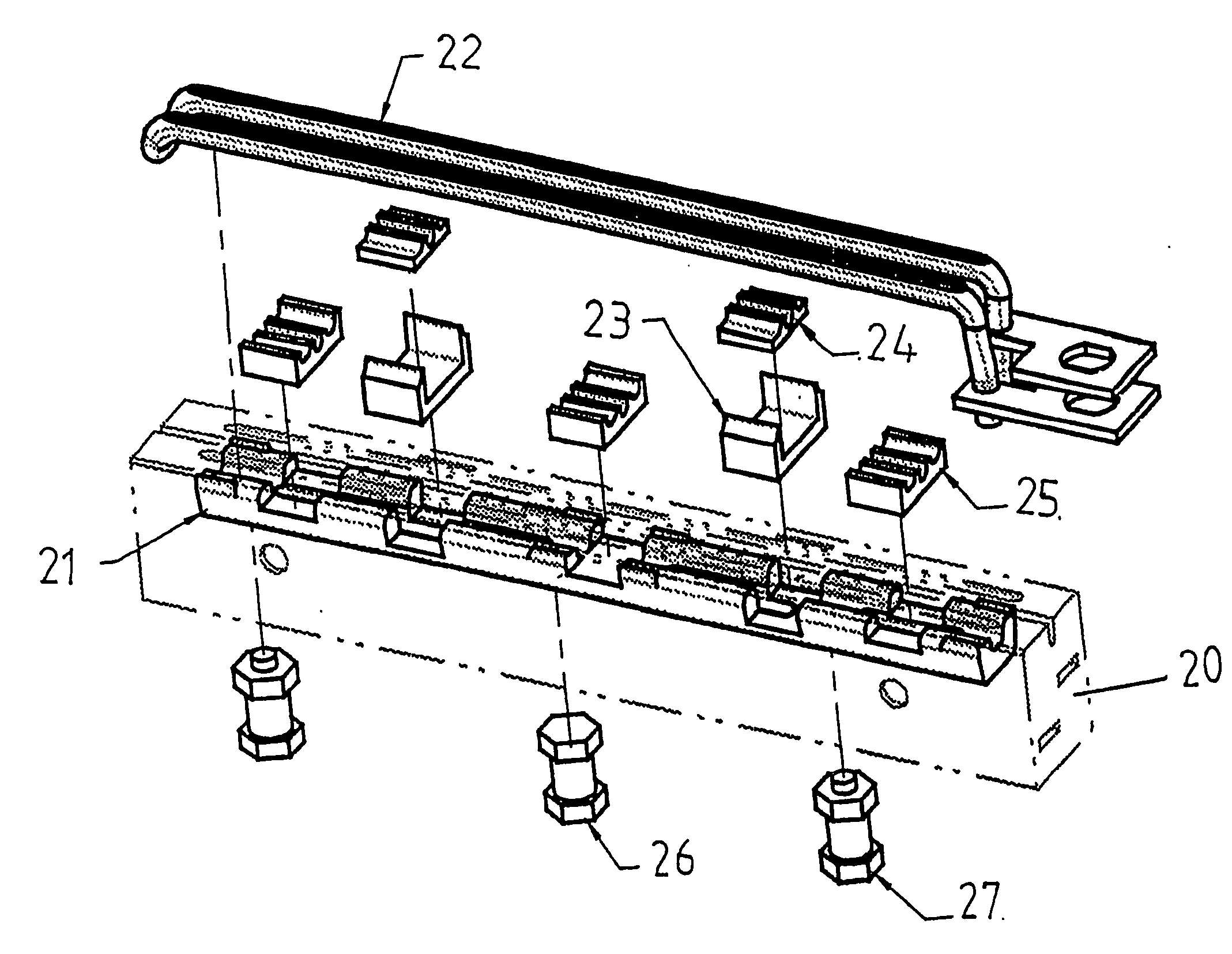

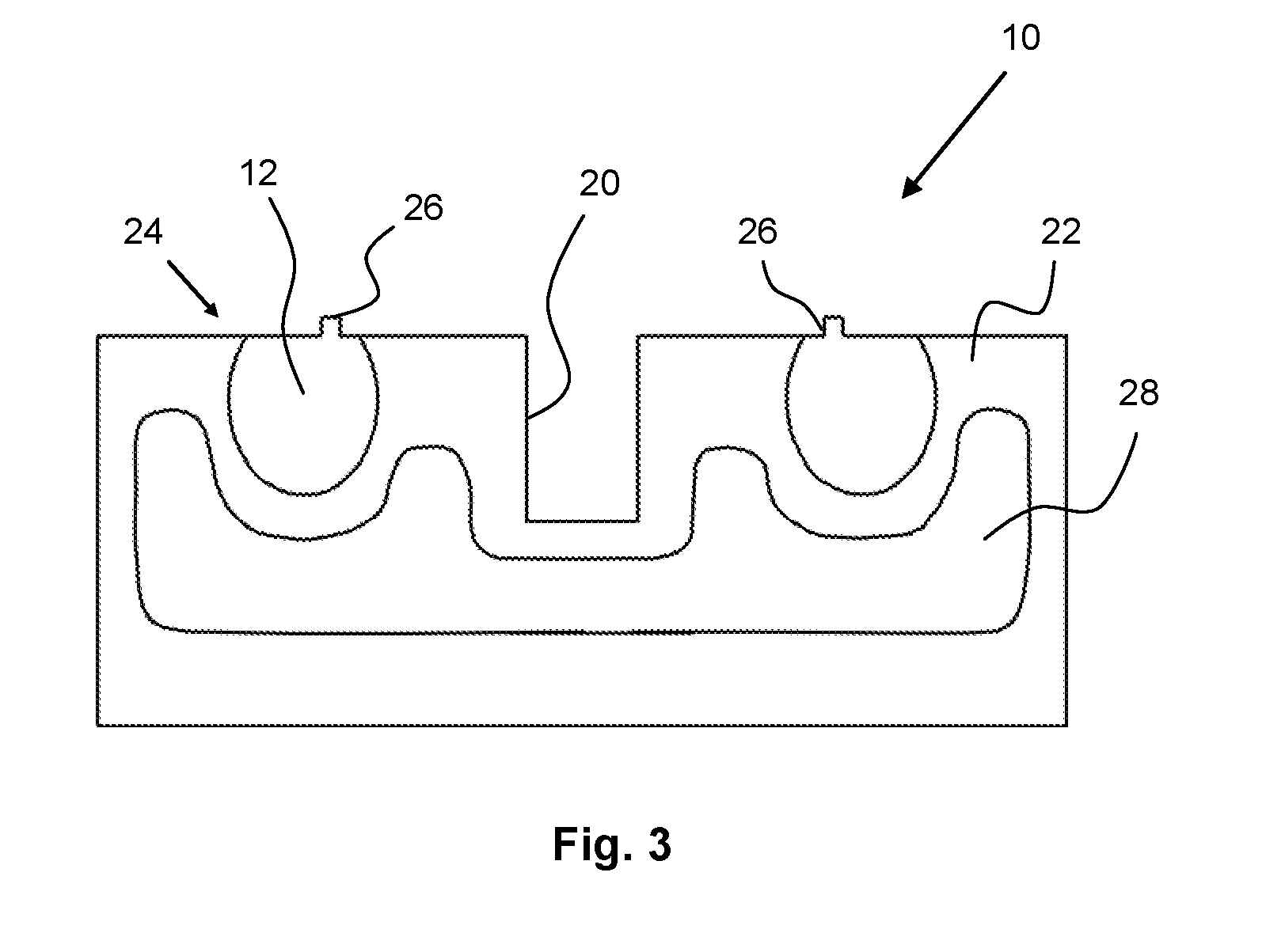

Sensing device for monitoring sleep status and respiration disorder event

ActiveCN1875880AAvoid discomfortIncreased sensitivityDiagnostic recording/measuringSensorsSleep statePressure sense

The invention relates the sensing device used to check sleeping state and interference with respiration. The device comprises spring mattress 1, and pressure sensing device. The spring mattress 1 comprises at least two vent longitudinal partition cushion (11, 12, 13, 14), the adjacent side walls (11a, 12a) are near, the bottoms of cushions(11b, 12b) are connected with each other, the sensing device is sealed elastic body(21, 22) with fluid, in the elastic body there is sensing elements(21a, 22a), the output end of sensing elements are connected with data processing device by wires, and the sealed elastic body(21, 22) is installed on the mattress. The invention improves the comfort degree and sensibility.

Owner:BEIJING XINXING YANGSHENG TECHN CORP

Induction sealing of inorganic substrates

A method of sealing at least two inorganic substrates together using an induction energy source comprising applying to at least one of the substrates a paste composition including a glass frit, and an induction coupling additive, bringing at least a second substrate into contact with the paste composition, and subjecting the substrates and paste to induction heating, thereby forming a hermetic seal between the two inorganic substrates.

Owner:FELLOWES INC

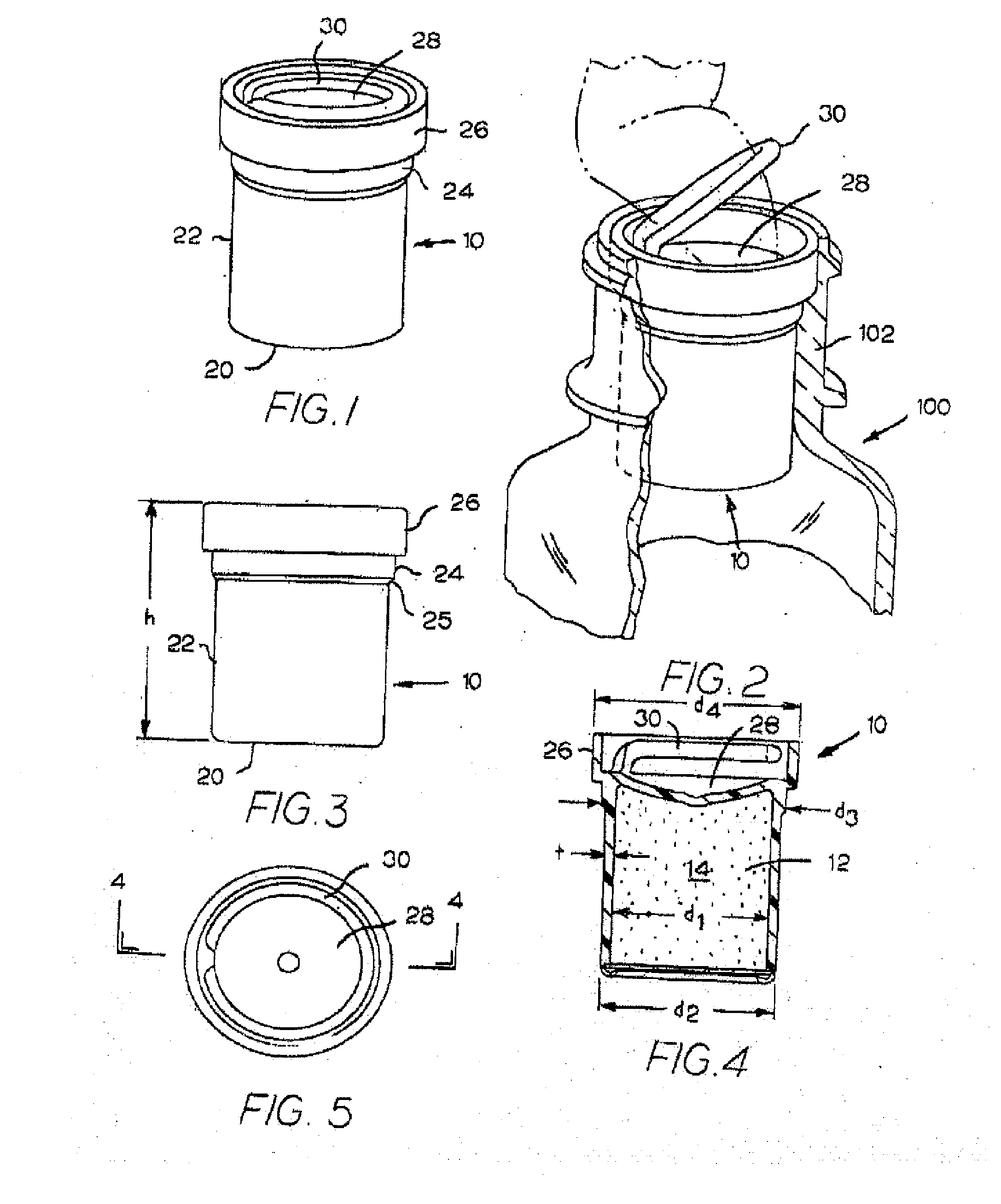

Packaging Insert

InactiveUS20070257046A1Easy to openEasy to removeClosures with oxygen absorbersClosure with auxillary devicesEngineeringBottle

The present invention relates to a packaging insert that comprises a chamber that can be filled with an adsorbent. When the insert is positioned within a closed bottle, the adsorbent can entrap any moisture or gases generally targeted by the adsorbent selected. The insert is designed such that the container can be induction sealed with the insert positioned within the neck of the container.

Owner:SUD CHEM INC

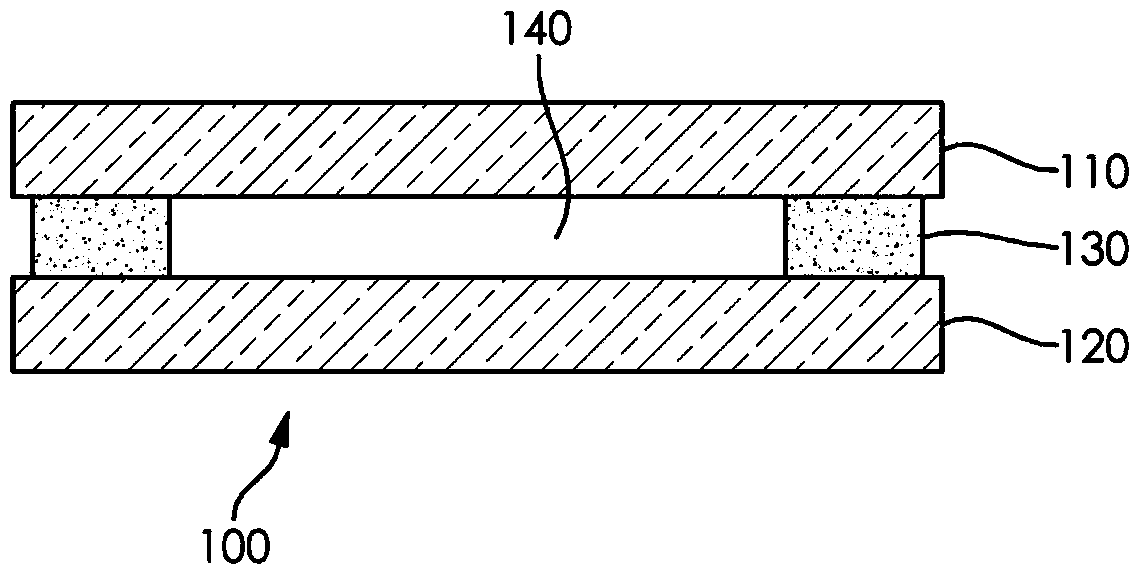

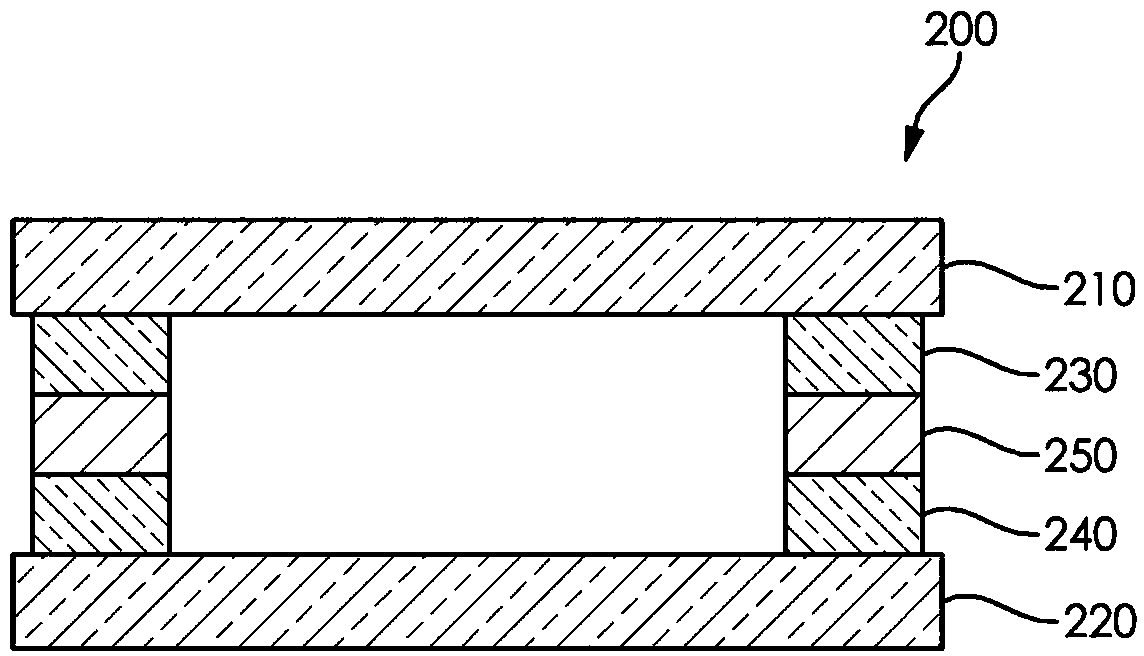

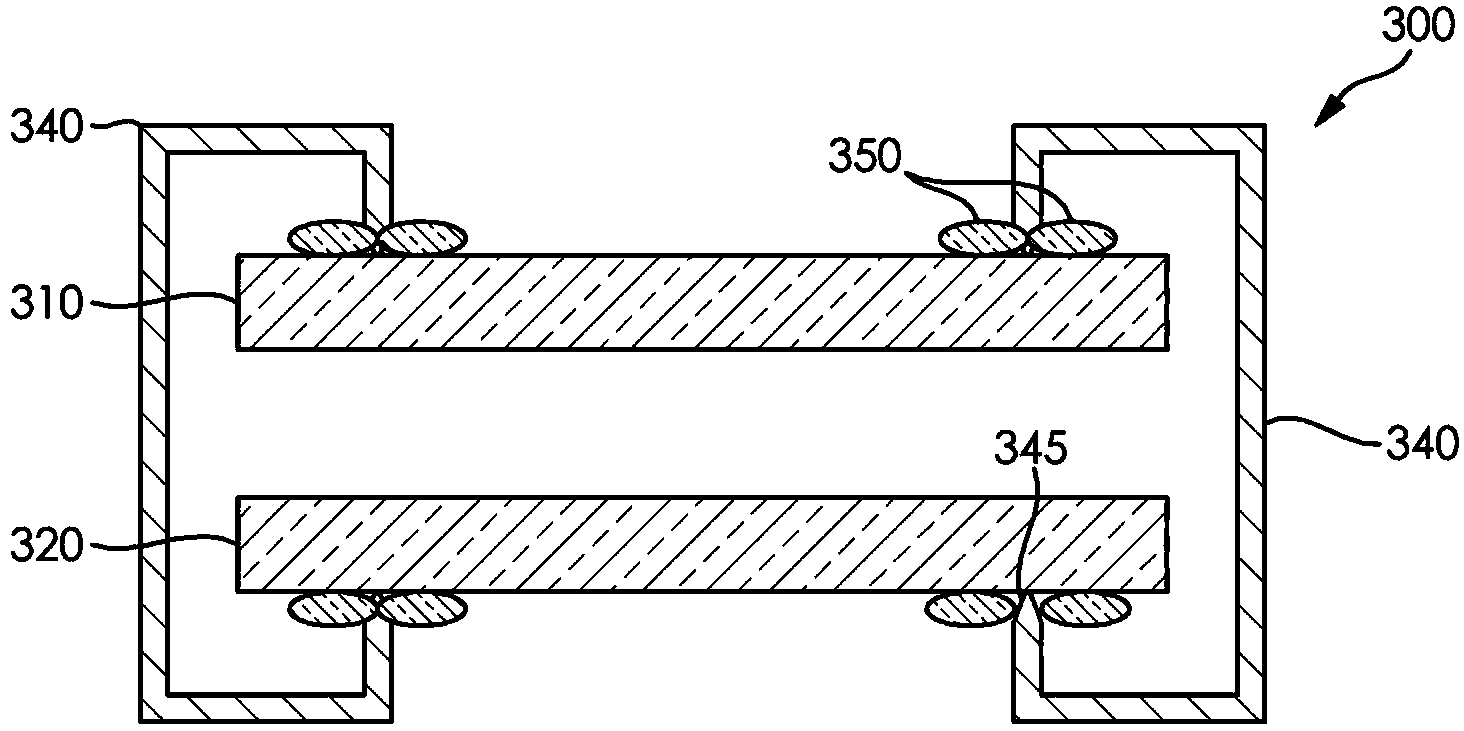

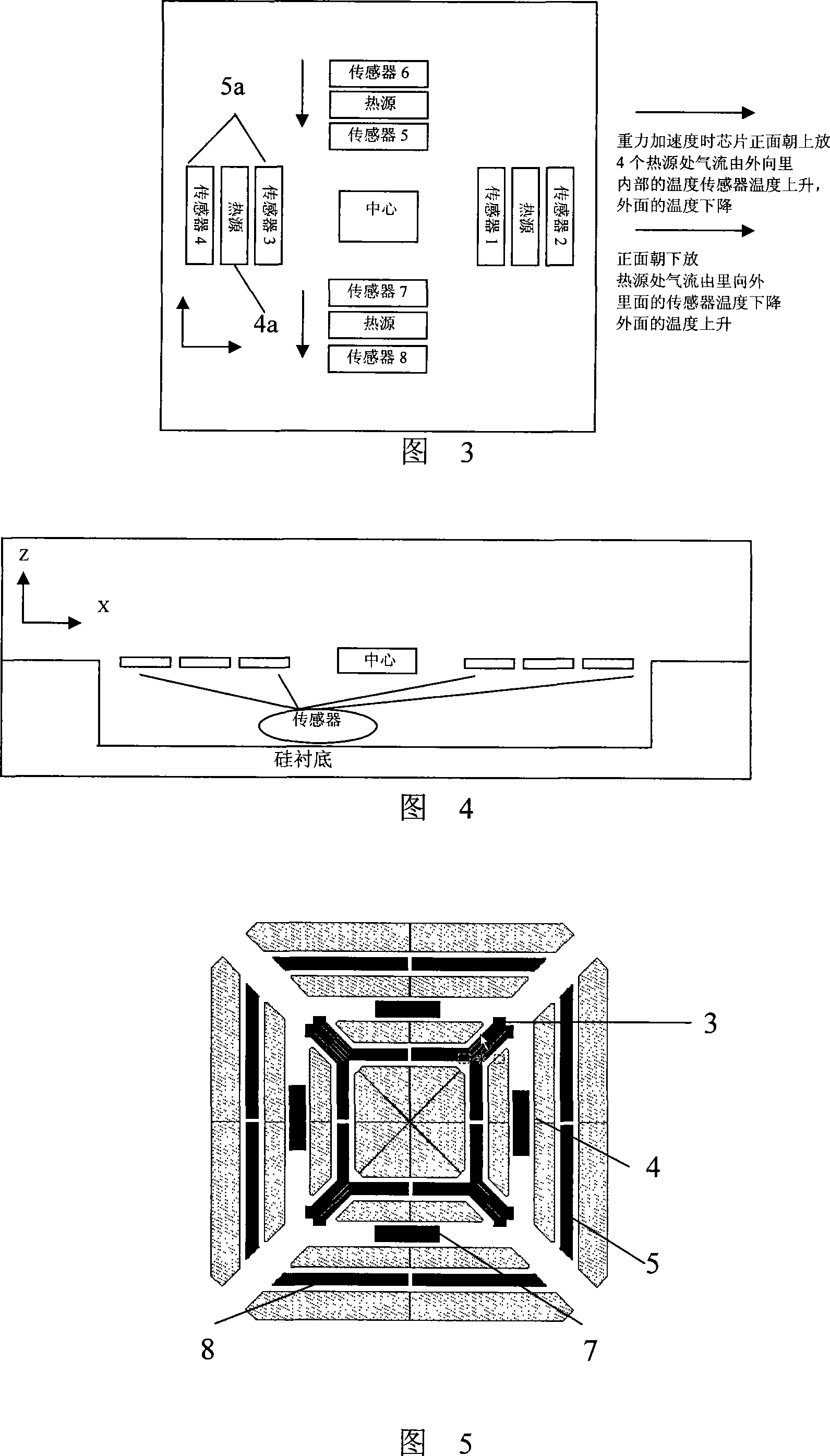

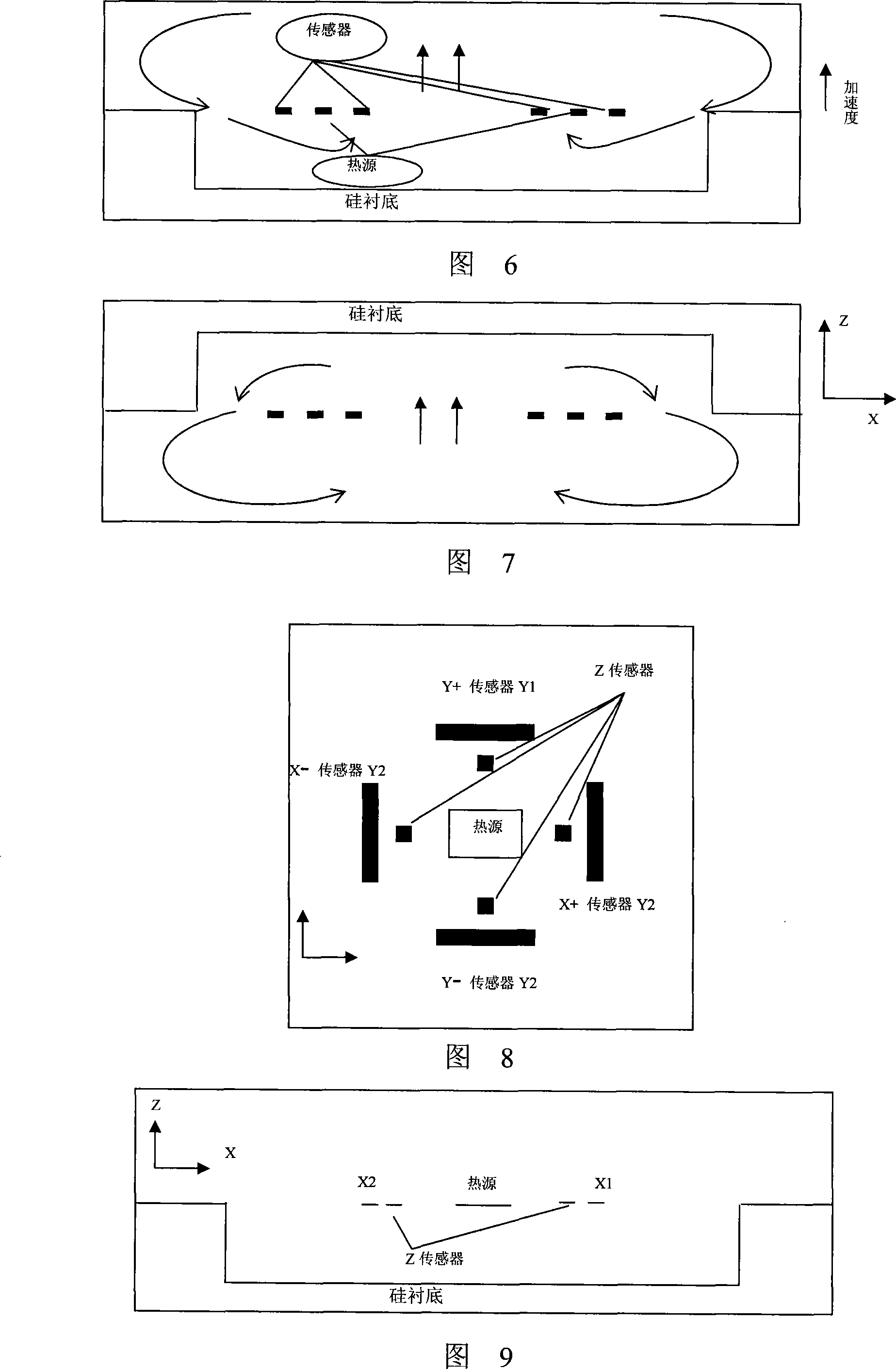

Single-chip tri-axis acceleration sensor

ActiveCN101187673ASmall sizeLow costAcceleration measurement using interia forcesVolume/mass flow measurementAviationFailure rate

The invention belongs to the technical field of the sensors and relates to a thermal convecting one-chip three-axial accelerating sensor. Basic principles of the invention are that air inside a sealed cavity body is inducted to do thermal convection through a heat-sensitive component, and an accelerating signal is transmitted through calculations. The invention comprises a packing cavity which is located on the surface of a heating wire temperature sensor and an etching cavity which is located under the surface of the heating wire temperature sensor. The packing cavity and the etching cavity are arranged in symmetry in four groups of sensors around center. The invention applies for a plurality of fields as automobile, game industry, aviation, ship navigation system, product for civilian use, military, and the like. The invention adopts thermal convection principles to test accelerating information, and has no mass block, and can work under high-g. The invention has impact resistance without adhesions or granules, low cost, low failure rate, high rate of good product, high sensibility, and strong anti-interference. Compared with original one-chip three-axial accelerating sensors of MEMSIC Company, a test for accelerating inside a three-dimensional space is available.

Owner:MEMSIC SEMICON WUXI

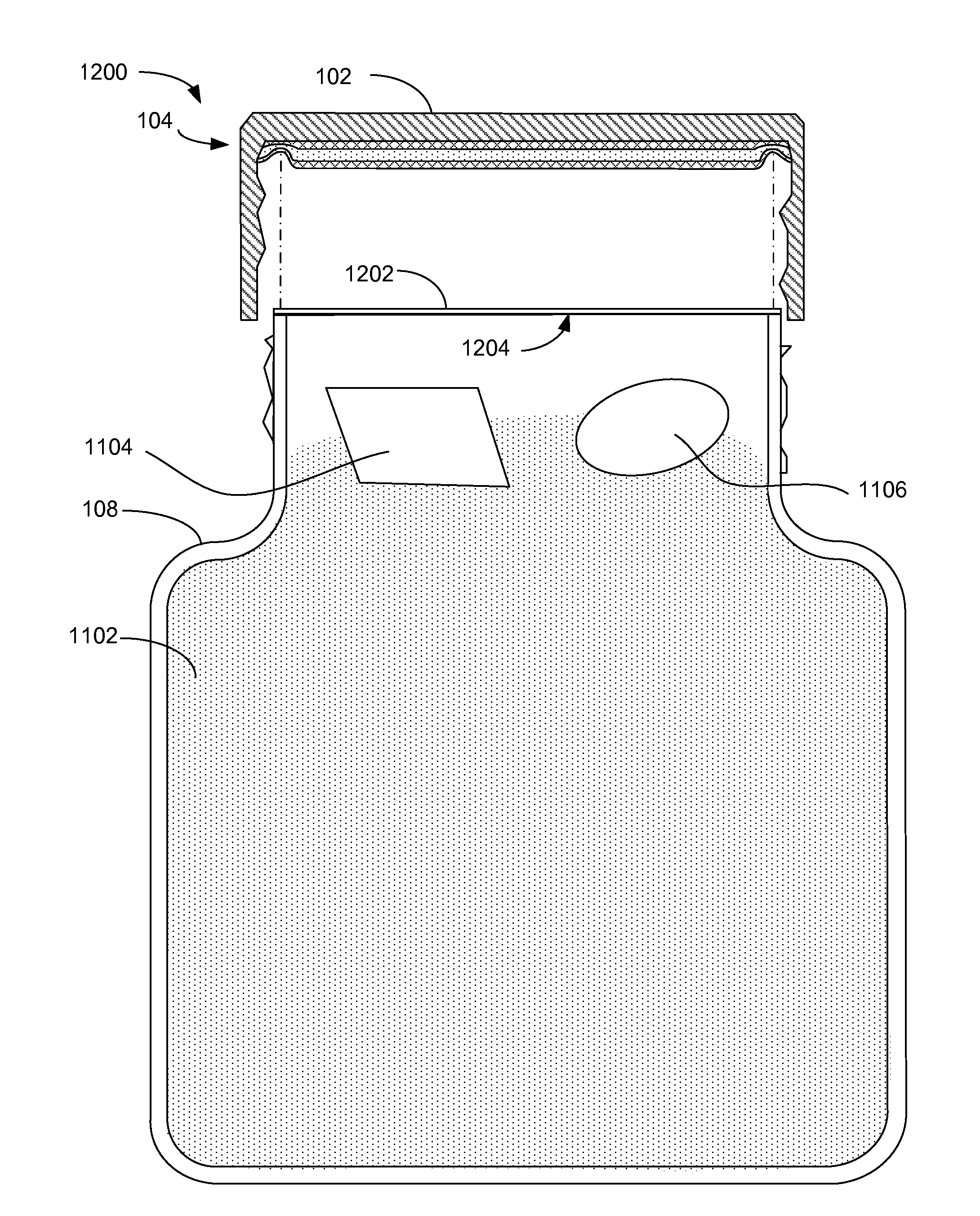

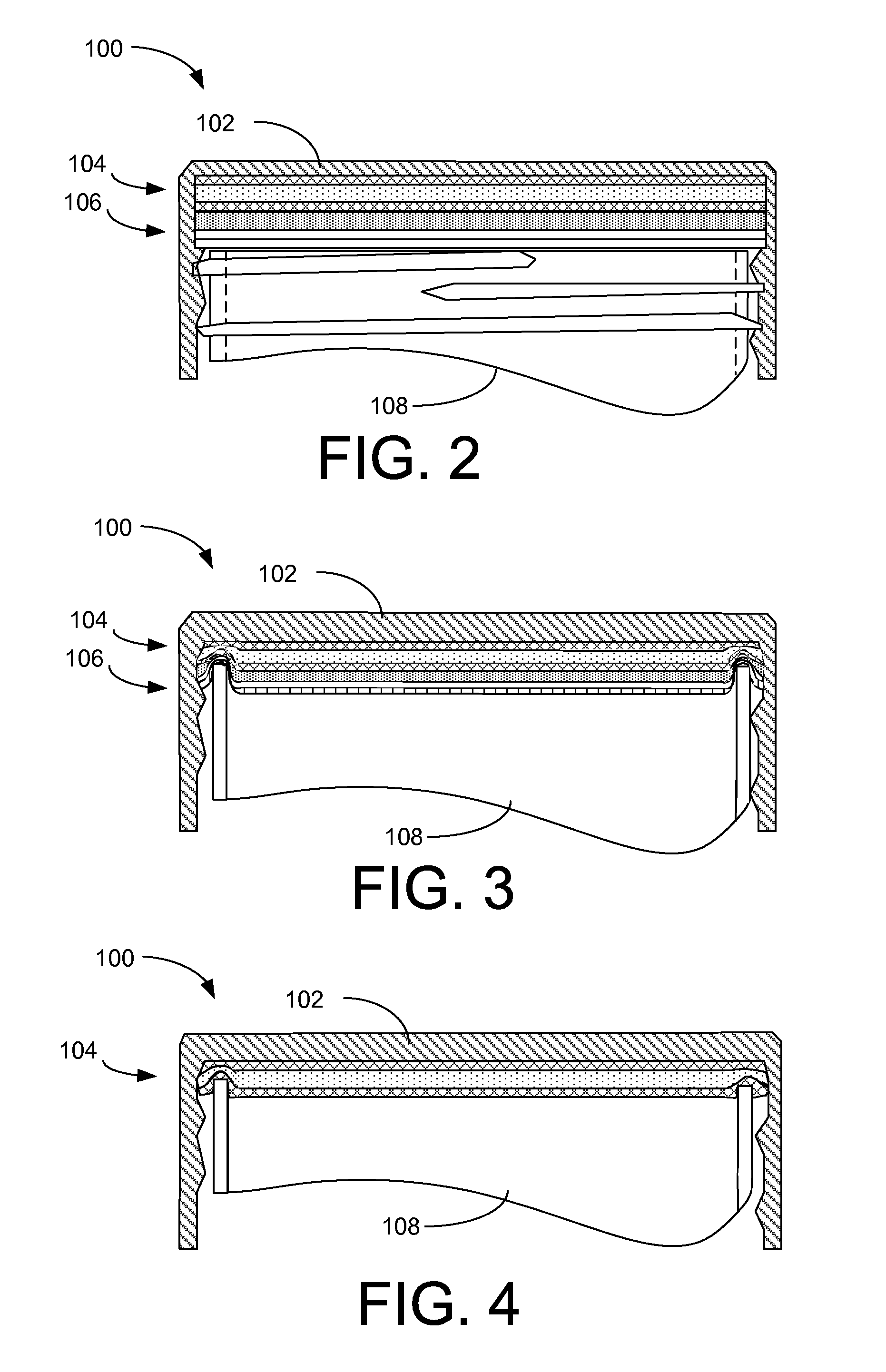

Long-term packaging of food for consumer use

InactiveUS20120048825A1Low oxygen permeabilityLong-term resilienceCapsDecorative coversLow-density polyethyleneDesiccant

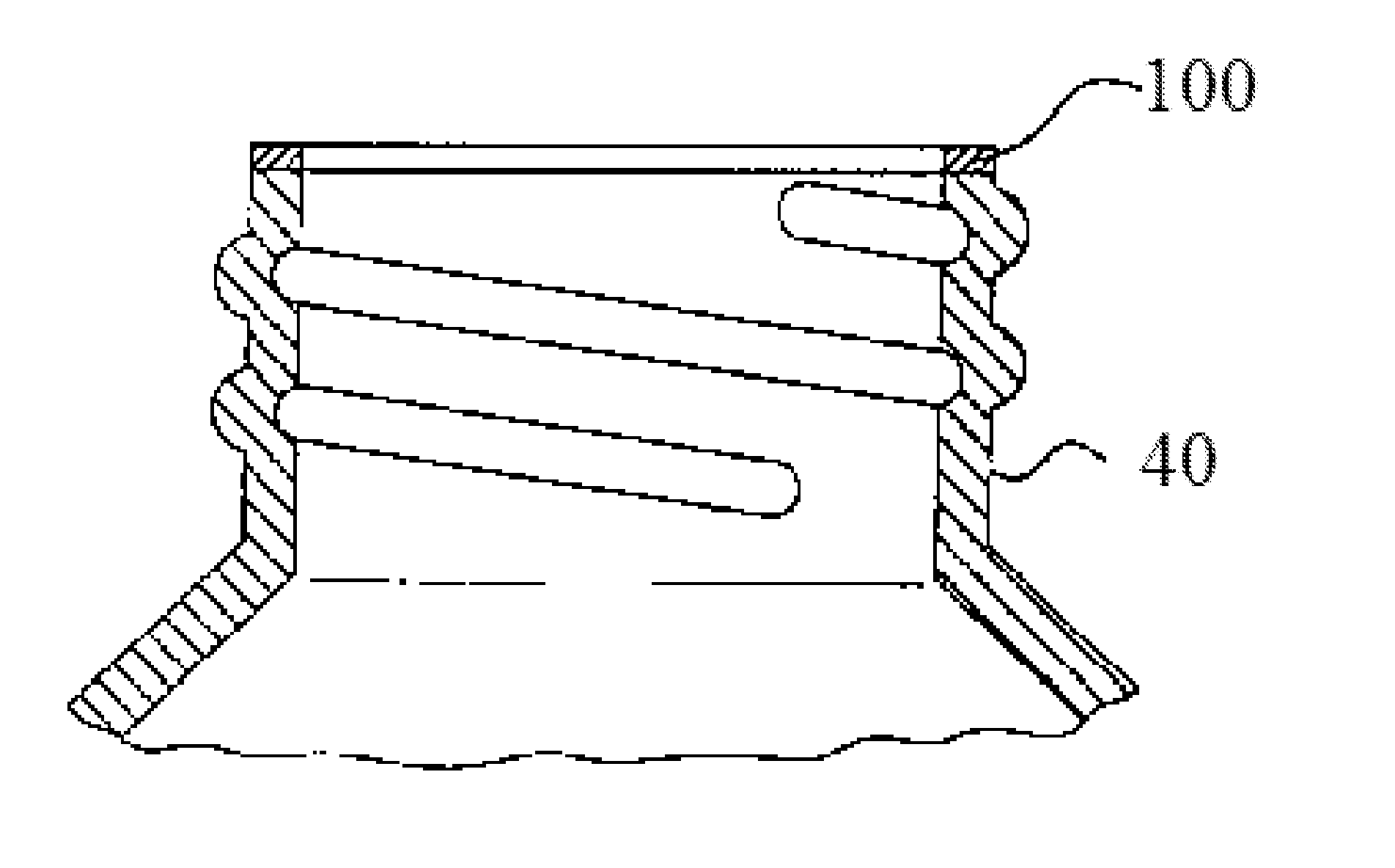

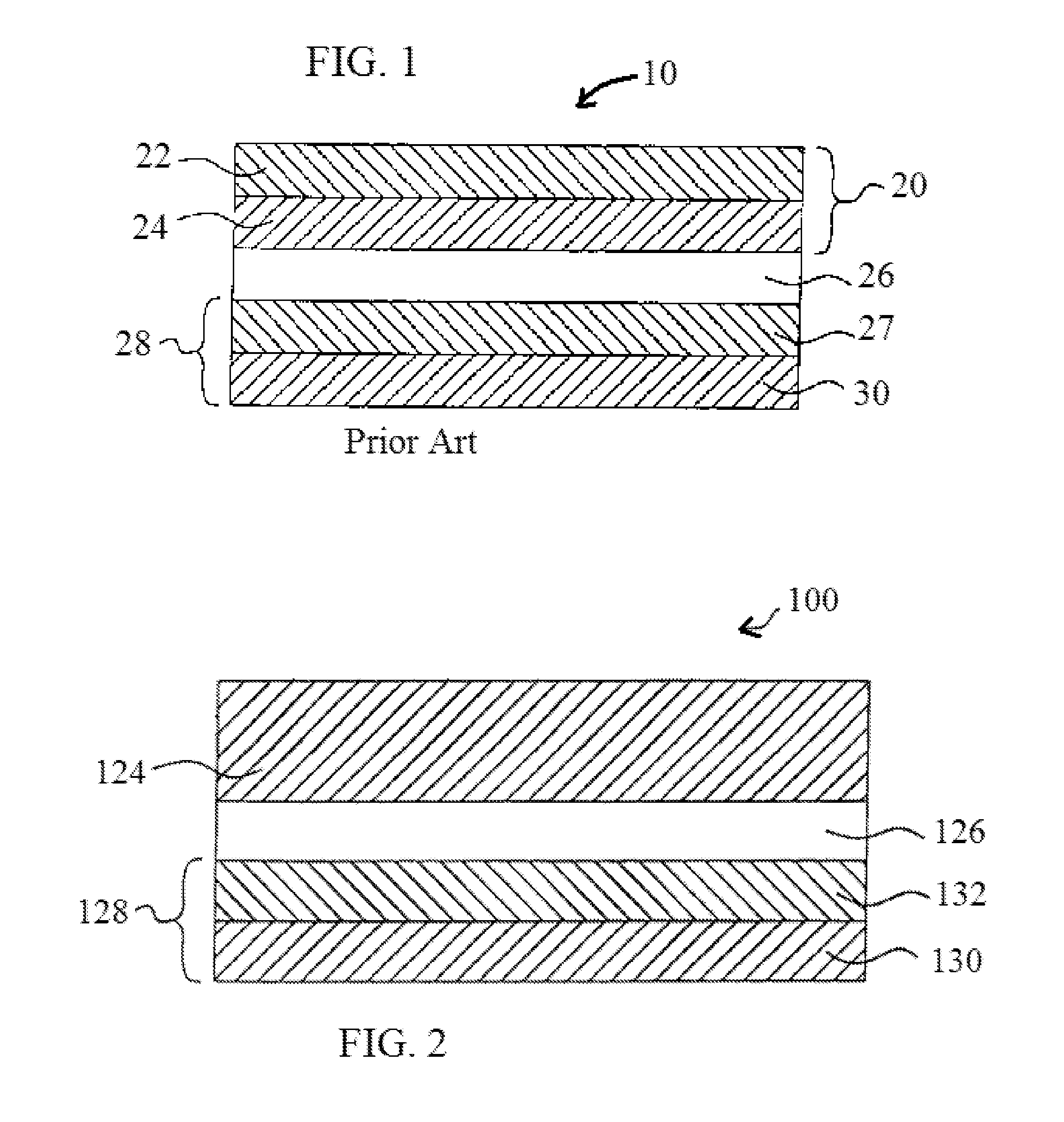

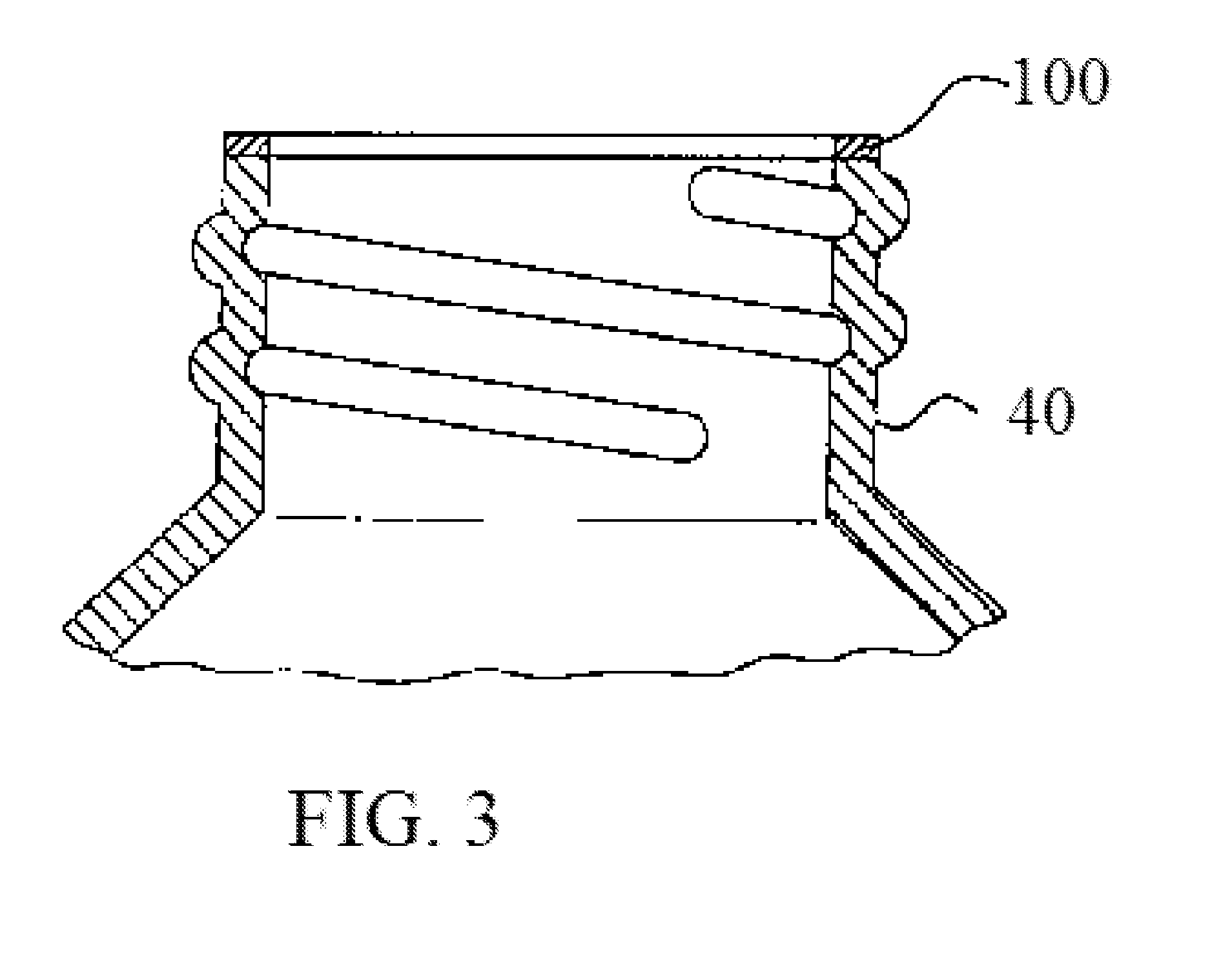

Long-term packaging using a combination of an induction seal and a reseal without release layers, both of which are activated by the induction heating process. The exemplary induction seal comprises a laminate of a heat-sealing layer, an aluminum foil layer, and a foam backing The exemplary reseal comprises a low-density polyethylene foam core sandwiched between first and second layers of solid low-density polyethylene film. The reseal deforms during the induction heating process to be shaped to engage the outer and inner peripheral surfaces of the finish, so that the reseal is hermetic even after the induction seat is removed. Preferred containers are PETE with PP compression closures. Replaceable desiccant and oxygen scavengers may used with food or other contained material. Precise timing of induction heating is required to achieve the desired result. Kits for making such packaging are disclosed.

Owner:FOODWISE TRN

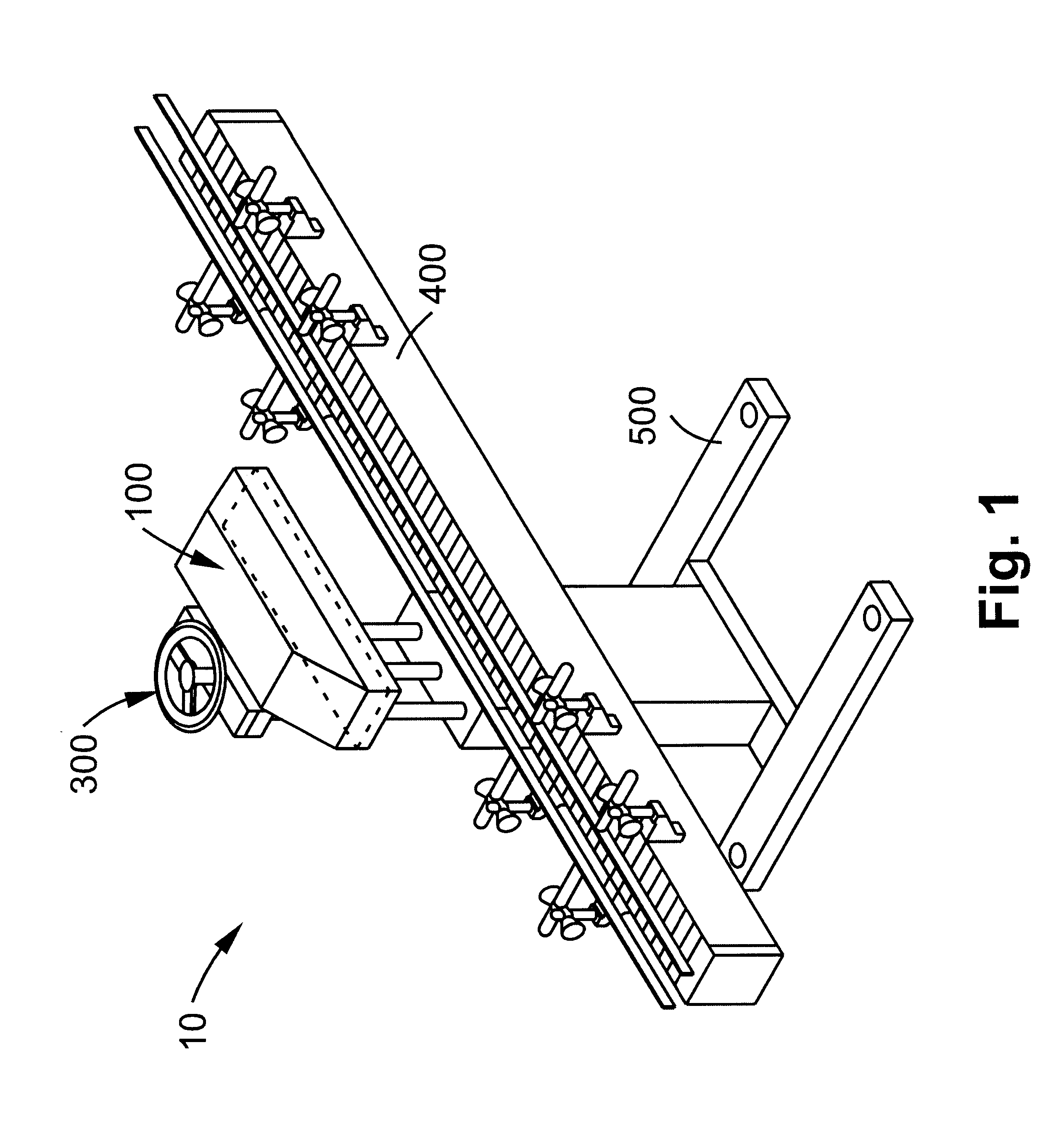

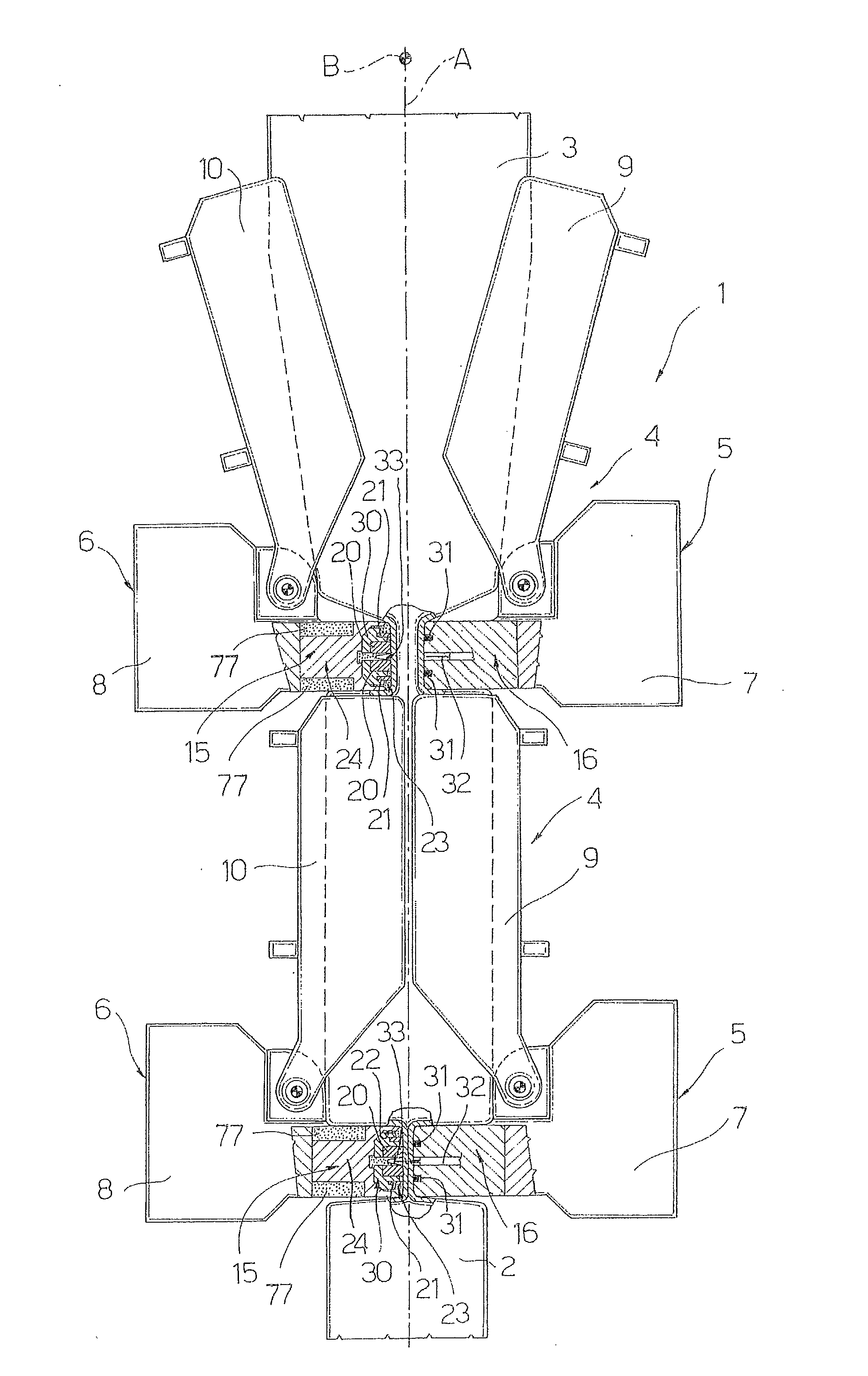

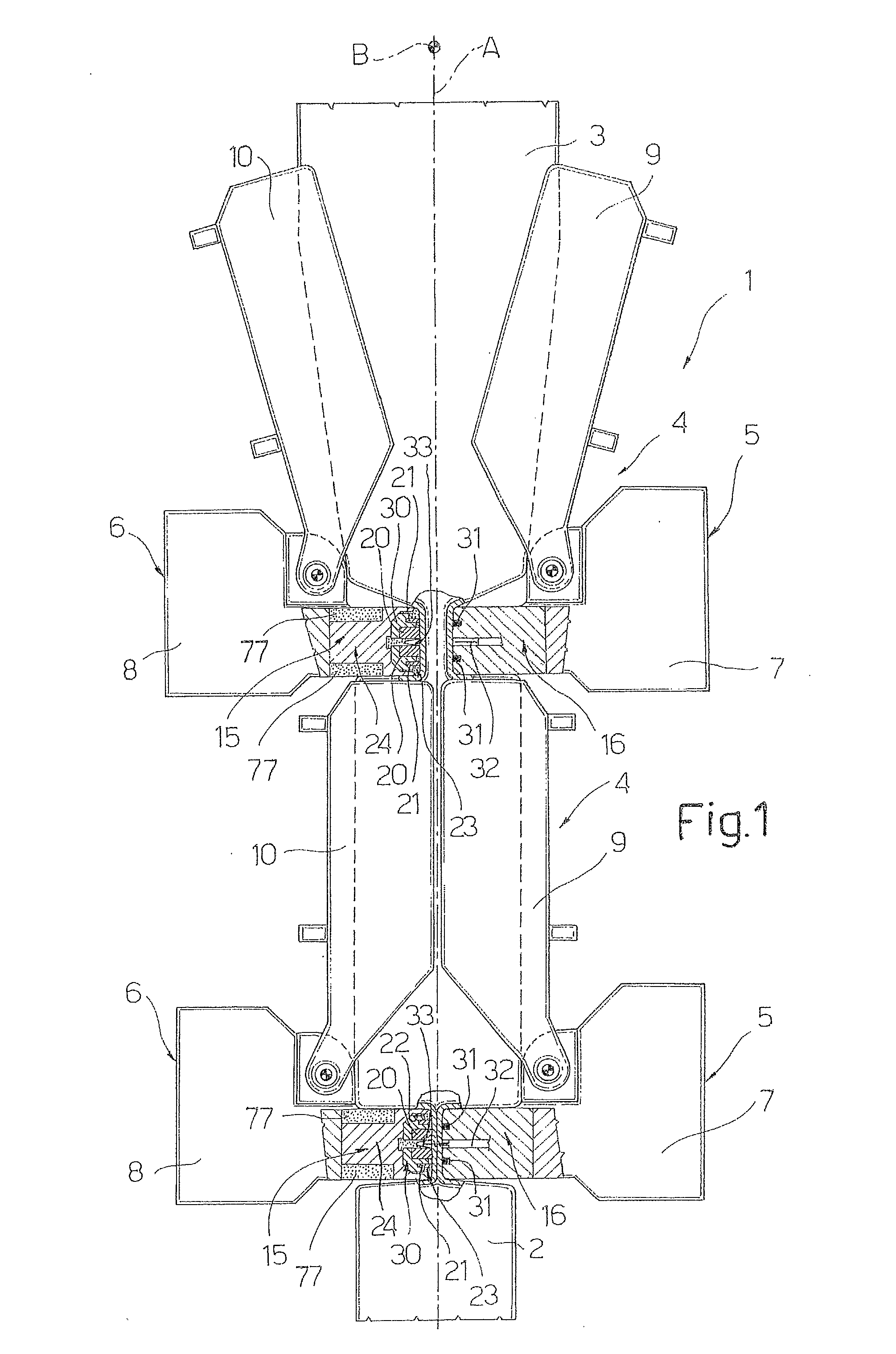

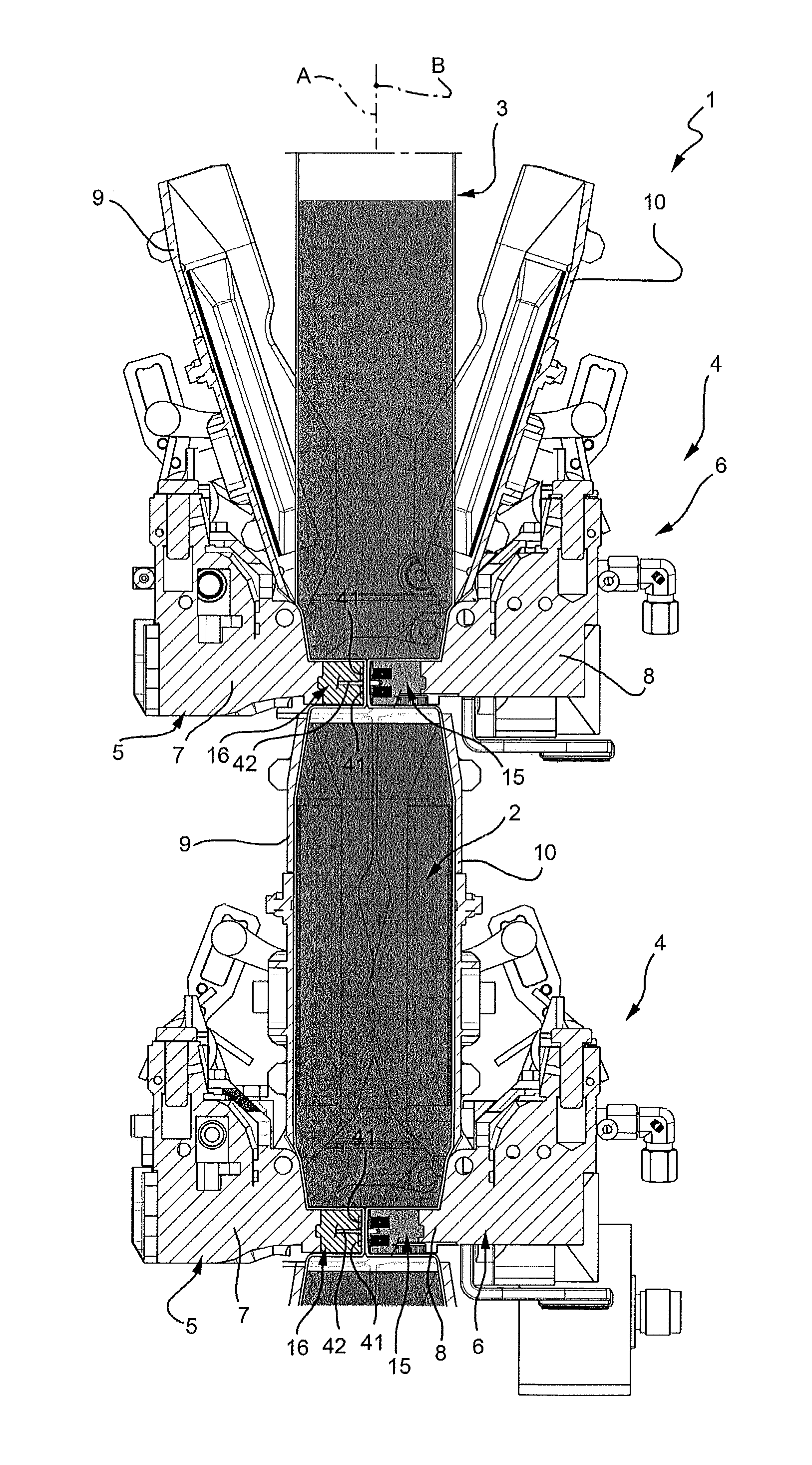

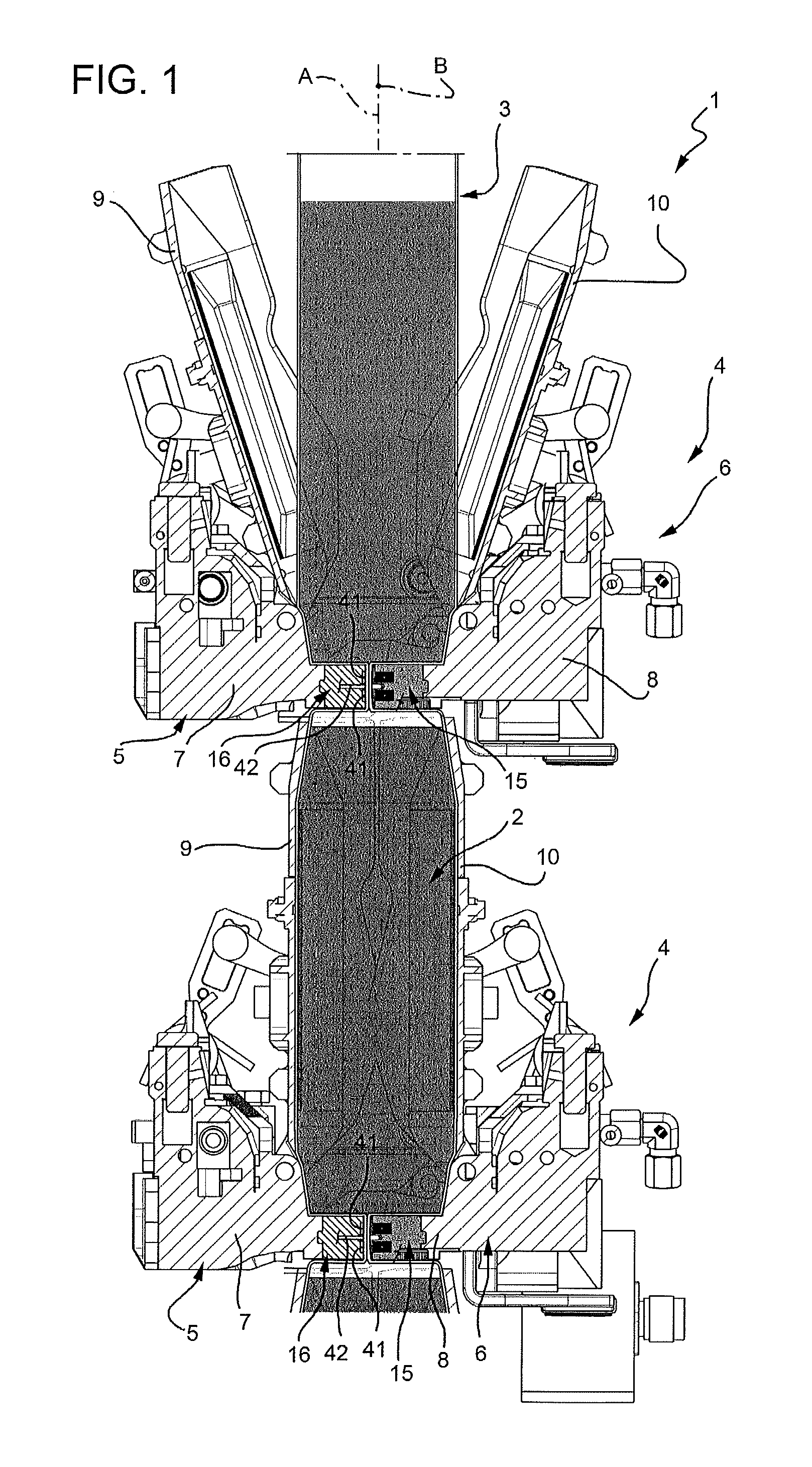

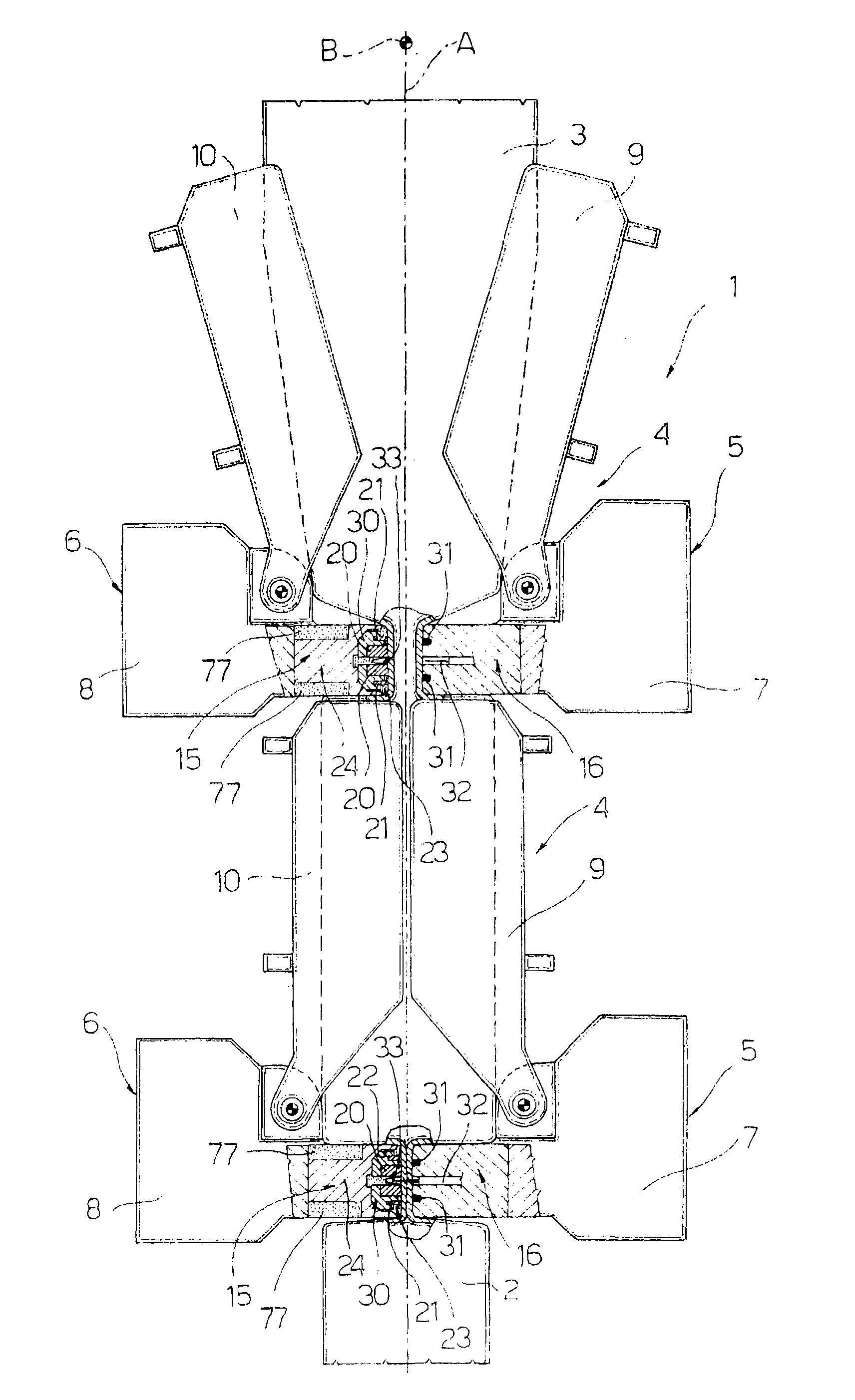

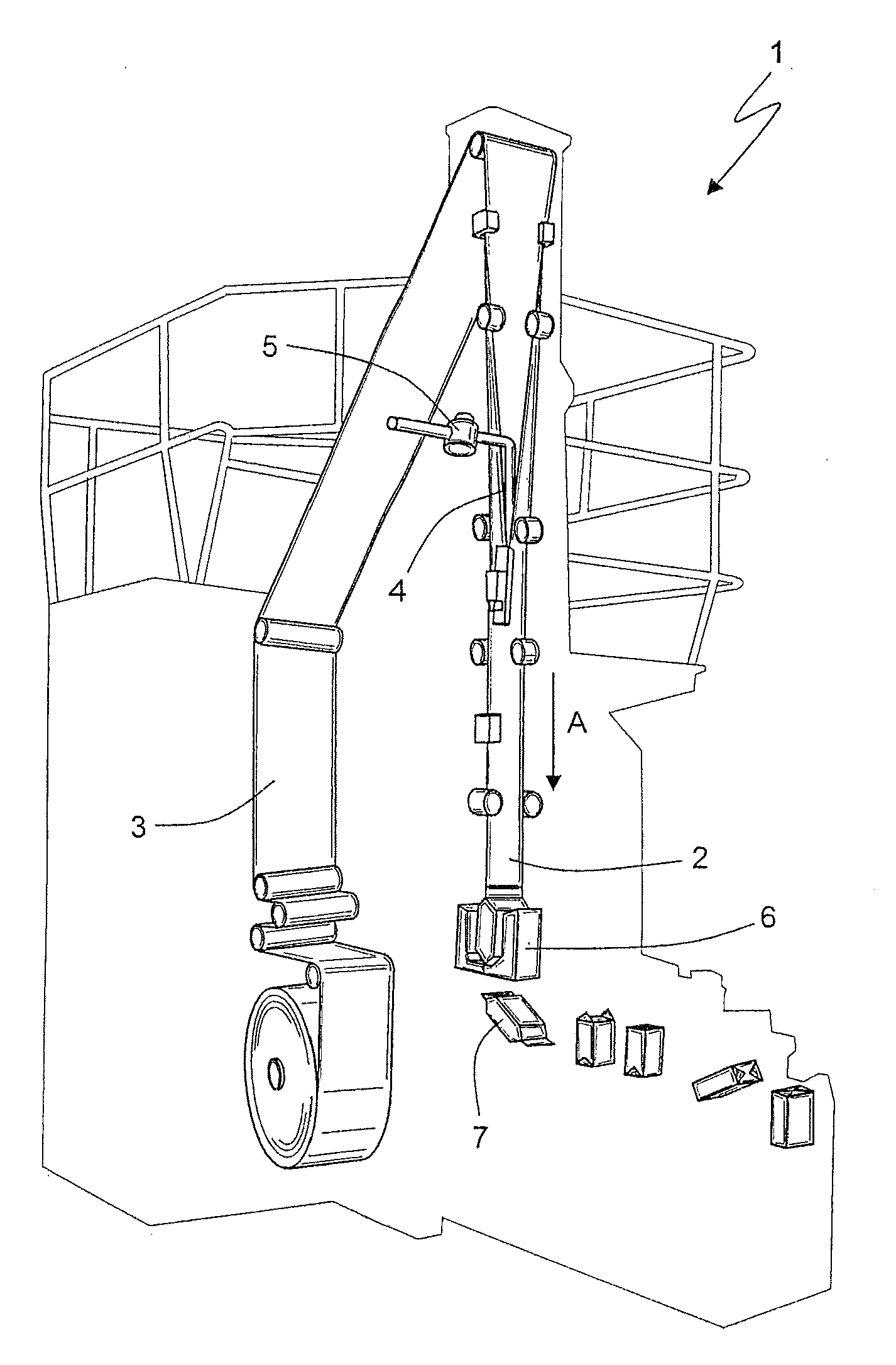

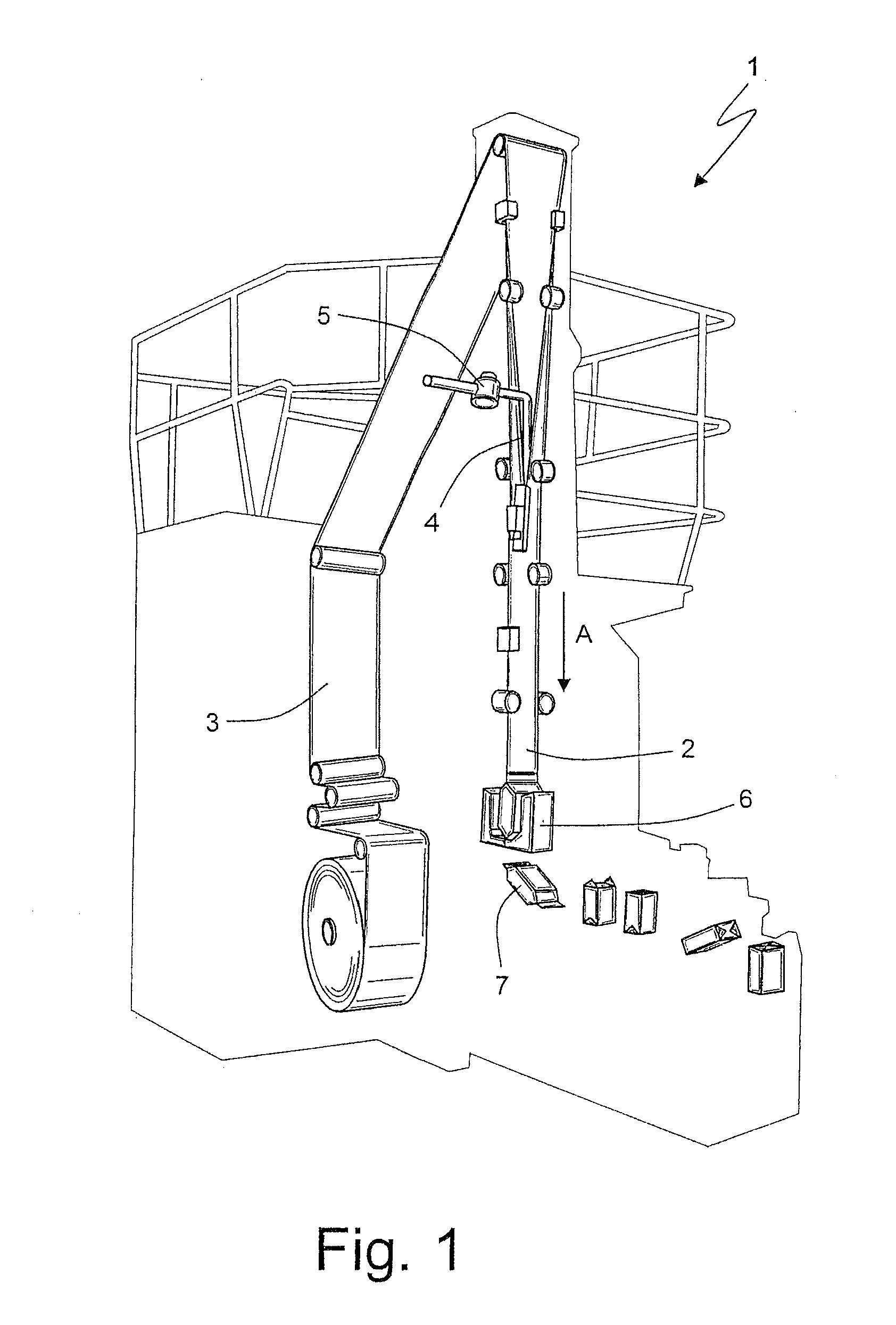

Folding unit for forming sealed packages of pourable food products

An induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products, comprising: at least one first inductor which comprises, in turn, a first active surface adapted to be arranged on the side of packaging material and to heat-seal it; and a member made of plastic material; first active surface is covered by the member made of plastic material adapted to cooperate with the packaging material during its heat-sealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

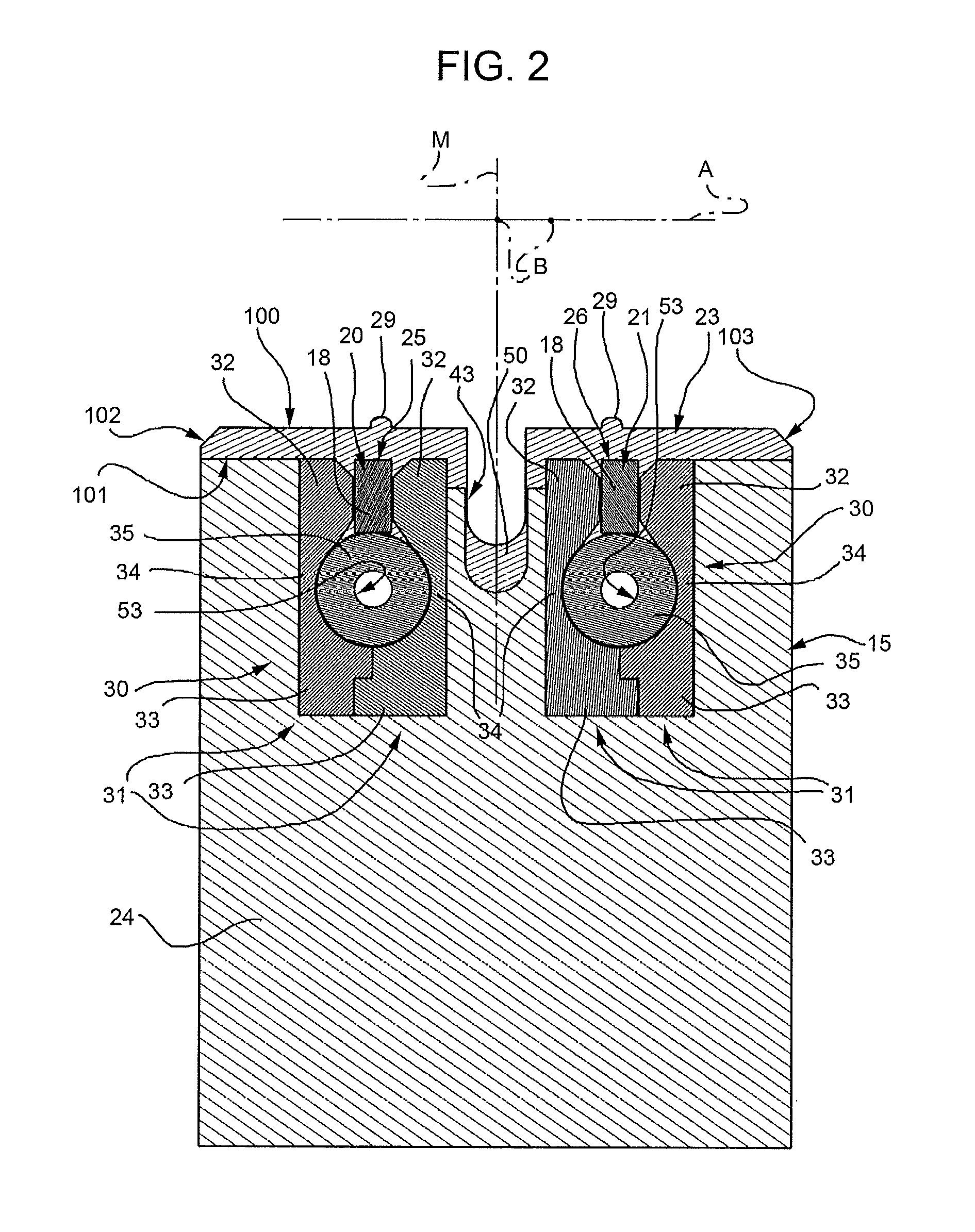

Induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products

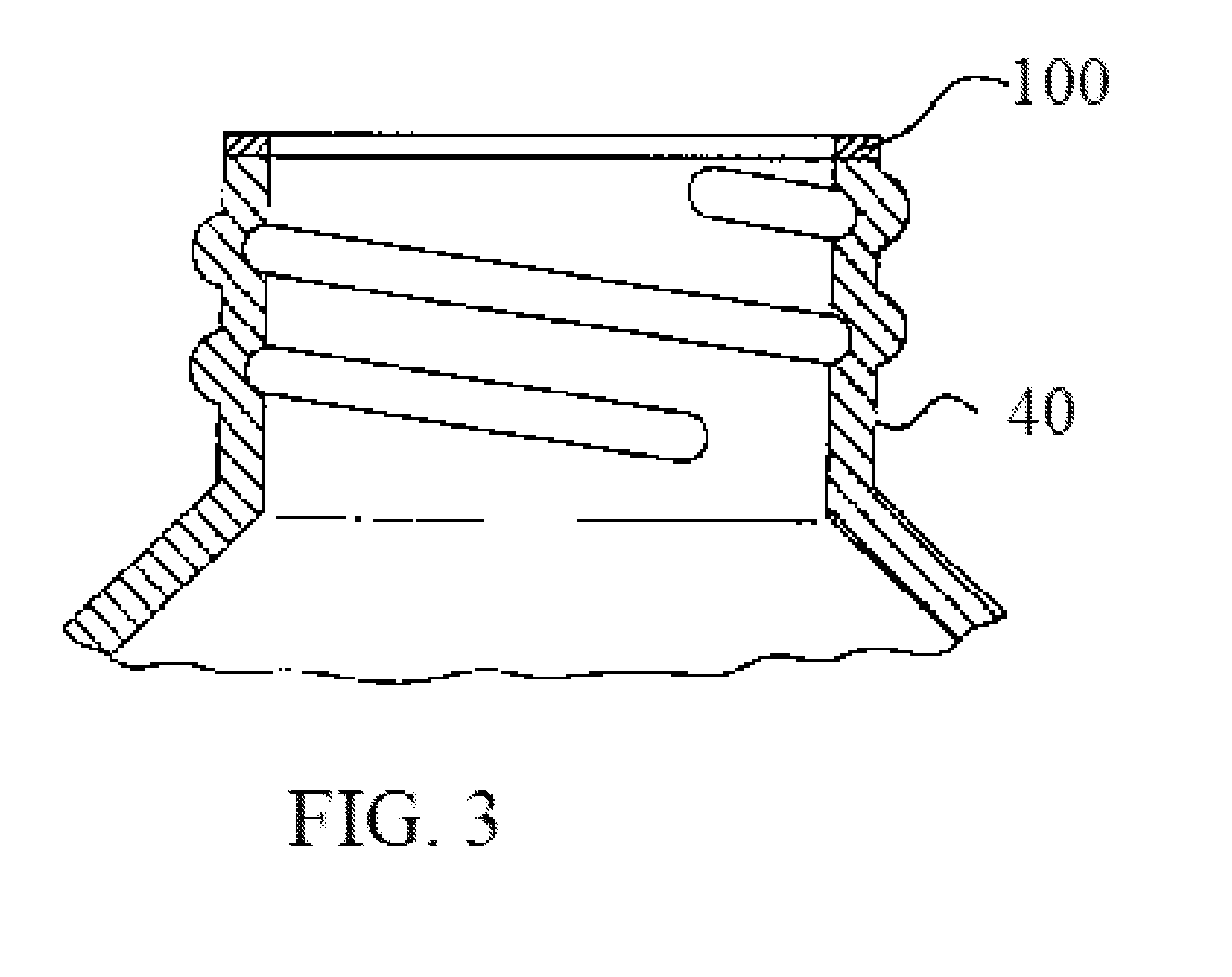

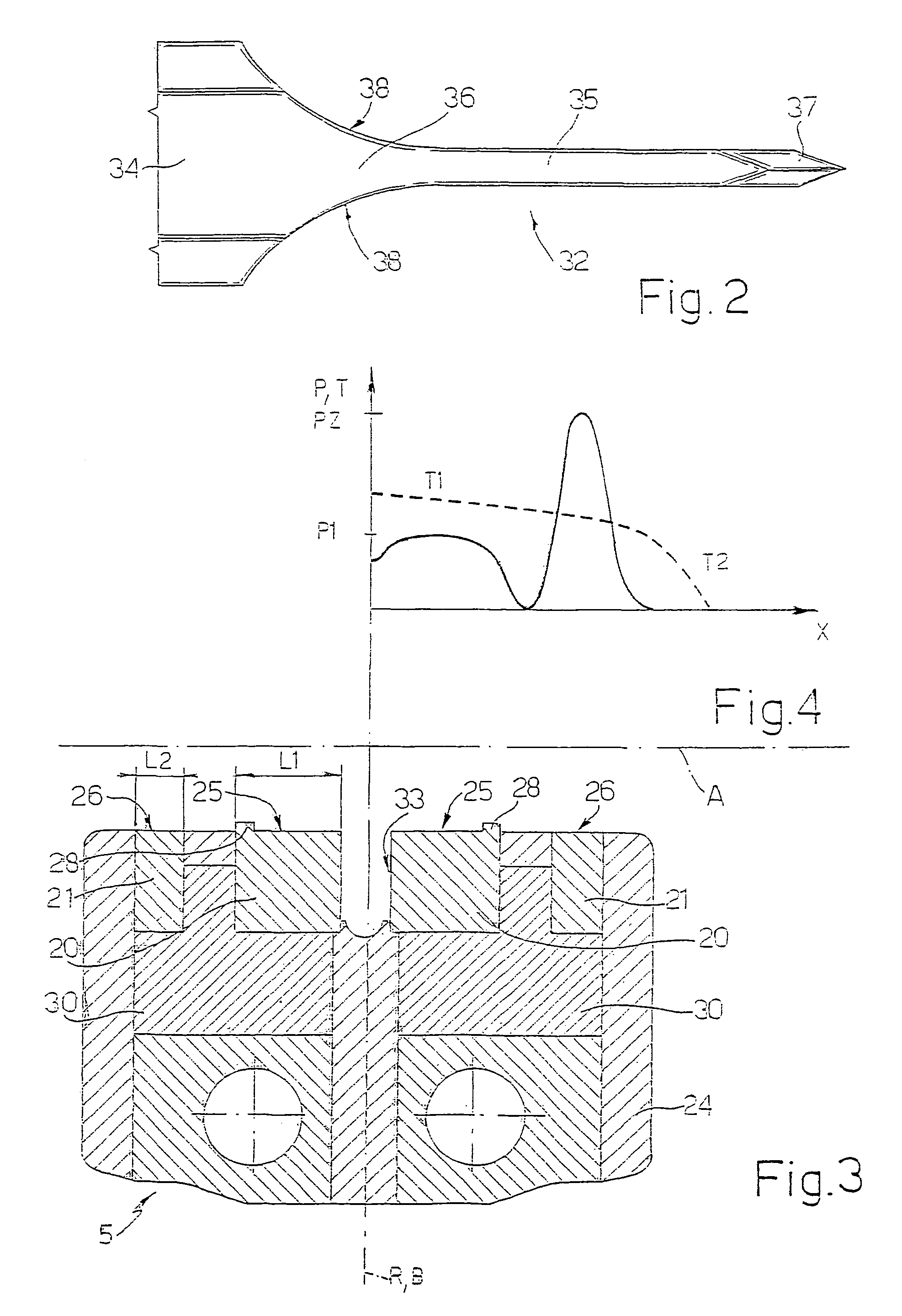

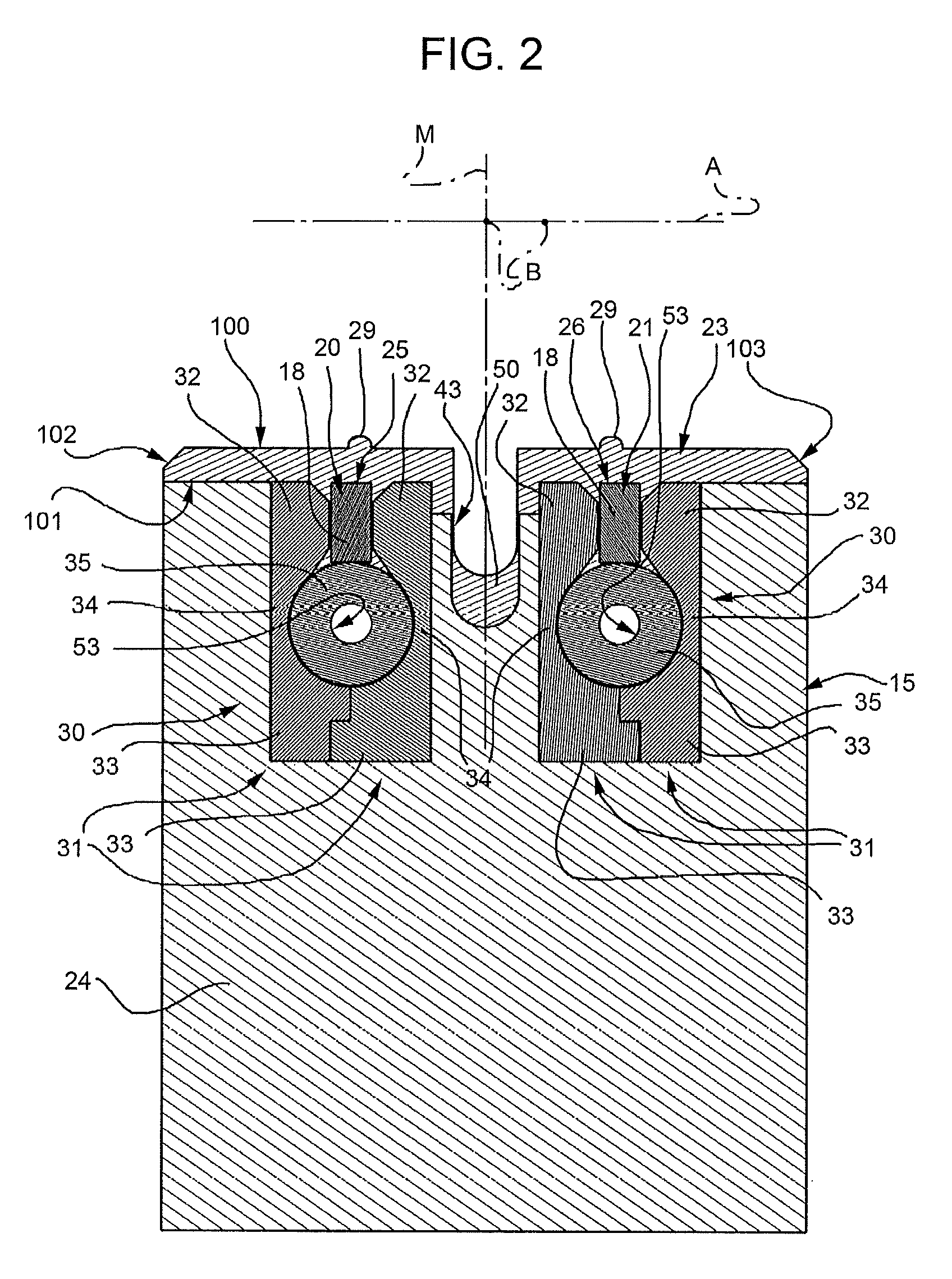

An induction sealing device (15) for heat sealing packaging material for producing sealed packages of pourable food products and fed in a first direction, the sealing device having inductor means (20, 21) which interact with the packaging material by means of at least one active surface (25, 26); a supporting body (24) made of heat-conducting material and housing the inductor means (20, 21); an insert (30) made of magnetic flux-concentrating material and housed in the supporting body (24); and a member (23) made of plastic material, and having at least a first portion (19) interposed, in the first direction (A), between the supporting body (24) and the insert (30) so as to be at least partly surrounded by the supporting body (24).

Owner:TETRA LAVAL HLDG & FINANCE SA

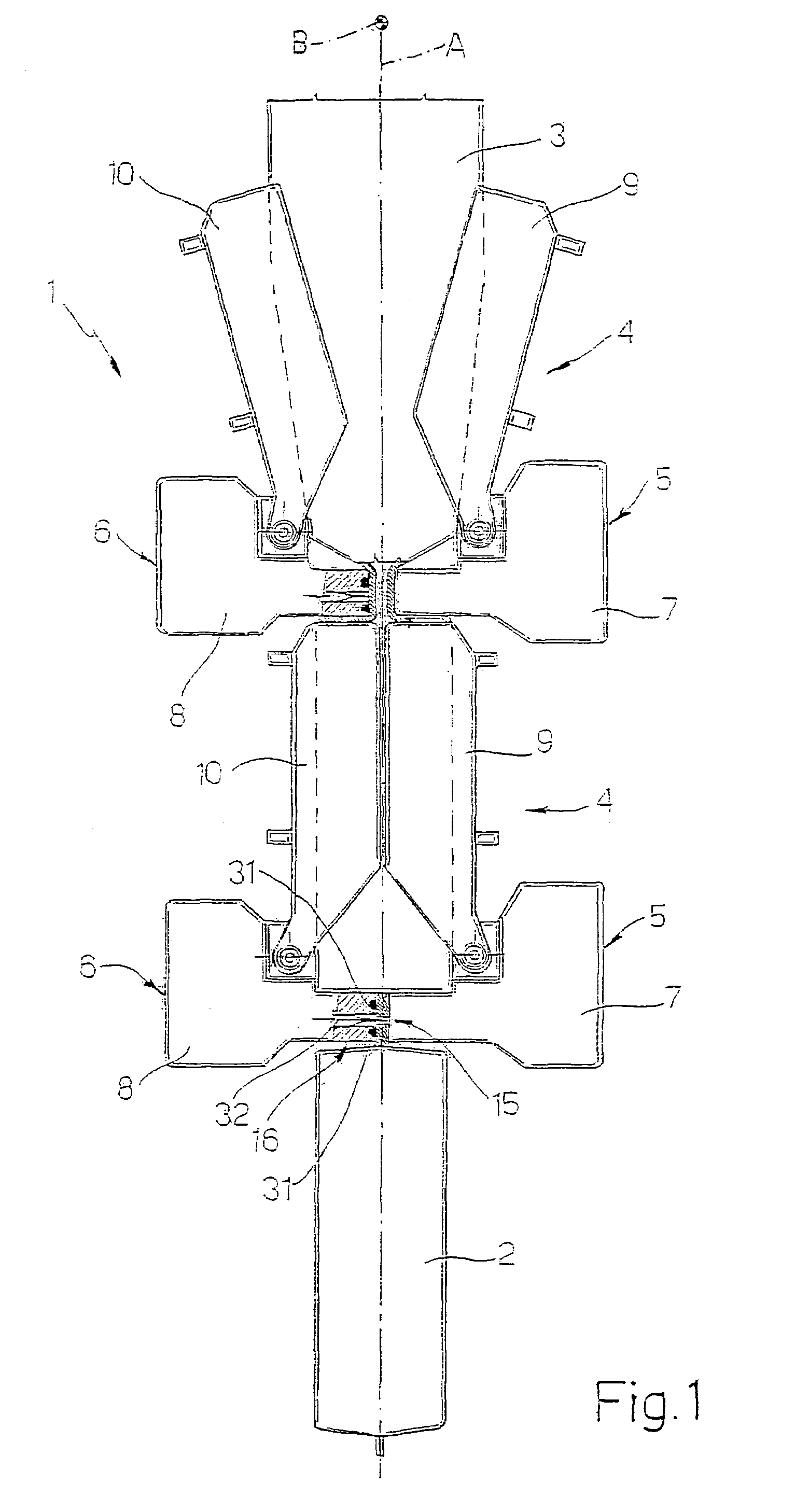

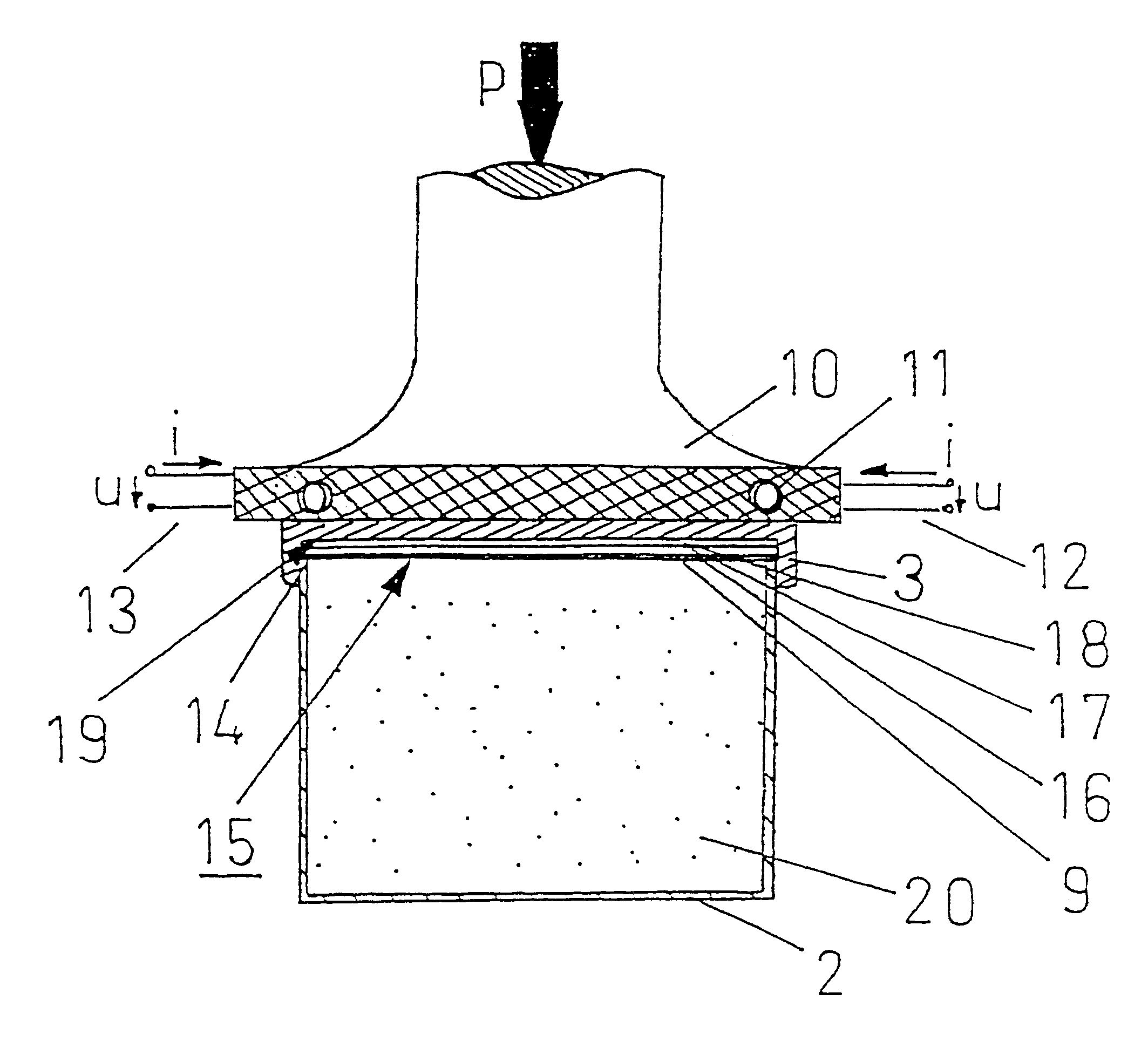

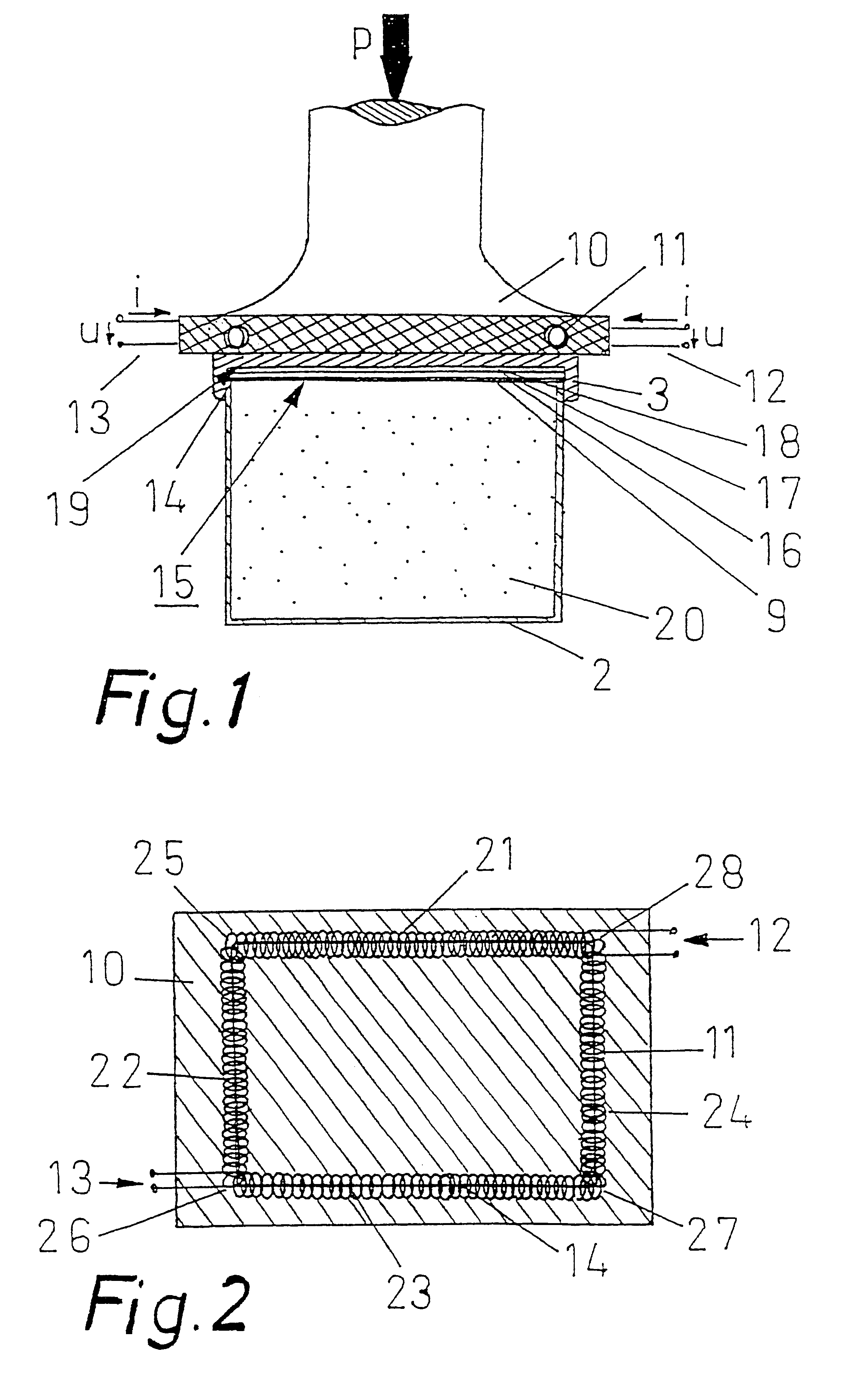

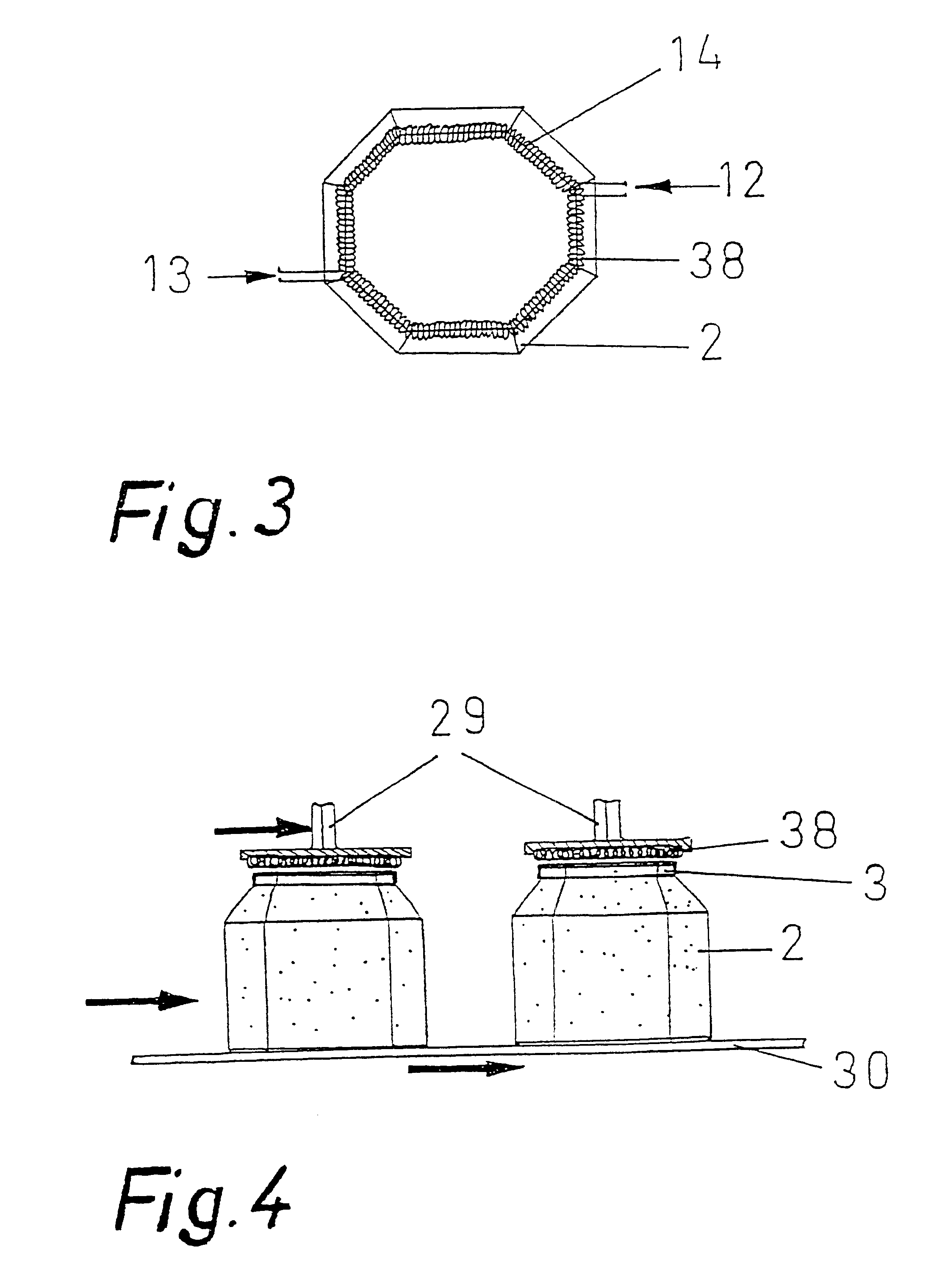

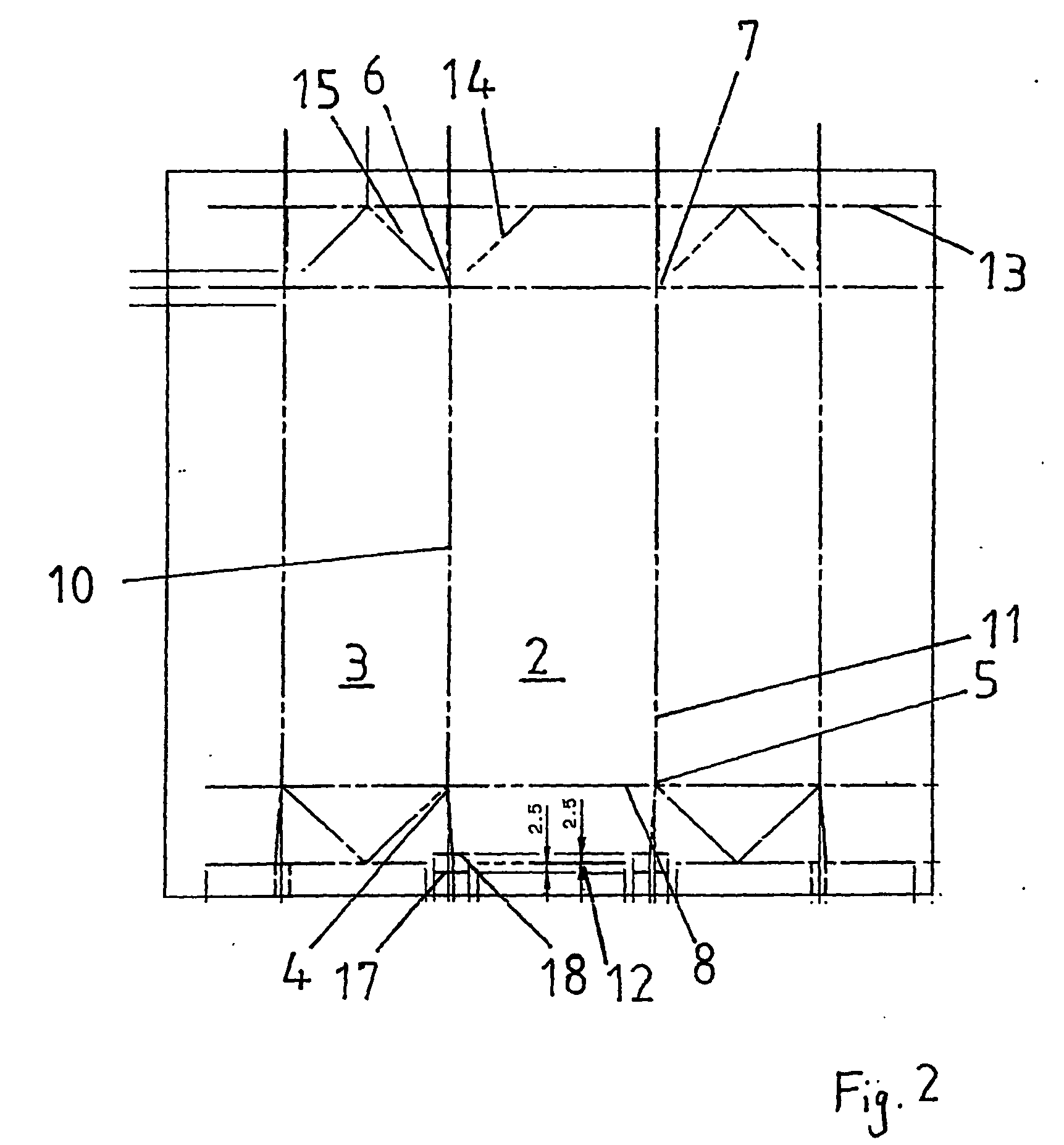

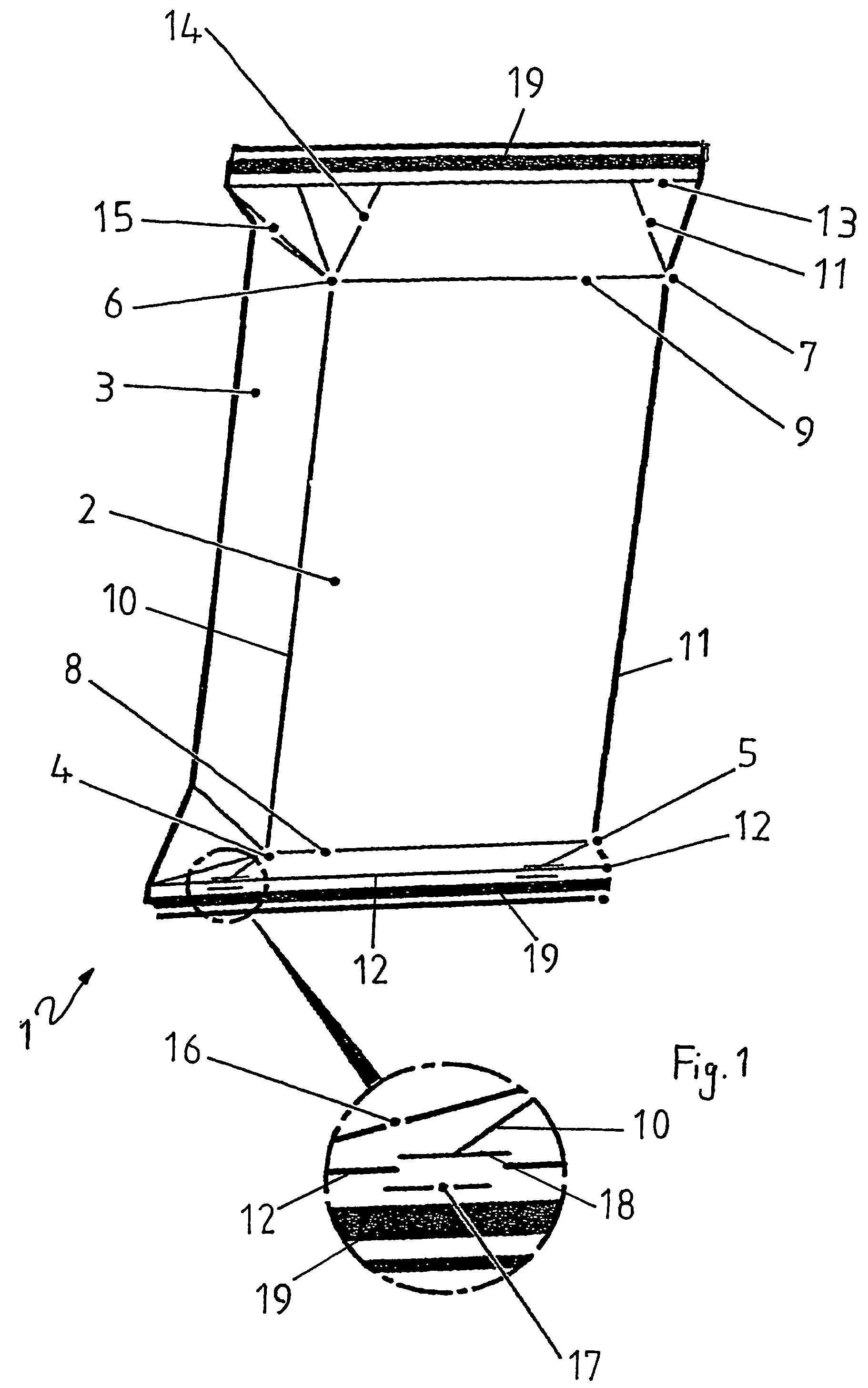

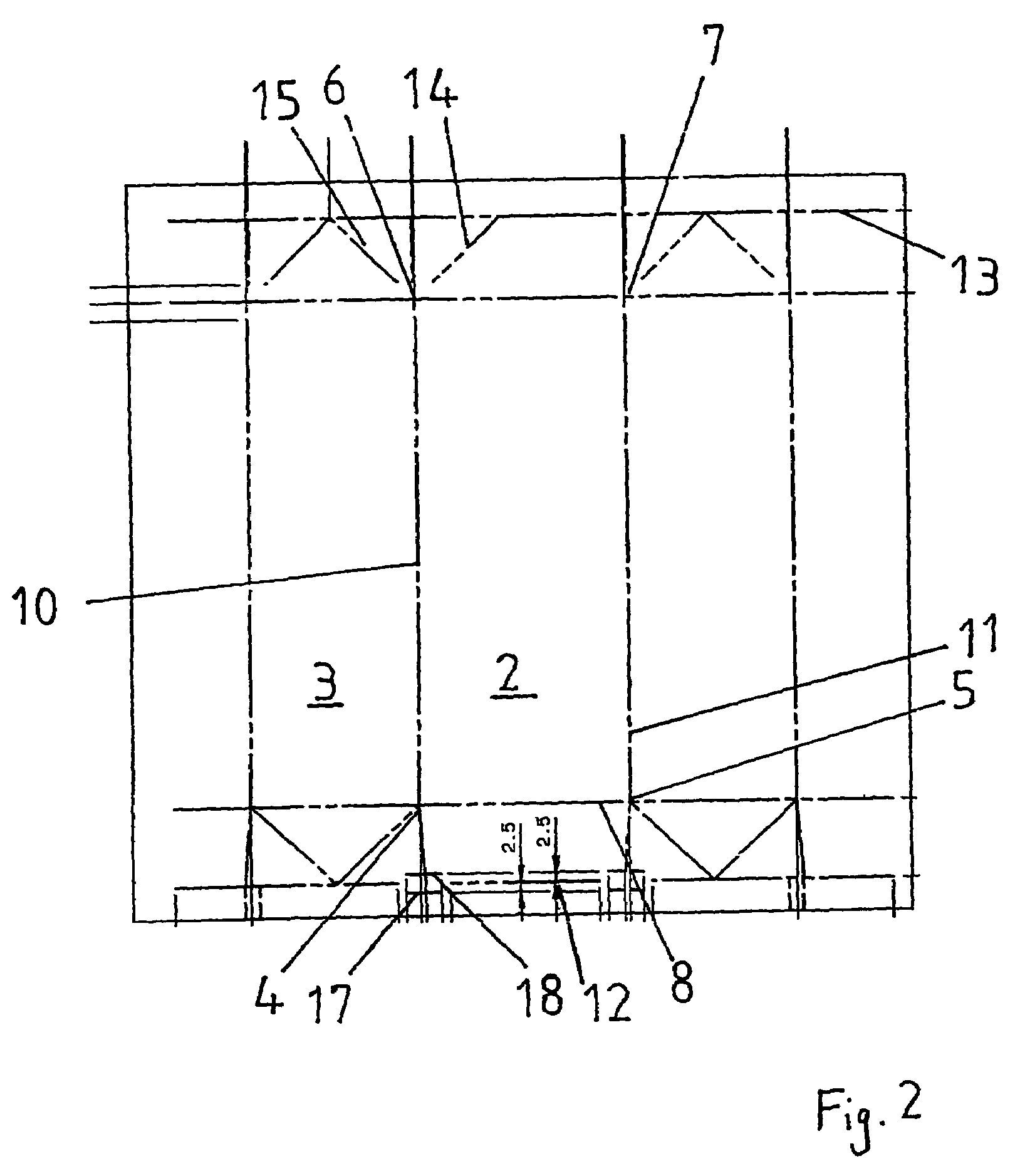

Method and device for induction sealing

A sealing device for sealing non-circular, in particular polygonal, for example tetragonal, hexagonal, octagonal or elliptical, container openings comprises one or a plurality of induction loops (11, 38, 41) for sealing purposes. Containers (2) comprise joined-on closure devices (3) with sealing discs (15) joined onto a sealing edge (14) of the container opening. The induction loops (11, 38, 41) are adapted to the shape of the sealing edge (14) and the spacing between the induction loop (11, 38, 41) and sealing edge (14) is constantly adjustable and selectable.

Owner:ALFELDER KUNSTWERKE HERM MEYER

Sealing jaw

InactiveUS20060124626A1Reliable and durable seamOhmic-resistance heating detailsWrapper twisting/gatheringSolid componentInduction sealing

A sealing jaw for manufacturing a sealing seam in a heat-sealable packaging material. The invention furthermore relates to an induction sealing device with a sealing jaw and to a packaging machine with induction sealing device. In order to provide a sealing jaw with which a sealed and durable sealing seam can be produced, even when solid components of the in-filled product are trapped between the jaws that have to be moved towards one another, a sealing jaw is proposed with means of a sealing jaw with a sealing surface that is provided in order to come into contact with the heat-sealable material, and a rod or bar-shaped heating device that is provided in order to heat up the heat-sealable material, wherein a pressure element is provided on the sealing surface, projecting above said sealing surface, and distanced from the heating device.

Owner:TETRA LAVAL HLDG & FINANCE SA

Sealing jaw

A sealing jaw for manufacturing a sealing seam in a heat-sealable packaging material. The invention furthermore relates to an induction sealing device with a sealing jaw and to a packaging machine with induction sealing device. In order to provide a sealing jaw with which a sealed and durable sealing seam can be produced, even when solid components of the in-filled product are trapped between the jaws that have to be moved towards one another, a sealing jaw is proposed with means of a sealing jaw with a sealing surface that is provided in order to come into contact with the heat-sealable material, and a rod or bar-shaped heating device that is provided in order to heat up the heat-sealable material, wherein a pressure element is provided on the sealing surface, projecting above said sealing surface, and distanced from the heating device.

Owner:TETRA LAVAL HLDG & FINANCE SA

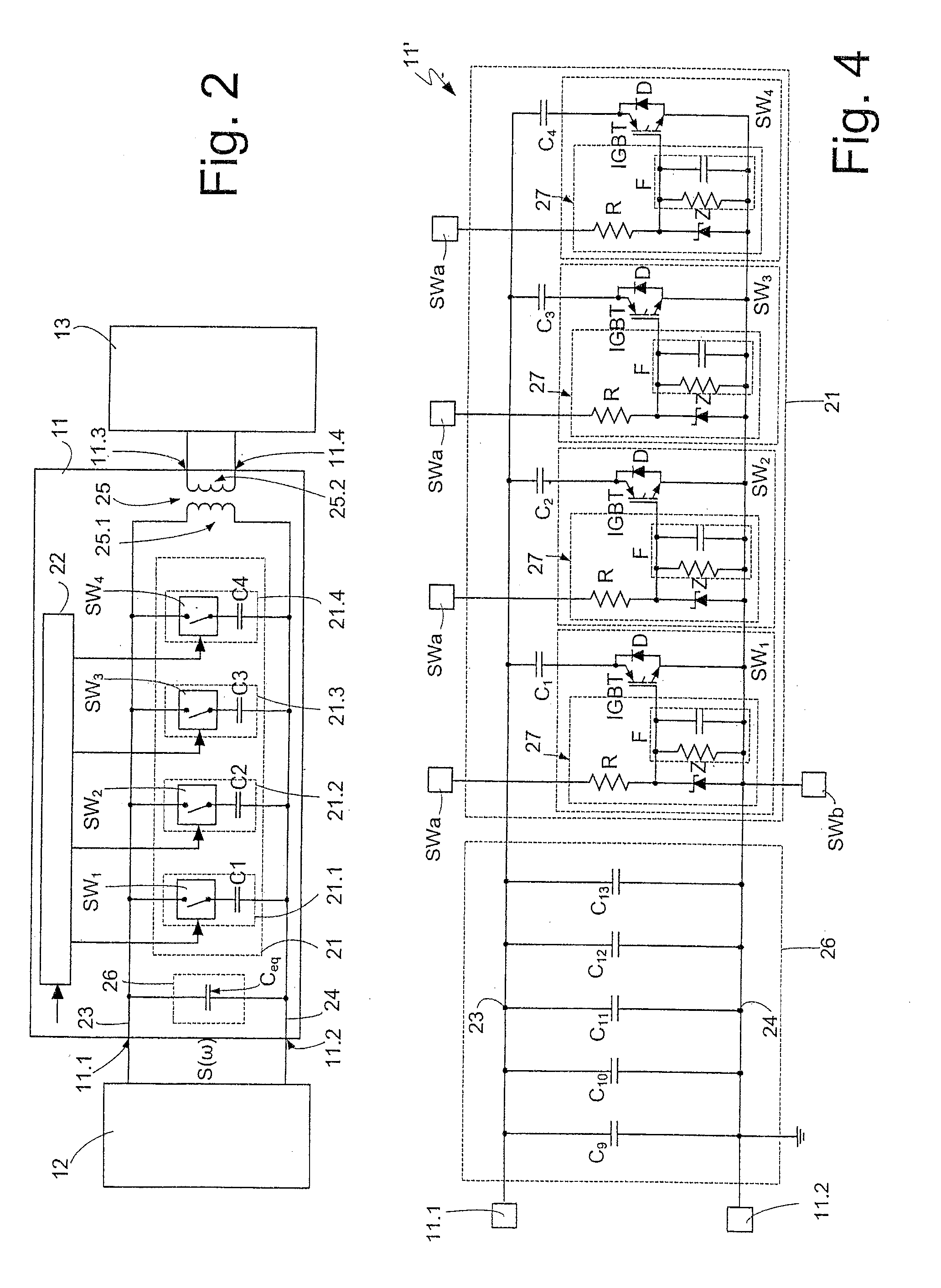

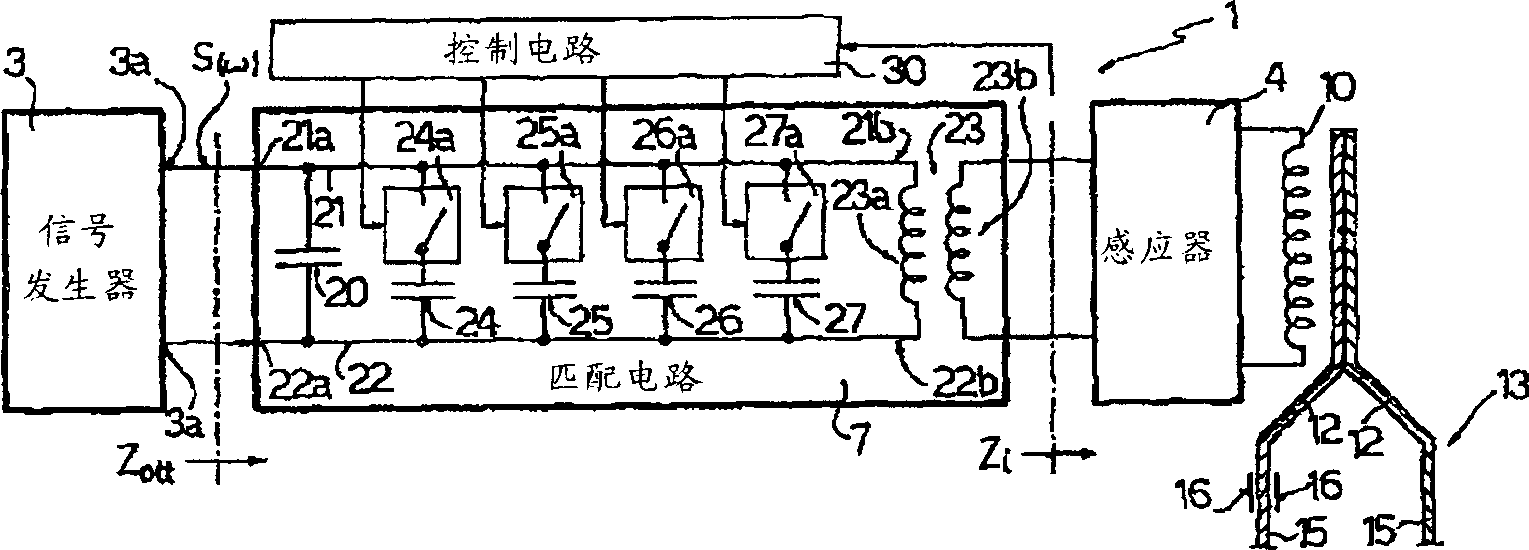

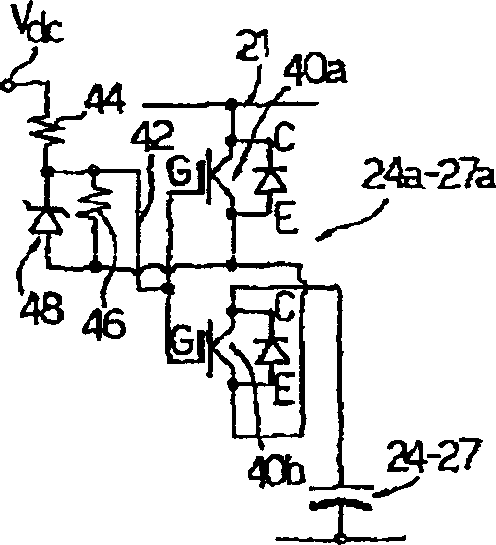

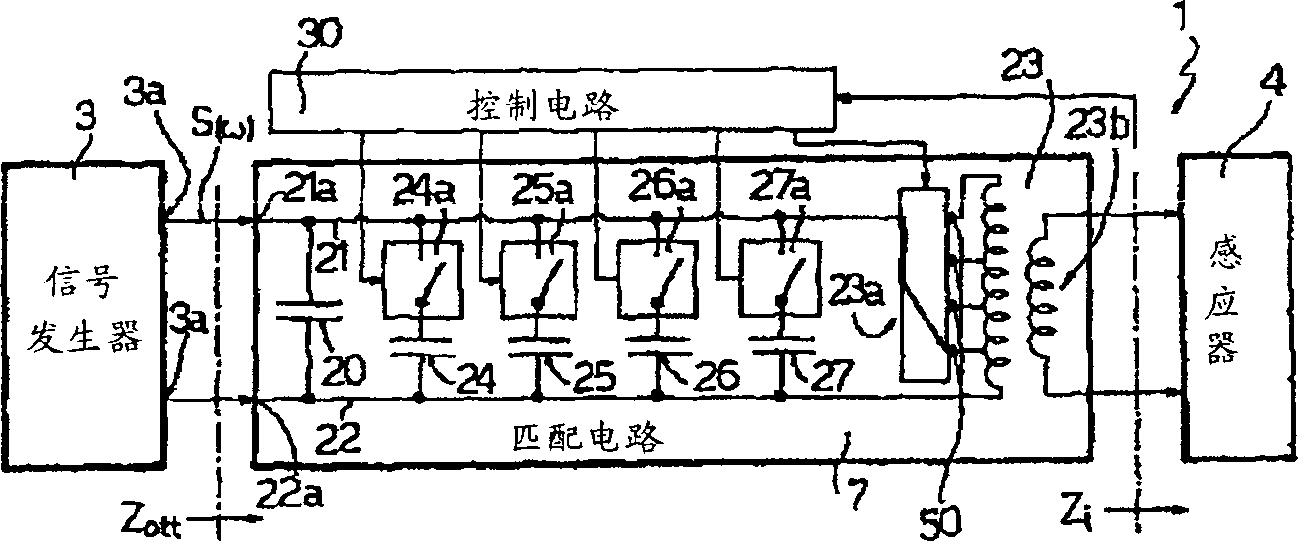

Self-configuring induction sealing device for use to produce pourable food product packages

ActiveUS20110225929A1Drawback can be obviatedMultiple-port networksWrapper twisting/gatheringCapacitanceControl signal

An induction sealing device for producing packaged pourable food products from heat-seal sheet packaging material. The sealing device has a signal source, an inductor, and an impedance matching circuit connected between the signal source and the inductor. The impedance matching circuit has: two input terminals; a first and second line connected to the input terminals; a variable-capacitance stage having capacitive modules each made up of a capacitive element and a controlled switch; and a control stage to control the controlled switches. Each controlled switch includes: input terminals receiving a respective control signal from the control stage, with one input terminal of each controlled switch connected to the second line; a single two-way controlled switching element having a control terminal connected to the other input terminal of the controlled switch; a first current-conducting terminal connected to the first line, and a second current-conducting terminal connected to the second line.

Owner:TETRA LAVAL HLDG & FINANCE SA

Folding unit for forming sealed packages of pourable food products

An induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products, comprising: at least one first inductor which comprises, in turn, a first active surface adapted to be arranged on the side of packaging material and to heat-seal it; and a member made of plastic material; first active surface is covered by the member made of plastic material adapted to cooperate with the packaging material during its heat-sealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

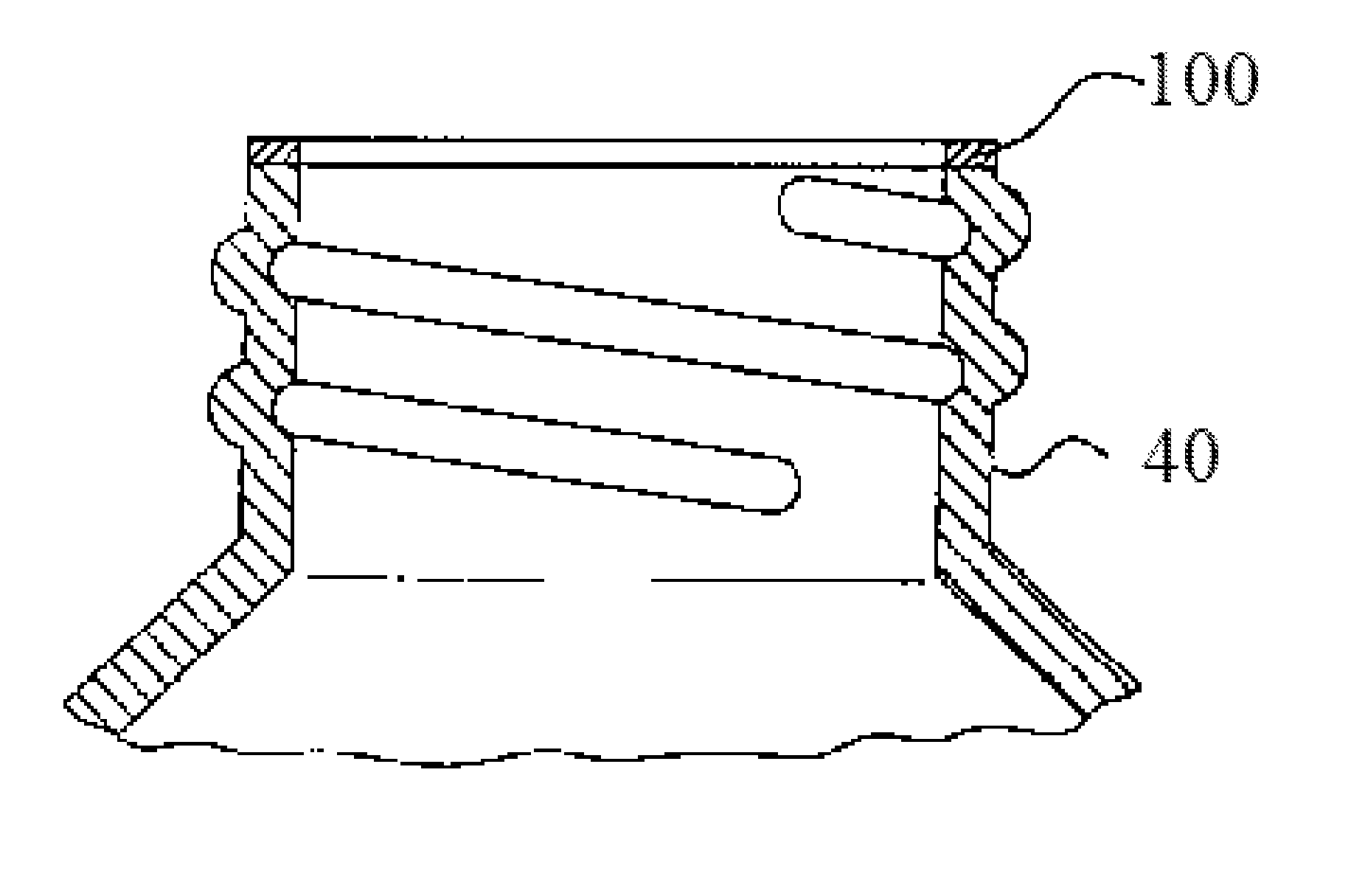

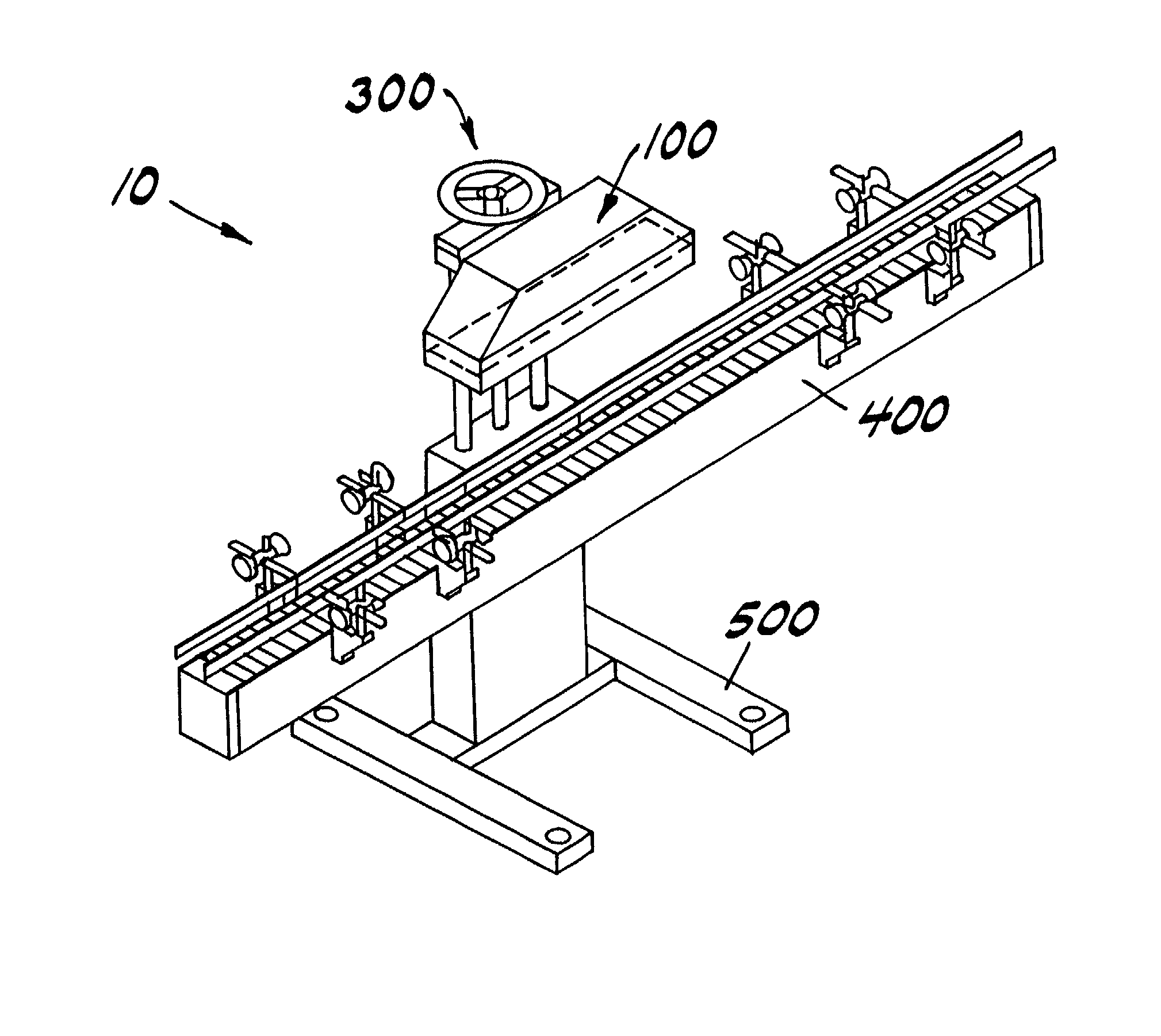

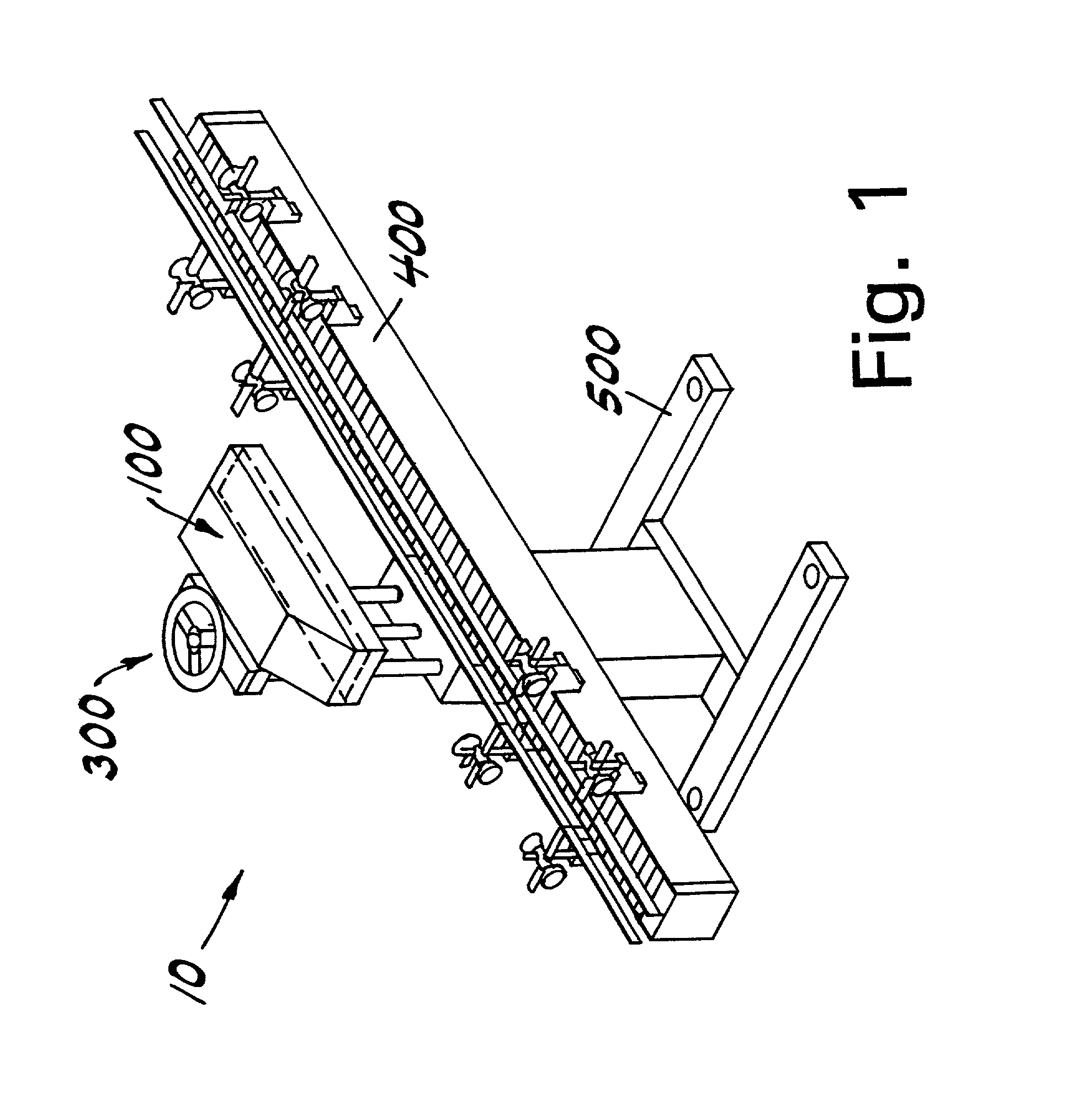

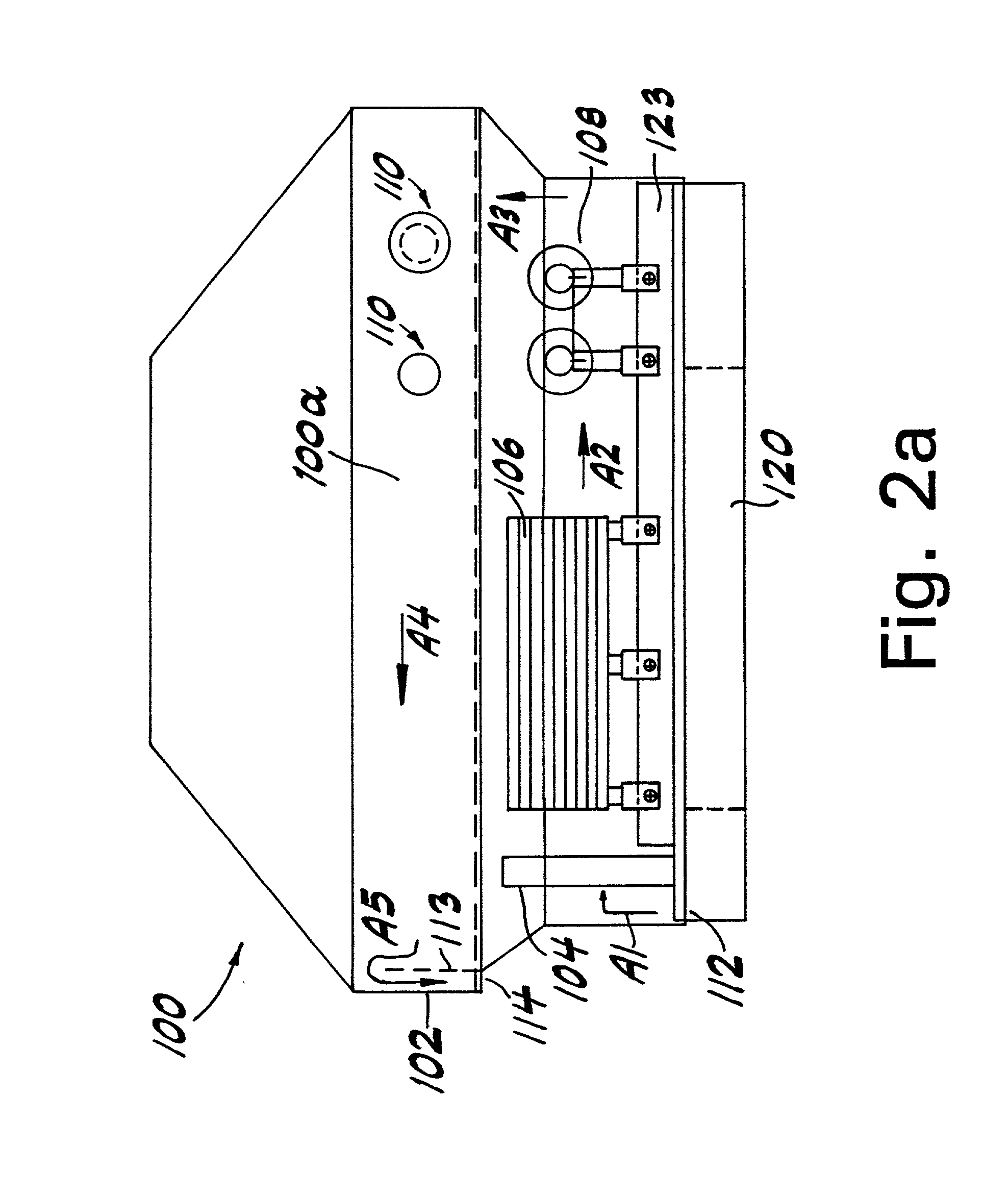

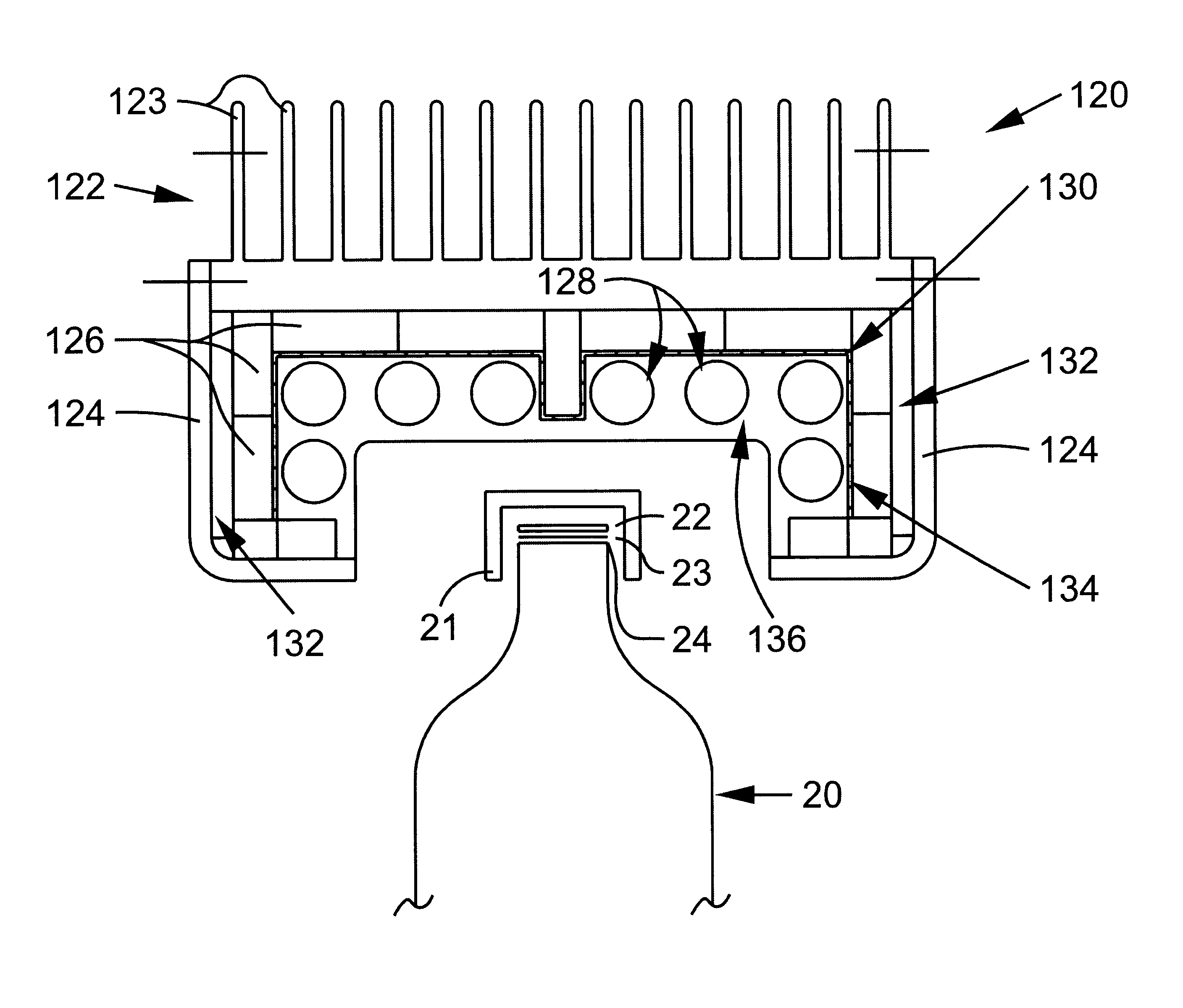

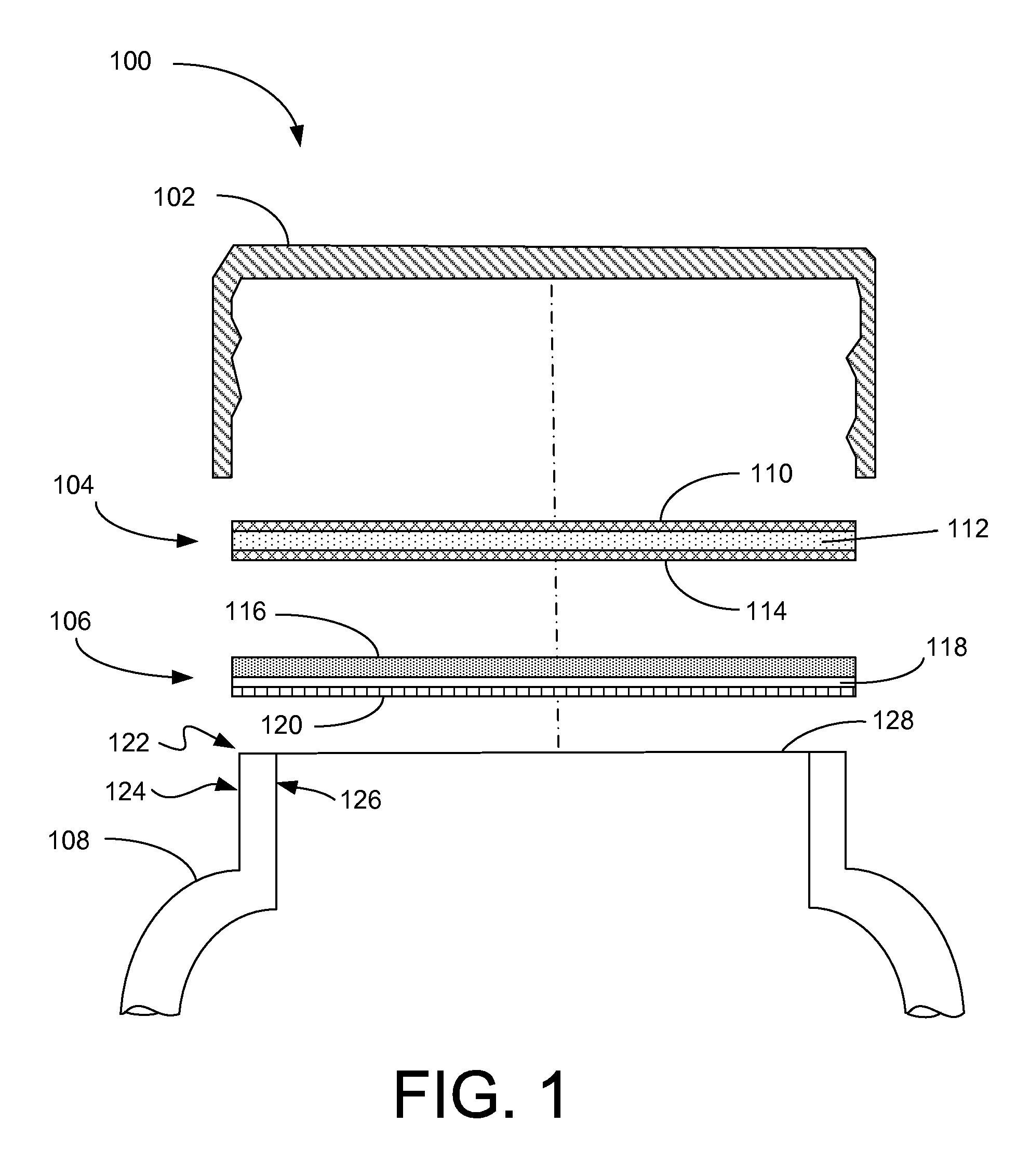

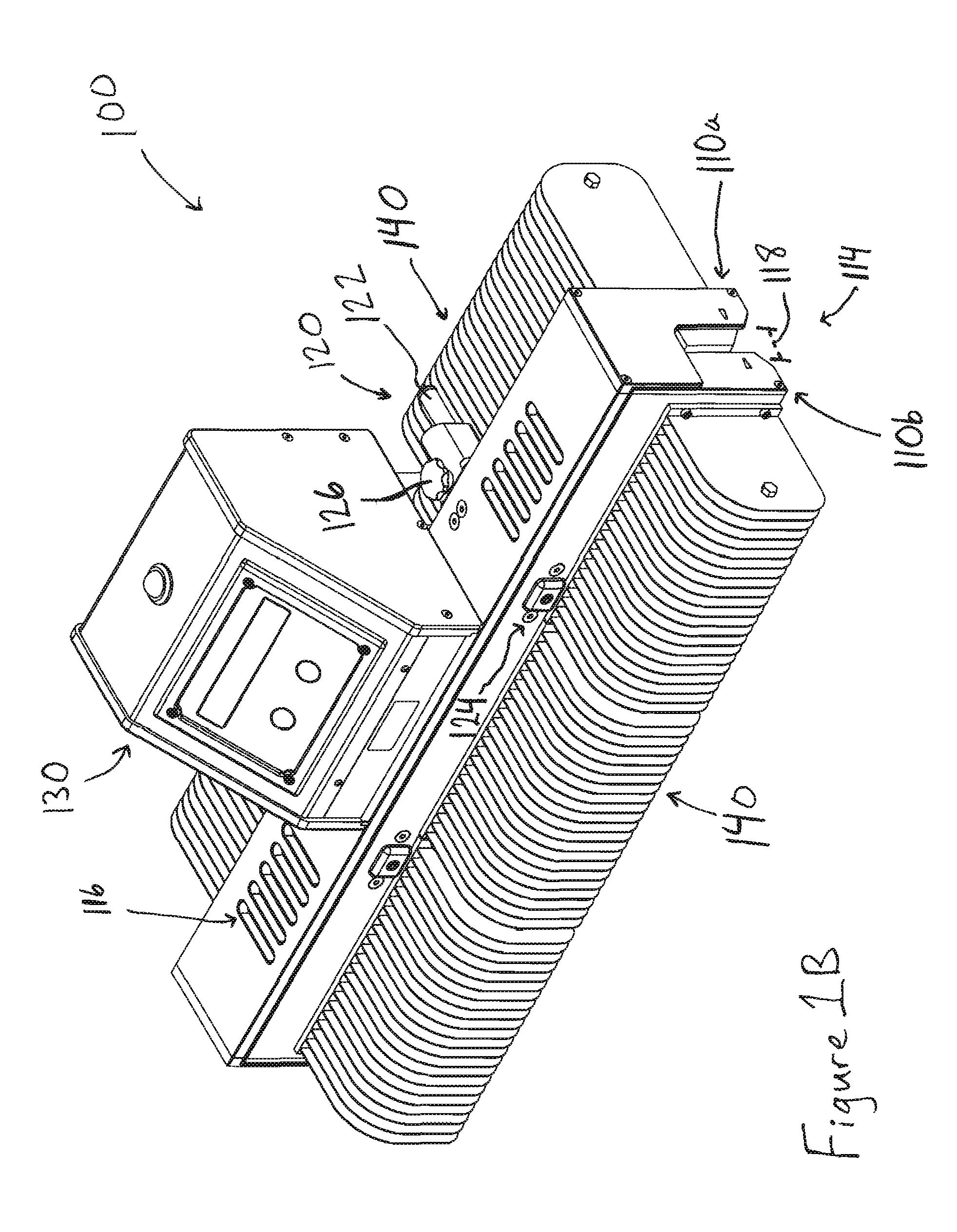

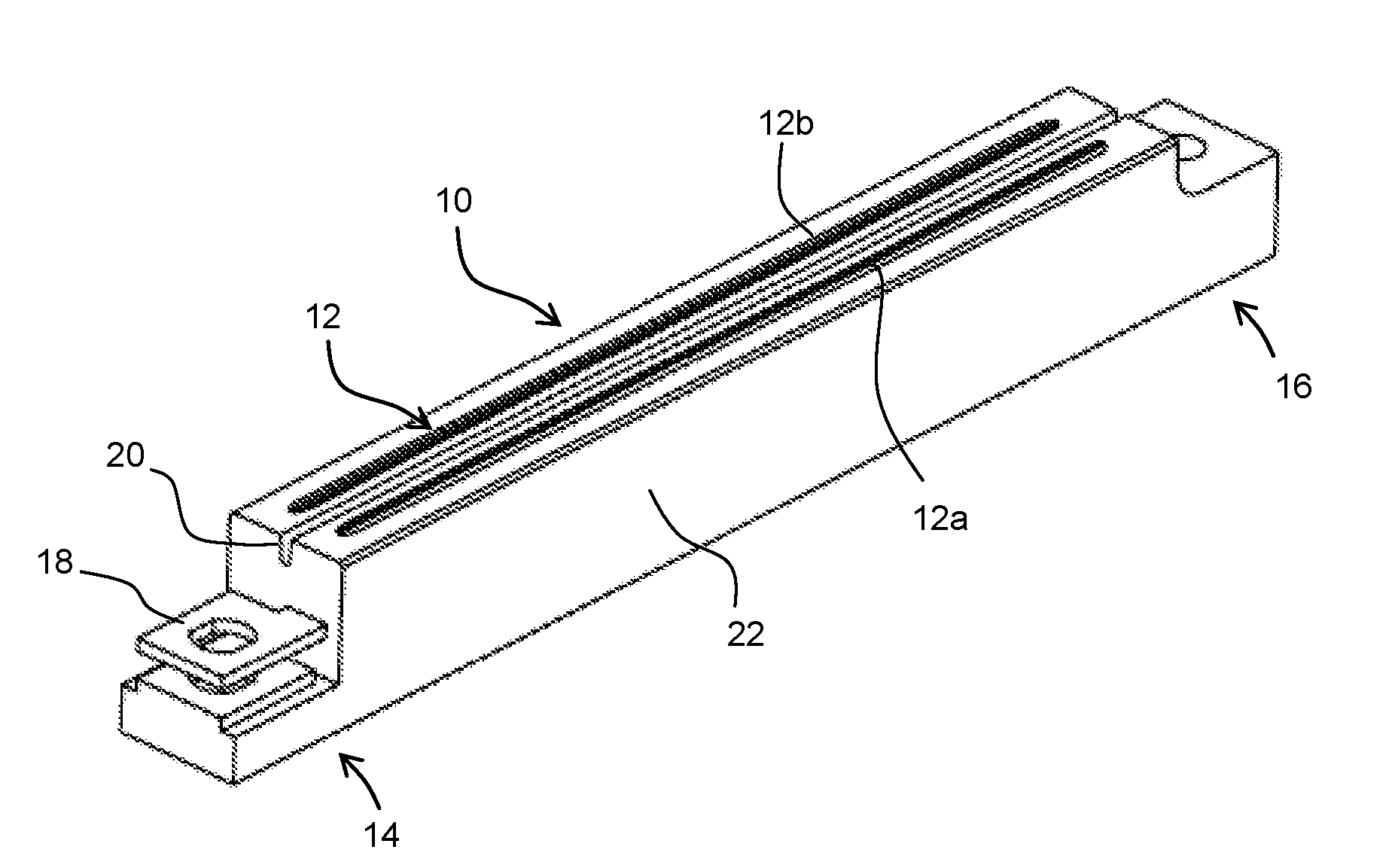

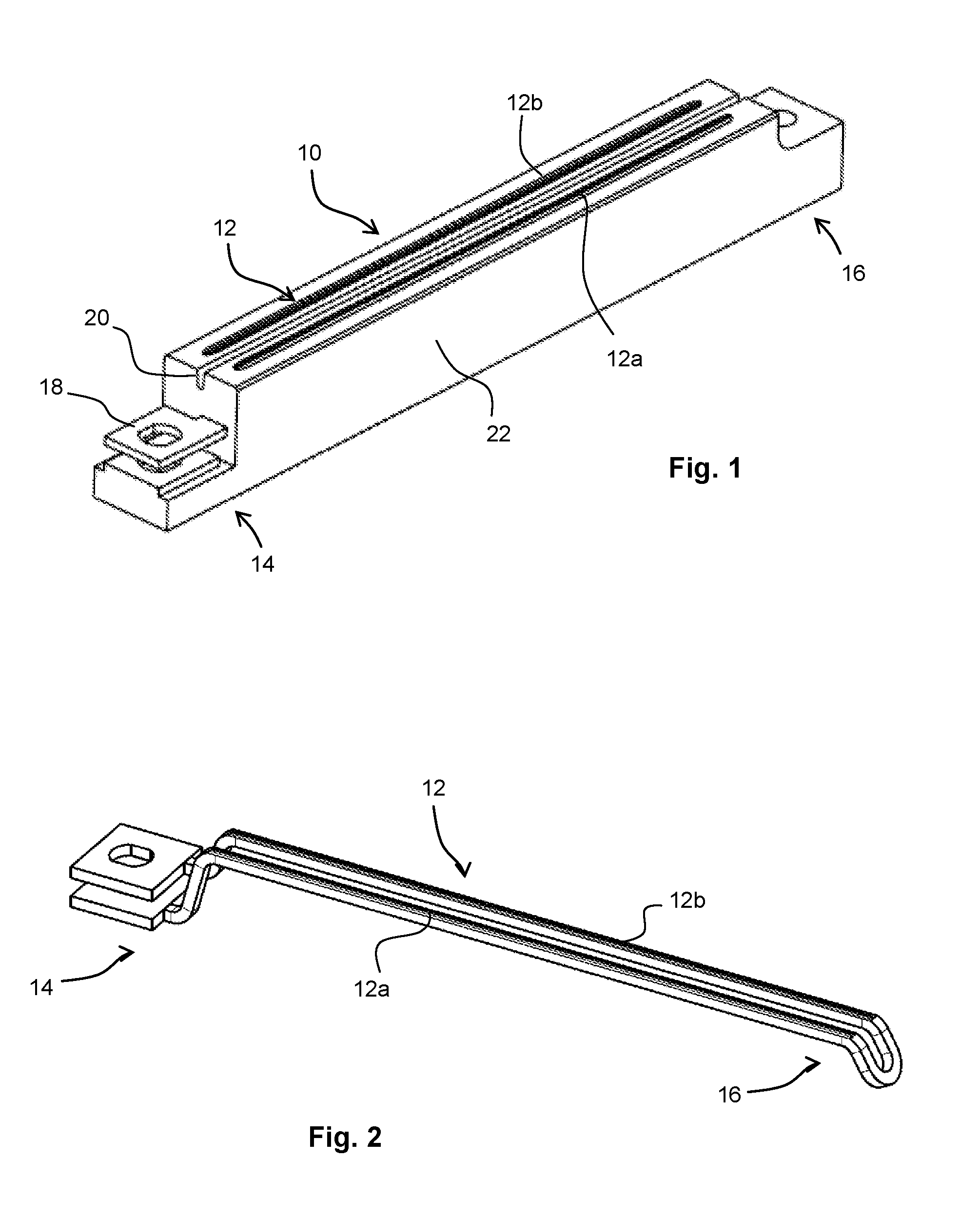

Adjustable electromagnetic sealing device

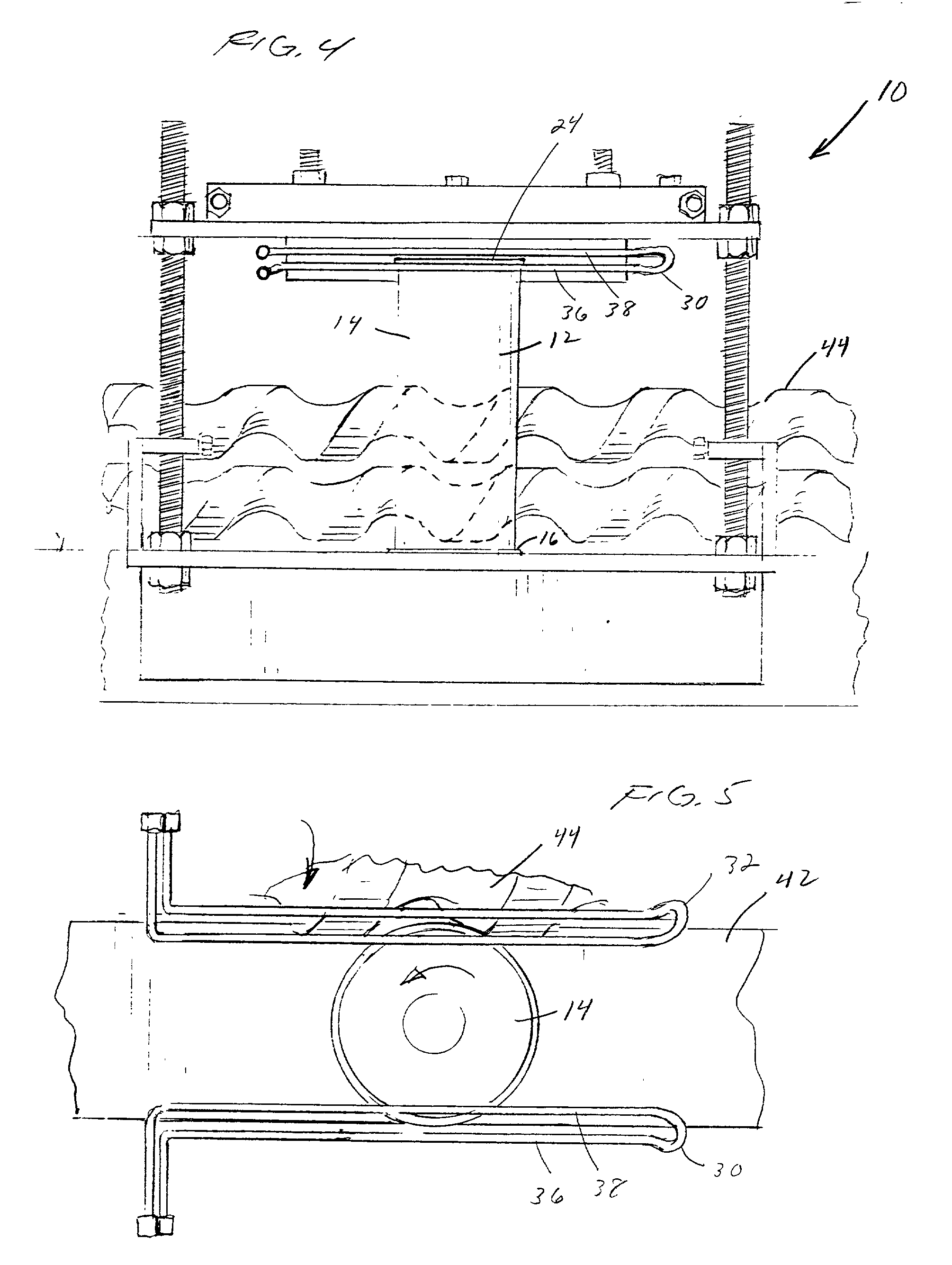

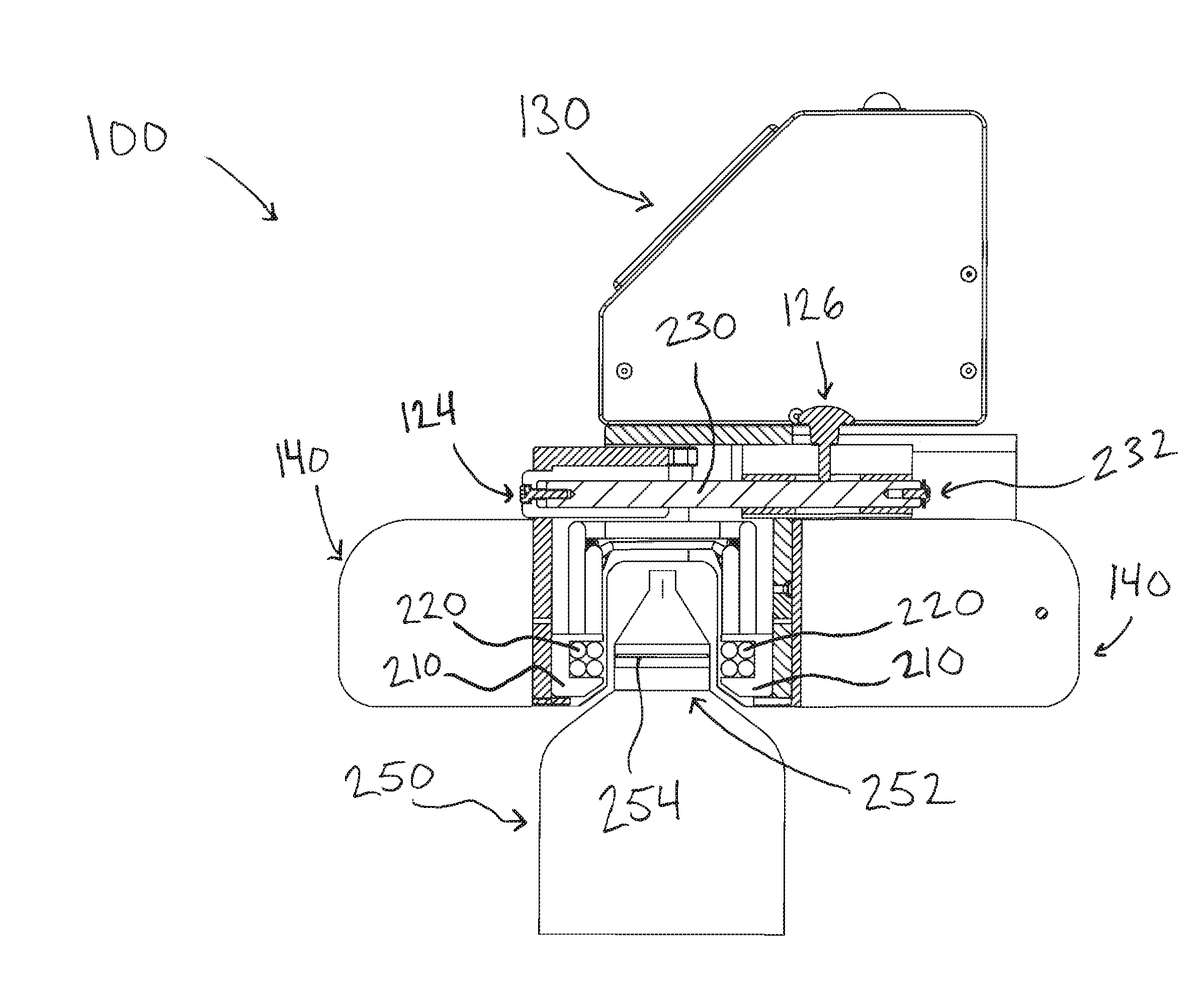

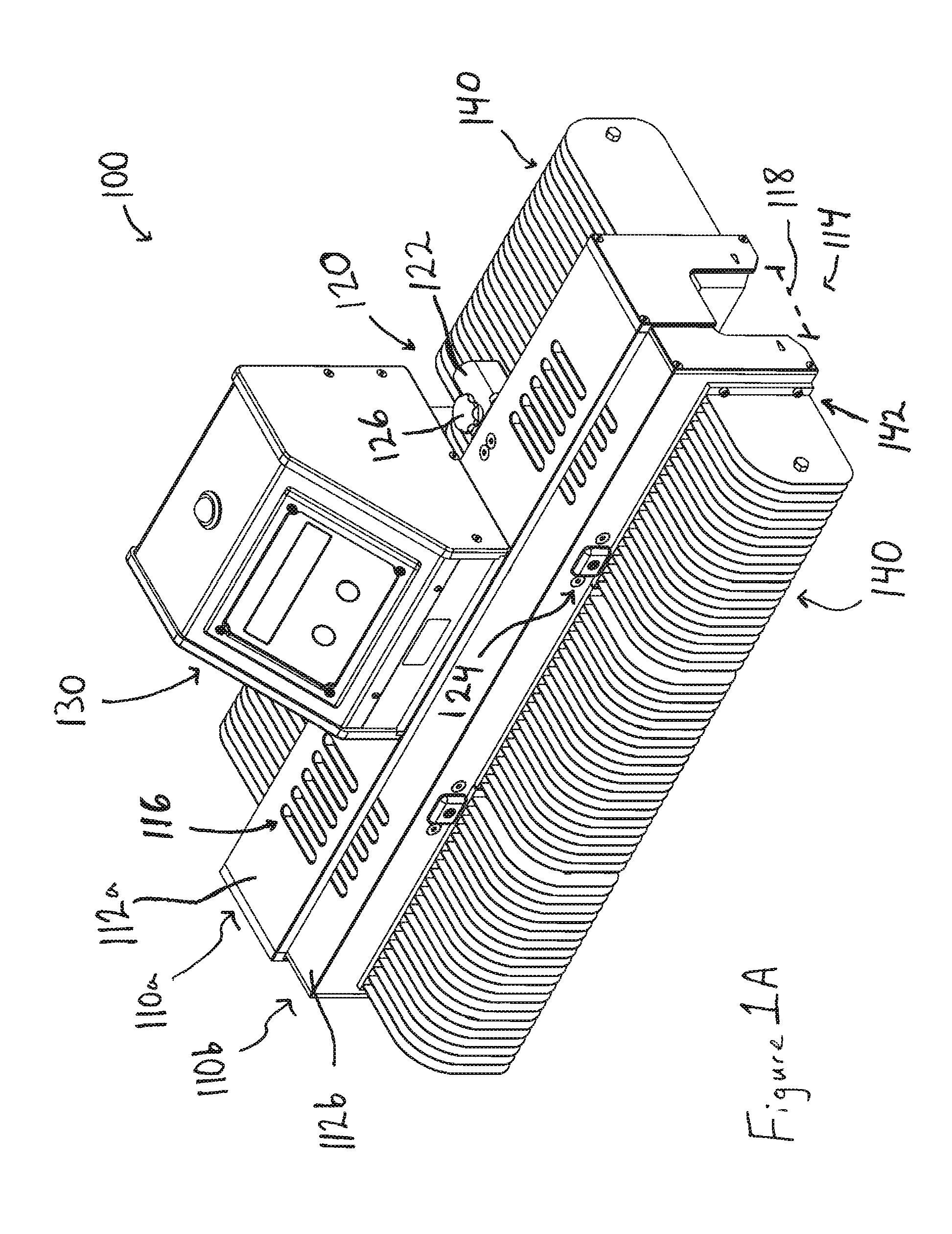

ActiveUS7834298B2Eliminates and reduces inefficiencyReducing capital equipment expenditureHigh frequency current welding apparatusDomestic articlesLitz wireElectromagnetic field

The present invention is an inductive sealing unit, which includes a conductive coil assembly that has at least two sections. At least one of the sections is adjustable with respect to the other. Each section has a magnetic flux concentrator, such as a ferrite core. A flexible conductive coil, such as litz wire, is disposed with respect to the magnetic flux concentrator to provide an electromagnetic field which induces heat sufficient to seal an object. The assembly can be adjusted to accommodate different size objects to be sealed.

Owner:ULTRAFLEX INT

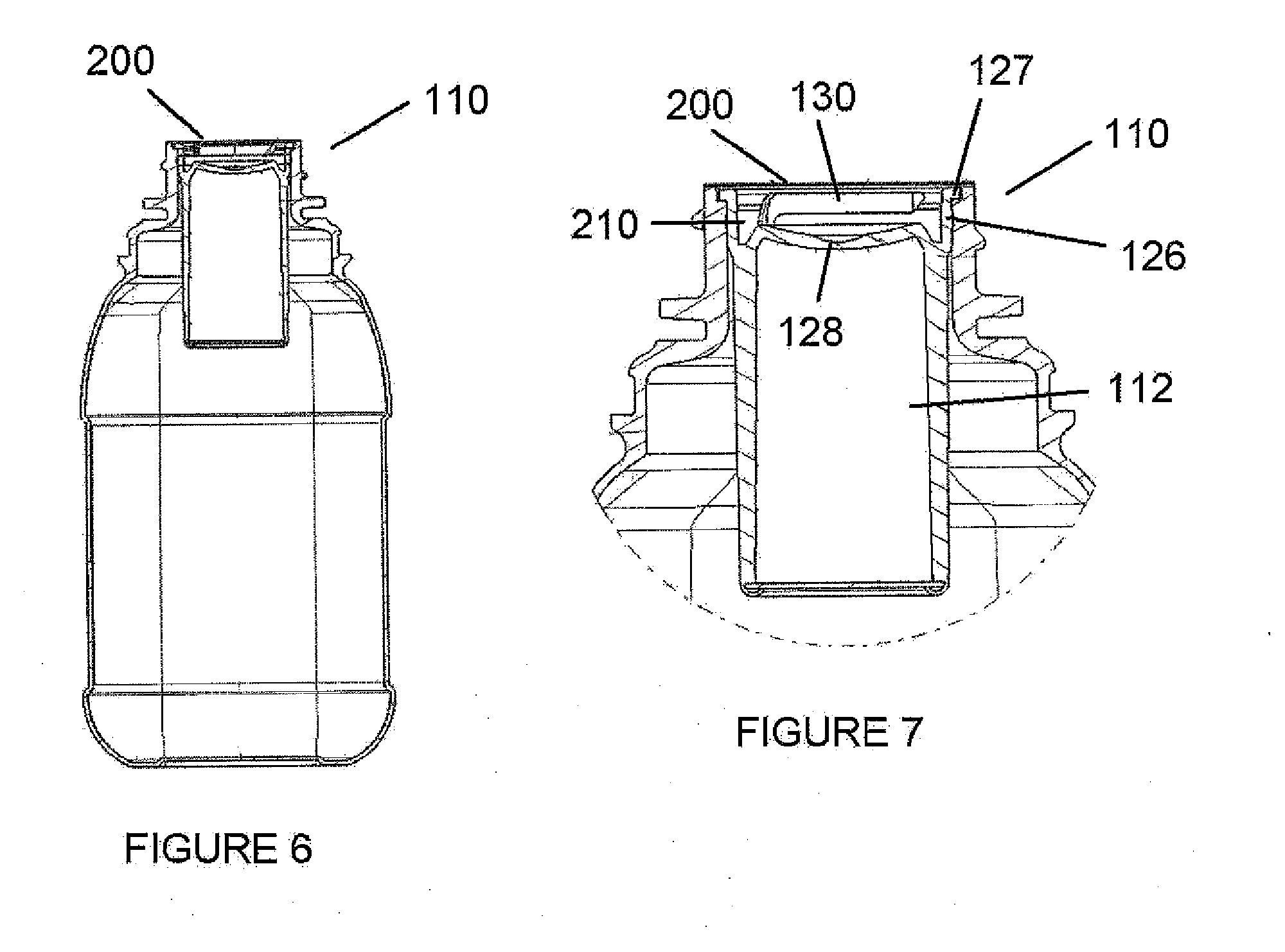

Induction sealing device and corresponding method for producing packages of pourable food product.

ActiveCN1767937AEliminate shortcomingsMultiple-port networksDiscontinuous tuning by electric meansCapacitancePlastic materials

An induction sealing device that can be used to produce packaging for pourable foods. For this purpose, a tube of sheet packaging material (13) is transversely sealed. The packaging material includes at least one layer (12) of an induction-heatable material. The induction-heatable material is The heated material is covered by plastic material (16). The sealing device has: a generator (3) for generating an alternating power signal S(ω); an inductor (4) for receiving the alternating power signal S(ω) so as to transmit the signal to the layer (12). ) induces parasitic currents in the plastic material (16) and locally melts the plastic material (16) to form a transverse seal; and a matching circuit (7) for optimal power between the generator (3) and the inductor (4) transmission. The matching circuit (7) includes an inductive-capacitive circuit in which the capacitance of the capacitive elements (20, 24, 25, 26, 27) with variable capacitance is adjustable, so that the current-voltage phase angle can be brought close to zero.

Owner:TETRA LAVAL HLDG & FINANCE SA

Synthetic two piece induction seal products

A two-piece induction seal for use in creating clean, safe, and secure inner seals on containers having a monolayer plastic formed from synthetic fibers with stable pore dimensions for fluid permeability while retaining dimensional stability for compression. An inductive innerseal membrane is provided having a first side and a second side thereof, with an adhesive layer at the first side of the membrane. The second side of the membrane is detachably bound to the synthetic material with a wax layer. The synthetic material is further suitable for absorbing substantially all of said wax layer when said wax layer is in liquid form.

Owner:SELIG SEALING PROD INC

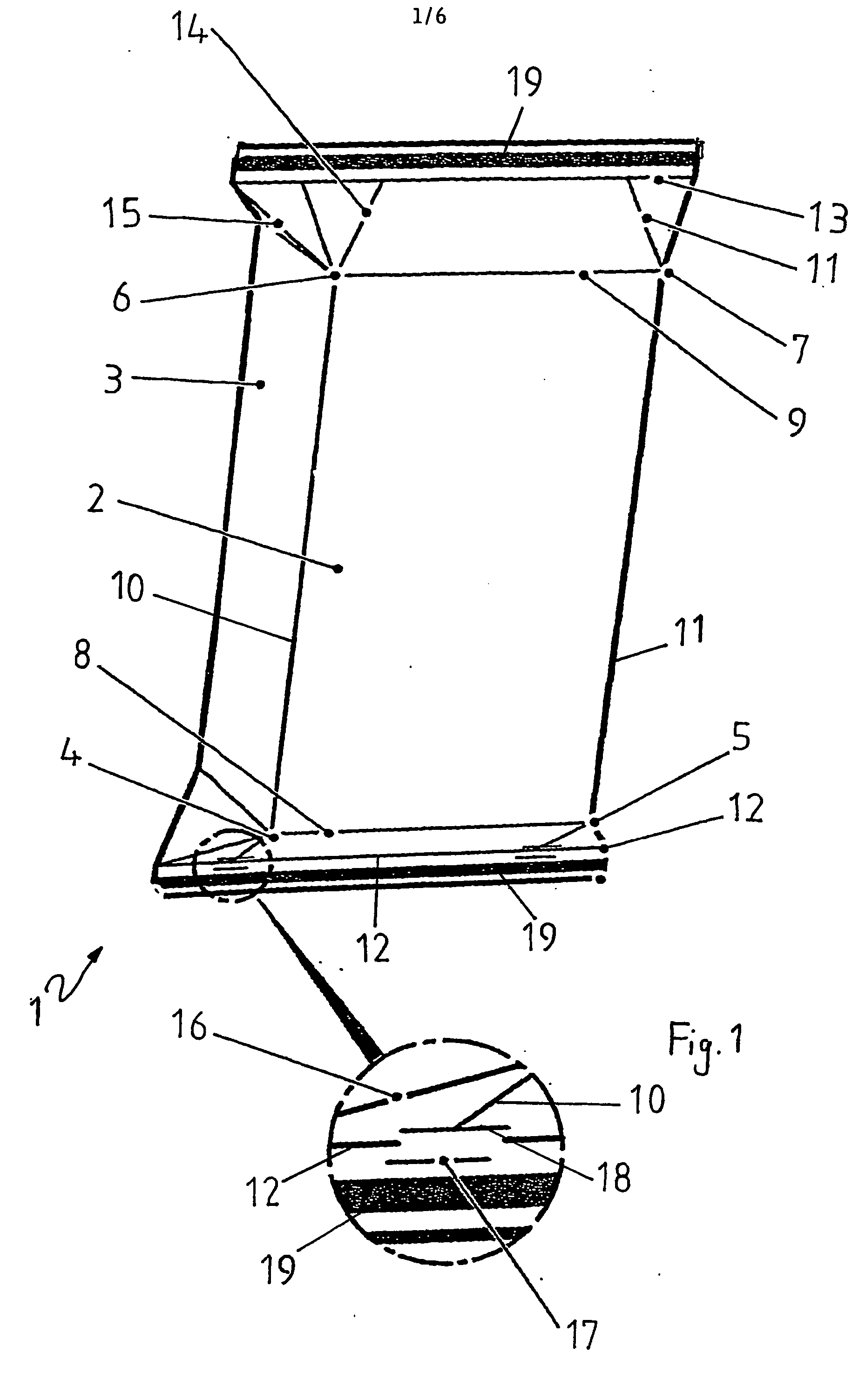

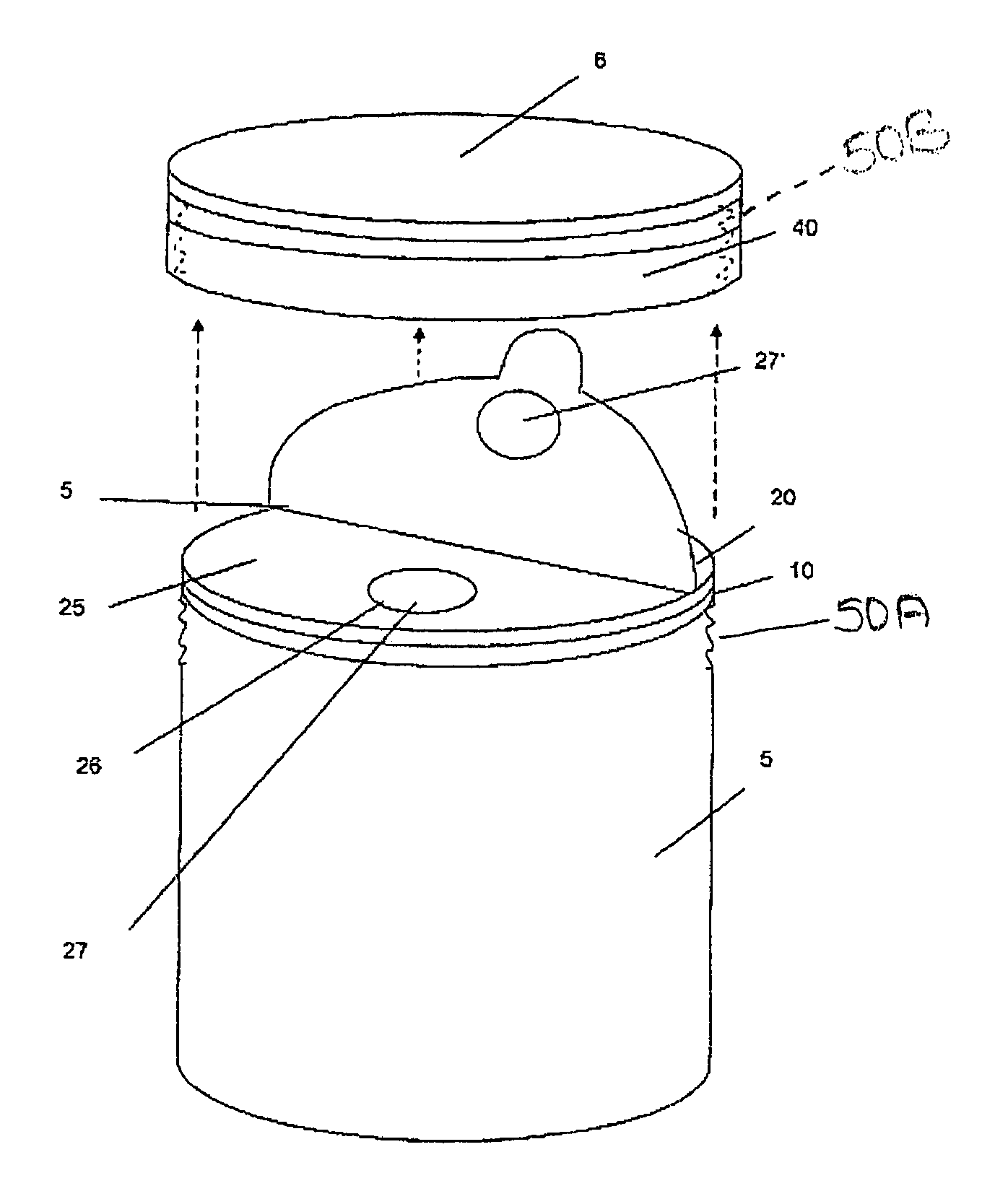

Sealing disk for induction sealing a container

A sealing disc (10) is used for closing orifices of containers (5). It has a film (20) for inductively coupling heat into the sealing disc (10). A sealing layer (25) is provided on that side of the film (20) which is intended to face the interior of the container (5) in order to seal, in sealtight fashion, the sealing disc (10) on the orifice of the container (5). Lines of weakness (26) are provided in the sealing layer (25) so as to form a removal opening (27) once the film (20) has been drawn off. One or more layers (40), which are connected detachably to the film (20), are provided on that side of the film (20) which is remote from the sealing layer (25). The layers (40) detach mare easily from the lam (20) than the sealing layer (25) and also detach more easily from the orifice of the container (5) than the sealing layer (25). The layers (40) are formed such that said layers tightly close the removal opening (27) once the film (20) has been drawn off and the layers (40) have been placed onto the sealing layer (25) again.

Owner:ALFELDER KUNSTWERKE HERM MEYER

Induction sealing device and method for manufacturing an induction sealing device

ActiveUS20160221250A1Extended service lifeExcessive wearWrapper twisting/gatheringPackaging protectionInductorAlloy

The present invention relates to an induction sealing device for heat sealing packaging material for producing sealed packages. The present invention also relates to a method of manufacturing such an induction sealing device. The device comprises at least one inductor made of an alloy comprising silver and copper.

Owner:TETRA LAVAL HLDG & FINANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com