Induction sealing device and corresponding method for producing packages of pourable food product.

A technology for sealing equipment and food, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as reducing power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

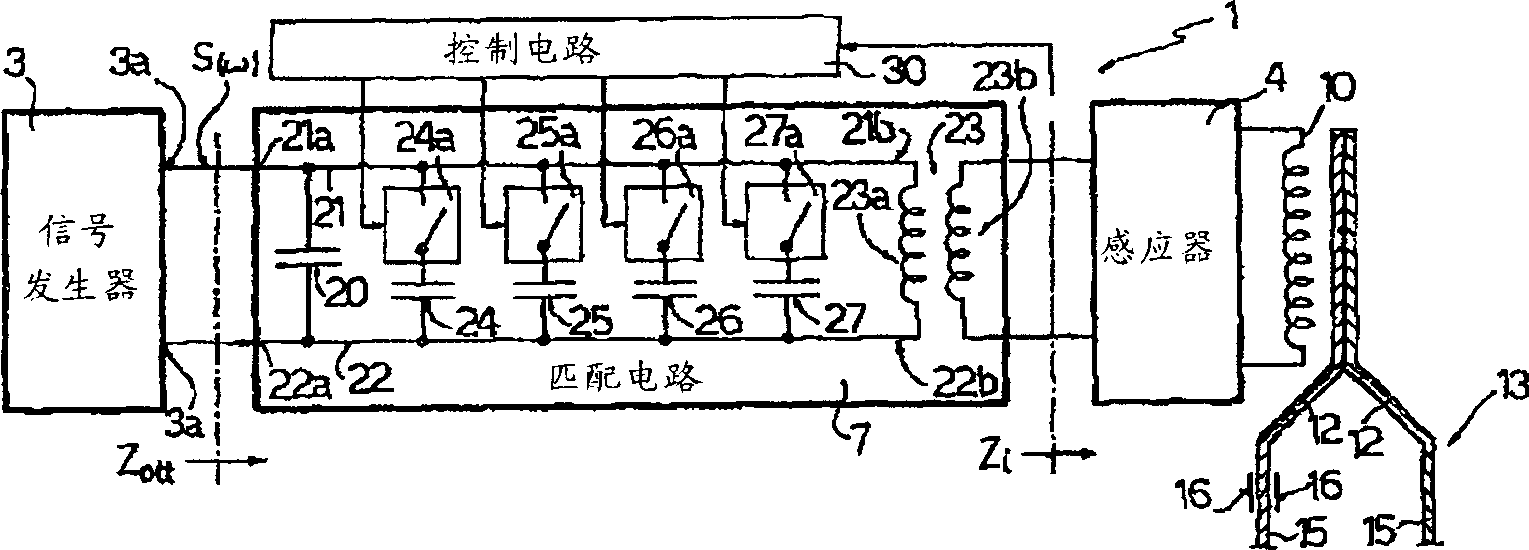

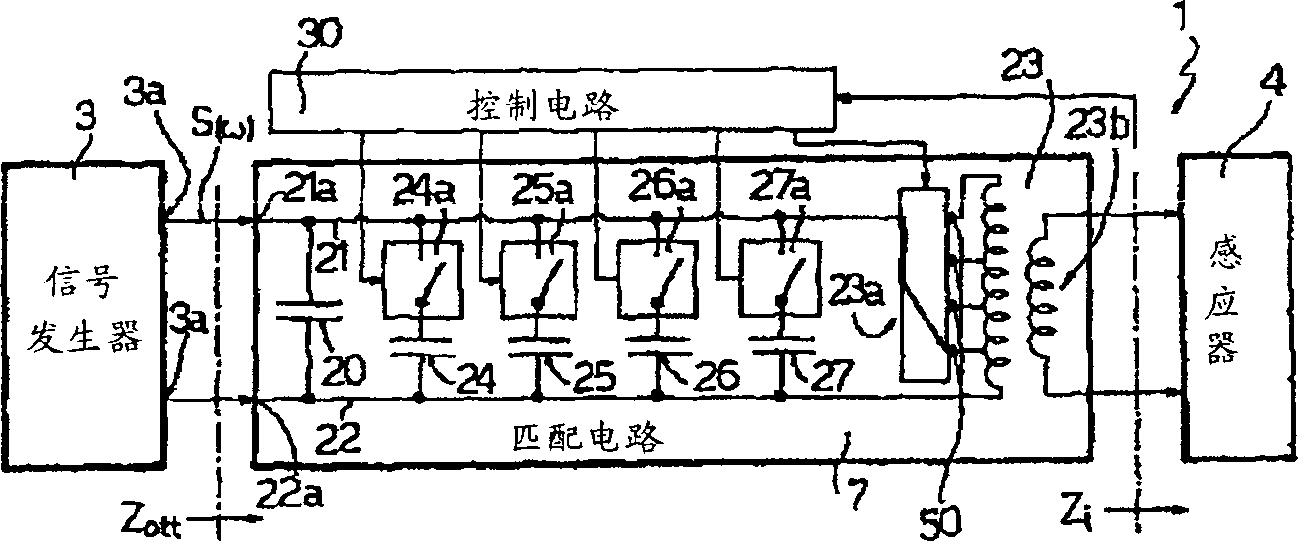

[0022] figure 1 Reference numeral 1 in represents an integral part of the induction sealing apparatus for producing a pourable food product package.

[0023] More specifically, the sealing device 1 includes: a generator 3 for generating an alternating power signal S(ω); an inductor 4 for receiving the alternating power signal S(ω); and a matching circuit 7 for To optimize the power transfer between generator 3 and inductor 4.

[0024] More specifically, the generator 3 can produce a variable voltage (such as a sinusoidal) signal of an intermediate frequency (such as 530 kilohertz) in a conventional manner, and its peak voltage is around several hundred volts (such as 540 volts), and can generate continuous A pulsed or pulsed alternating power signal S(ω) and provides maximum power (eg 2500 watts) when the phase angle between current and voltage (both measured at the output of the generator 3) is close to zero.

[0025] The inductor 4 is defined by the winding 10 in a convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com