Geared cam expandable interbody implant and method of implanting same

a technology of interbody implants and cams, applied in the field of spinal implants, can solve problems such as lack of reliable ability for fine adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

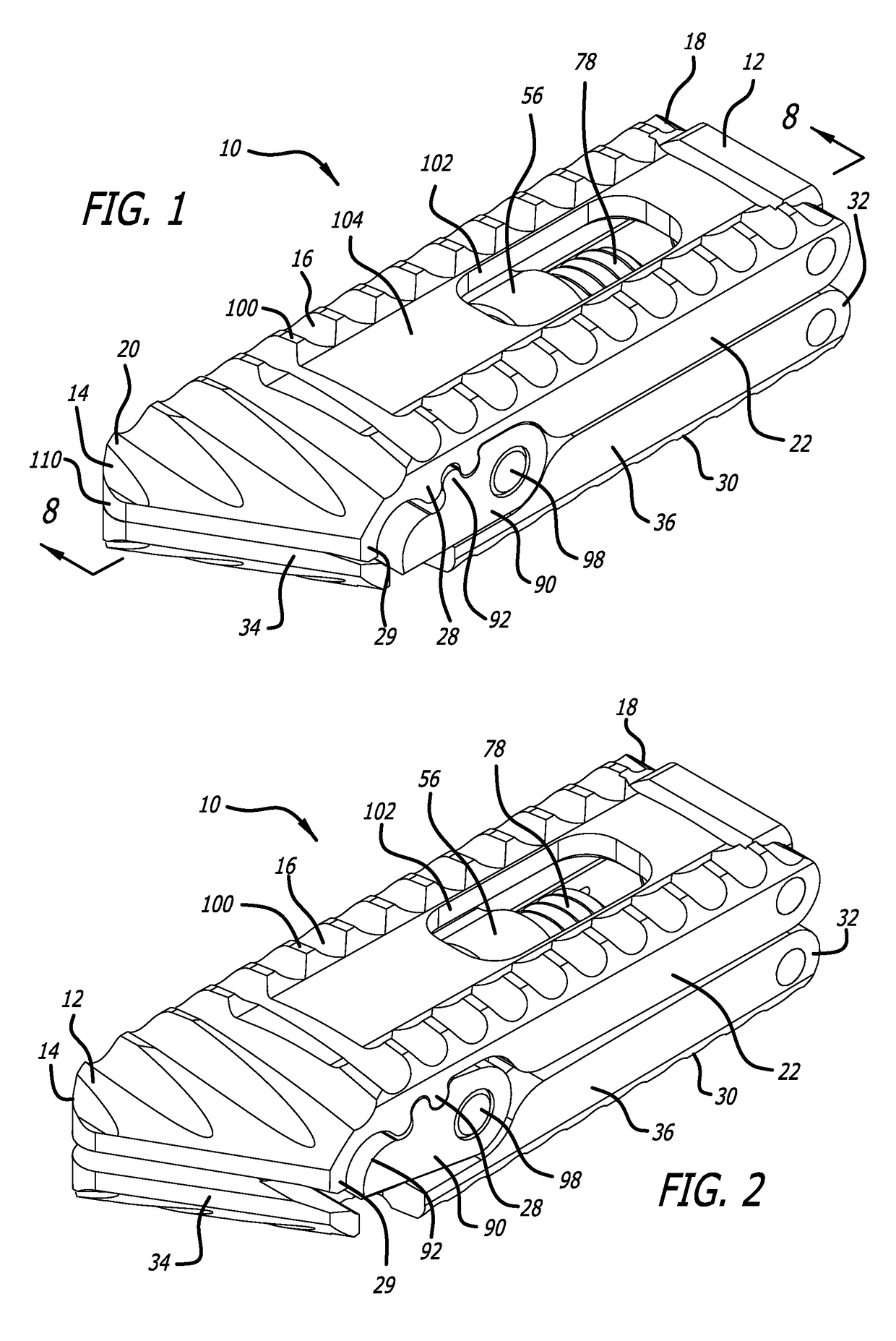

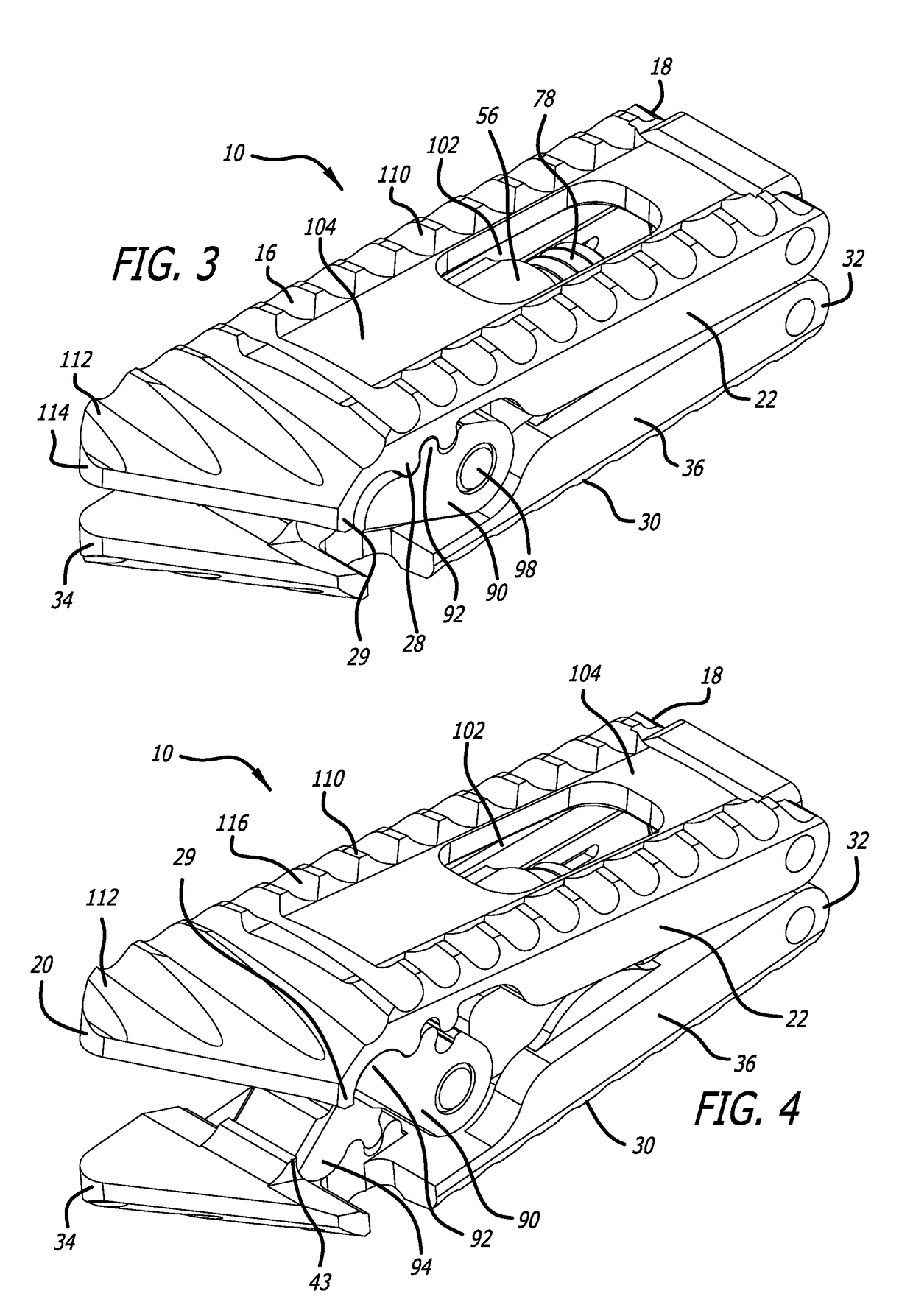

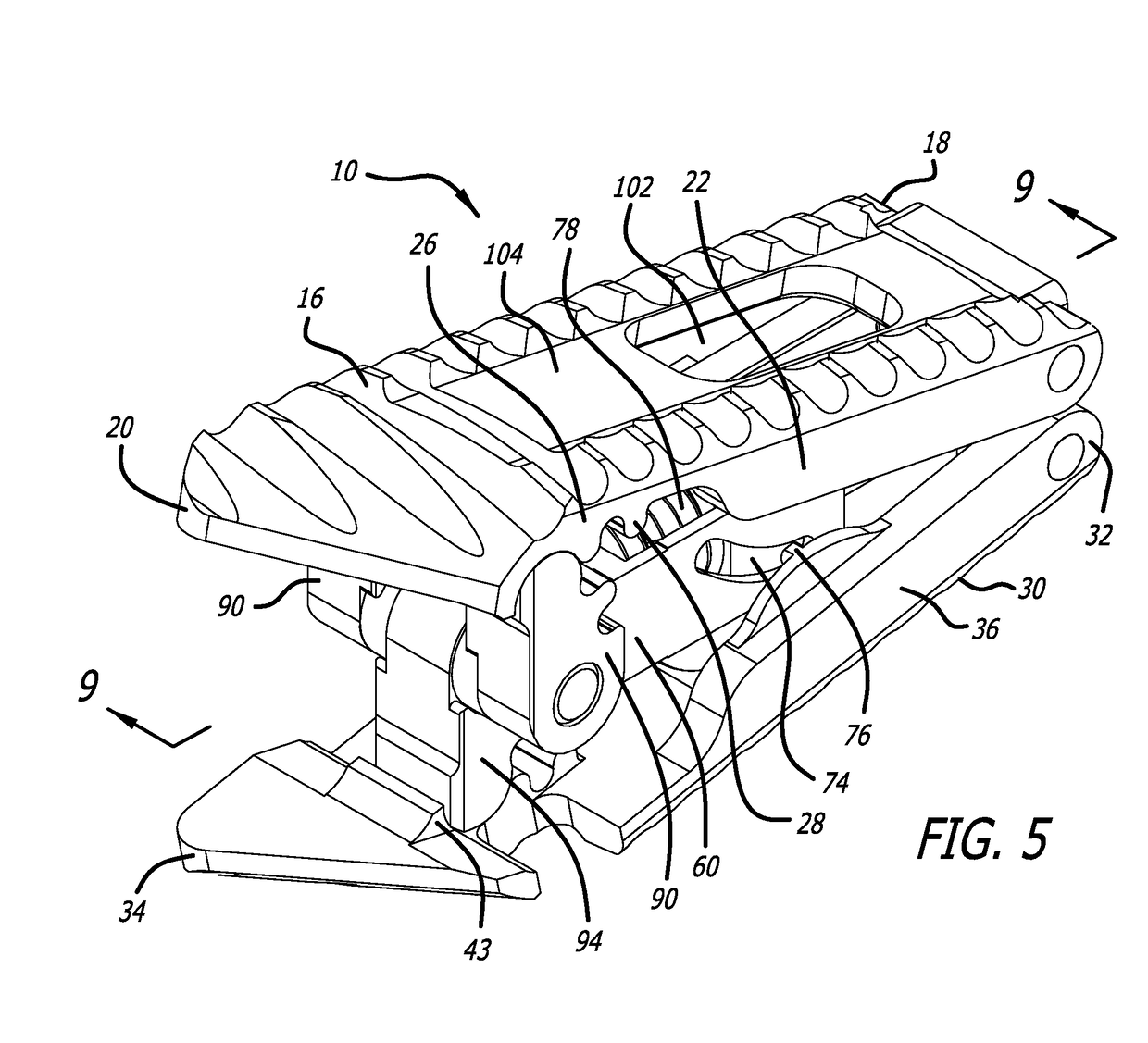

[0053]A geared cam expandable spinal implant 10 is configured to be inserted in a surgically-enhanced disc space between an upper vertebral body and an adjacent lower vertebral body. The implant 10 includes a proximal end 12 and a distal end 14, defining a mid-longitudinal axis L-L therebetween.

[0054]In one embodiment, the implant 10 includes an upper endplate 16. As depicted in FIGS. 6, 8, and 9, the upper endplate 16 includes a proximal end 18, a distal end 20, side surfaces 22, and an inner surface 24. The inner surface 24 includes an upper rack portion 26, which includes downwardly-projecting teeth 28, and a distal-most downwardly-projecting tooth 29.

[0055]In one embodiment, the implant 10 includes a lower endplate 30. The lower endplate 30 includes a proximal end 32, a distal end 34, side surfaces 36, and an inner surface 38. The inner surface 38 includes a lower rack portion 40, which includes upwardly-projecting teeth 42, and a distal-most upwardly-projecting tooth 43.

[0056]I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com