Induction sealing of inorganic substrates

A matrix, inorganic technology, applied in the field of sealing design, can solve the problem of glass losing toughness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

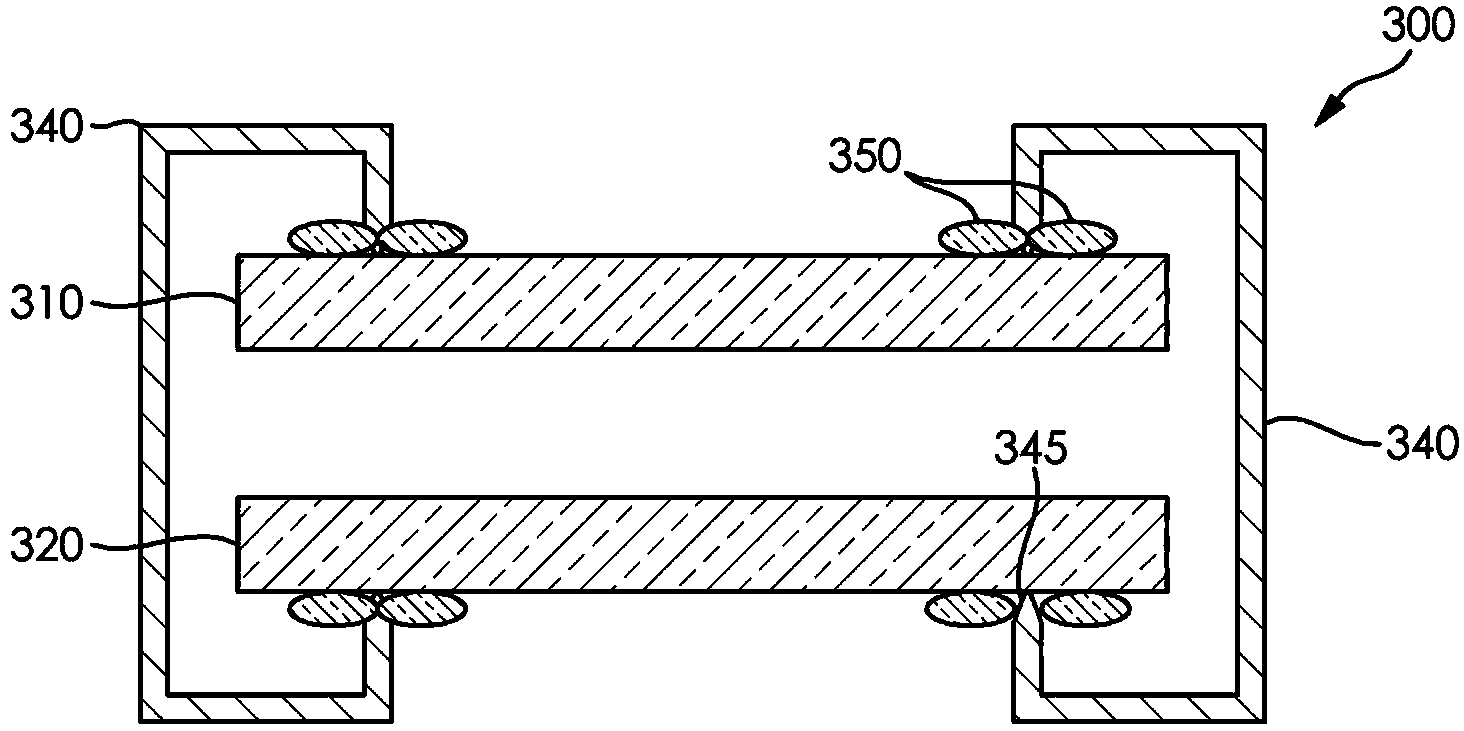

[0025] In most selective sealing methods, localized heating occurs due to the presence of suitable absorbers or couplants in the sealing material, or due to preferential absorption of intentional electromagnetic waves, or due to selective induction of eddy current sealing in the vicinity of the seal. This results in selective heating of the seal. The control of various aspects of this selective sealing, such as: the amount and location of absorption and heat generation; control of heat dissipation through materials and sealing design to minimize the occurrence of thermal gradients or thermal shock, especially the selective sealing method of induction sealing, They are also another aspect of the invention.

[0026] The present invention involves the control of the amount of induced eddy current, where this energy is deposited, and the rate at which this energy is deposited, so that a high quality seal is formed where ruptures due to thermal shock or thermal expansion mismatch t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com