Guide plate molding machining device and using method thereof

A guide plate and processing device technology, which is applied to manufacturing tools, casting and forming equipment, metal processing equipment, etc., can solve the problems of insufficient product machining allowance, consumption of cutting nozzles, shrinking working surface, etc., so as to reduce the cost of auxiliary materials and labor. , The effect of improving work efficiency and sufficient machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

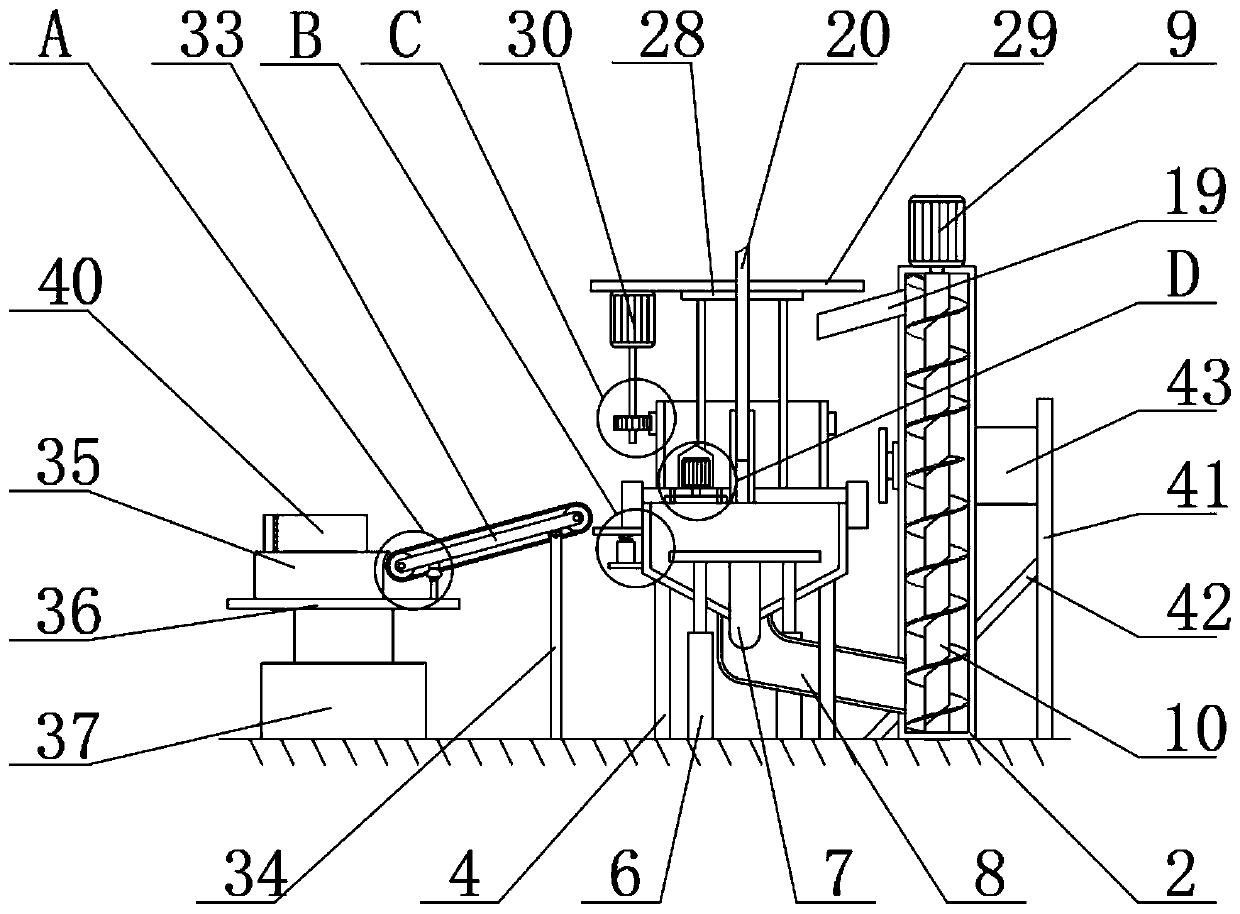

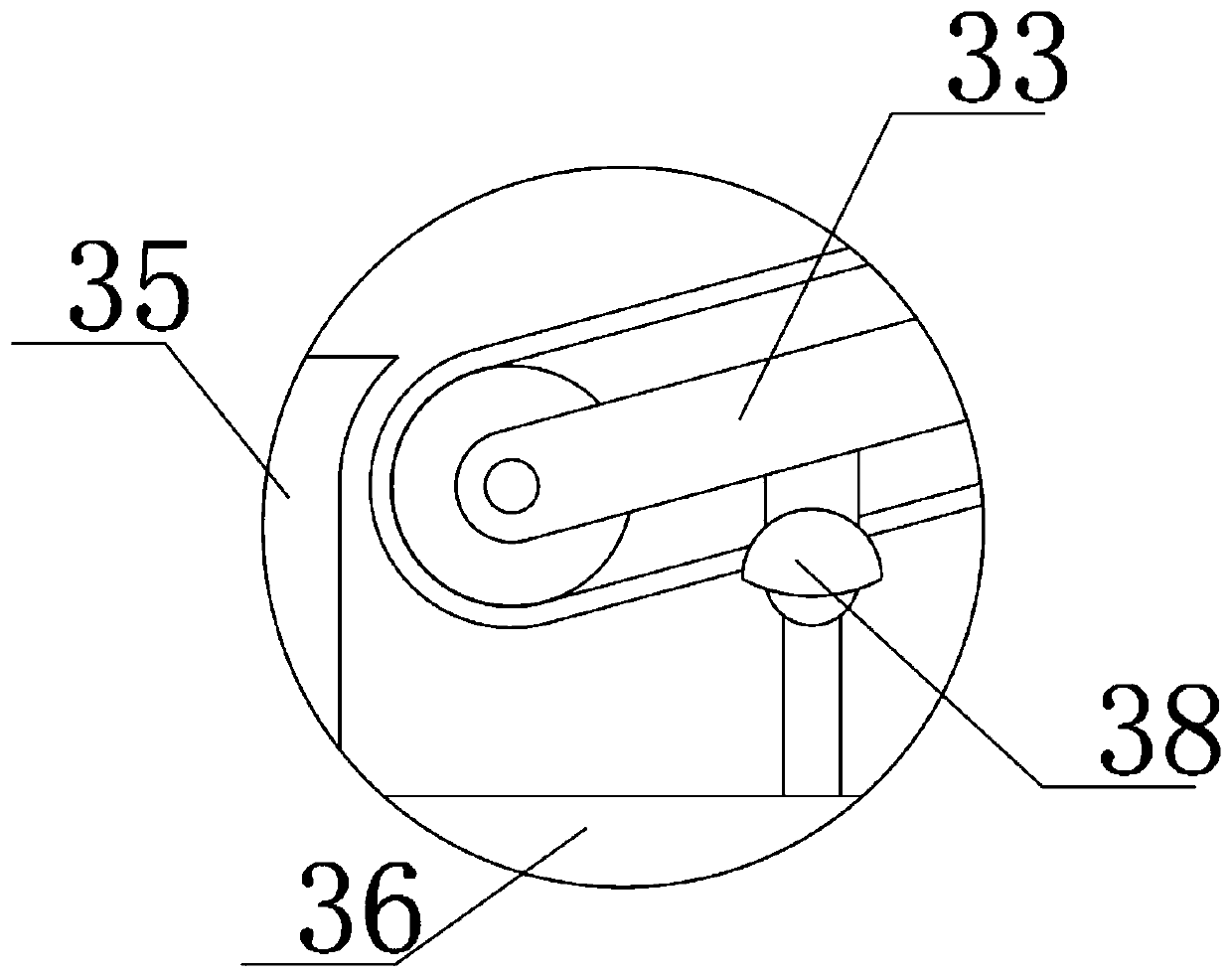

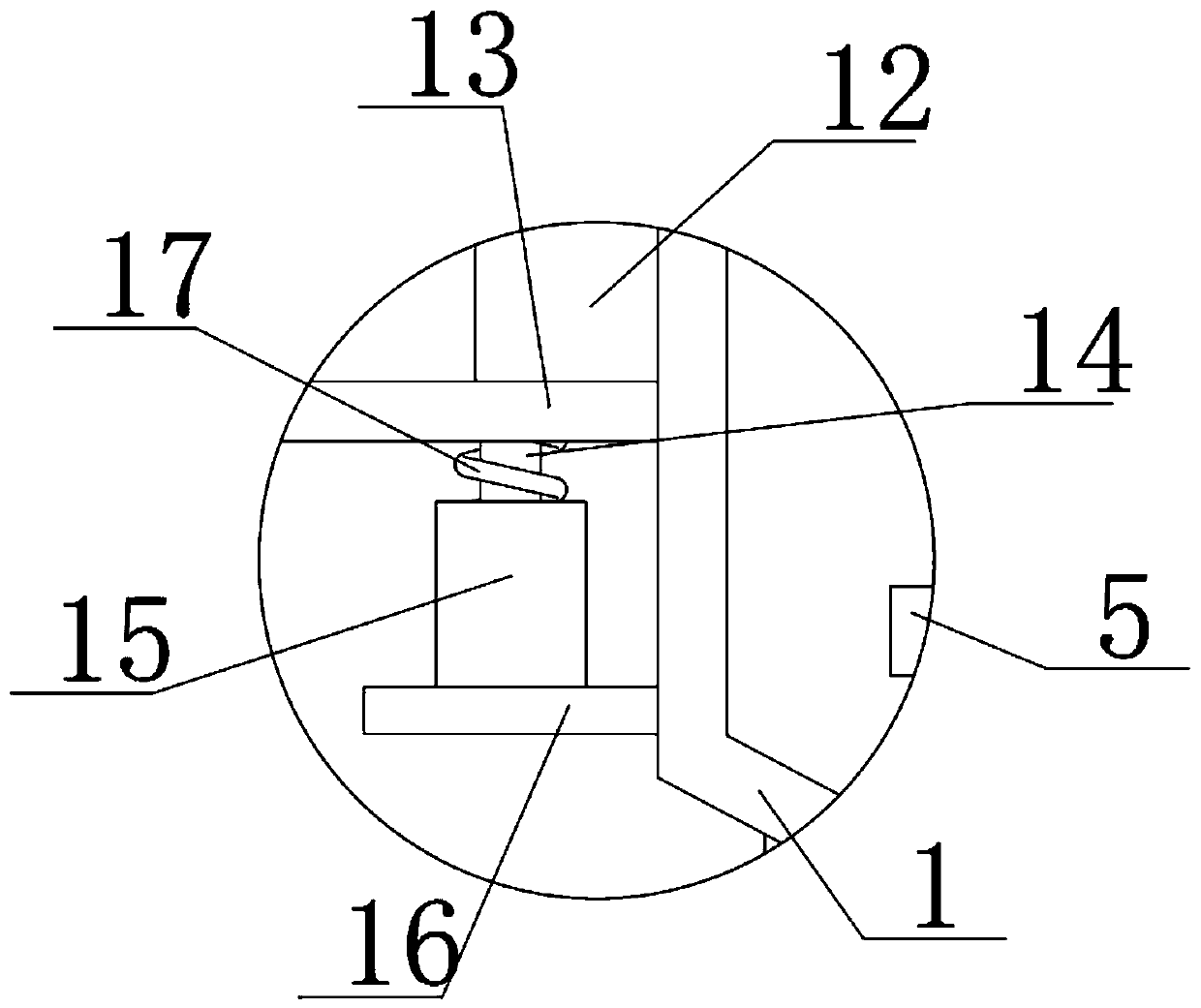

[0033] Example: see Figure 1-10 , the present invention provides a technical solution:

[0034] A guide plate molding process and its use method, comprising a forming box 1, a return cylinder 2 and a collecting plate 35, the bottom end surface of the forming box 1 is fixedly connected with a support leg 4, and the bottom end of the support leg 4 is fixed to the ground connection, the inner side of the forming box 1 is provided with a placement plate 5, the setting of the placement plate 5 is convenient for taking out the material, the bottom end surface of the placement plate 5 is fixedly connected with the first hydraulic rod 6, and the first hydraulic rod 6 It runs through the forming box 1, and the first hydraulic rod 6 is slidingly connected with the forming box 1, the bottom end surface of the first hydraulic rod 6 is fixedly connected with the ground, and the bottom end surface of the placement plate 5 is fixedly connected with a blocking block 7, so The blocking block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com