The way to form ultra -deep anti -seepage walls

A cut-off wall and ultra-deep technology, applied in sheet pile walls, sea area engineering, construction, etc., can solve the problems of increasing the difficulty of concrete pouring, prone to collapse accidents, and extremely high equipment requirements, so as to avoid major engineering quality accidents and avoid Concrete segregation and the effect of improving the quality of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

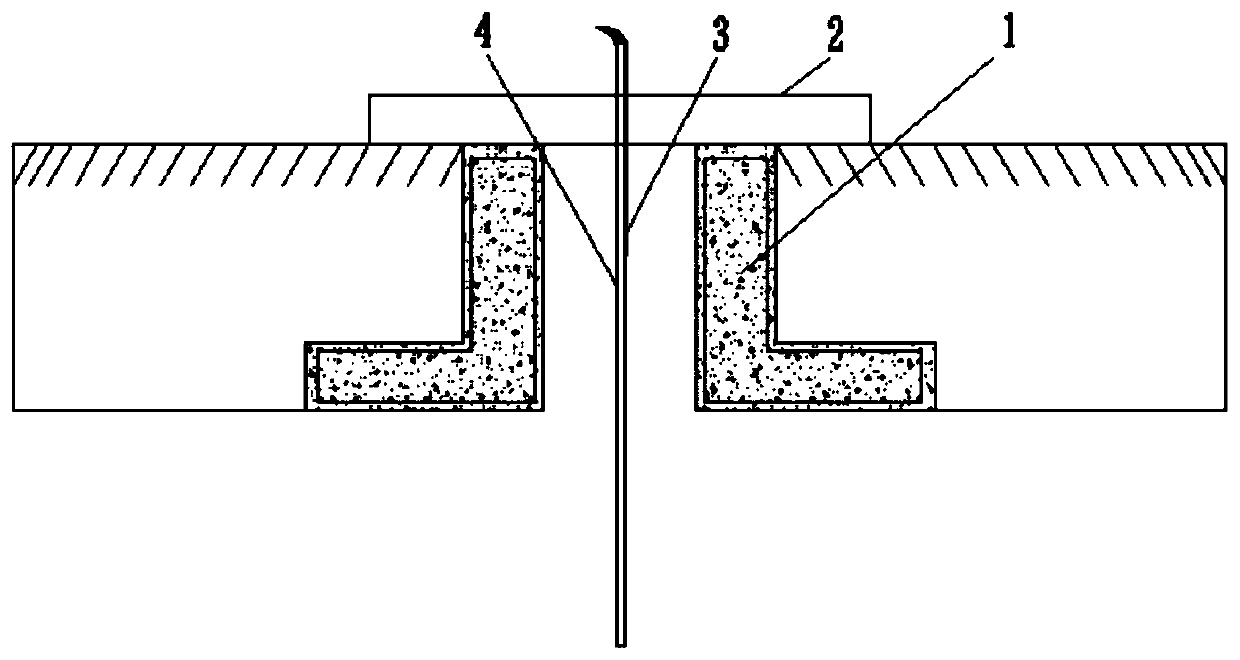

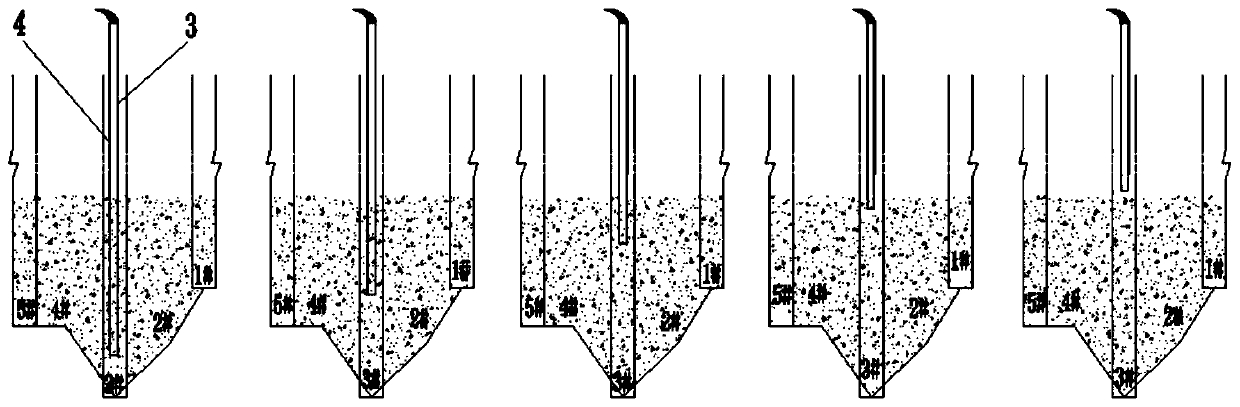

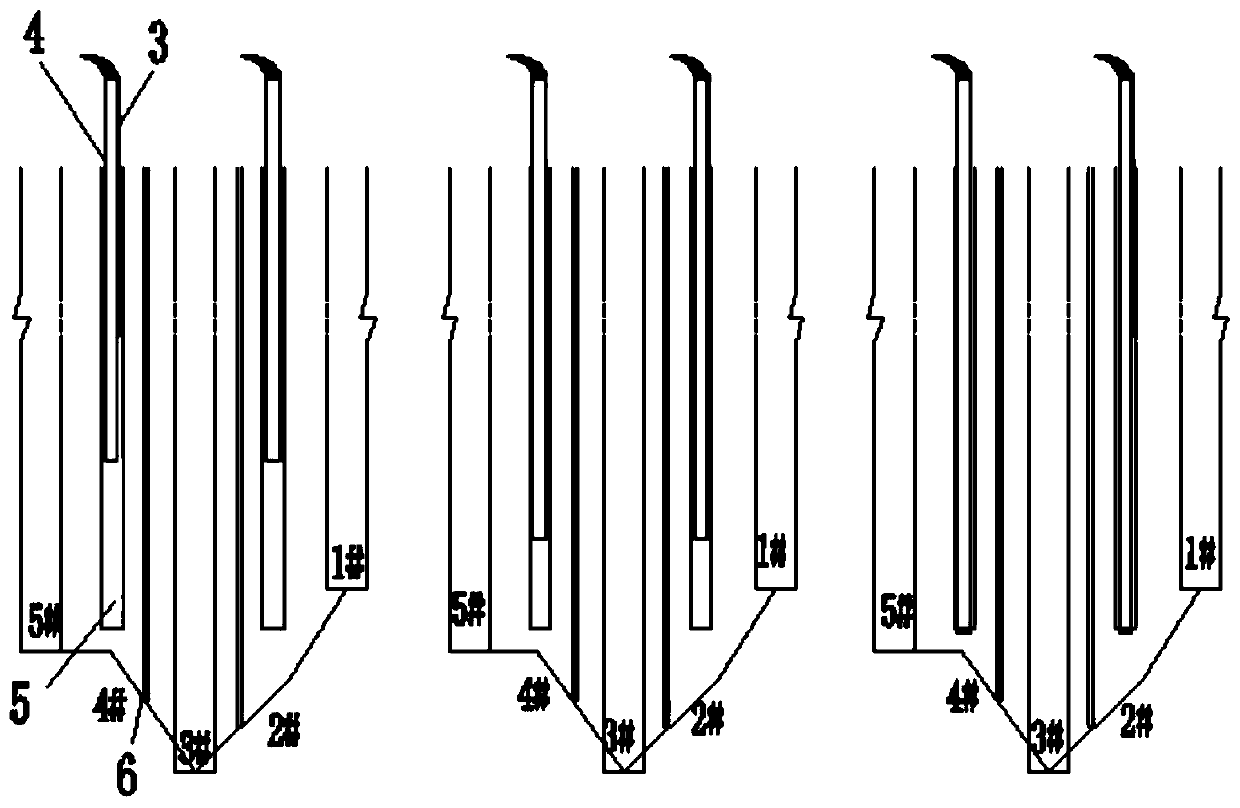

[0050] As one of the most important anti-seepage facilities in the foundation engineering of earth-rock dams, the cut-off wall plays an important role in ensuring the safety of the dam and reducing seepage in the reservoir area. No more than 100m. For projects where the depth of the hole exceeds 100m or the maximum depth of the cut-off wall exceeds 150 meters or even 180 meters, because the depth of the slot holes limits the application of existing technologies, researchers in this field urgently need to provide anti-seepage An effective solution for wall construction. Based on this, the inventor provides a kind of mixed slurry flocculation that can continuously pour concrete during the construction of ultra-deep cut-off walls, and the poured concrete will not form with the mud in the hole due to the long overall pouring time. The method of discharging the solid matter, so that the formed anti-seepage wall will not break the wall, greatly improve the quality of the anti-seepage w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com