Construction method of ultra-deep anti-seepage wall

A construction method and anti-seepage wall technology, applied in sheet pile walls, water conservancy projects, marine engineering and other directions, can solve problems such as unsmooth construction, concrete cementation layer, easy to slip drilling, etc., to avoid concrete segregation and ensure hole clearing effect. , The effect of preventing the drilling tool from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

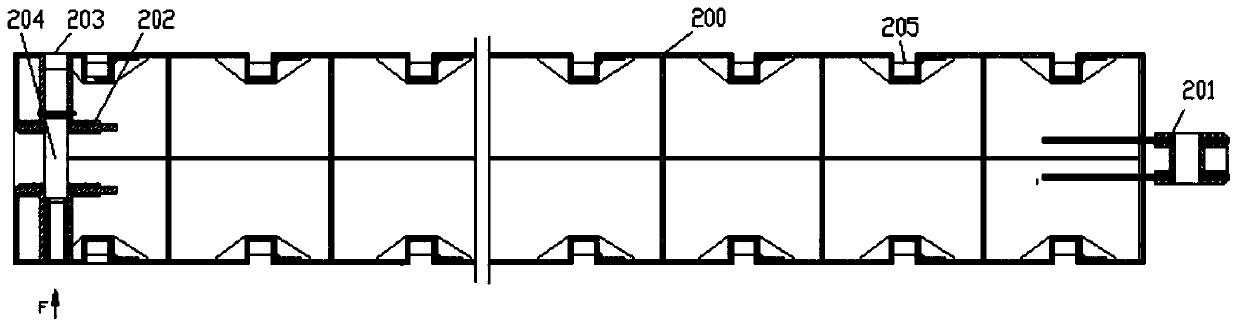

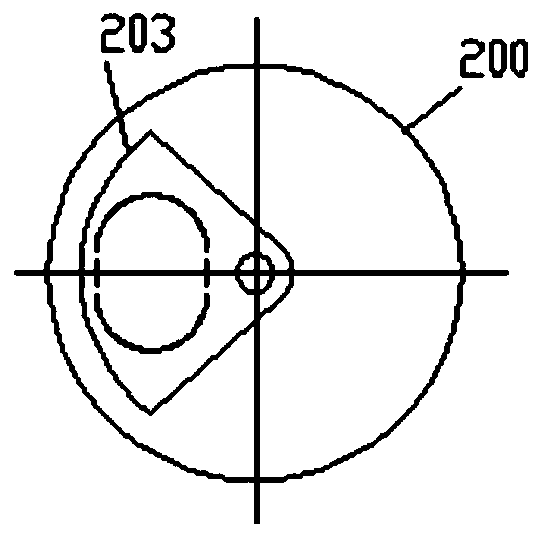

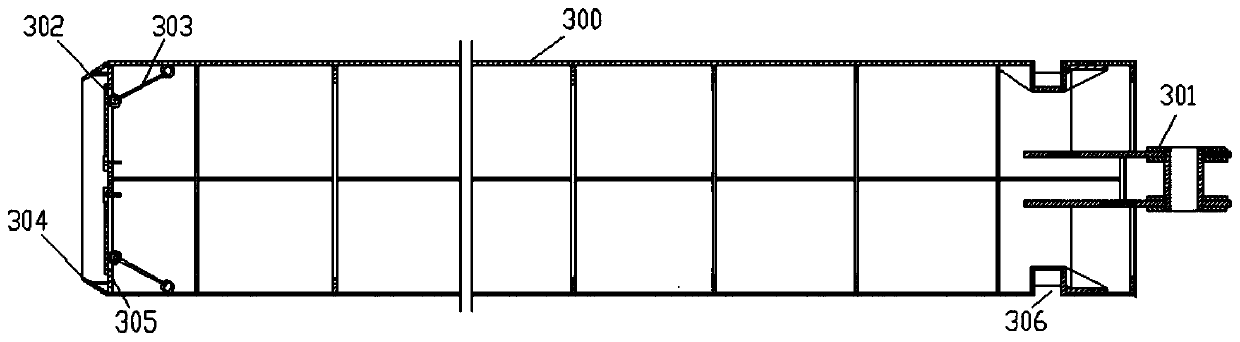

[0062] Such as Figure 21 Shown is the flowchart of the ultra-deep cut-off wall construction method of the present invention, as can be seen from the figure, it comprises:

[0063] In the process of groove-forming ultra-deep cut-off wall, if the cut-off wall needs to be embedded in the bedrock of the high and steep slope of the river bed, the slot hole shall be formed by composite blasting;

[0064] After the slots are formed, concrete is poured into the slots by the method of dynamic hole cleaning to prevent the cementation and hardening of the mixed slurry flocs formed by the sedimentation of the upper layer of concrete and the mud in the slots, so that the continuous pouring of concrete forms a continuous wall in the vertical direction;

[0065] While pouring concrete into the slot hole, prevent the poured concrete from entering the inside of the joint pipe and causing the joint pipe to be cast dead through the valve assembly of the joint pipe at the end of the slot hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com