The method of forming ultra-deep anti-seepage wall

An anti-seepage wall and ultra-deep technology, applied in sheet pile walls, marine engineering, construction, etc., can solve the problems of no effective construction of anti-seepage wall, restricting the construction period of the anti-seepage wall, affecting the quality of the anti-seepage wall, etc. Construction period, high drilling efficiency, and the effect of preventing drilling tools from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

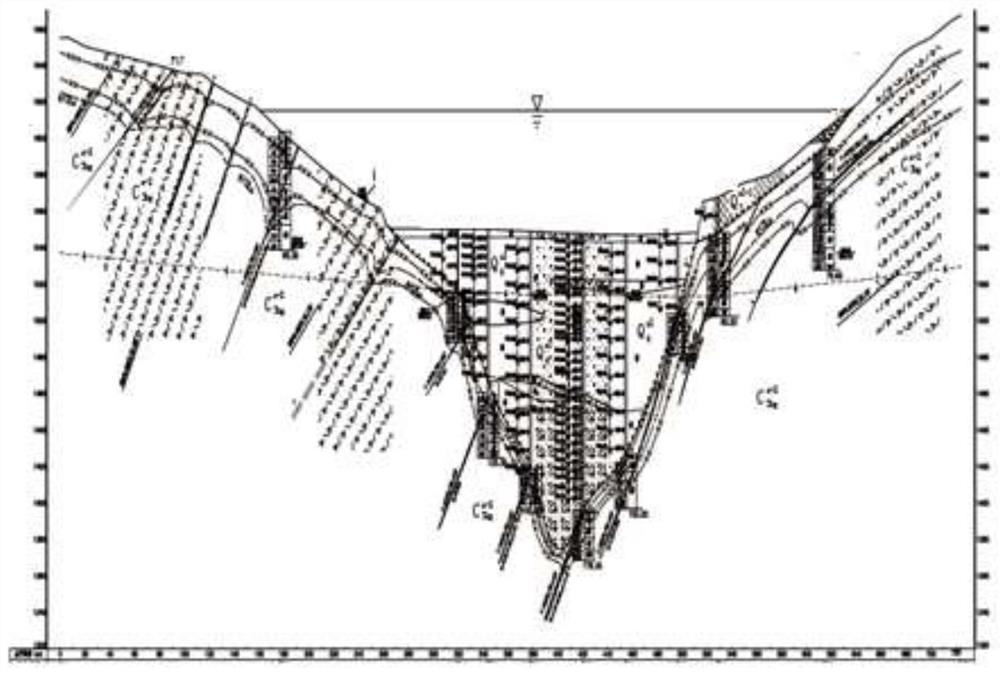

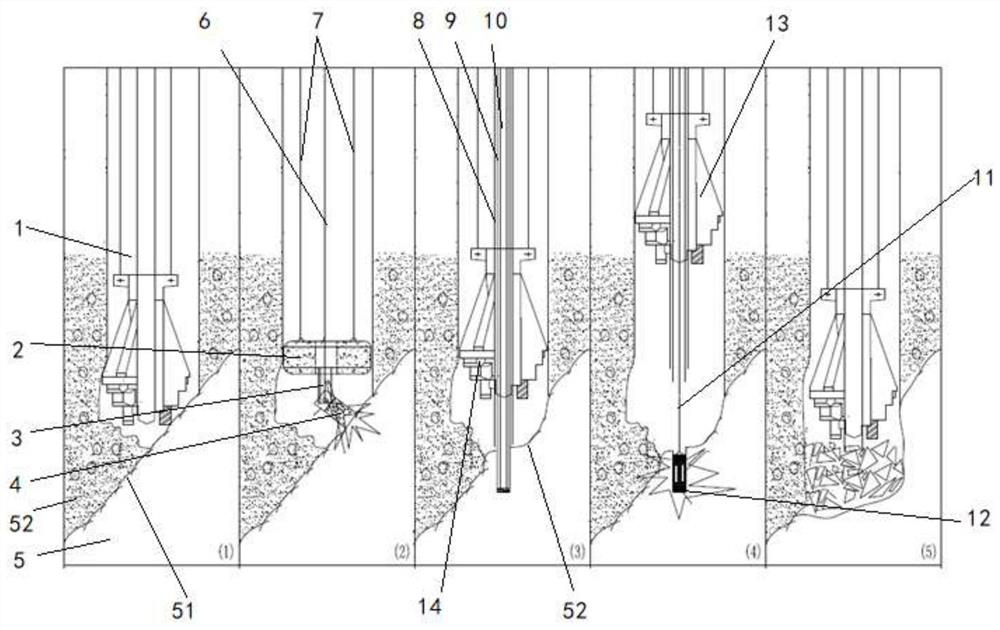

[0039] As one of the most important anti-seepage facilities in the foundation engineering of earth-rock dams, the cut-off wall plays an important role in ensuring the safety of the dam and reducing seepage in the reservoir area. No more than 100m, and the construction time is sufficient, and the construction is carried out under the condition of suitable natural environment, but under the condition of harsh construction conditions, the hole depth exceeds 150m or even the deepest depth exceeds 180m, the bedrock surface of the river bed is deep "V" shape and Projects where the slope of the bedrock surface on one or both sides of the river bed is greater than 55° (such as figure 1 As shown), there is an ultra-deep covering layer of sand and pebbles, and because the depth of the slots limits the application of the prior art, researchers in the field urgently need to provide an effective solution for the construction of the cutoff wall under the above circumstances. Based on this, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com