Method of drilling hole in PCB

A drill-through and drill technology, which is applied in the field of PCB manufacturing, can solve the problems of inability to adjust flexibly and completely solve the problems such as the pull-off and reliability of the inner layer thick copper drilling pad, so as to reduce the damage of the drill and the hole wall. The effect of good quality and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for drilling holes on a PCB, which is suitable for manufacturing a PCB with a thick copper layer at the drilling position.

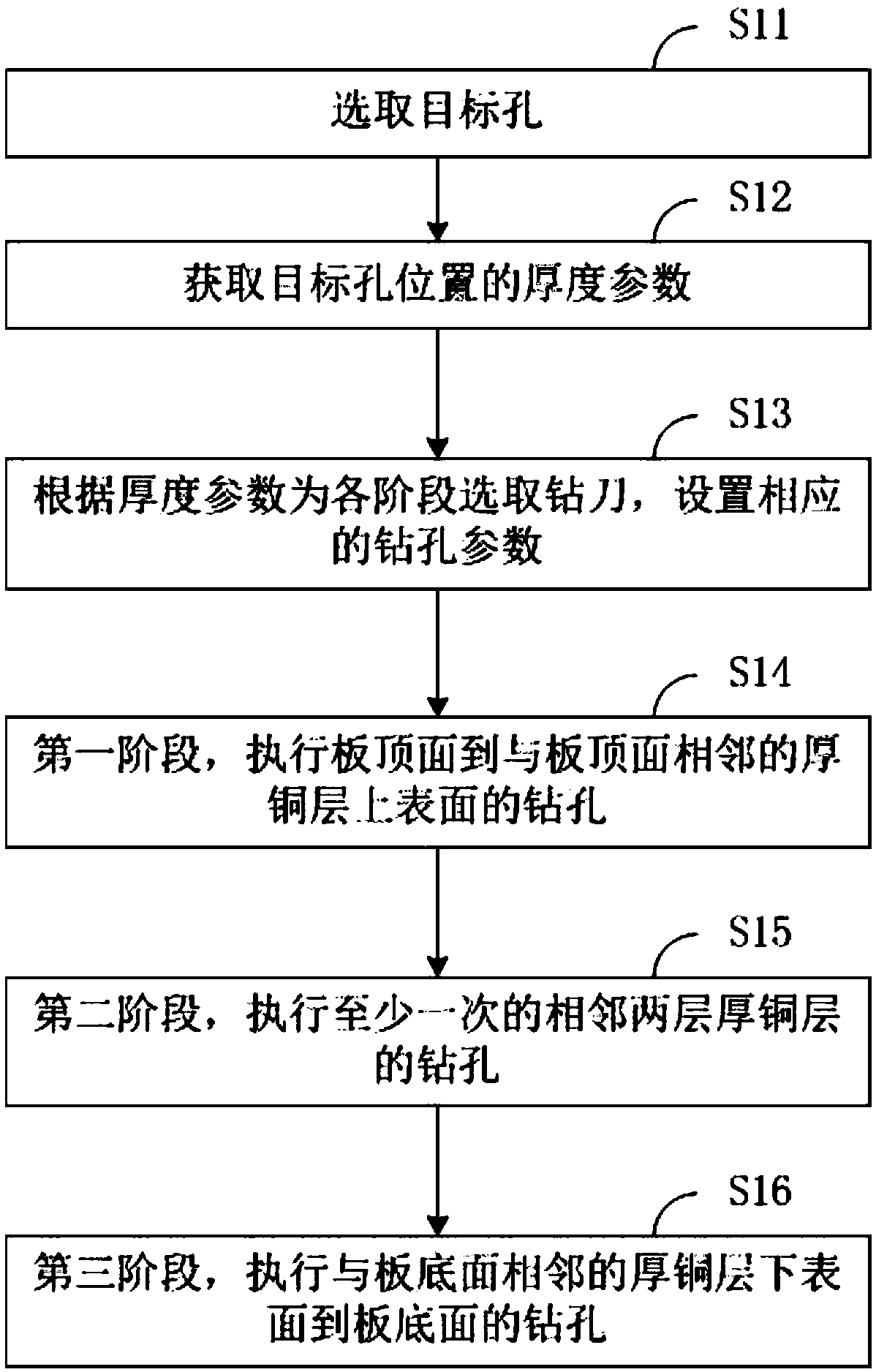

[0049] figure 1 It is a flowchart of a method for drilling holes on a PCB provided in this embodiment. Such as figure 1 As shown, the method includes the following steps:

[0050] S11, select the target hole.

[0051] The copper layer at the drilling position of the target hole includes a thick copper layer; the thick copper layer is a copper layer with a copper thickness ≥ 2OZ.

[0052] S12: Obtain the thickness parameter of the target hole position.

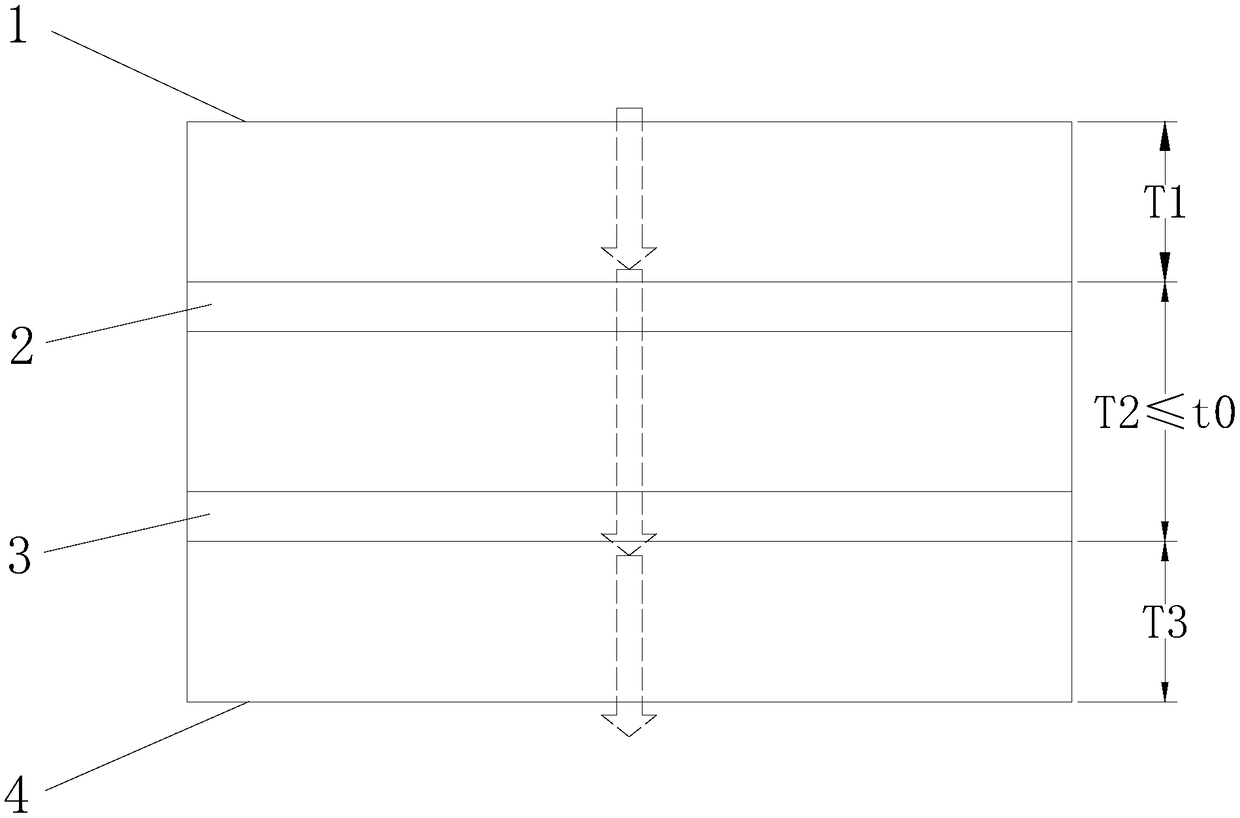

[0053] The drilling is divided into three stages. In the first stage, drilling is performed from the top surface of the board to the upper surface of the thick copper layer adjacent to the top surface of the board; in the second stage, the drilling of two adjacent thick copper layers is performed at least once. Drilling; In the third stage, drilling is performed from the l...

Embodiment 2

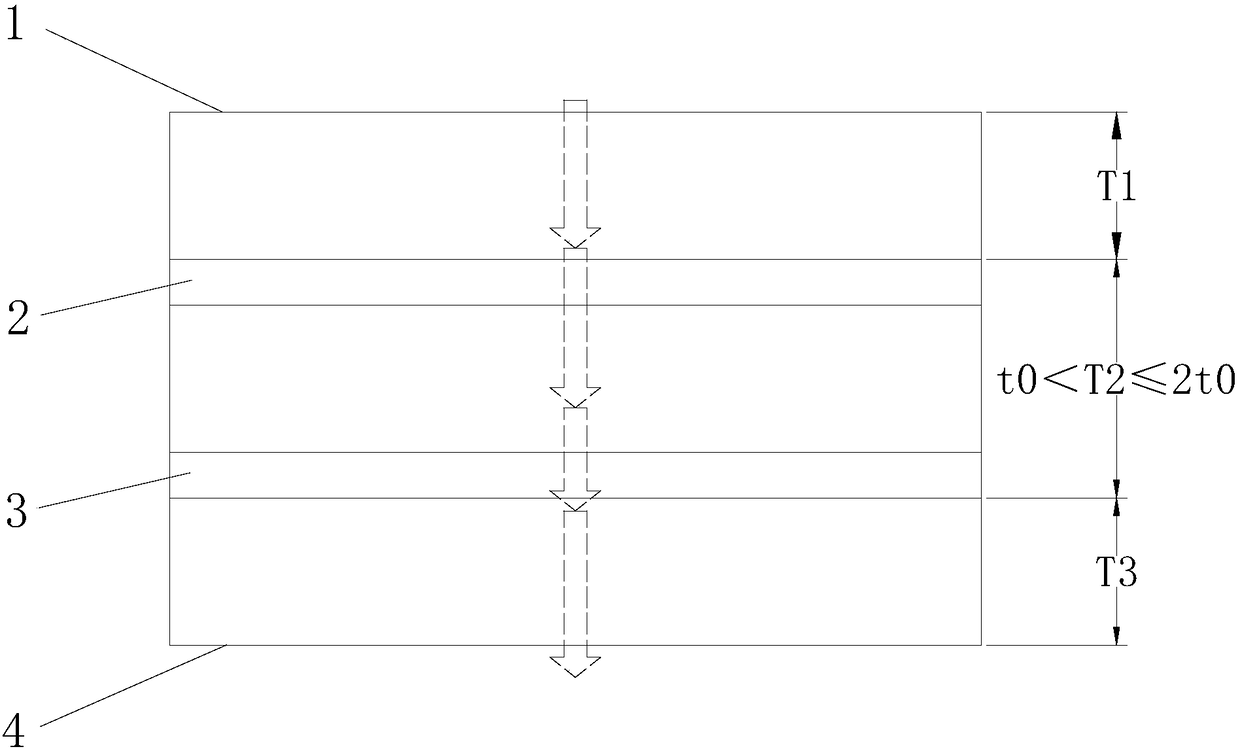

[0072] On the basis of the foregoing embodiment, this embodiment modifies the specific implementation method of step S15, and provides other drilling steps for the case of T2>2t0.

[0073] Figure 5 It is a schematic diagram of the drilling step of T2>2t0 in this embodiment. Take the PCB with 2 thick copper layers as an example, such as Figure 5 As shown, if T2>2t0, the number of cutting times is three times, which specifically includes the following steps:

[0074] Drill through the thick copper layer 2, and the drilling distance ≤ t0;

[0075] Drill to the upper surface of the lower thick copper layer 3;

[0076] Drill through the lower thick copper layer 3, the drilling distance ≤ t0.

[0077] Among them, t0 is the single maximum drilling distance through the thick copper layer, and t0≤1.5mm.

[0078] If the PCB includes multiple thick copper layers, the two adjacent thick copper layers form a group. For each group of T2, if T2>2t0, repeat the above steps. The thick copper layer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com