Vertical hole grouting type building block its construction process thereof

A construction technique and block technology, applied to building components, walls, buildings, etc., can solve problems such as inconvenient transportation and installation, high water absorption rate of foamed cement, and difficulty in quality assurance, and achieve manpower saving, simple construction, and energy saving material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

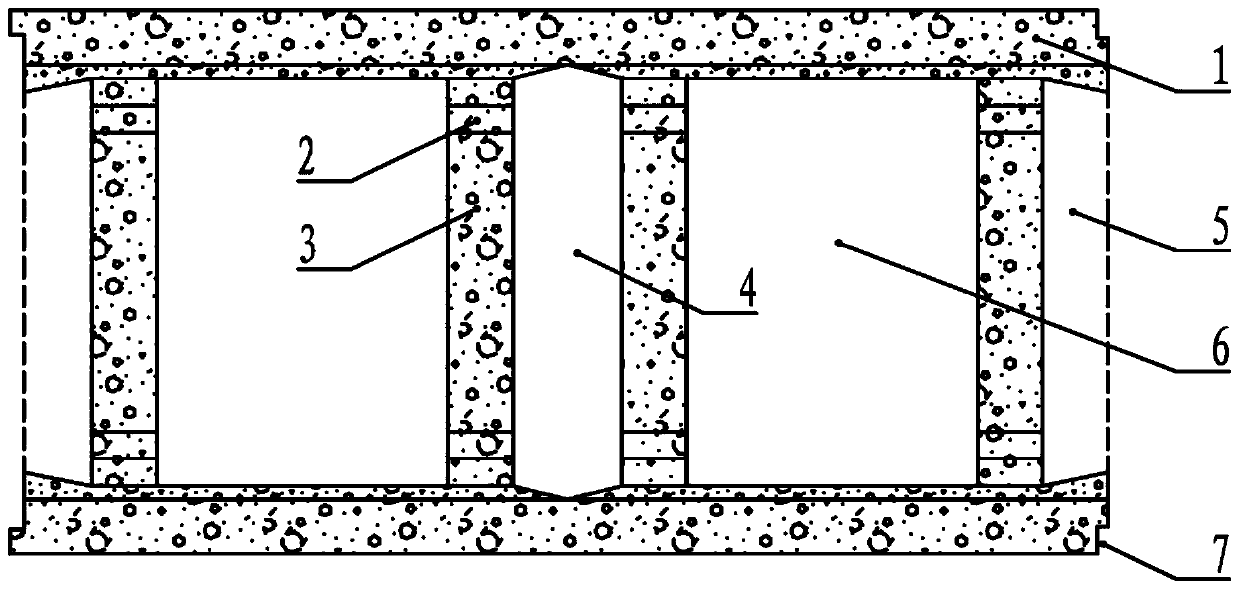

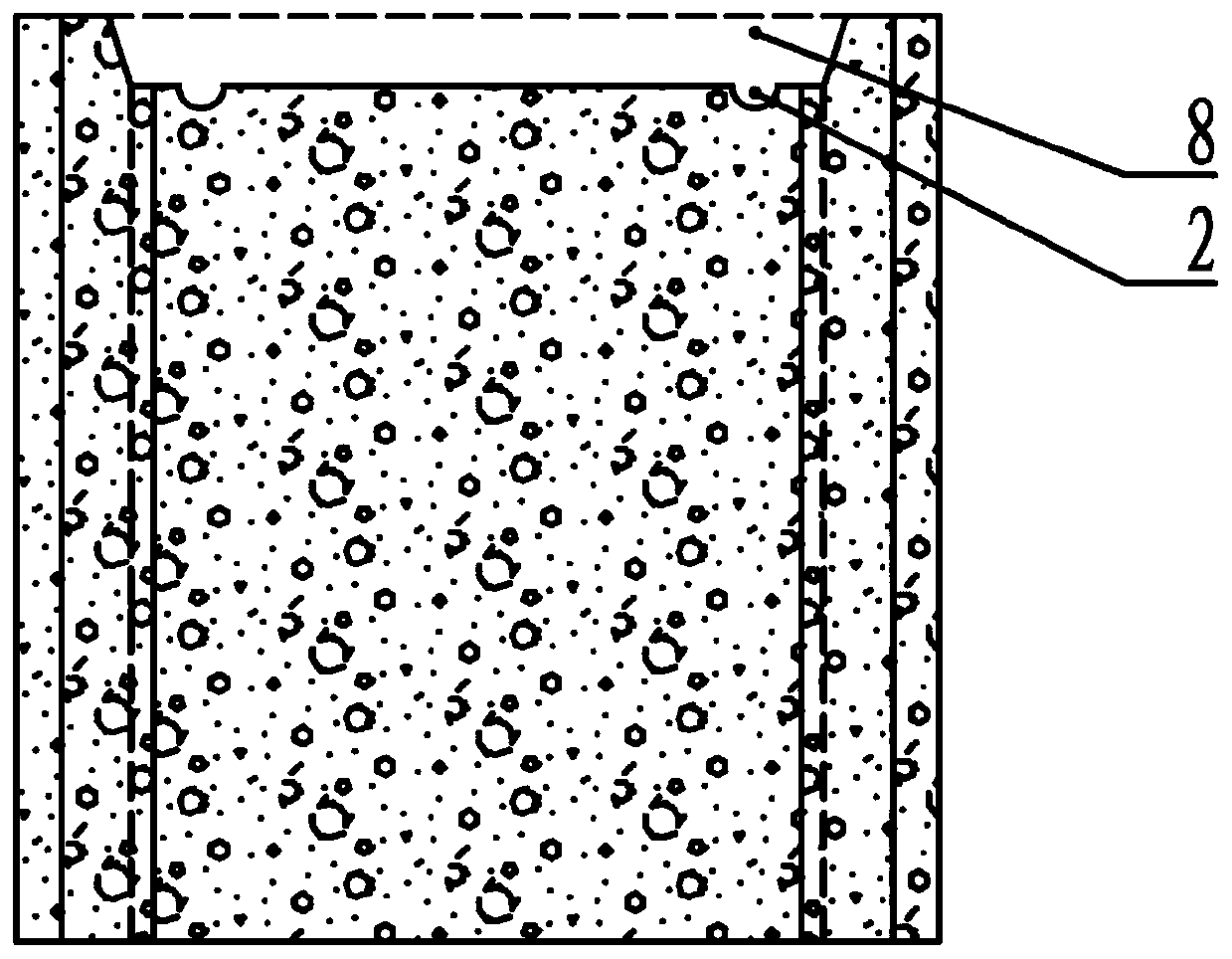

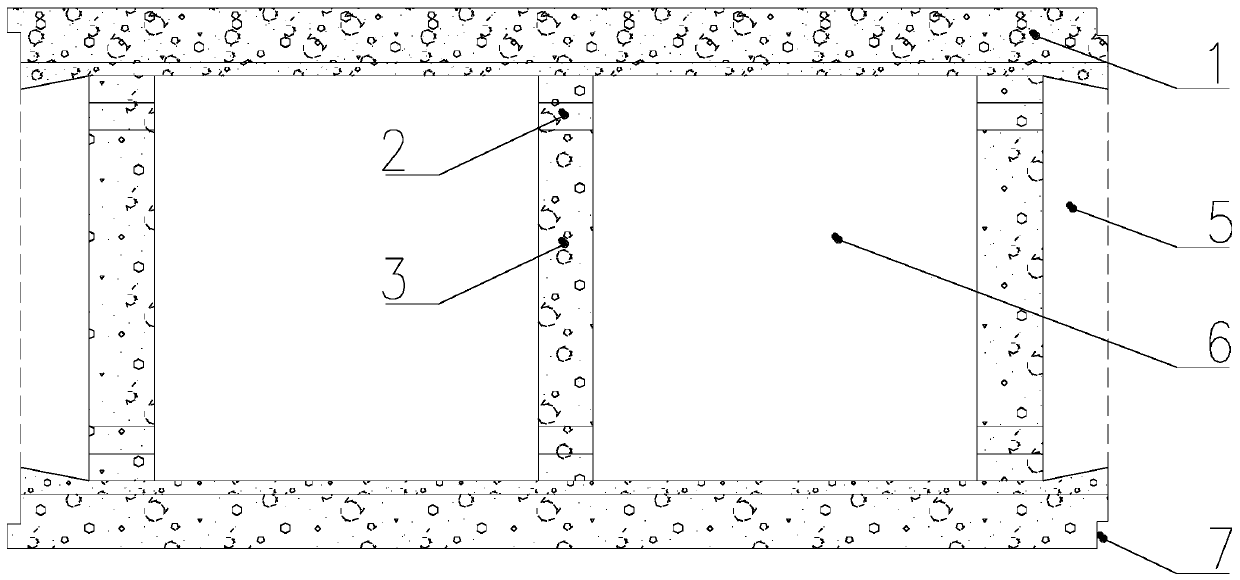

[0042] Refer to attached figure 1 , 3 , a vertical hole grouting block, the upper end of the block is provided with an upper groove 8, the left and right ends of the block are provided with end grooves 5, and the groove bottom of the upper groove 8 of the block is A groove 2 is reserved for reinforcing bars along the length direction of the block. A hole 6 is vertically penetrated in the middle of the block. The end groove 5 is a closing groove with a small mouth and a large bottom. Grouting in the internal groove 5.

[0043] Further, refer to figure 1A grouting hole 4 is provided vertically through the middle of the block, and holes 6 are arranged on both sides of the grouting hole 4 .

[0044] Further, the block includes two parallel block side plates 1, and a connecting beam 3 is arranged between the two block side plates 1, and the connecting beam 3 is connected to the block side plate 1 and the end groove 5. The cavities between the bottom plates of the trough form ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com