Thermosetting resin composition, prepreg, laminated board and printed circuit board

A resin composition, thermosetting technology, applied in the directions of printed circuits, circuit substrate materials, printed circuit components, etc., can solve the problems of deteriorating interlayer adhesion, decreased interlayer adhesion of laminates, poor dispersion of molybdenum compounds, etc. , to achieve the effect of improving the quality of the hole wall, reducing hole cracking, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] As the preparation method of the resin composition of the present invention, it can be prepared by known methods such as blending, stirring, and mixing the thermosetting resin, inorganic filler, porous molybdenum compound, curing agent and accelerator, and various additives.

[0055] The solvent in the present invention is not particularly limited, but specific examples include alcohols such as methanol, ethanol, butanol, ethyl cellosolve, butyl cellosolve, ethylene glycol-methyl ether, carbitol, butanol, etc. Carbitol and other ethers, acetone, butanone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone and other ketones, toluene, xylene, mesitylene and other aromatic hydrocarbons, ethoxy Ethyl acetate, ethyl acetate and other esters, N,N-dimethylformamide, N,N-dimethylacetamide, N-methyl-2-pyrrolidone and other nitrogen-containing solvents. The above-mentioned solvents can be used alone or in combination of two or more, preferably aromatic hydrocarbon solvent...

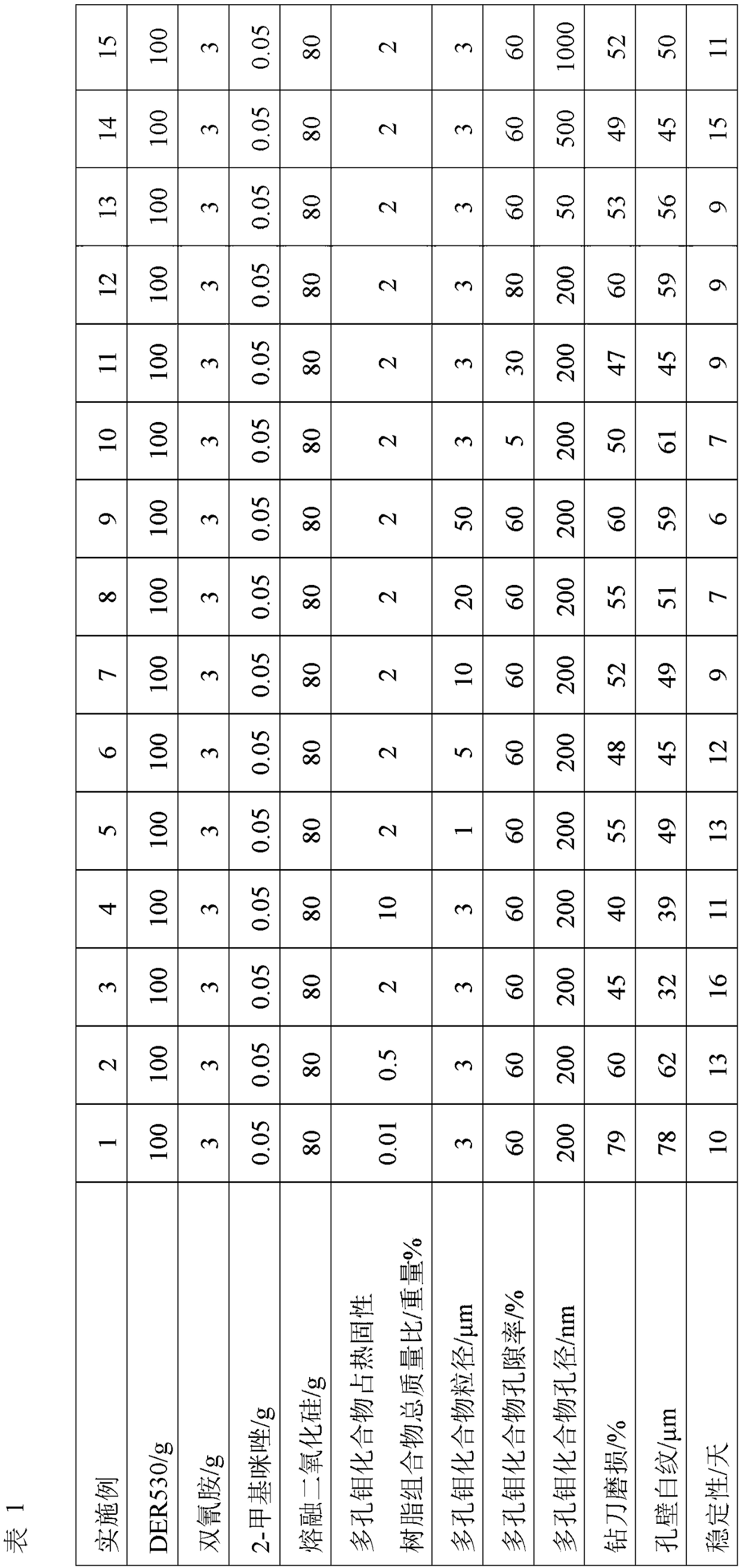

Embodiment 1-22

[0079] Brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530) (epoxy resin), dicyandiamide (curing agent), 2-methylimidazole (promoter agent), porous zinc molybdate (porous molybdenum compound) and fused silica (Singapore Sibelco, 525, average particle size 2μm) were added to methyl ethyl ketone (solvent), and mechanically stirred to prepare a 65% by weight glue , and then impregnated with glass fiber cloth (7628, Zhuhai Zhubo Electronic Materials Co., Ltd.) (reinforcement material), after heating and drying to form a prepreg (prepreg), place copper foil on both sides, pressurize and heat to make a copper-clad laminate.

[0080] The copper-clad laminates of Examples and Comparative Examples were prepared according to the following preparation process:

[0081] (1) Glue making: Add the solvent into the batching container, add epoxy resin, curing agent and accelerator respectively under stirring; after stirring for ...

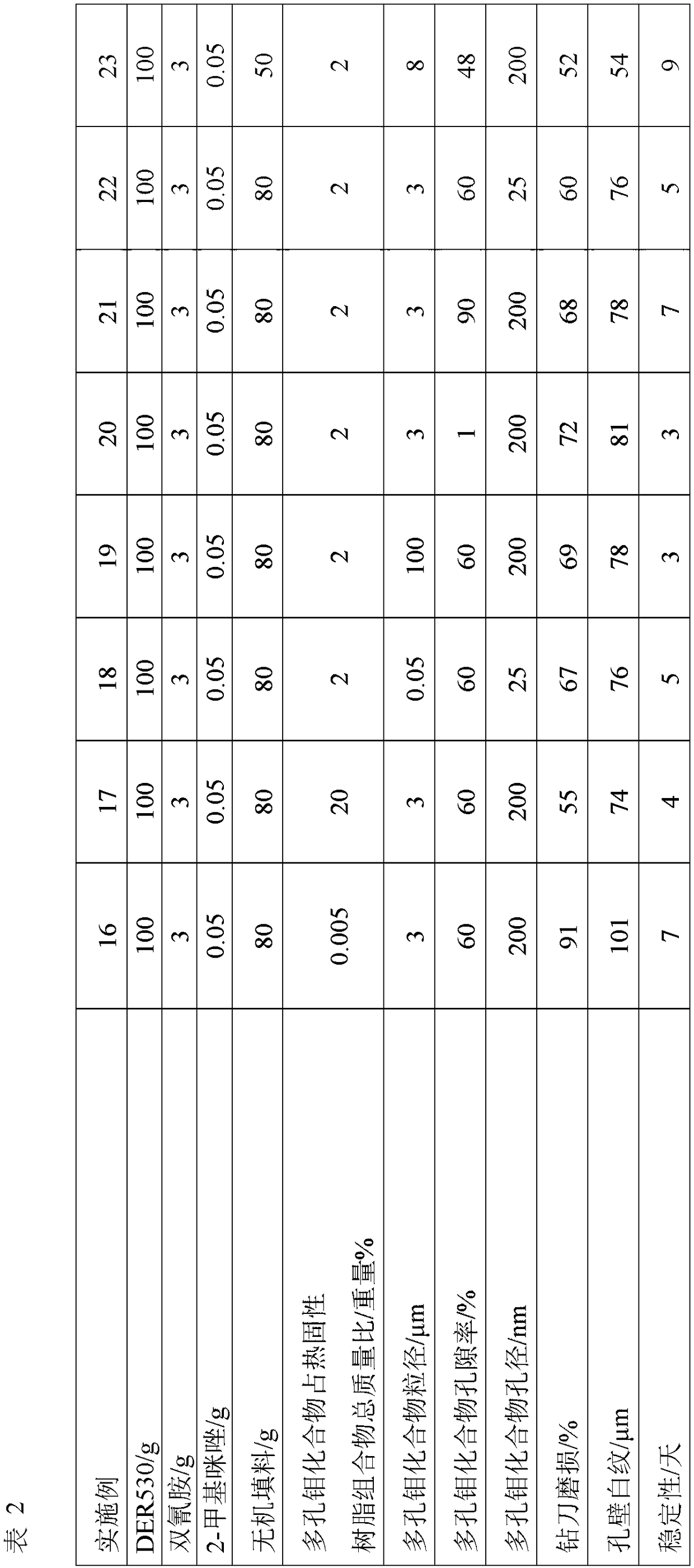

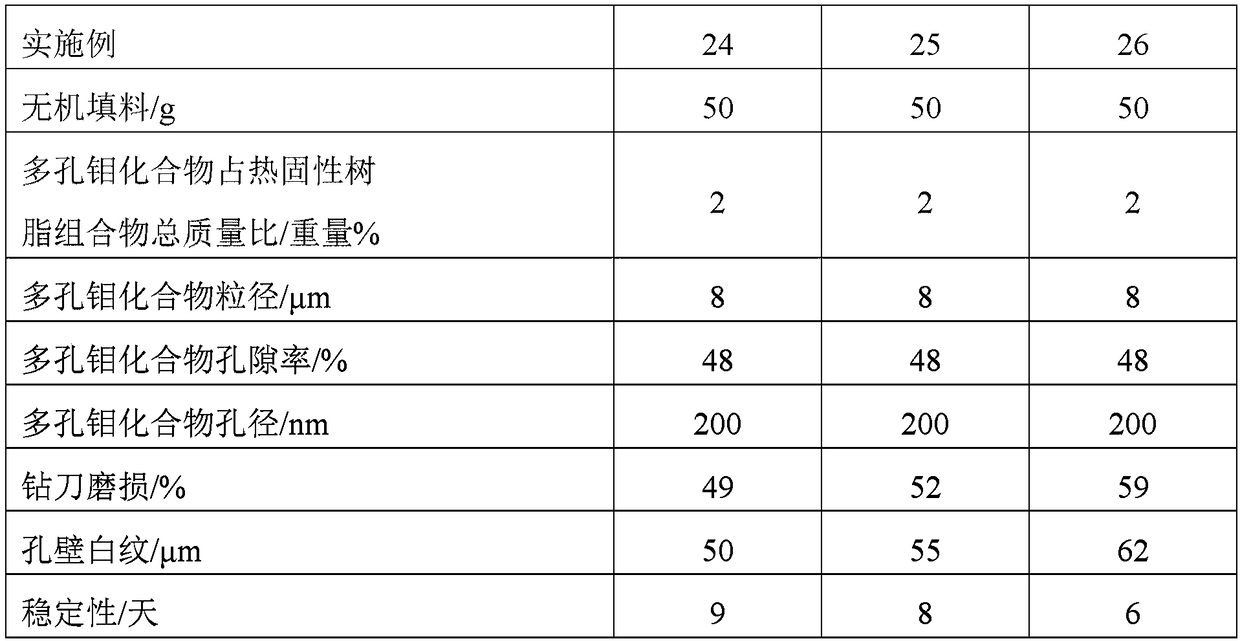

Embodiment 23

[0093] Brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530) (epoxy resin), dicyandiamide (curing agent), 2-methylimidazole (promoter agent), porous molybdenum dioxide (prepared according to CN 105977479 A) (porous molybdenum compound) and boehmite (Anhui Yishitong Material Technology Co., Ltd., BG601, average particle size 0.5 μm) were added to butanone (solvent) , mechanically stirred to prepare a 65% glue by weight, and then impregnated with glass fiber cloth (7628, Zhuhai Zhubo Electronic Materials Co., Ltd.) (reinforcement material), and formed a prepreg (prepreg) after heating and drying, and placed copper foil on both sides , pressurized and heated to make a copper-clad laminate.

[0094] In the same manner as in Example 1, a copper-clad laminate using a resin composition was obtained. Table 2 shows the measurement and evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com