Light interior partition wall board and walling method for wall body

A light-weight technology for interior partition walls, applied to walls, buildings, building components, etc., can solve the problems of slow hydration reaction, difficulty in squeezing and leveling pulp, increasing labor and consumables, etc., to achieve easy management, convenient construction, The effect of improving fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

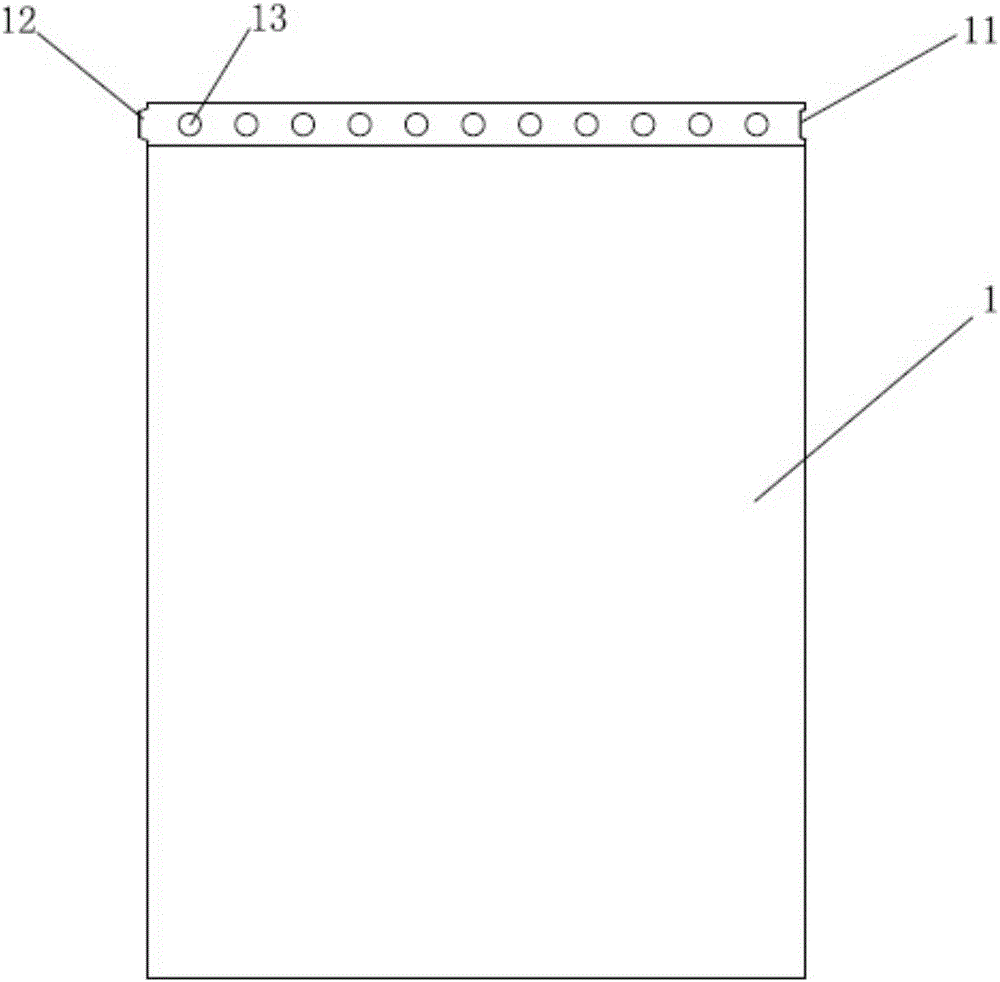

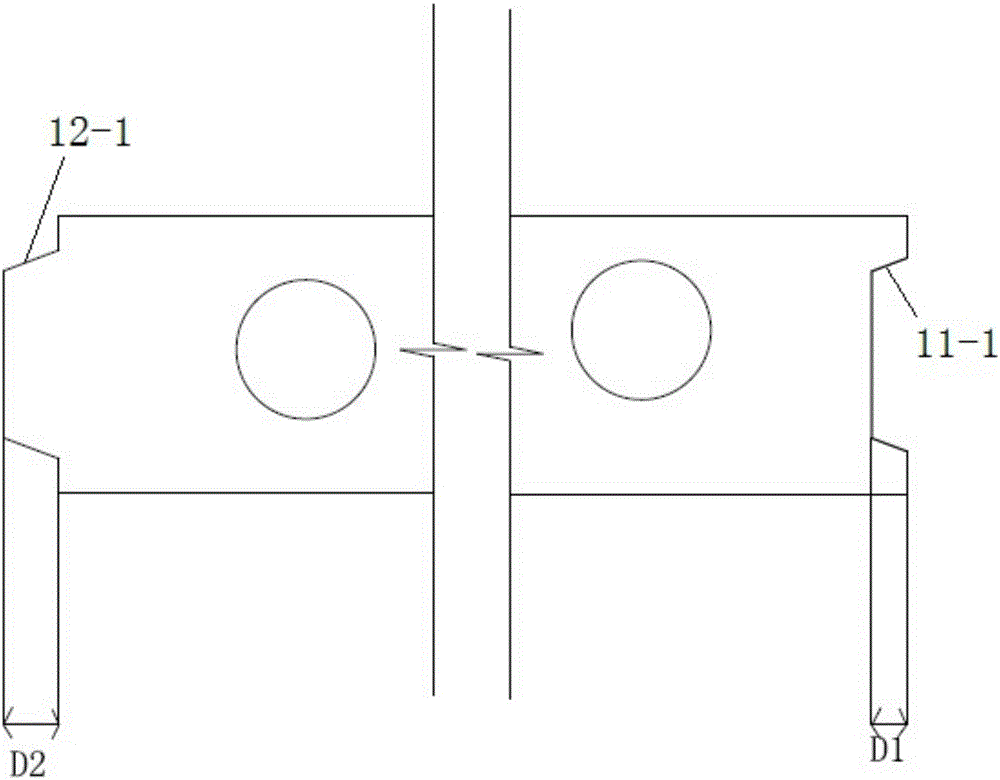

[0033] See figure 1 and figure 2 , a light-weight inner partition wall panel of this embodiment, comprising a wall panel main body 1; two longitudinal sides of the wall panel main body 1 are respectively provided with grooves 11 and protrusions 12 whose widths match each other; the length of the protrusions 12 D2 is 13 mm; the depth D1 of the groove 11 is 5 mm, and the length D2 of the protrusion 12 is 8 mm larger than the depth D1 of the groove 11 . The groove 11 has two inclined groove leading sides 11 - 1 ; the protrusion 12 has two protrusion leading sides 12 - 1 with the same inclination angle. The groove 11 and the protrusion 12 run through the entire side of the main body 1 of the wallboard longitudinally. At least one hollow groove 13 is longitudinally provided on the wallboard main body 1 .

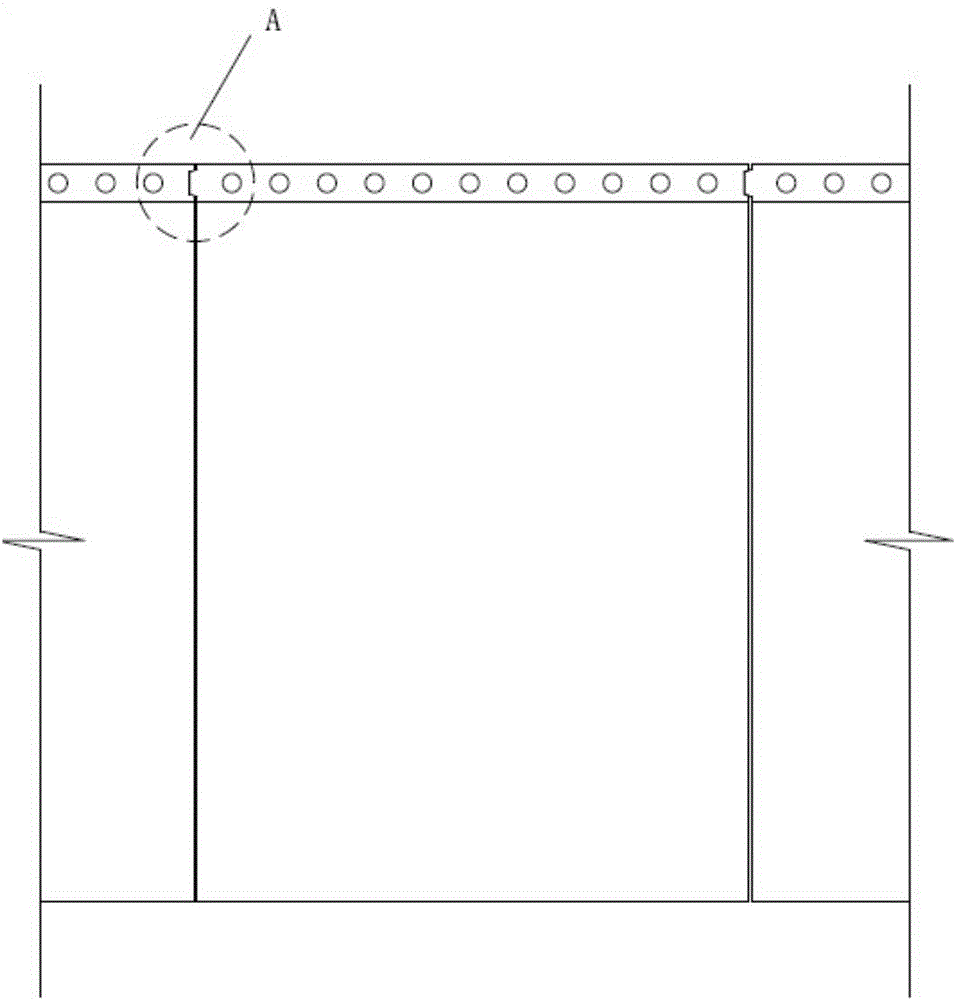

[0034] Such as image 3 and Figure 4 Shown, the method for building a wall with a lightweight inner partition wall comprises the following steps:

[0035] Step 1: Transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com