Gypsum wall in-situ concreting equipment system and construction method thereof

A technology of on-site pouring and construction methods, which is applied to the on-site preparation of building components, formwork/formwork/work frame, construction, etc., and can solve the problems of on-site slurry leakage and low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

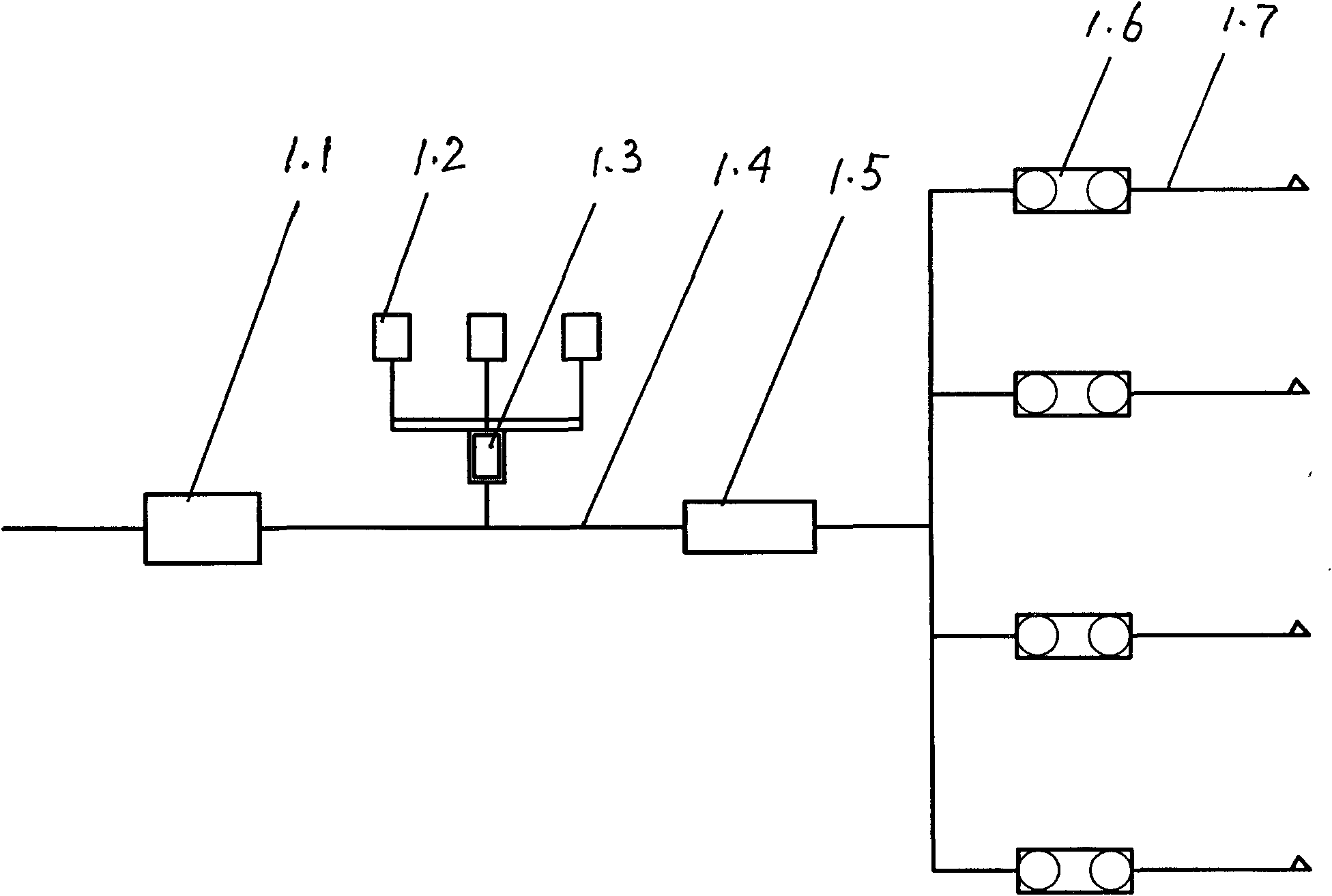

[0033] Embodiment one of the equipment system of the present invention: trailer type

[0034] Install the fan, silo, and feeder on the trailer. During construction, use the vehicle to drag the trailer to the construction site, set up the pipeline, branch valve, and pipeline-type screw mixing-feeding pump unit, and then proceed to construction. This system is suitable for large-scale construction and high-rise buildings.

Embodiment approach 2

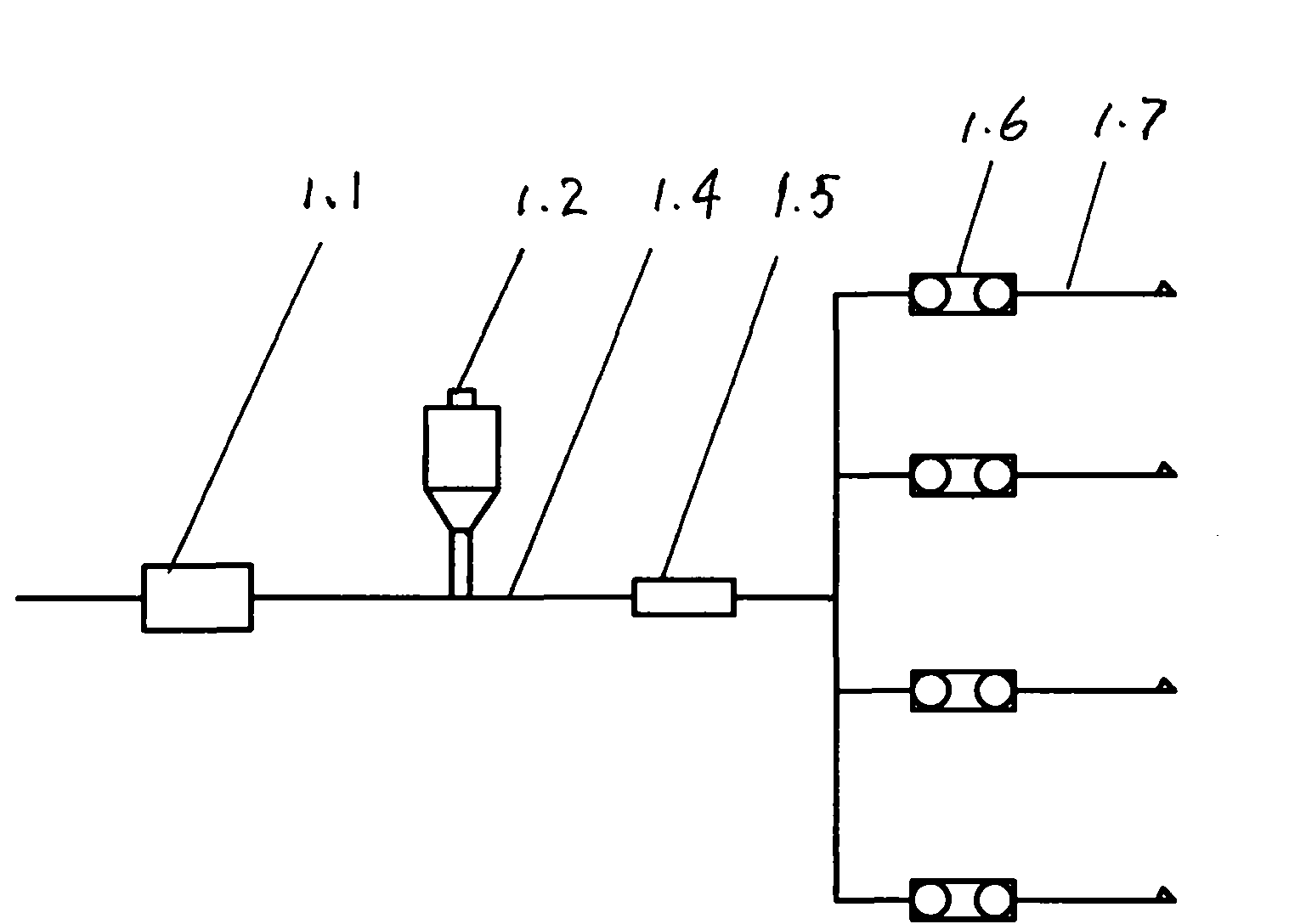

[0035] Implementation plan two: vehicle-mounted

[0036] Install the entire system on the vehicle. That is, the fan, silo, feeder, conveying street, and branch valve are integrated on the vehicle, and the long arm of the high-rise crane is set. When working, extend the long arm to make it suitable for working on each floor. This system is suitable for medium-rise buildings.

Embodiment approach 3

[0037] Implementation plan three: cart type

[0038] This system is a small system, suitable for small, low-rise buildings. Install the fan, silo, feeder, branch valve, and pipeline-type screw mixing-feeding pump unit on a small cart, and rely on manpower to push.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com