Method of constructing underground diaphragm wall by cement deep mixing

A construction method and cement technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of lack of integrity, poor continuity of the diaphragm wall, poor permeability resistance, etc. Compact structure, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

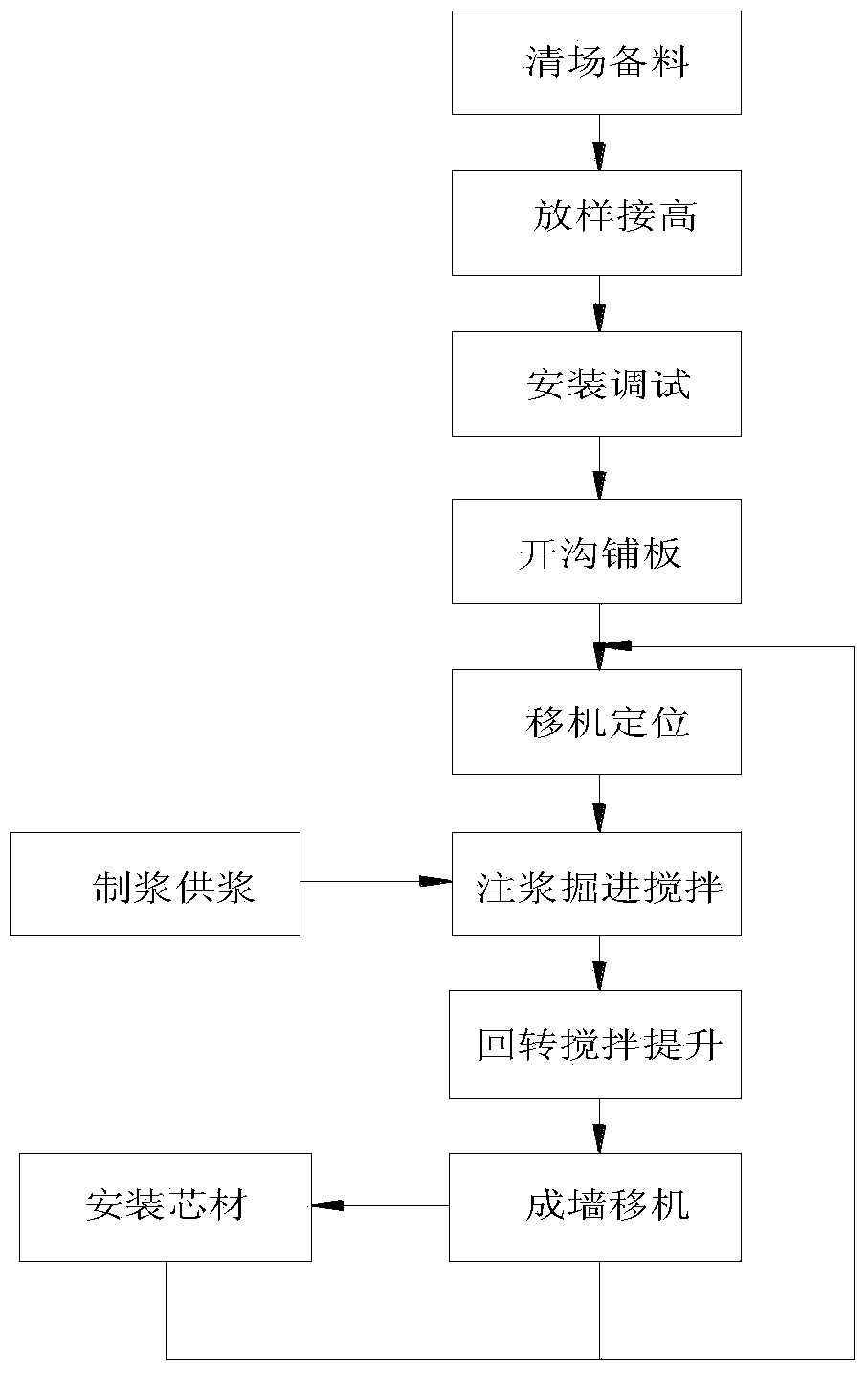

[0022] See attached figure 1 ,

[0023] 1. Clear the site, prepare materials, level and compact the construction site, remove ground and underground obstacles, and the working surface should not be less than 7m. When the ground surface is too soft, measures should be taken to prevent mechanical instability. Prepare enough cement and admixtures.

[0024] 2. Surveying and setting out The axis of the wall construction shall be determined according to the design requirements, and an elevation control pile shall be arranged every 50m, and a clear mark shall be made.

[0025] 3. Installation and commissioning to support the mobile machine and the main engine in place; erect pile frames; install pulping, grouting and gas-making equipment; connect water, electric and gas circuits; run and test run.

[0026] 4. Ditching and decking The excavation cross-section is a storage ditch with a depth of 1m and a width of 1.2m to solve the residual slurry storage and slurry return supply durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com