Novel automatic wall painting machine

A wall-painting machine, an automatic technology, applied in the direction of construction and building structure, can solve the problems of poor plastering effect at the corner of the wall, the wall cannot be plastered, the thickness of the wall is uneven, etc., to achieve simple structure, easy operation and effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

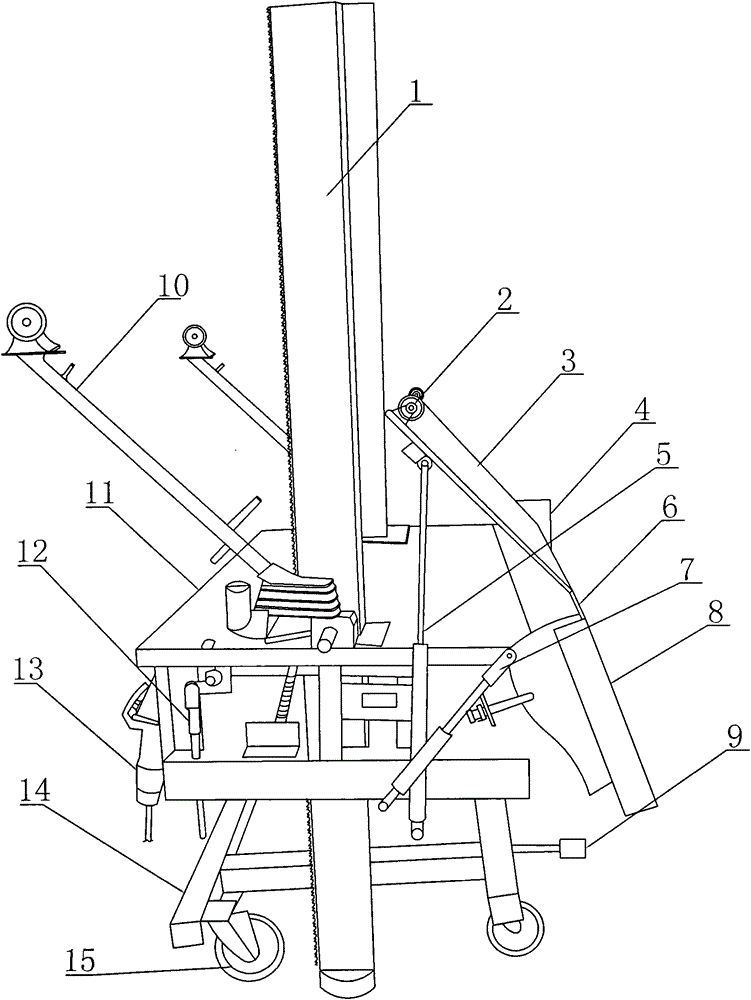

[0012] Examples such as figure 1 As shown, a new type of automatic plastering machine is composed of a base 14, a plastering host 11, a directional rod 1, a baffle plate 3, and a plastering board 6; a universal wheel 15 is provided under the base 14, and a plastering host is provided above 11. The directional rod 1 passes through the plastering host 11 and the base 14 vertically, and the plastering host 11 is provided with a plastering board 6 and a baffle 3 against the wall; the directional rod 1 is provided with gear teeth, and through the gear teeth It is engaged with the gears of the plastering host 11 and the base 14, and the directional rod 1 is combined in sections. A trimmer is provided at the connection between the base and the directional rod, and the trimmer can adjust the directional rod up and down in a small distance; the plastering hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com