Hydraulic jam release tool for filtering type desander filter net and using method thereof

A desander and filtering technology, which is applied in the field of hydraulic jam release tools, can solve the problems of hidden safety hazards, time-consuming and labor-intensive work, and low construction efficiency, and achieve the effects of improving operating efficiency, convenient use, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

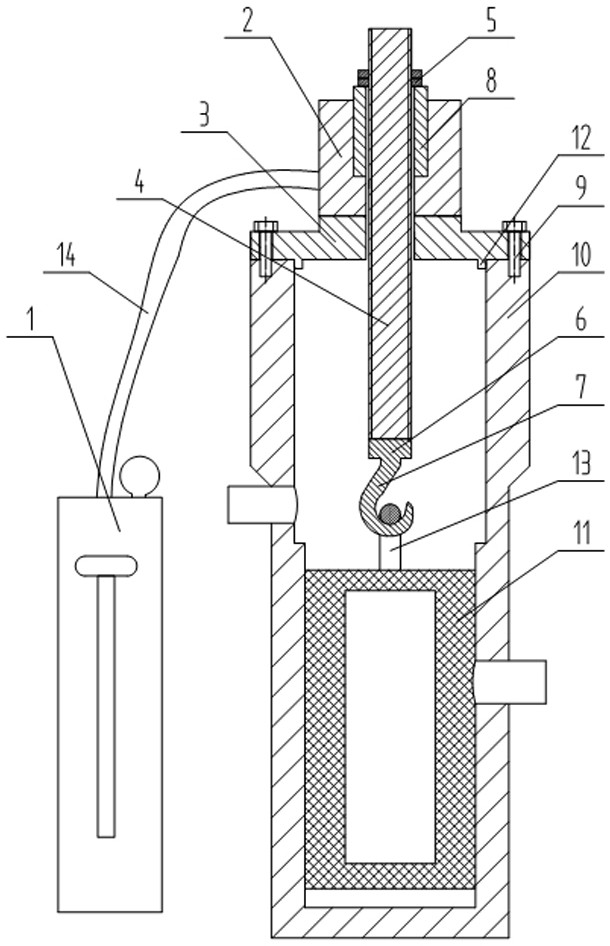

[0020] Embodiment one: as attached figure 1 As shown, the hydraulic unblocking tool for the filter screen of the desander includes a hydraulic manual pump 1, a hollow hydraulic jack 2, a gland 3, a screw 4, connectors, a pressure plate 5 and bolts 9, and the gland The middle part of 3 is provided with a mounting hole through up and down, the upper end of the screw 4 passes through the mounting hole, the lower end of the screw 4 is fixedly connected with a connecting piece for connecting the filter screen 11, and the hollow hydraulic jack 2 is seated on the top surface of the gland 3, corresponding to the gland The lead screw 4 at the upper position of 3 passes through the through hole on the plunger 8 of the hollow hydraulic jack 2, and the outer side of the lead screw 4 at the position above the plunger 8 is detachably and fixedly installed with a pressure bearing plate 5. The bottom surface is against the top surface of the plunger 8 , the outer diameter of the pressure plat...

Embodiment 2

[0026] Embodiment 2: A method of using the above-mentioned hydraulic deblocking tool for the filter screen of the filter type desander, comprising the following steps:

[0027] In the first step, the pressure bearing plate 5, the hollow hydraulic jack 2, and the gland 3 are removed from the lead screw 4.

[0028] In the second step, the connector at the lower end of the screw 4 is connected to the suspension ring 13 on the filter screen 11, then the gland 3 is placed outside the screw 4 and the gland 3 is installed on the upper surface of the filter cartridge 10, and then the The hollow hydraulic jack 2 is set on the outside of the lead screw 4 and seated on the top surface of the gland 3, so that the lead screw 4 is located inside the through hole of the plunger 8 of the hollow hydraulic jack 2, and the pressure plate 5 is screwed on the lead screw 4, The bottom surface of the pressure bearing plate 5 is offset against the top surface of the plunger 8 of the hollow hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com