Thermosetting resin composition and application thereof

A resin composition, thermosetting technology, applied in the direction of electrical components, circuit substrate materials, printed circuit components, etc., can solve the problems of reduced interlayer adhesion of laminated boards, unsatisfactory results, and deterioration of interlayer adhesion. , to achieve the effects of improving compatibility, improving pore wall quality, and solving dispersion and settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

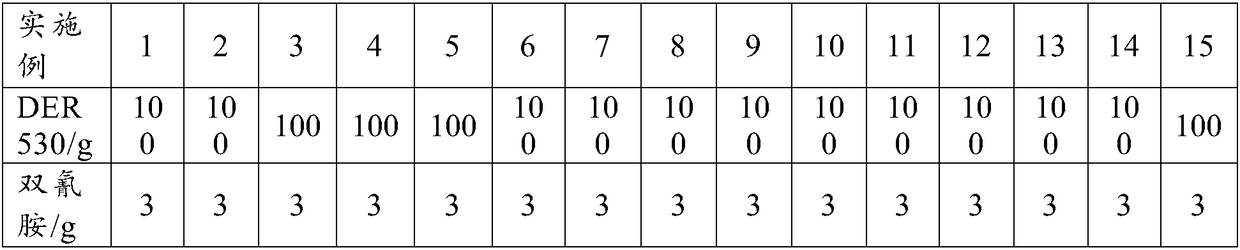

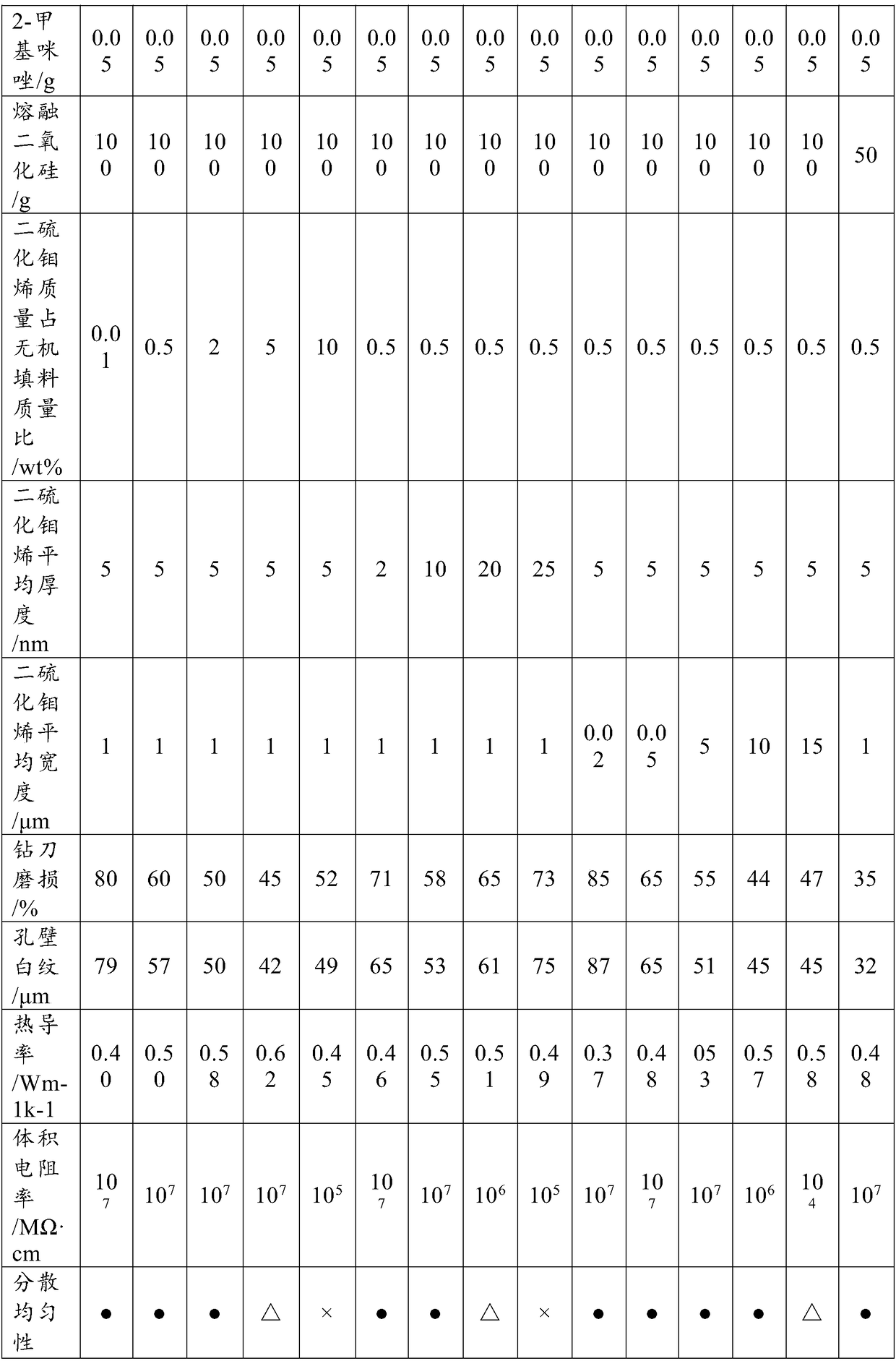

Embodiment 1~15

[0063] In Examples 1 to 15, the raw materials used are basically the same, and the difference lies in the ratio of each example. In Examples 1 to 15, the use of brominated bisphenol A epoxy resin as a thermosetting resin is used as an example. Dicyandiamide is an example as the curing agent of the present invention, and 2-methylimidazole is used as an example of the accelerator of the present invention, and the use of fused silica as an inorganic filler is an example. In other applications, the above-mentioned thermosetting resin, inorganic Fillers, curing agents, and accelerators are replaced by other materials listed in the present invention, and the technical effects obtained are basically the same as those of Examples 1 to 15 of the present invention. Here, it is only used as an example, and the specific proportions refer to Table 1:

[0064] Brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530) (epoxy resin),...

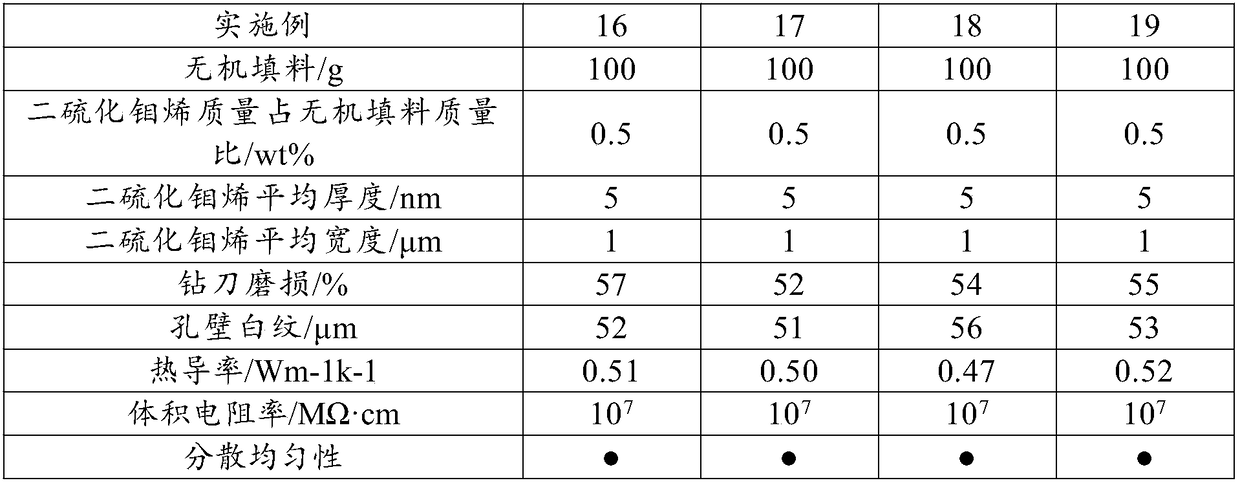

Embodiment 16

[0079] With 100g brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530) (epoxy resin), 3g dicyandiamide (curing agent), 0.05g 2-methyl Add imidazole (accelerator), 100g of boehmite coated with molybdenum disulfide (Anhui Yishitong Material Technology Co., Ltd., BG601, average particle size 0.5μm) into methyl ethyl ketone (solvent), mechanically stir It is prepared into a 65wt% glue solution, then impregnated with glass fiber cloth (7628, Zhuhai Zhubo Electronic Material Co., Ltd.) (reinforcement material), forms a prepreg after heating and drying, places copper foil on both sides, and pressurizes and heats it to form a prepreg. copper laminate.

[0080] The above prepreg is made into a printed circuit board, wherein the printed circuit board contains at least one piece of the above prepreg.

Embodiment 17

[0082] With 100g brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24g novolac resin (Japan Qunrong, hydroxyl equivalent 105, product name TD2090), Add 0.05g of 2-methylimidazole, 100g of E-glass micropowder (Jiangsu Lianrui New Materials Co., Ltd., DS1032, average particle size 3 μm) coated with molybdenum disulfide into butanone (solvent), and mechanically stir It is prepared into a 65wt% glue solution, and then impregnated with glass fiber cloth (7628, Zhuhai Zhubo Electronic Material Co., Ltd.) (reinforcement material), after heating and drying to form a prepreg, placing copper foil on both sides, and pressing and heating to form a prepreg copper laminate.

[0083] The above prepreg is made into a printed circuit board, wherein the printed circuit board contains at least one piece of the above prepreg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com