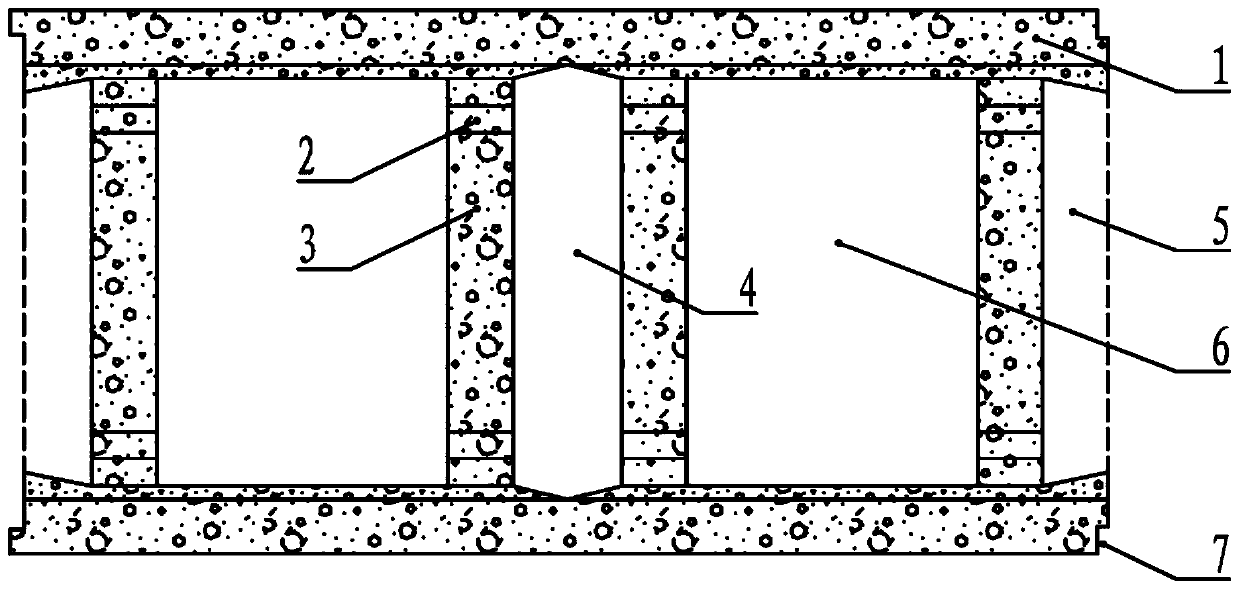

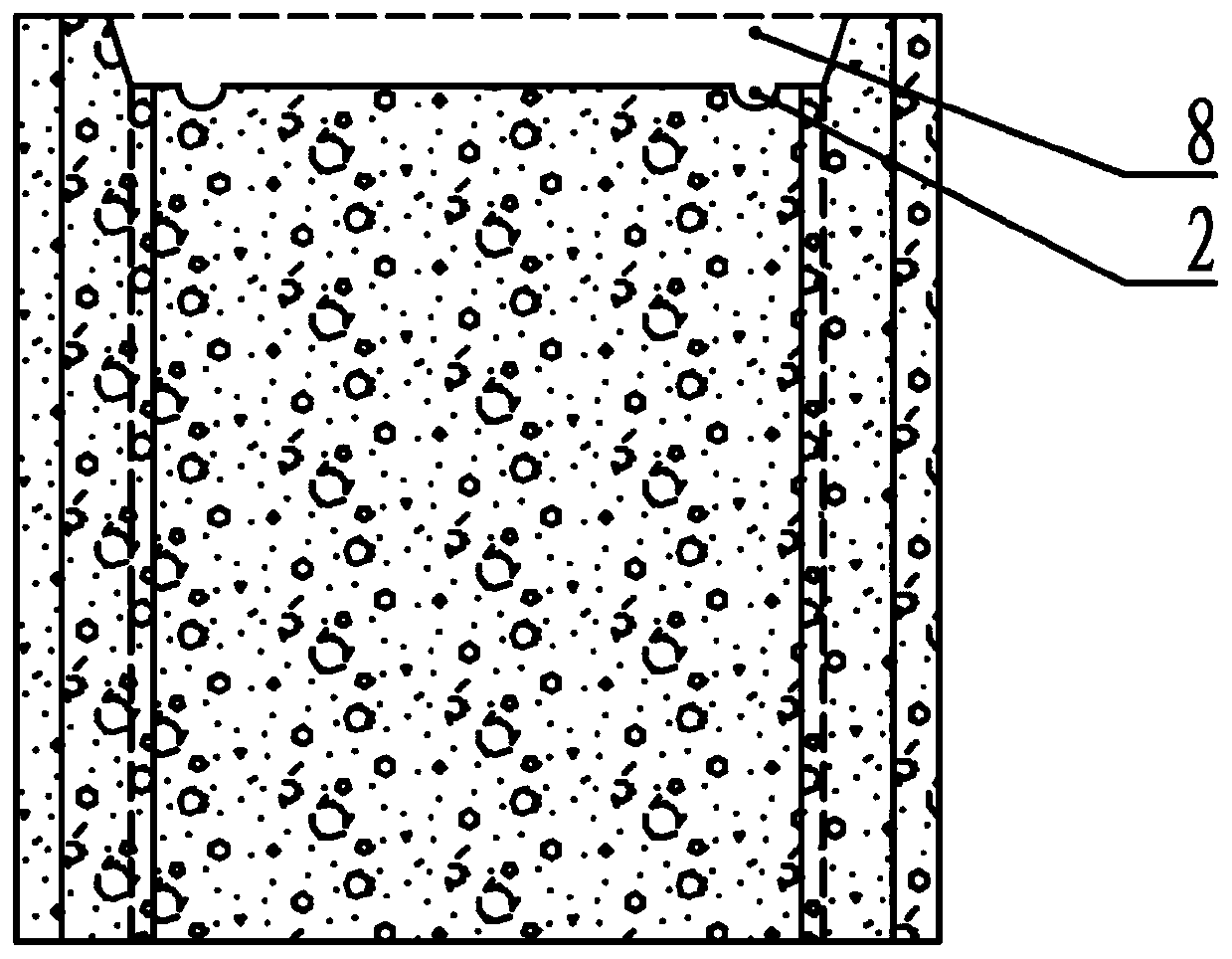

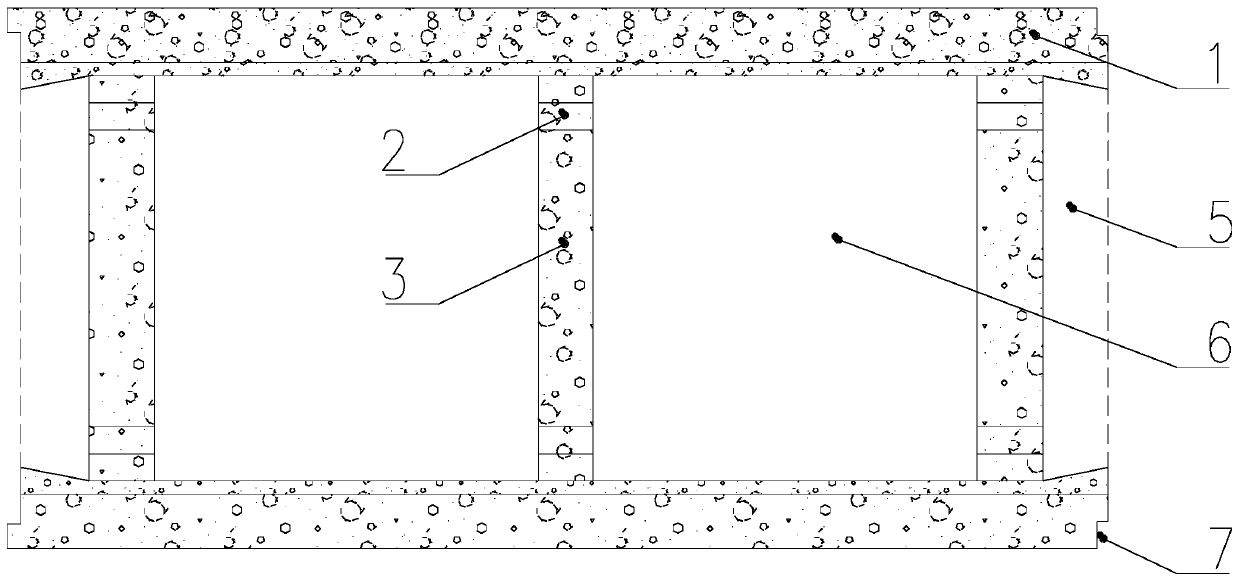

Construction technology for grouting type building blocks with aligned seams and assembled vertical holes

A construction technique and block technology, applied to building components, walls, buildings, etc., can solve the problems of hollowing, material consumption, waste of materials, etc., achieve obvious social and economic effects, improve seismic performance, and be easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Due to the small bonding area of the traditional bonding process during the masonry of hollow blocks, the integrity, stability, and earthquake resistance of the masonry are greatly reduced. The blocks used in the present invention are designed with holes penetrating up and down, and the holes are set to meet the structural strength of the blocks, reducing the manufacturing cost of the blocks themselves, and the blocks are designed with end grooves and / or grouting holes penetrating up and down. Pour mortar or concrete and other bonding materials into the internal grooves and / or grouting holes, and string the blocks together, which can greatly improve the stability and integrity of the masonry and improve the seismic performance of the masonry. This process avoids the adhesive mortar joints of the traditional process. After the blocks are completed with a string process, the wall surface is flat and does not need to be painted, and the masonry speed is fast, which turns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com