Drilling type boring machine

A roadheader and drilling technology are applied to roadway excavation. It can solve problems such as inability to excavate, drop of picks, increased energy consumption, etc., and achieve the effects of high excavation efficiency, flexible posture adjustment, and reduced loss of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

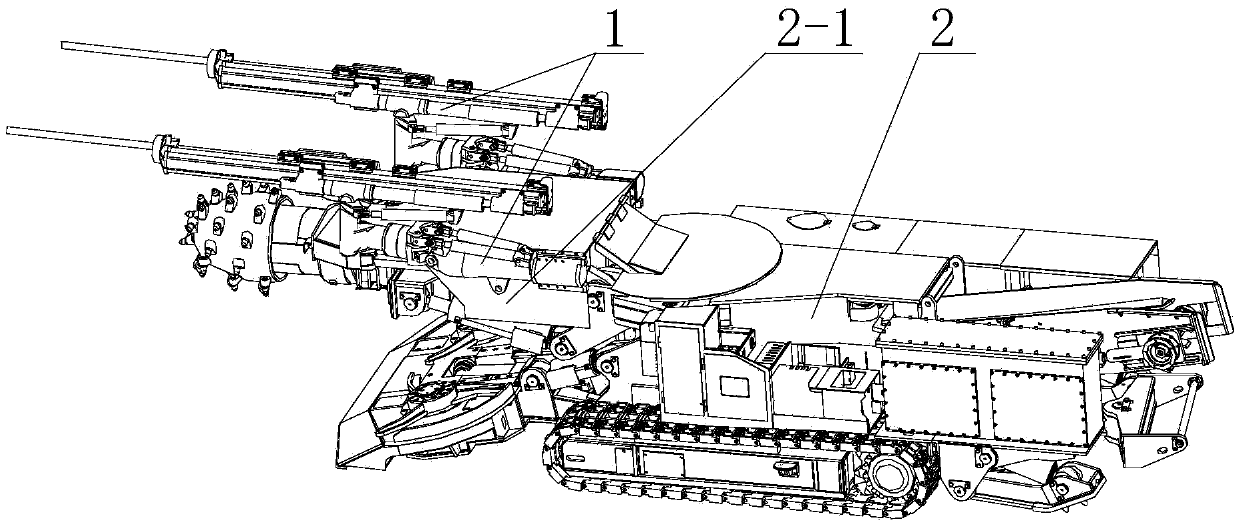

[0014] Such as figure 1 As shown, the drilling-type roadheader of the present invention is mainly composed of a drilling mechanism 1 and a roadheader 2. The drilling mechanism 1 is fixed on the roadheader cantilever 2-1, and follows the roadheader cantilever 2-1 up, down, left, and right swing.

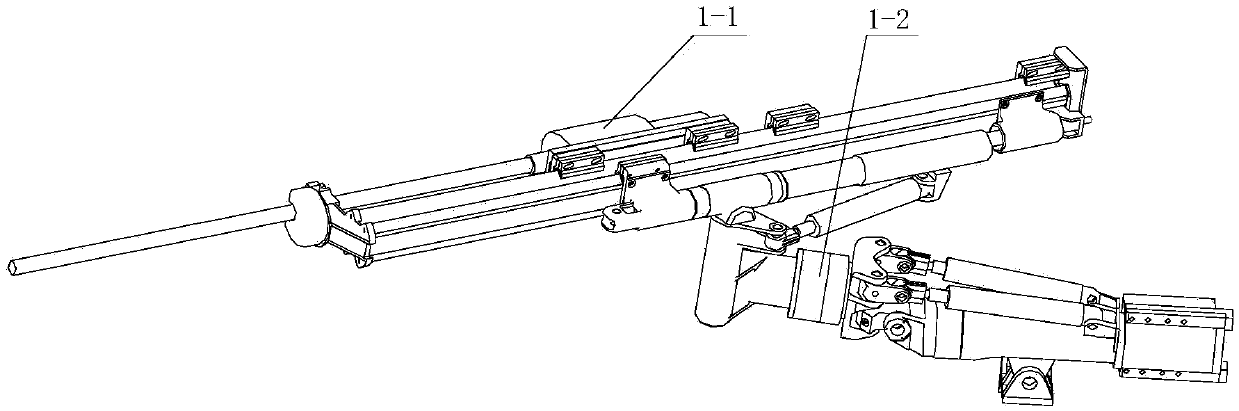

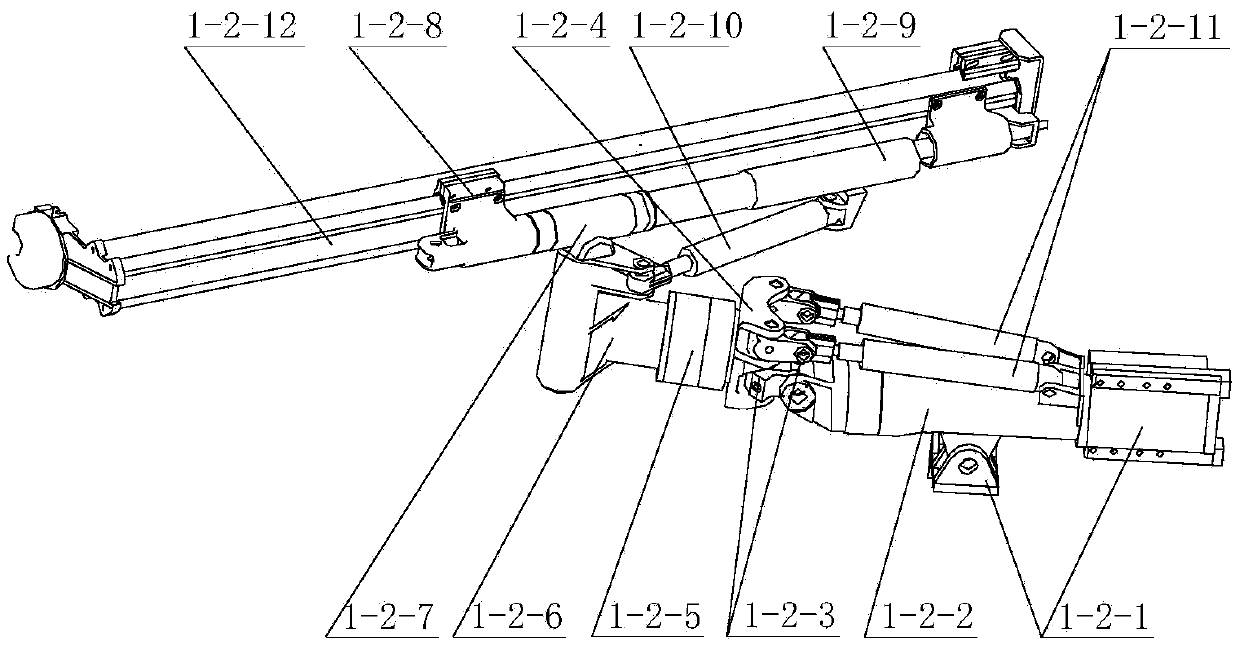

[0015] Such as figure 2 As shown, the drilling mechanism 1 includes a drilling mechanism main propulsion mechanism 1-1, and a drilling mechanism attitude adjustment mechanism 1-2 connected with the drilling mechanism main propulsion mechanism 1-1. The attitude adjustment mechanism 1-2 of the drilling mechanism and the main propulsion mechanism 1-1 of the drilling mechanism are fixed to one end of the guide rail 1-2-12 through one end of the main propulsion hydraulic cylinder 1-1-2, and fixed to the drilling rig 1- The chute 1-2-8 of 1-1 forms groove connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com