Two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and construction method thereof

A kind of cement-soil mixing pile, interchangeable technology, applied in earthwork drilling, sheet pile wall, foundation structure engineering, etc. Problems such as excess torque of power components, to achieve the effect of improving the stirring effect, improving the water-stop effect, and large diameter of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

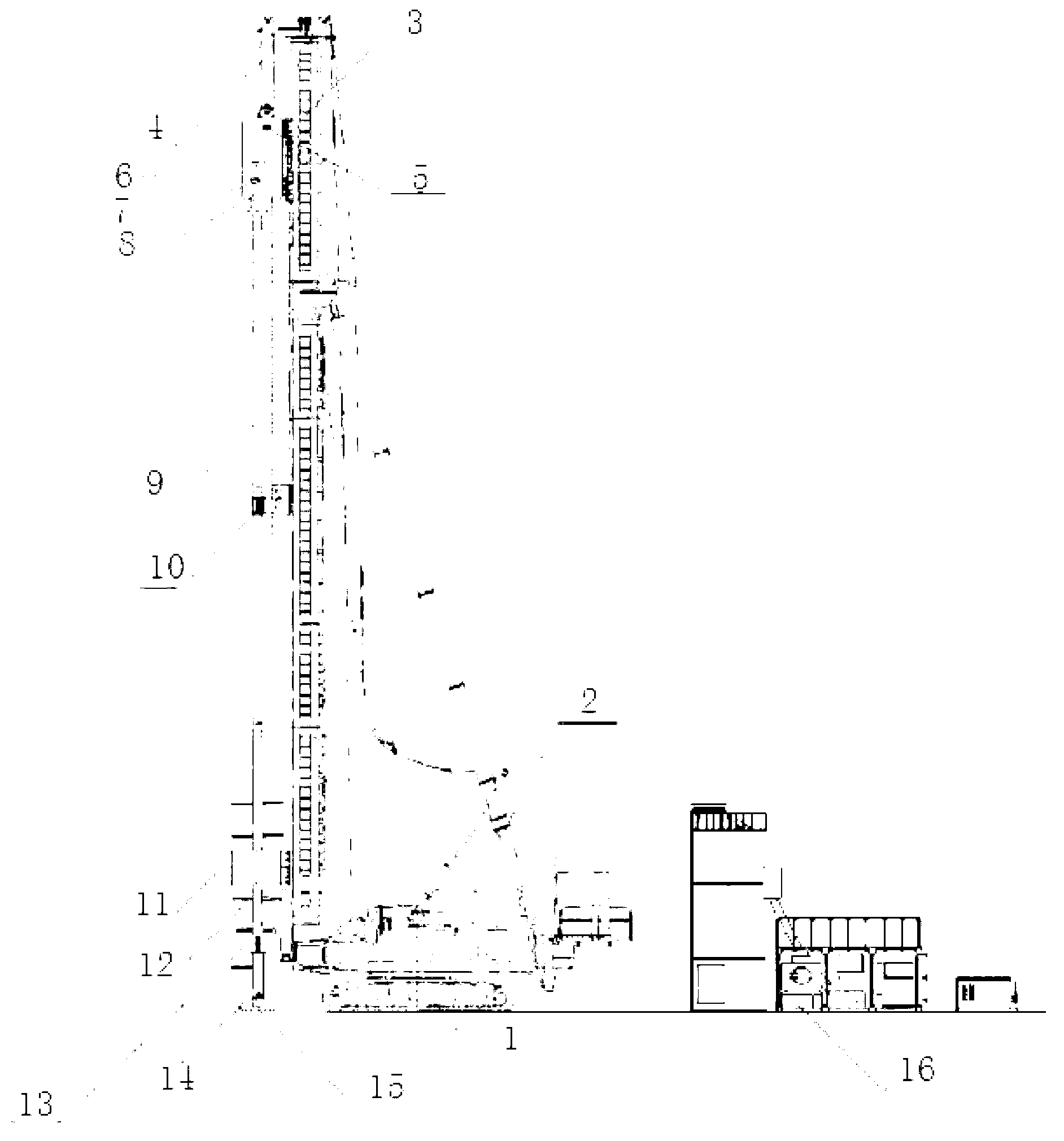

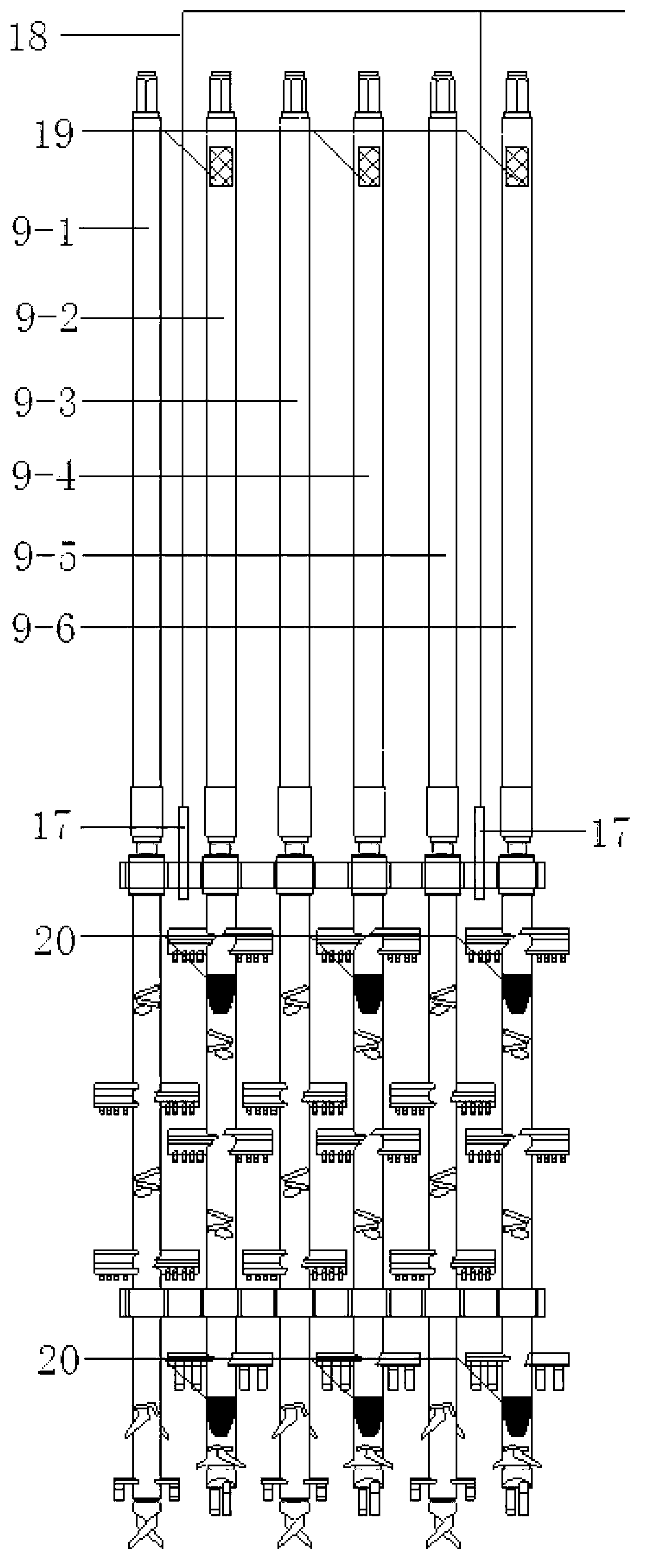

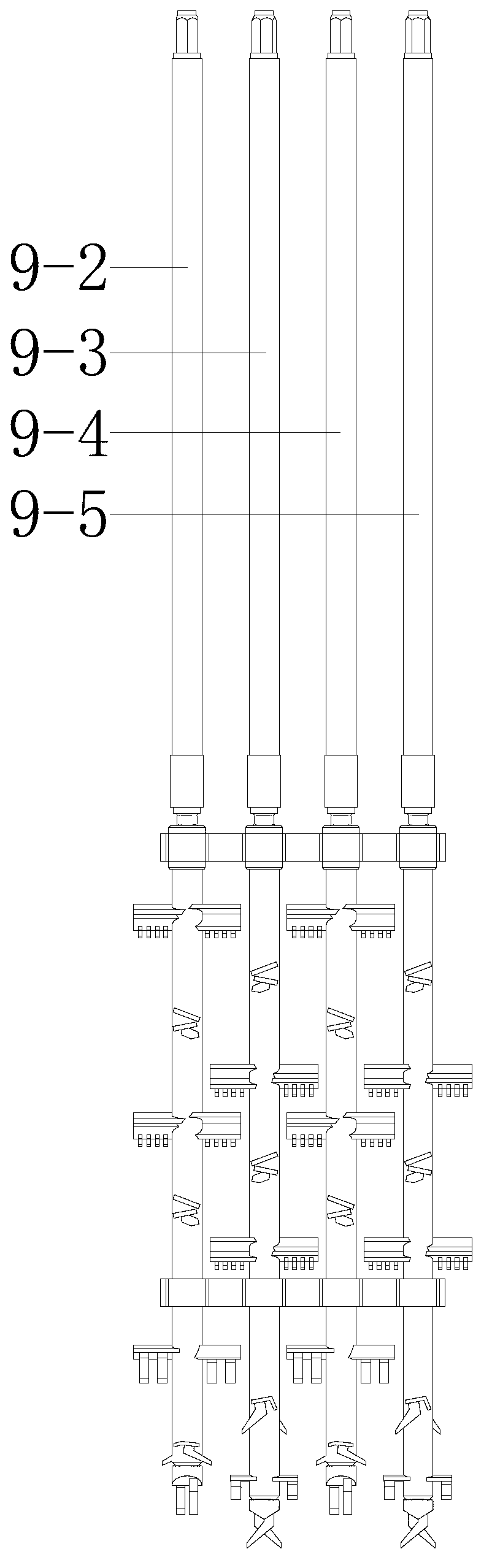

[0050] Such as Figure 1-Figure 2 As shown, a two-, four-, and six-axis interchangeable cement-soil mixing pile device includes a main engine 1, a hoist 2, a guide rod 3, a steel wire rope 4, a slurry inlet 5, a power assembly, a drill pipe 9, a winged Drill pipe 12, drill bit 14 and background cement slurry mixing system 16, the hoist 2 and guide rod 3 are fixed on the main engine 1, the power assembly includes a power head 6, a gearbox 7, a speed reducer 8, and the The power head 6 is connected to the pulley at the top of the guide rod 3 through the wire rope 4, and the wire rope 4 drives the power head 6 to go up and down. The middle supporting frame 10 is provided with a lower supporting frame 11 at the bottom, and the lower end of each drill rod 9 is connected with a winged drill rod 12. The winged drill rod 12 is provided with a hoop 13, and the lower end of the winged drill rod 12 is connected with a The multifunctional drill bit 14 is provided with a grouting port 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com