Multi-axis horizontal rotary jetting machine and its construction method

A technology of horizontal rotary jetting and main engine, which is used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of low production efficiency of single-axis equipment, achieve high construction accuracy, improve construction accuracy, and torque transmission centralized and decentralized. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

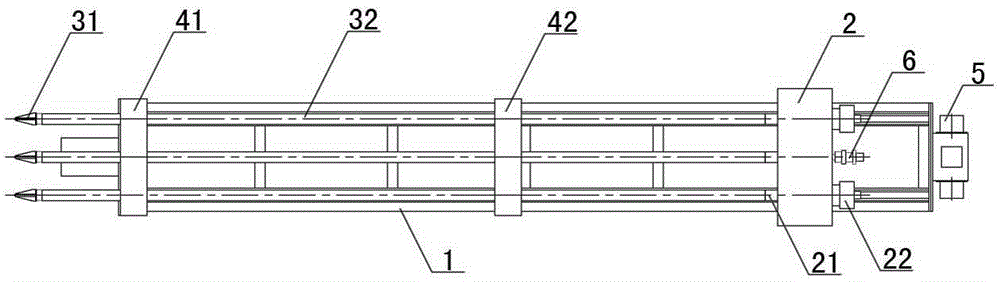

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

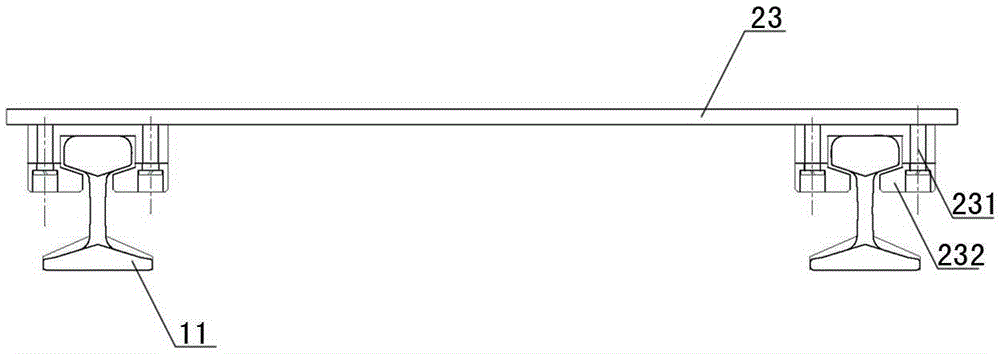

[0041] An embodiment of the present invention provides a multi-axis horizontal rotary spraying machine, including a chassis, a main engine and a drilling tool arranged on the chassis. The chassis can be an arch type chassis or a crawler type multifunctional drilling rig chassis. Its function is to adjust the attitude of the main engine and control the angle of the drilling tool during horizontal rotary spraying construction. The crawler-type chassis can be used in a wide range of construction environments and facilitates the movement of equipment. The hydraulic pump station includes motors, hydraulic pumps, oil tanks, brackets, couplings and other accessories, supporting the hydraulic system operation of the horizontal jet spray machine.

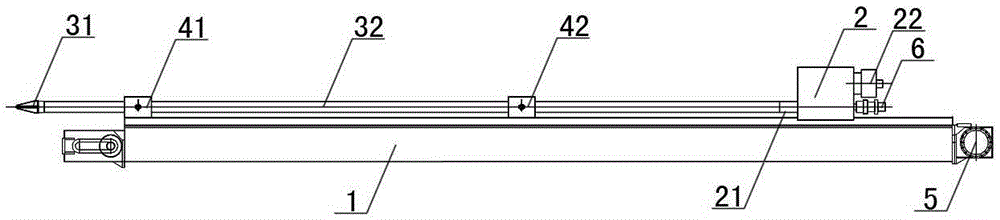

[0042] figure 1 It is a schematic diagram of the host structure of the multi-axis horizontal rotary jetting machine pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com