Patents

Literature

67results about How to "High impact frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent magnet punching machine

The permanent magnetic punch includes a yoke iron, a punching head reciprocating up and down inside the yoke iron, and an armature connected to the punching head. The present invention features that the permanent magnetic punch includes also a magnetic driving mechanism to make the yoke iron and the armature to constitute one magnetic loop, and the magnetic driving mechanism is provided with electromagnetic mechanism to apply electromagnetic drive force to the armature and permanent magnet to apply permanent magnetic attraction force to the armature. The present invention is superior to available electromagnetic punch, which has great power consumption and complicated control system.

Owner:平南县科学技术情报研究所

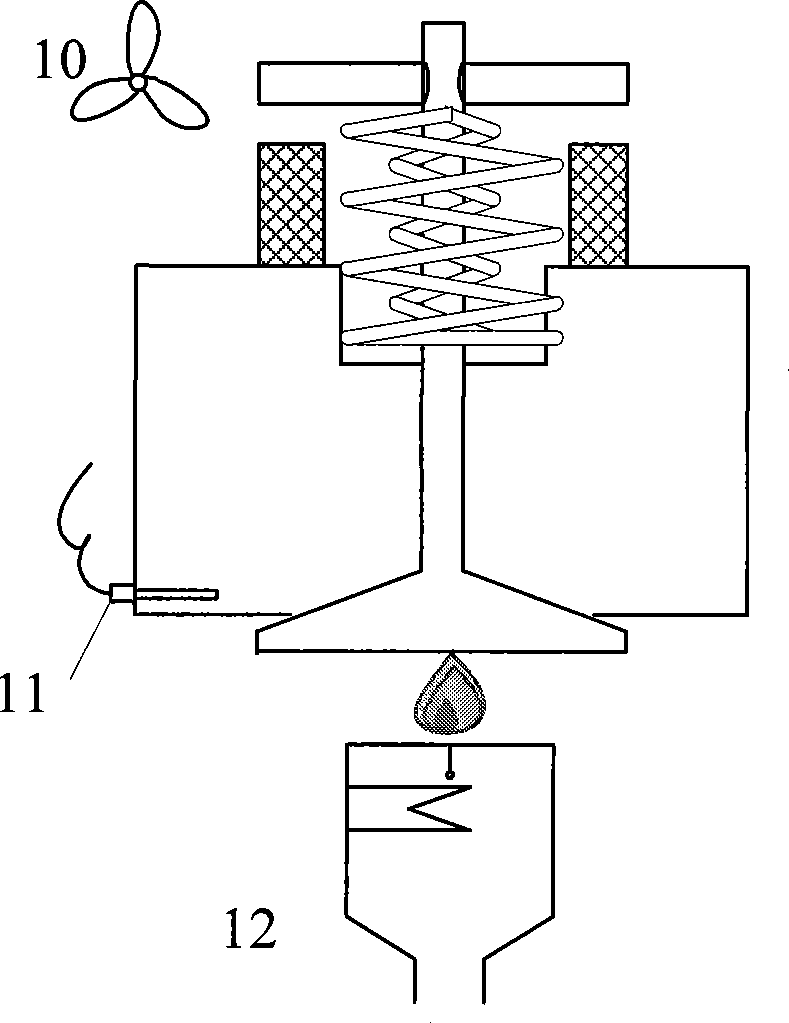

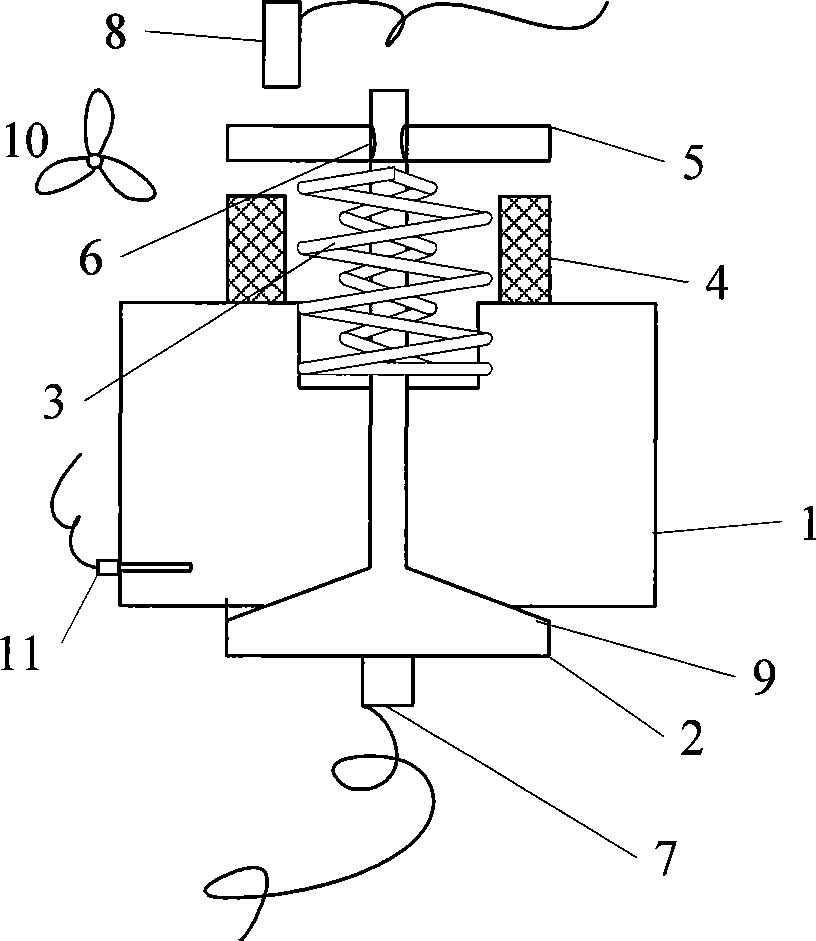

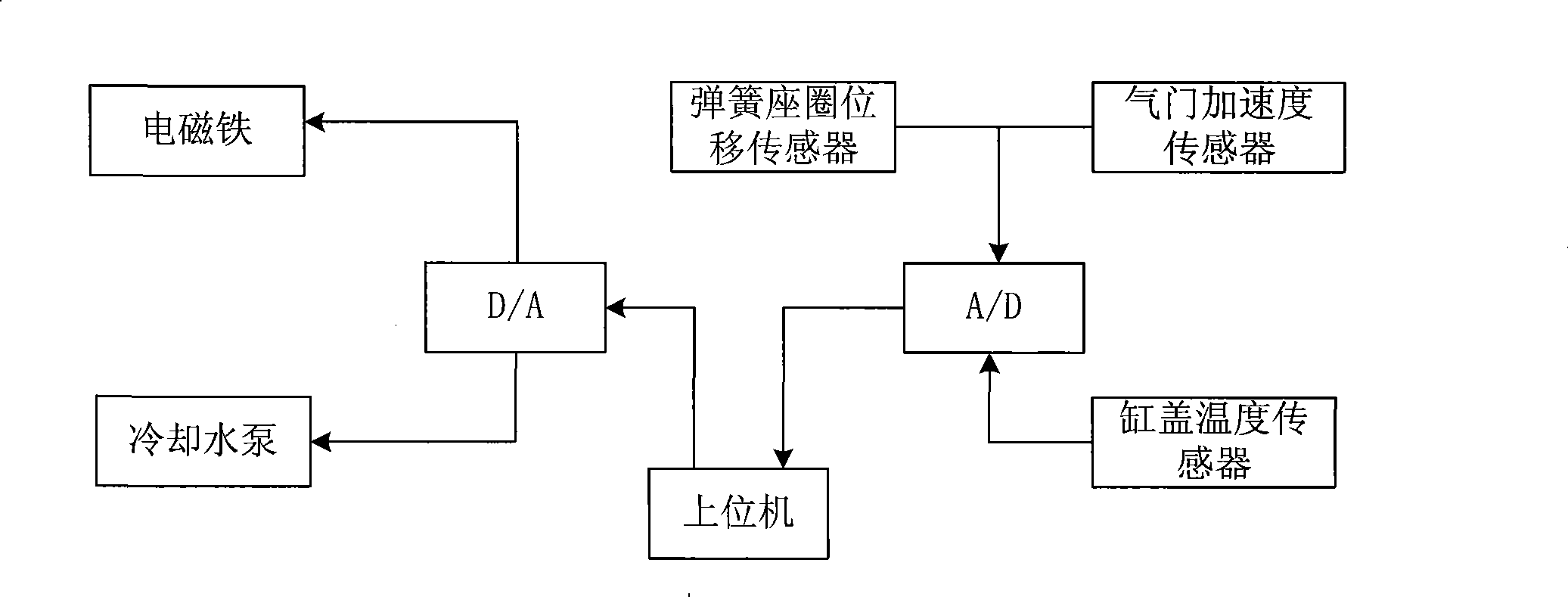

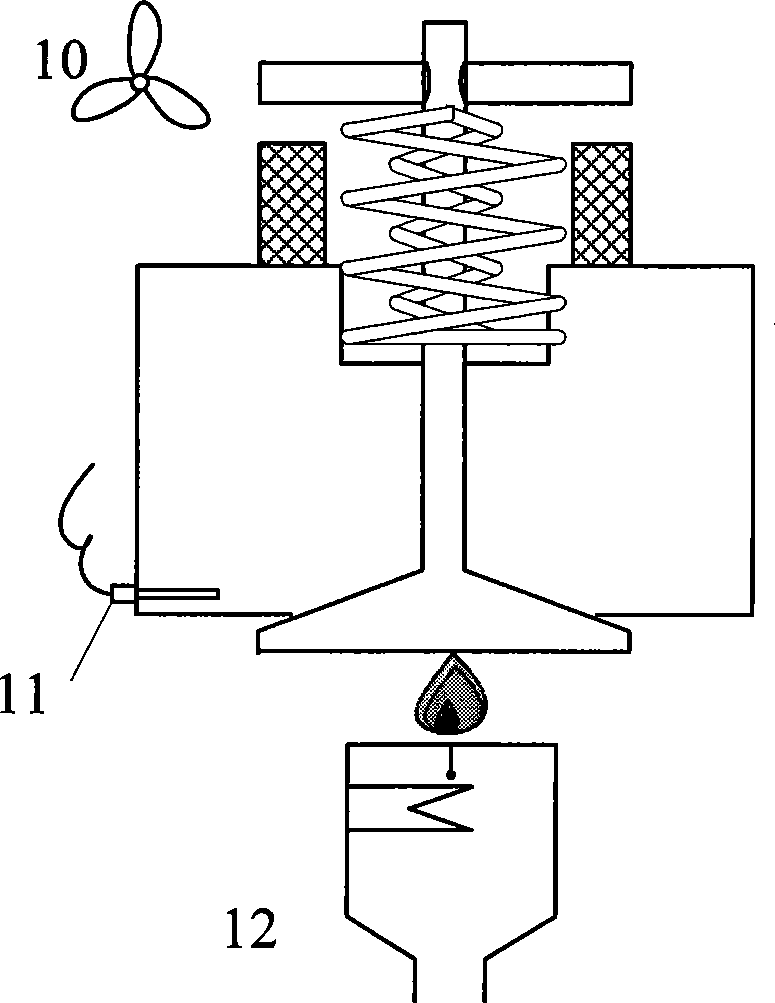

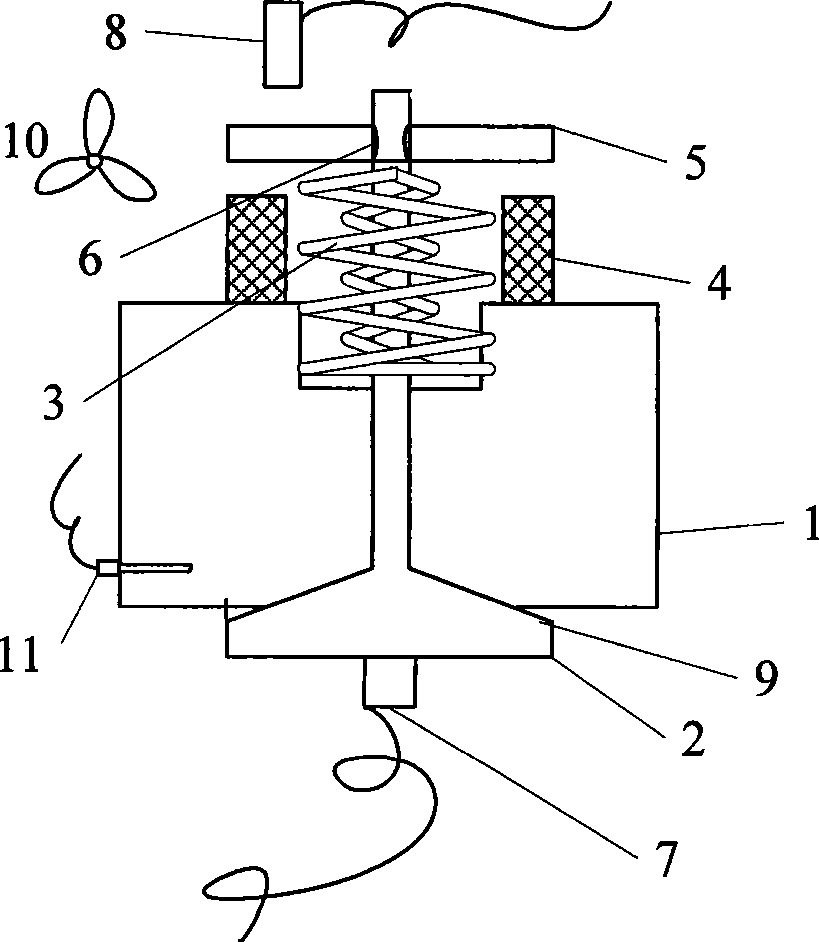

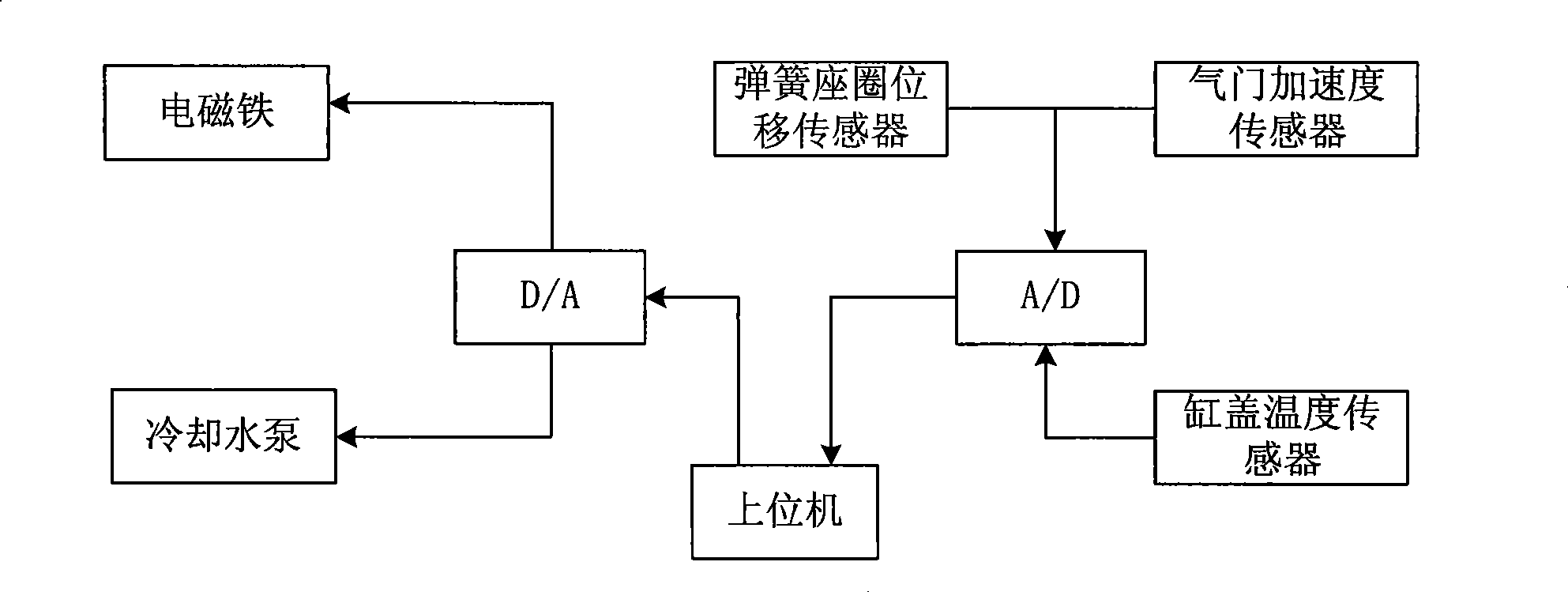

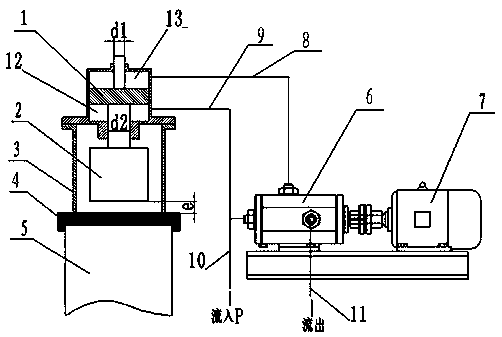

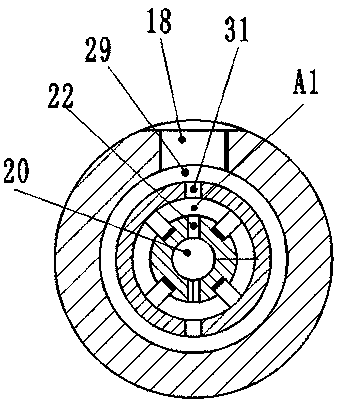

Abrasion test method of air valve and seat ring

InactiveCN101398358AHigh impact strengthGet rid of the bondageMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceCombustorControl engineering

The invention relates to a quick abrasion testing method in the field of power machinery technique, aiming at providing an abrasion testing method used for a valve and a seat ring which are used for an internal-combustion engine. The method comprises a calibration stage and a test stage; in the calibration stage, a valve base is provided with a valve acceleration sensor; a displacement sensor is arranged above a valve spring seat ring; an electromagnet coil gets the electricity; an upper bit machine records the dripping speed and distance of the valve and determines the power-on control strategy for the electromagnet; during the test stage, the valve is heated by an installed burner; and the upper bit machine determines the rotation speed control strategy of the cooling water pump of a water cooling system. The quick abrasion testing method can achieve extremely high impact frequency, and shorten the testing time; the dripping speed of the valve can be jointly determined by two different sensors and the accuracy of the test is improved; the temperature of the cylinder cover is kept at the temperature of the cylinder cover when the internal combustion machine works normally, thus ensuring the reliability of the testing conclusion. The parts are few, the structure is simple and the manufacture cost is low.

Owner:ZHEJIANG UNIV

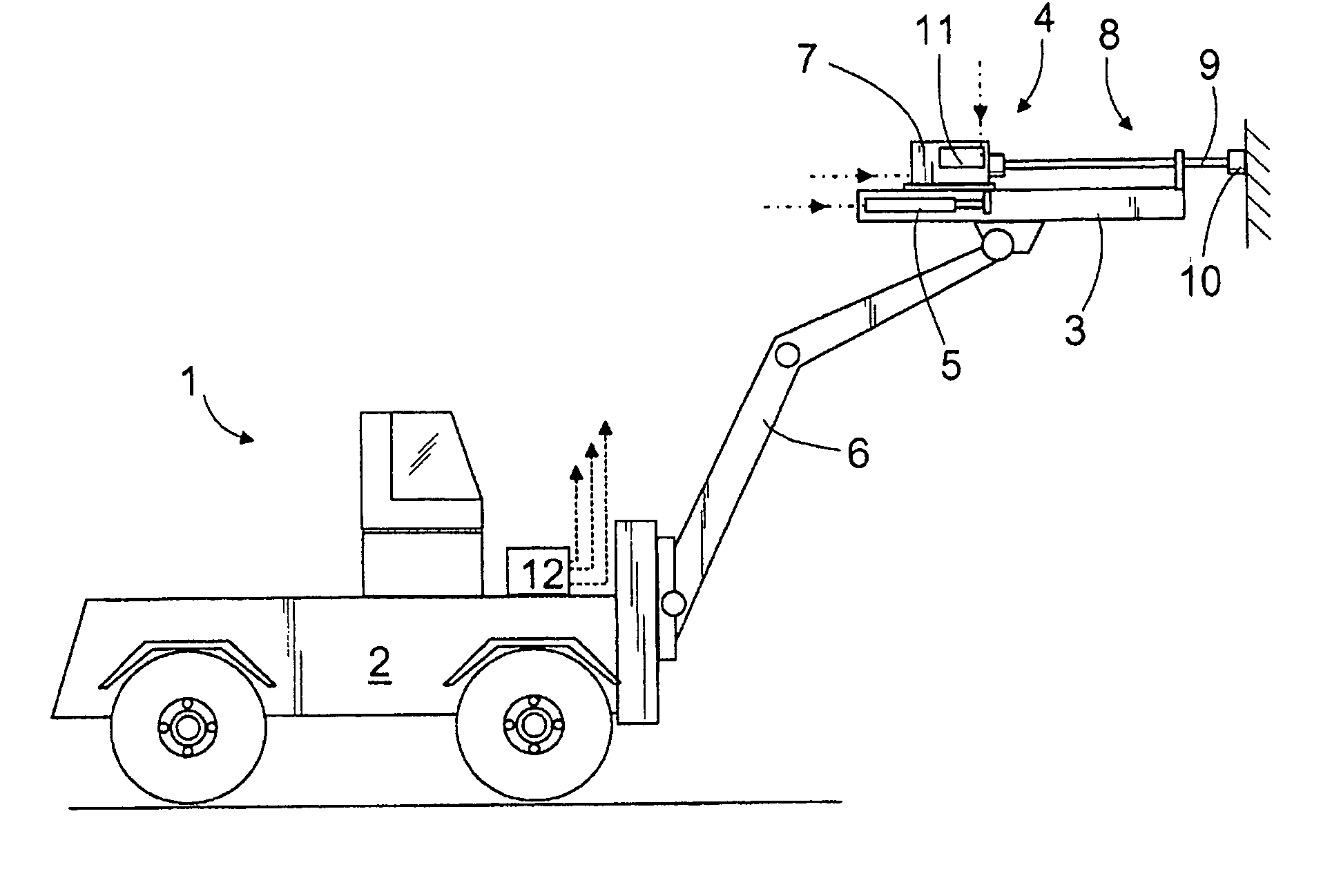

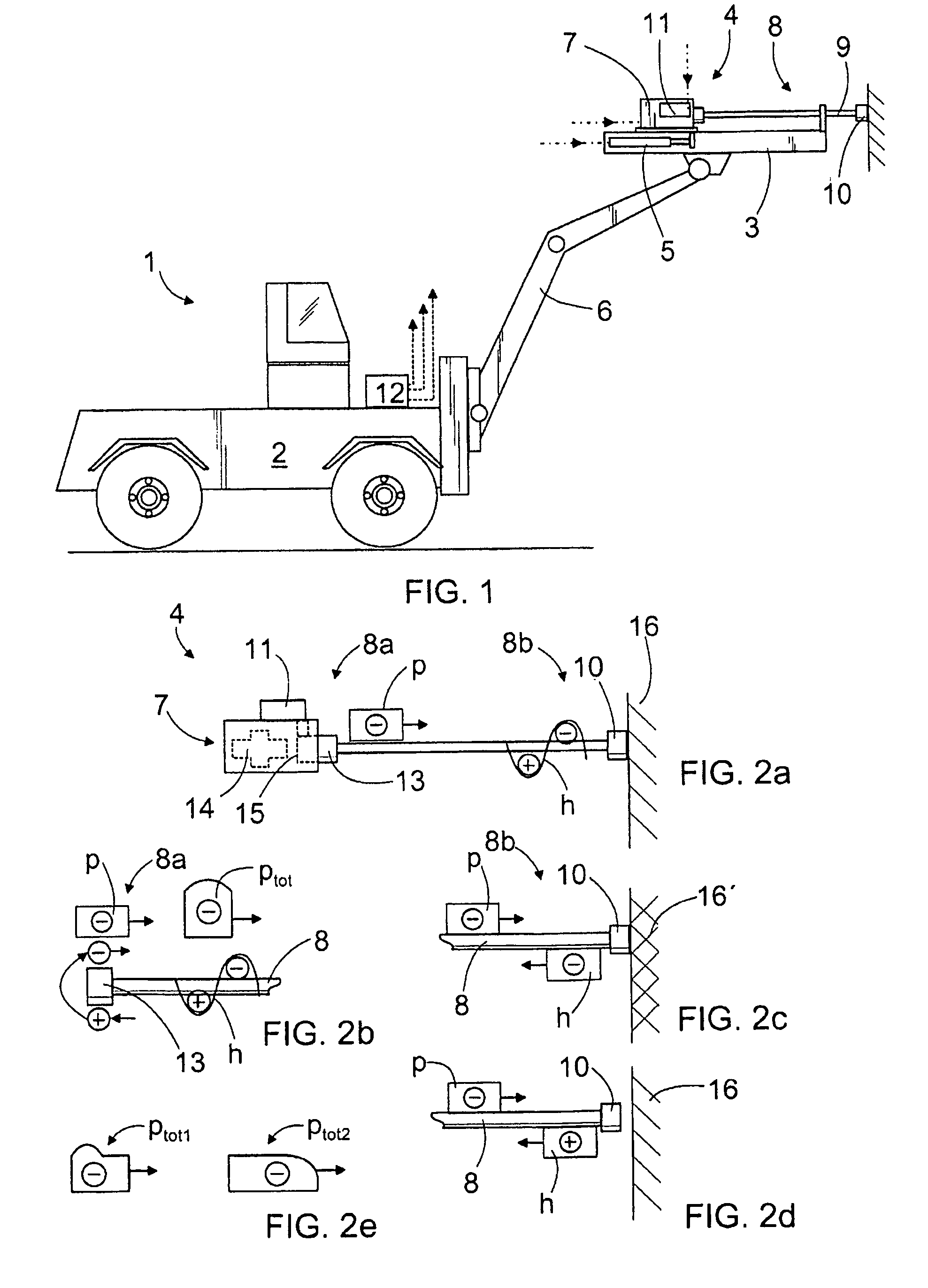

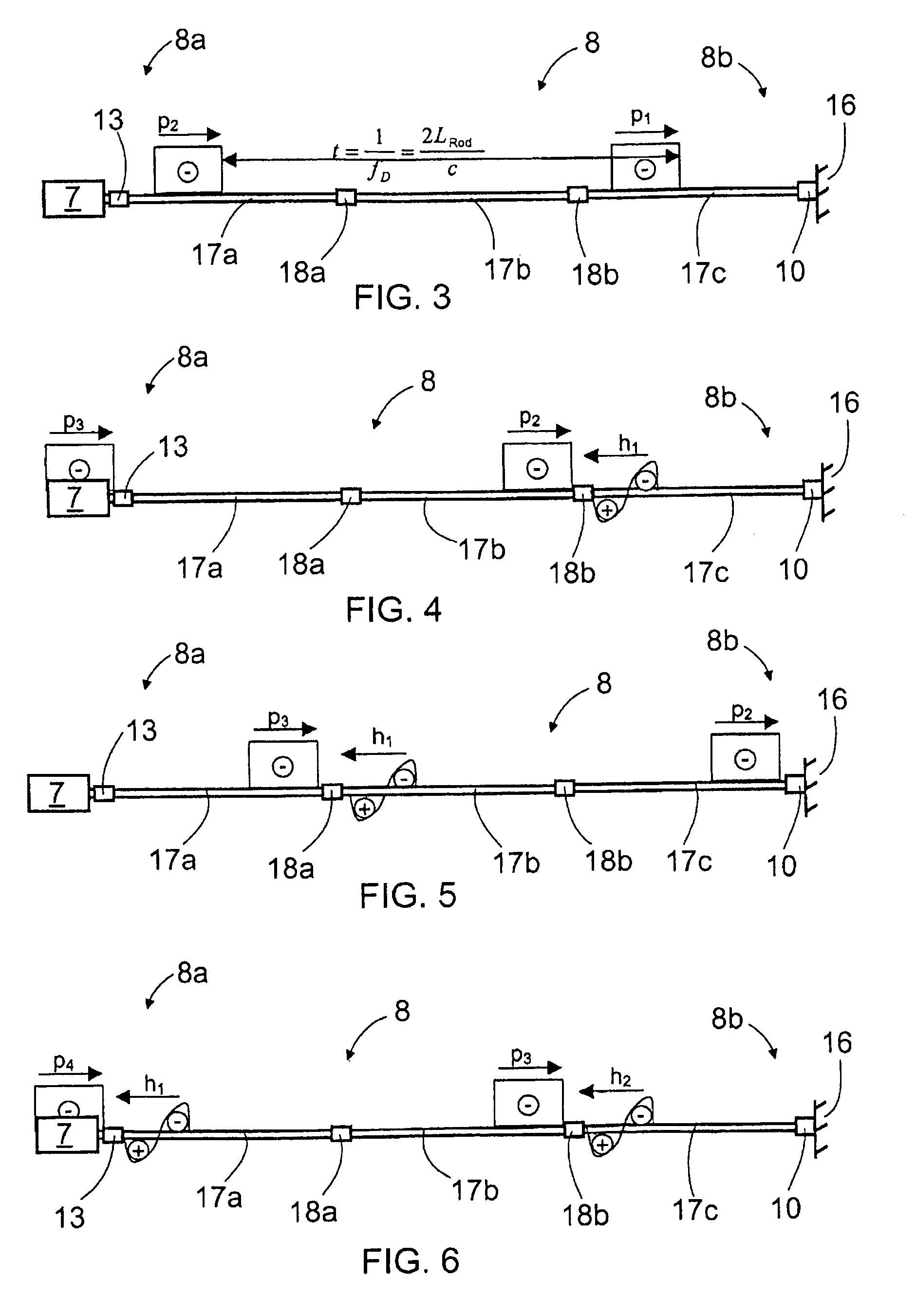

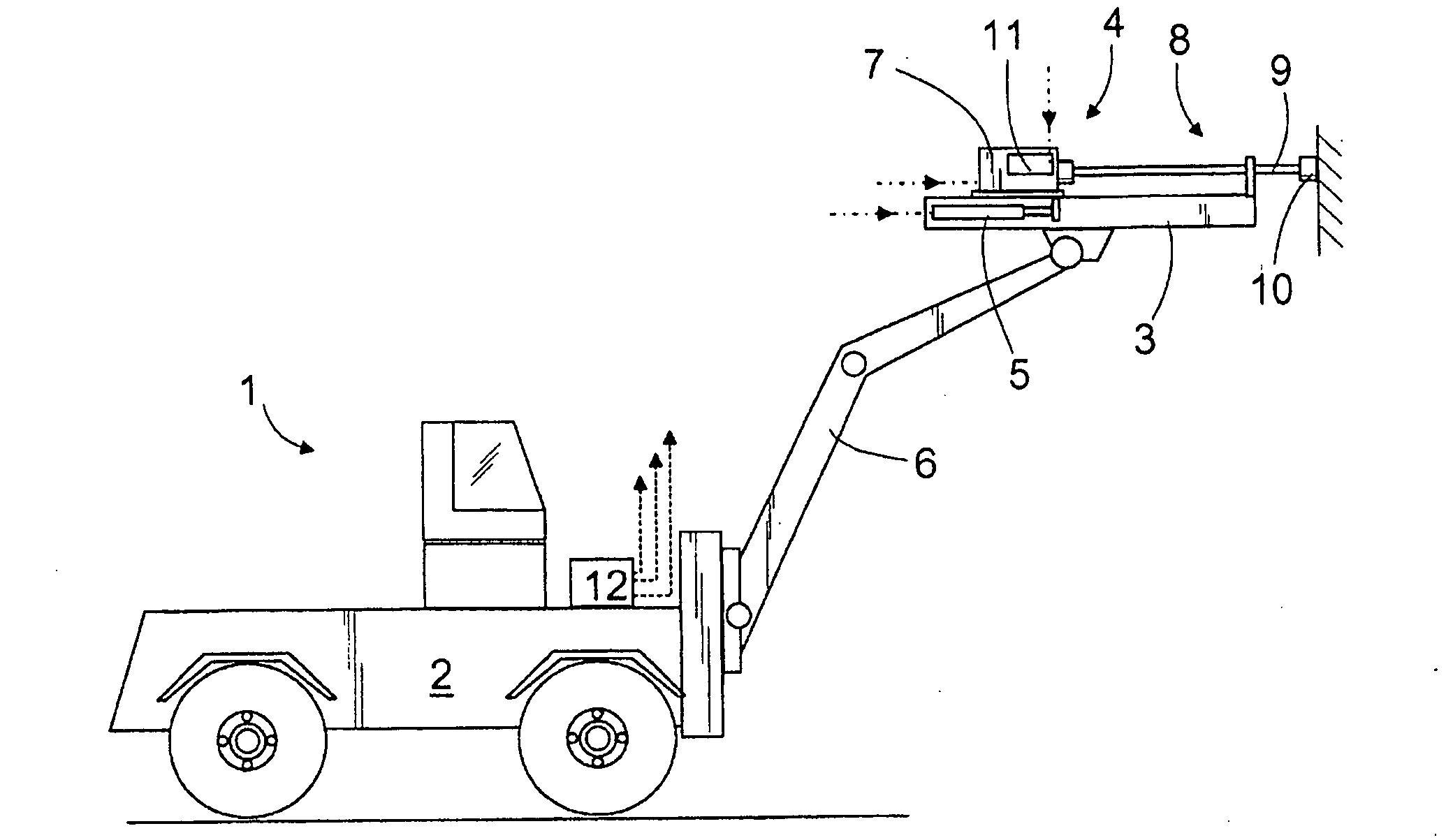

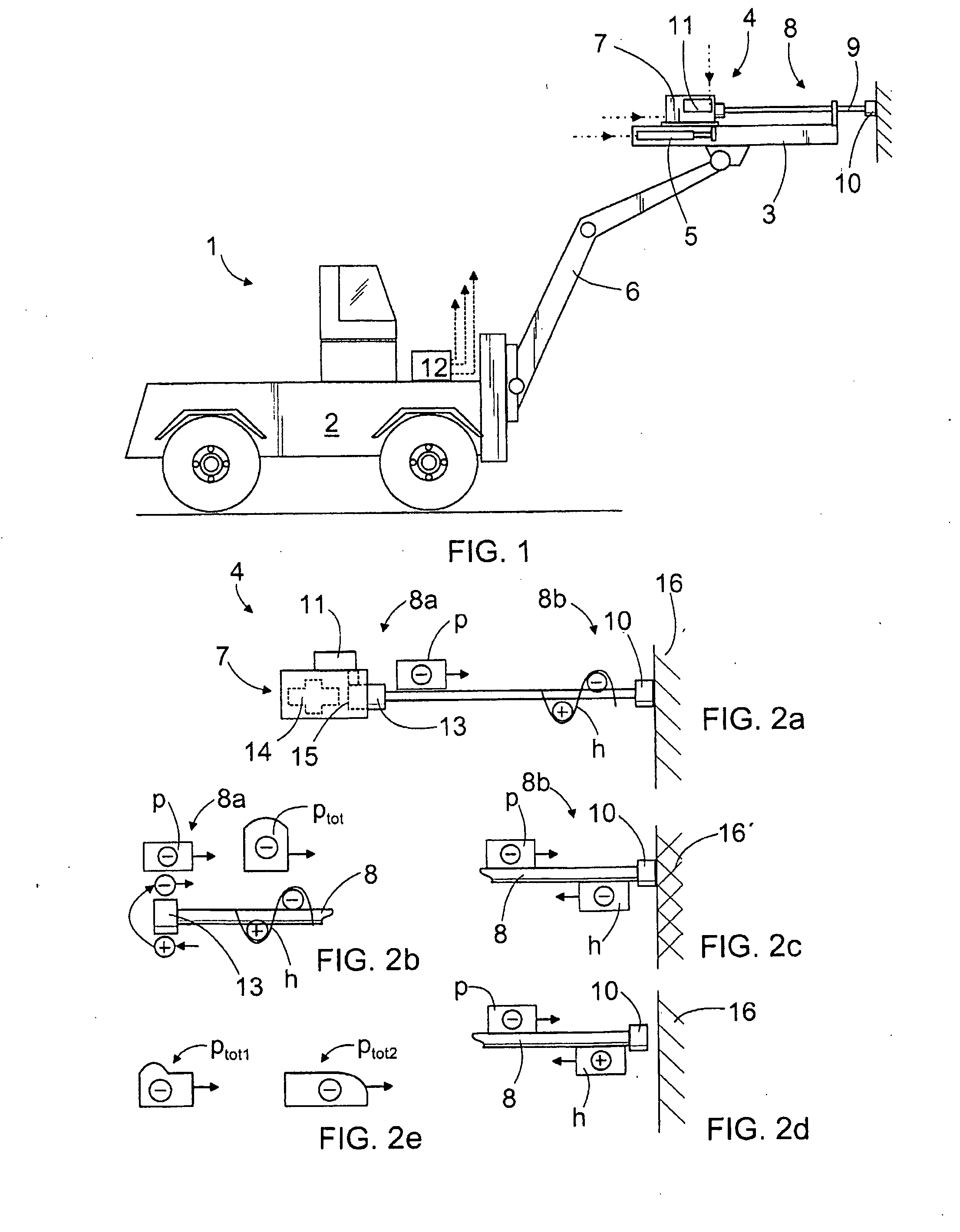

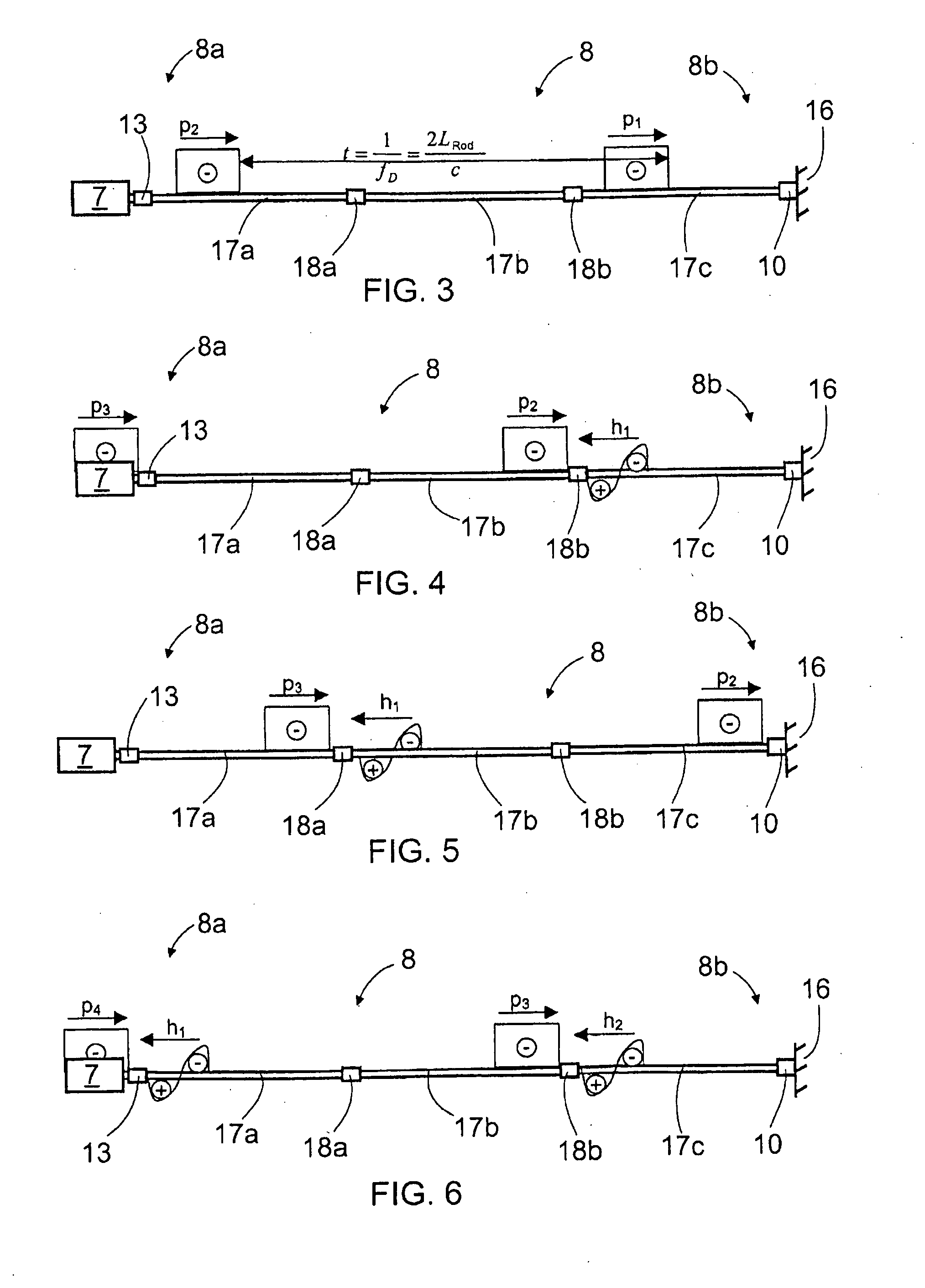

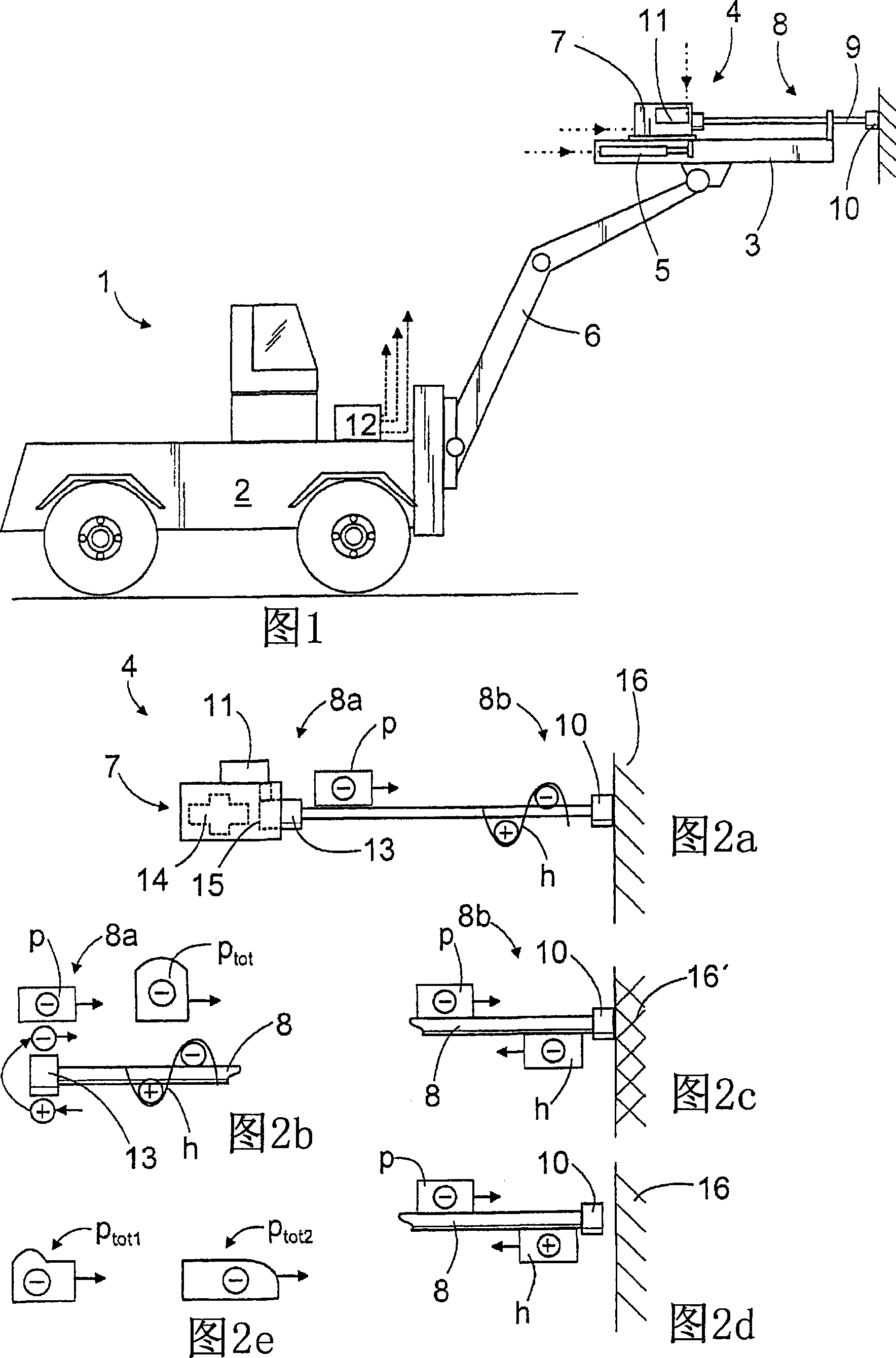

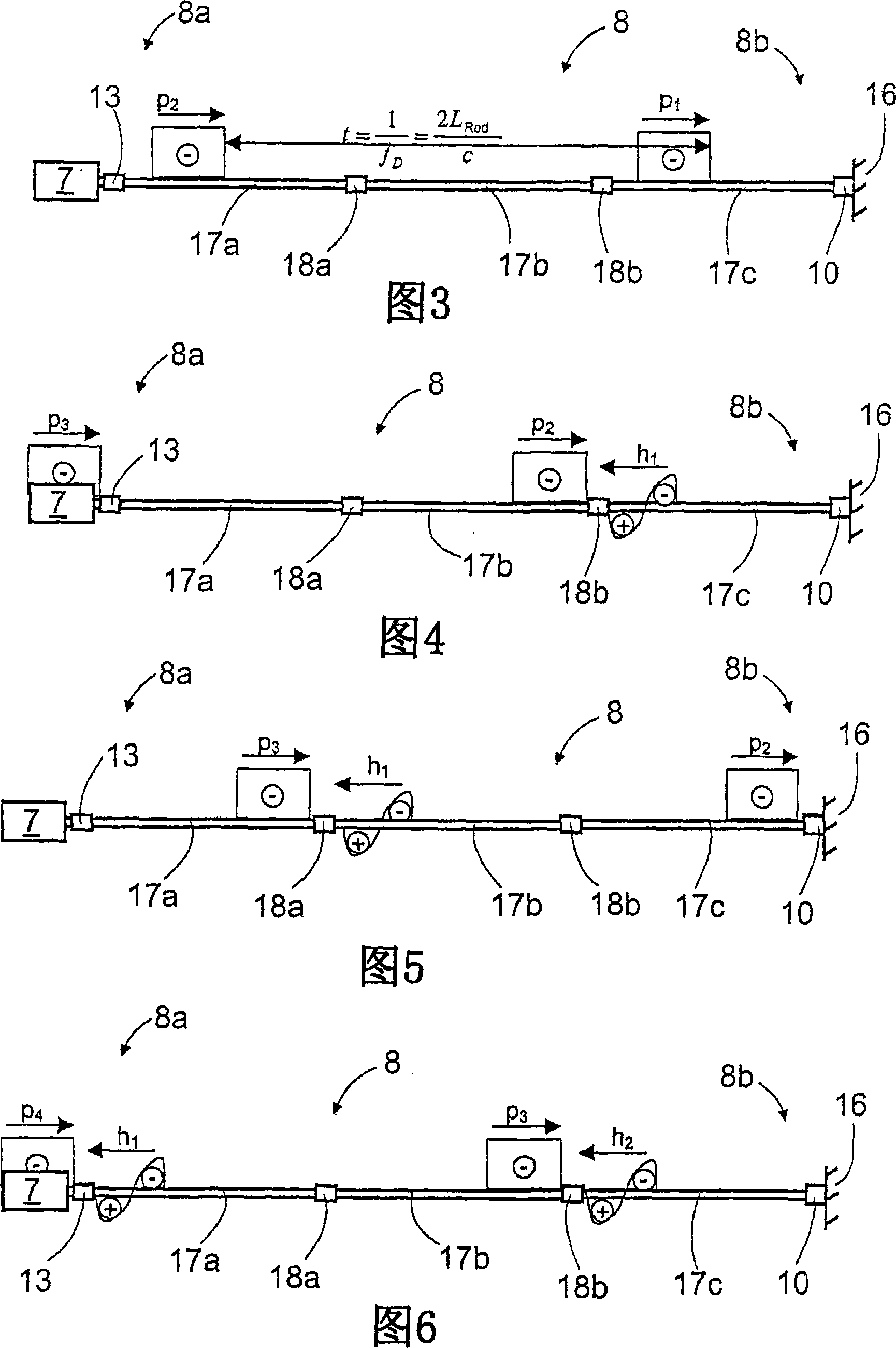

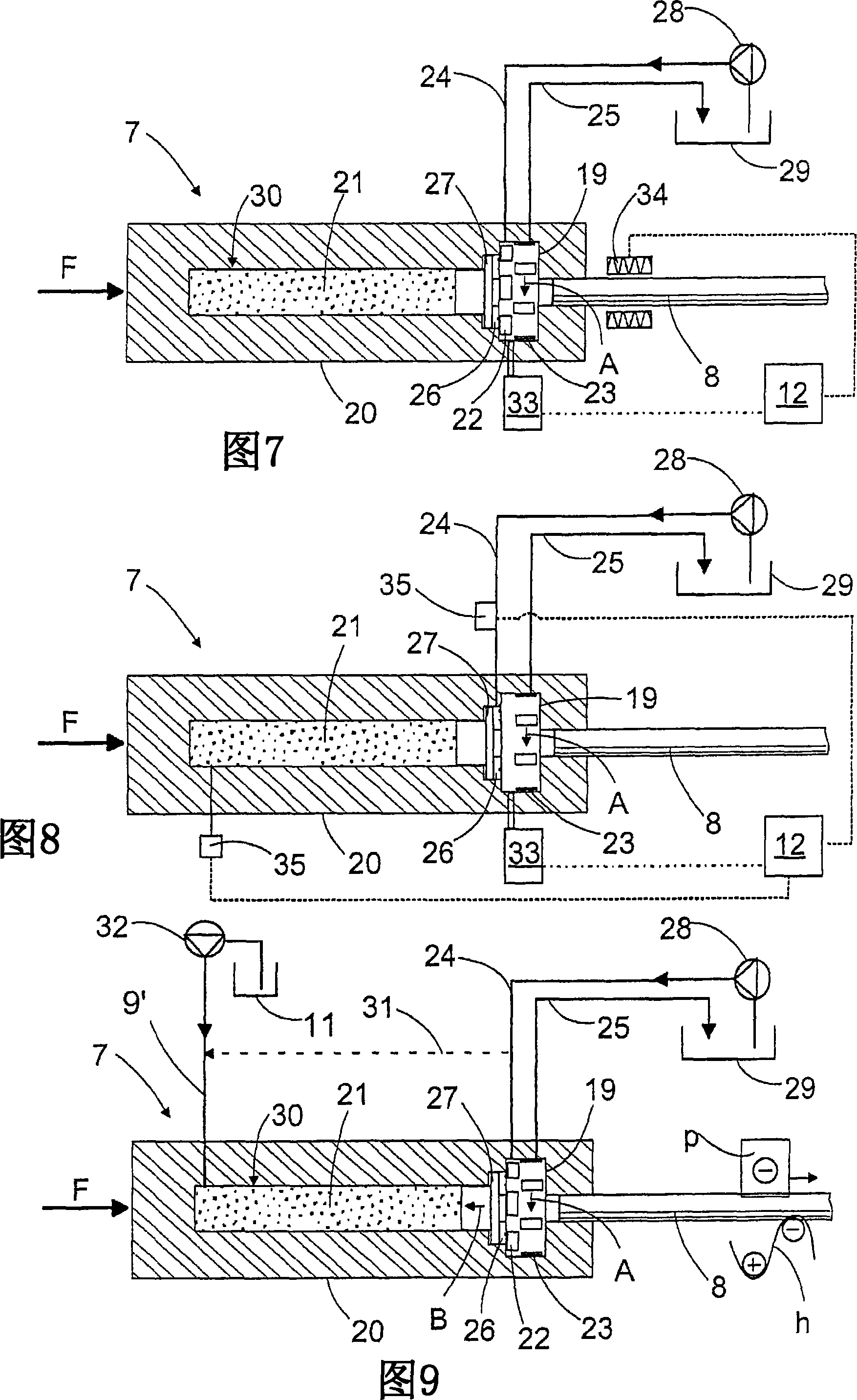

Method for controlling percussion device, software production, and percussion device

InactiveUS7717190B2Improve overall utilizationIncrease energy contentReciprocating drilling machinesConstructionsDevice formPropagation time

Owner:SANDVIK MINING & CONSTR OY

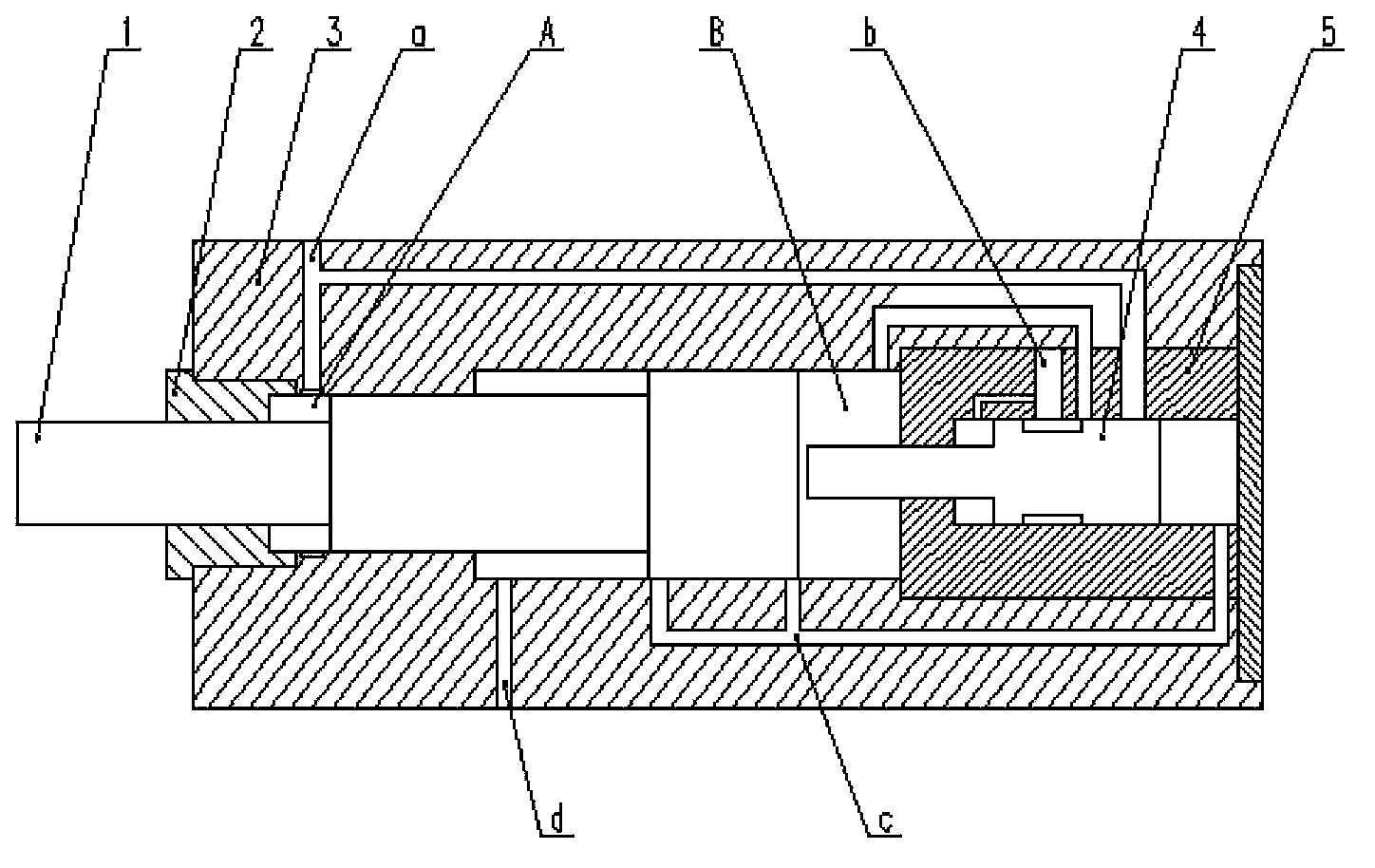

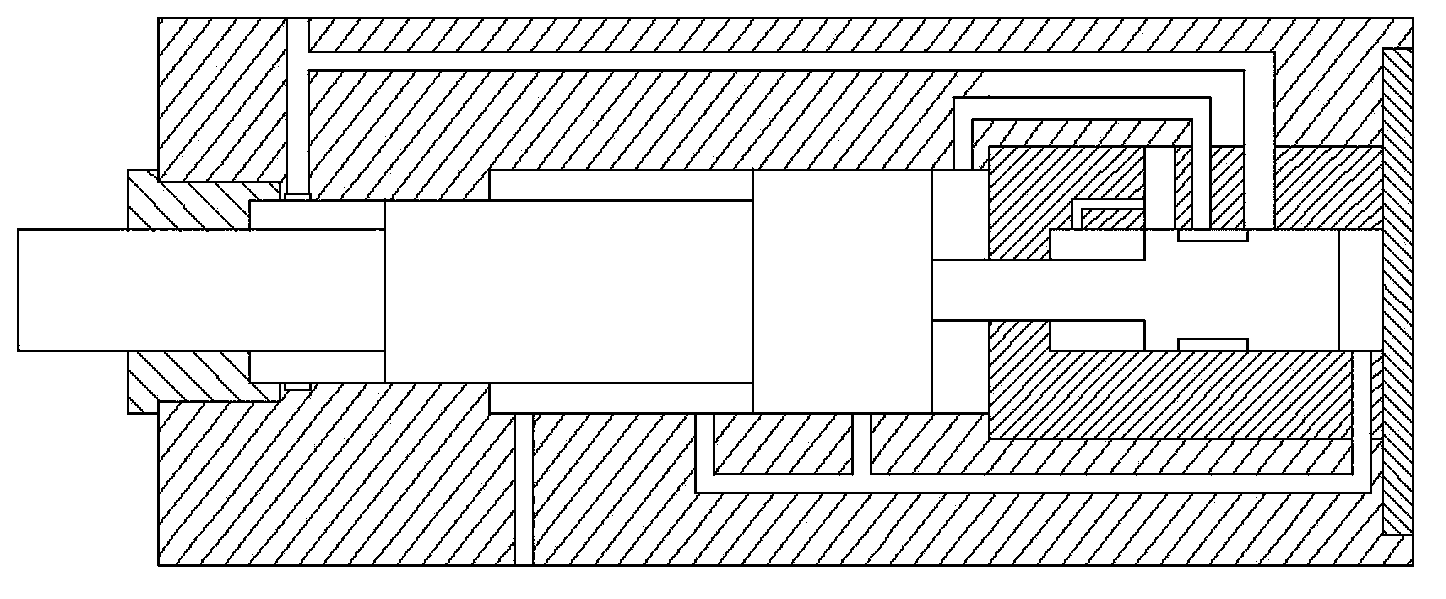

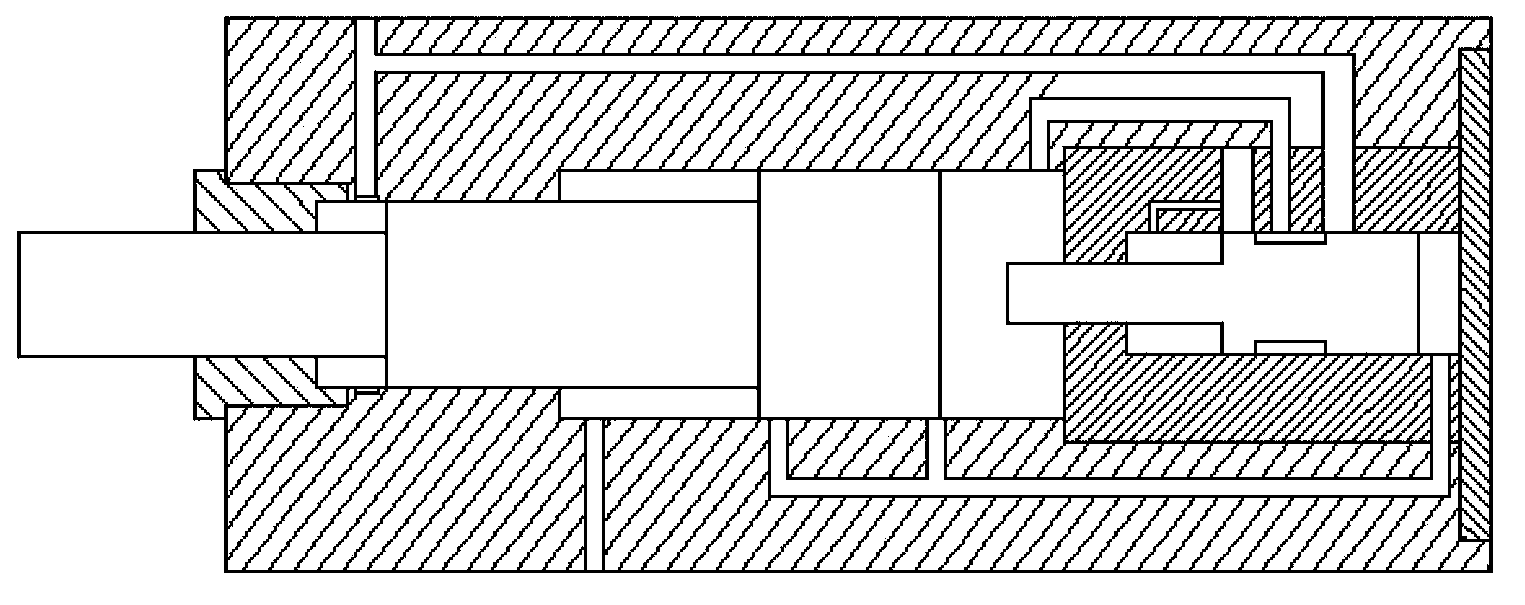

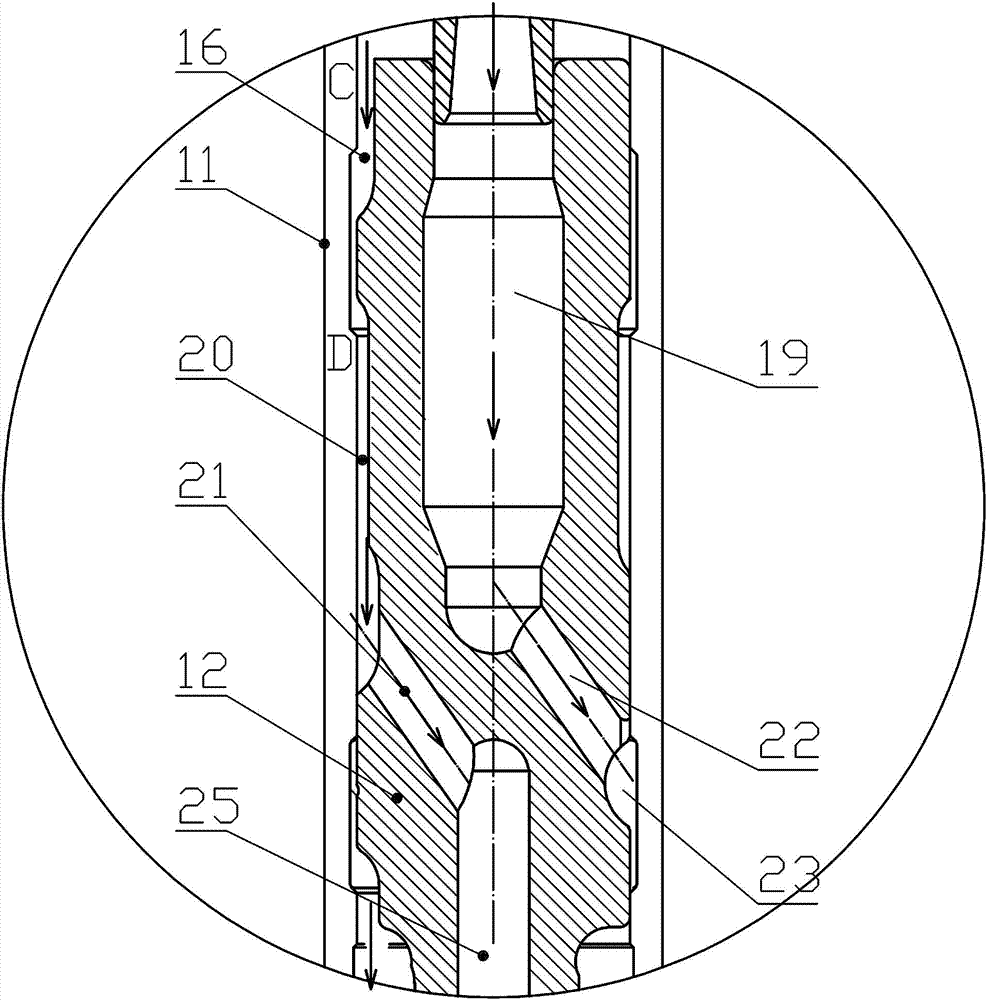

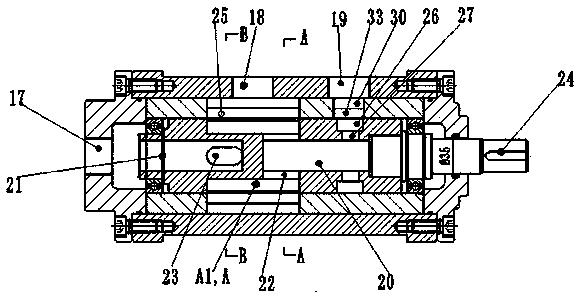

Hydraulic impacter

ActiveCN103352895AReduce processing difficultyHigh speedServomotor componentsEngineeringCylinder block

The invention discloses a hydraulic impactor. A piston comprises a striking section, a front-cavity section and a rear-cavity section; diameters of the striking section, the front-cavity section and the rear-cavity section are increased sequentially; the striking section of the piston is mounted on a cylinder body through a guide sleeve; the front-cavity section of the piston is arranged in a front cavity of the cylinder body; the rear-cavity section of the piston is arranged in a rear cavity of the cylinder body; a flat valve is mounted in the rear cavity of the cylinder body; a cavity is formed between the valve body of the flat valve and the rear-cavity section of the piston; the part, located outside the valve body, of a valve core of the flat valve is arranged in the cavity; the core valve of the flat valve and the piston are arranged coaxially; the front cavity of the cylinder body is connected with a high-pressure oil port; the rear cavity of the cylinder body can be communicated with high-pressure oil and return oil through a feedback oil duct and an oil guide groove respectively; and a rodless cavity of the flat valve can be connected with the rear cavity of the cylinder body and the return oil through the feedback oil duct. The hydraulic impactor improves the rock breaking efficiency, has an anti-idling function, prolongs the service life of a drill tool, and reduces the processing difficulty.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

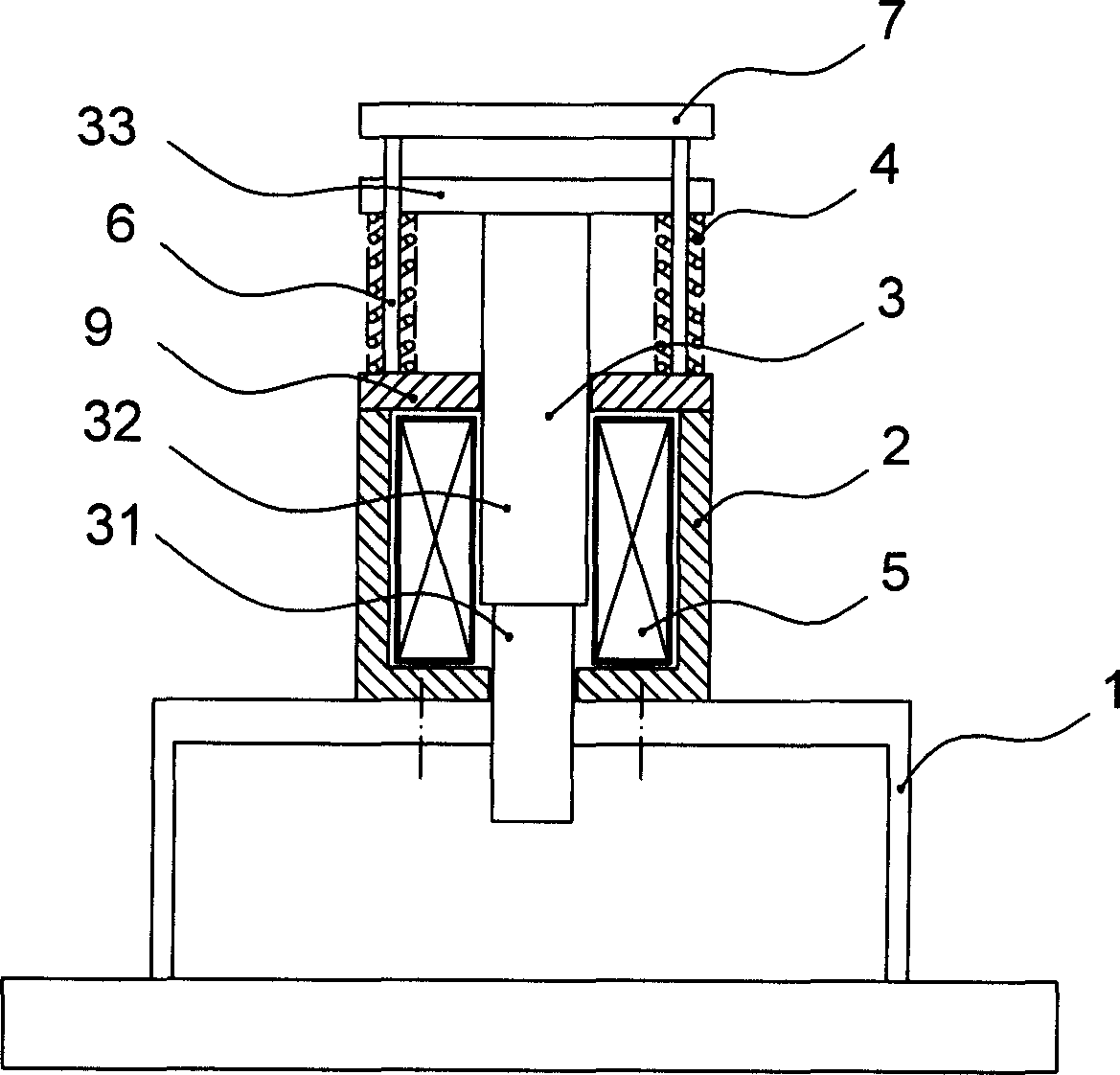

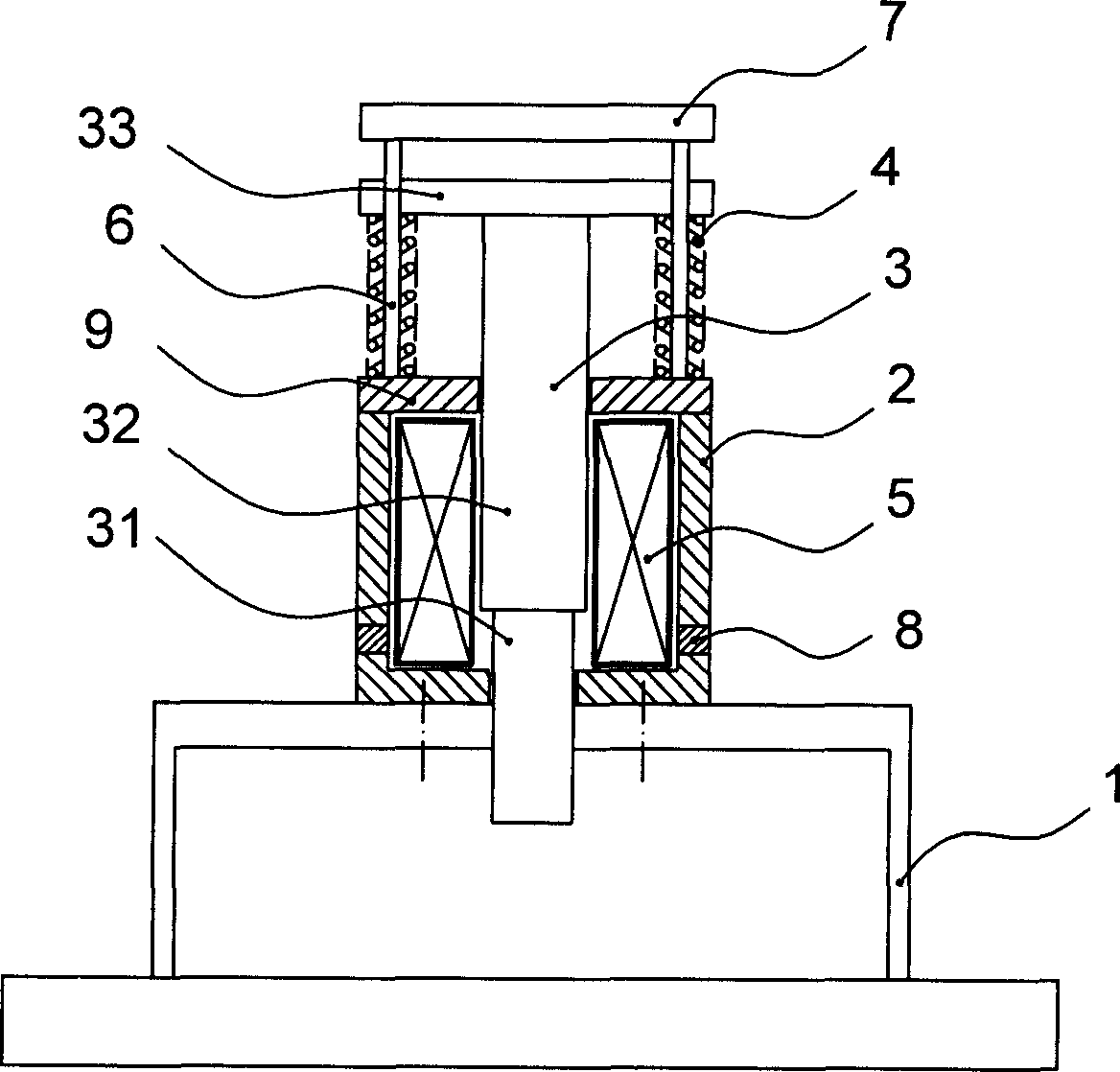

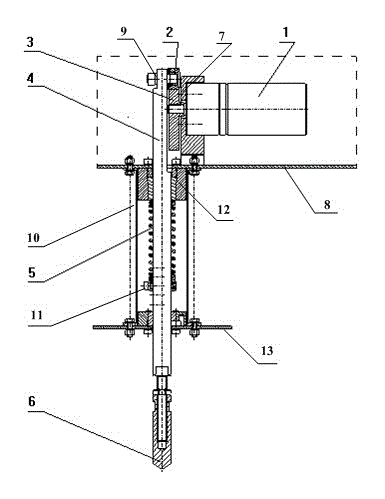

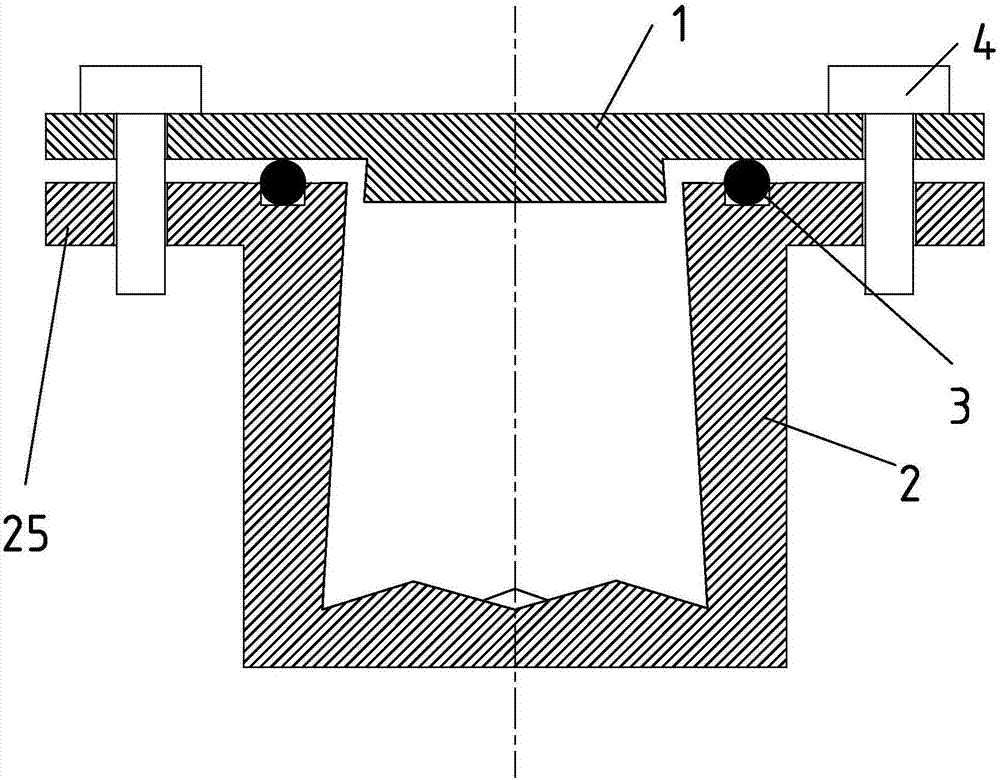

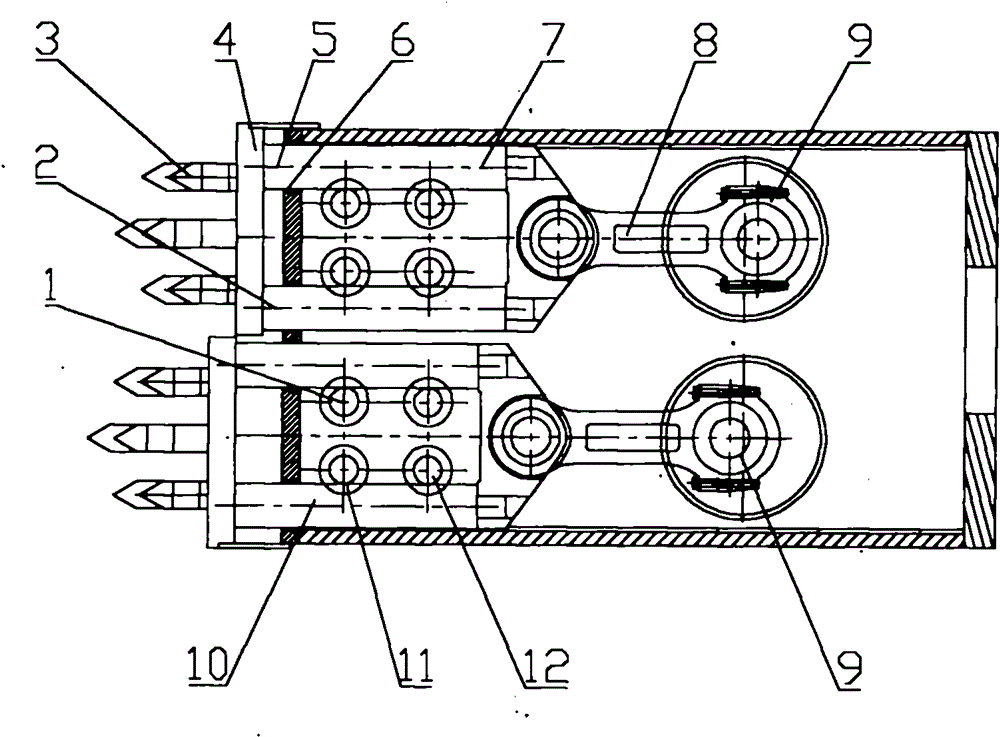

Abrasion test method of air valve and seat ring novel abrasion test system of valve and seat ring

InactiveCN101398359AHigh impact frequencyShorten test timeMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceEngineeringCombustion

The invention relates to a quick abrasion testing system in the field of power machinery technique, aiming at providing a novel abrasion testing system used for a valve and a seat ring used for an internal combustion machine; the system comprises a cylinder cover, a valve, a valve spring and a valve seat ring; the valve is positioned on the cylinder cover; the valve seat ring is positioned between the valve and the cylinder cover; the valve rod of the valve passes through the cylinder cover; the end of the valve rod fixes the spring seat ring by a valve lock lamp; one end of the valve spring is supported on the cylinder cover and the other end thereof pushes against the spring seat ring; the system also comprises an electromagnet which is arranged on the cylinder cover and positioned at the lower part of the spring seat ring; the quick abrasion testing system can achieve extremely high impact frequency, and shorten the testing time; the dripping speed of the valve can be jointly determined by two different sensors and the accuracy of the test is improved; and the temperature of the cylinder cover is kept at the temperature of the cylinder cover when the internal combustion machine works normally, thus ensuring the reliability of the testing conclusion. The parts are few, the structure is simple and the manufacture cost is low.

Owner:ZHEJIANG UNIV

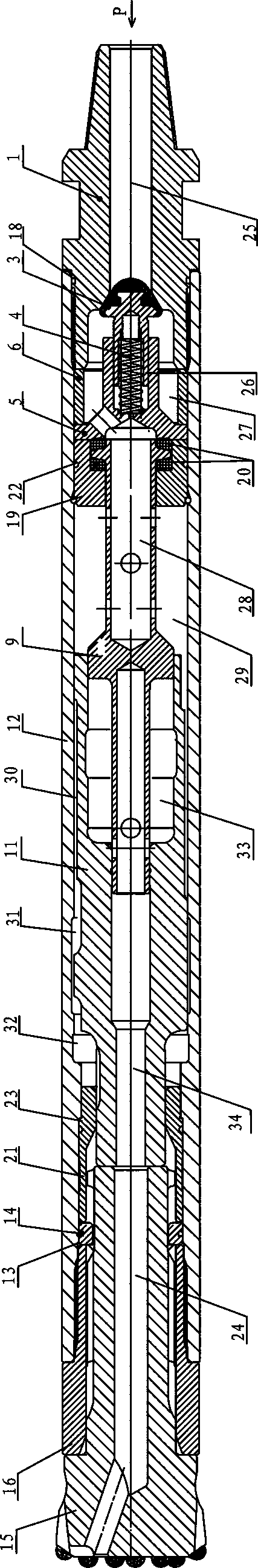

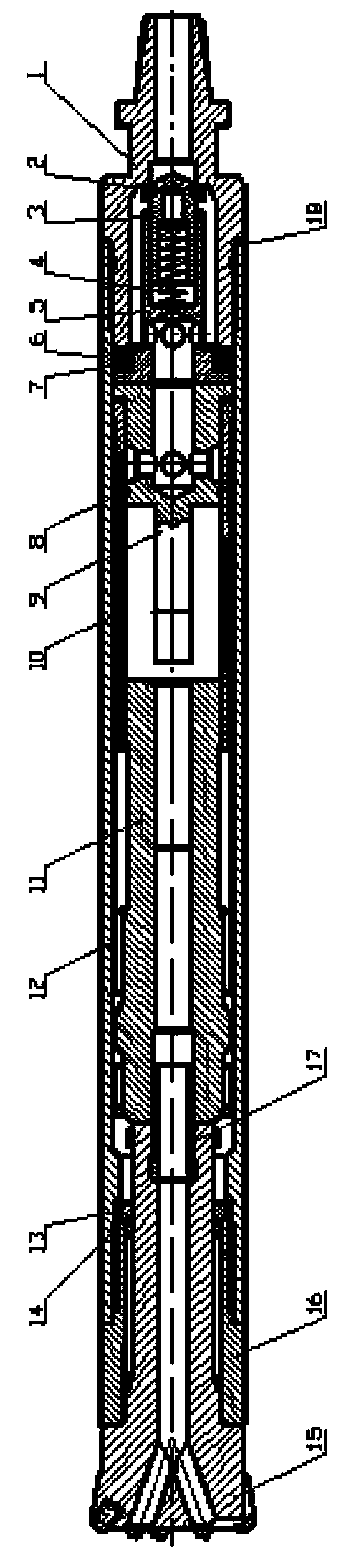

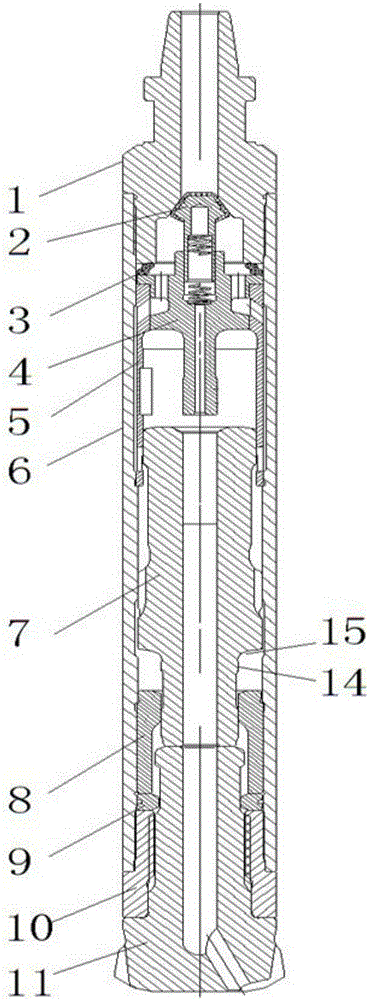

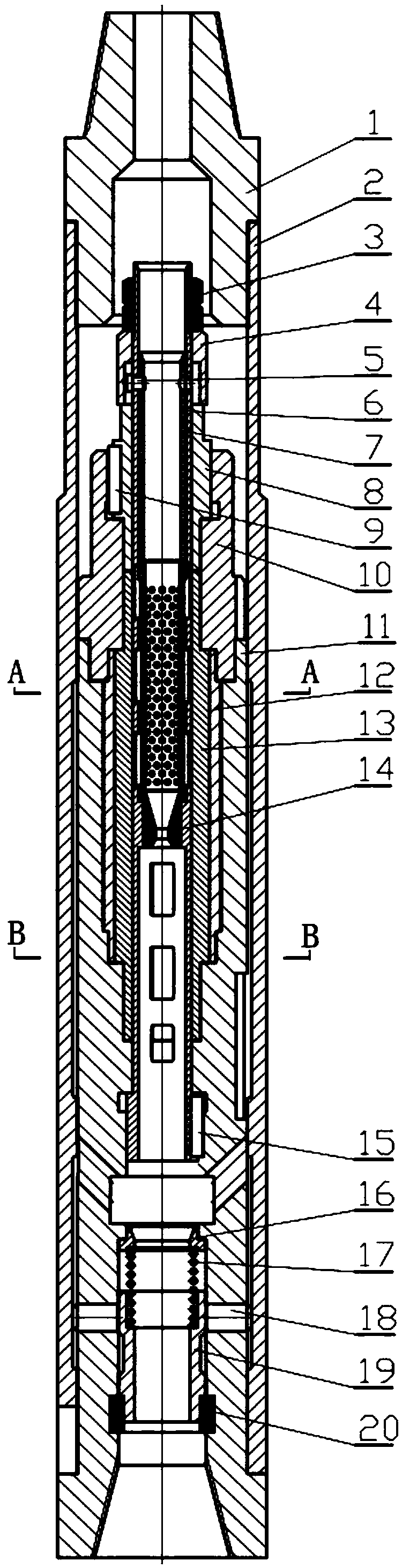

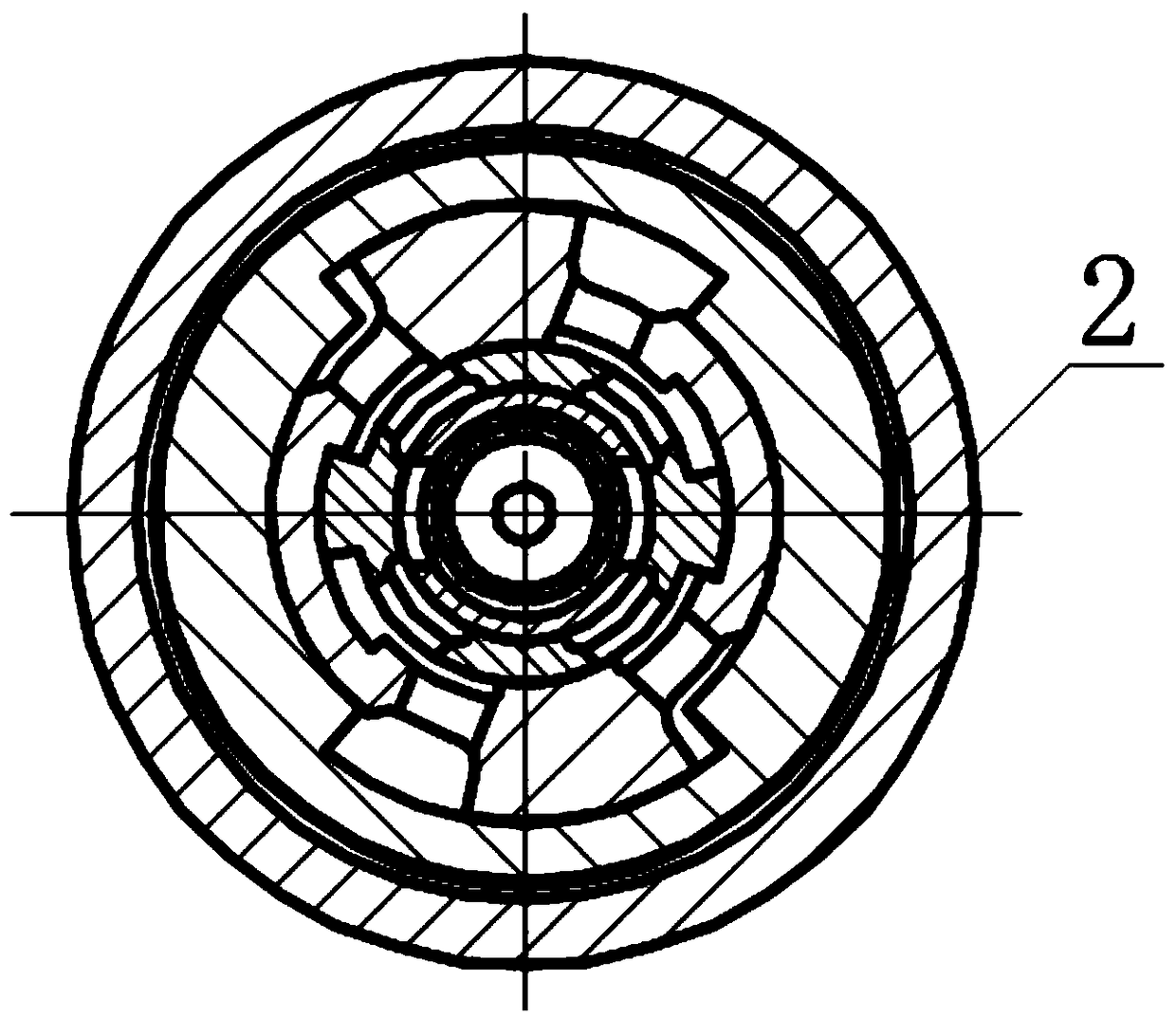

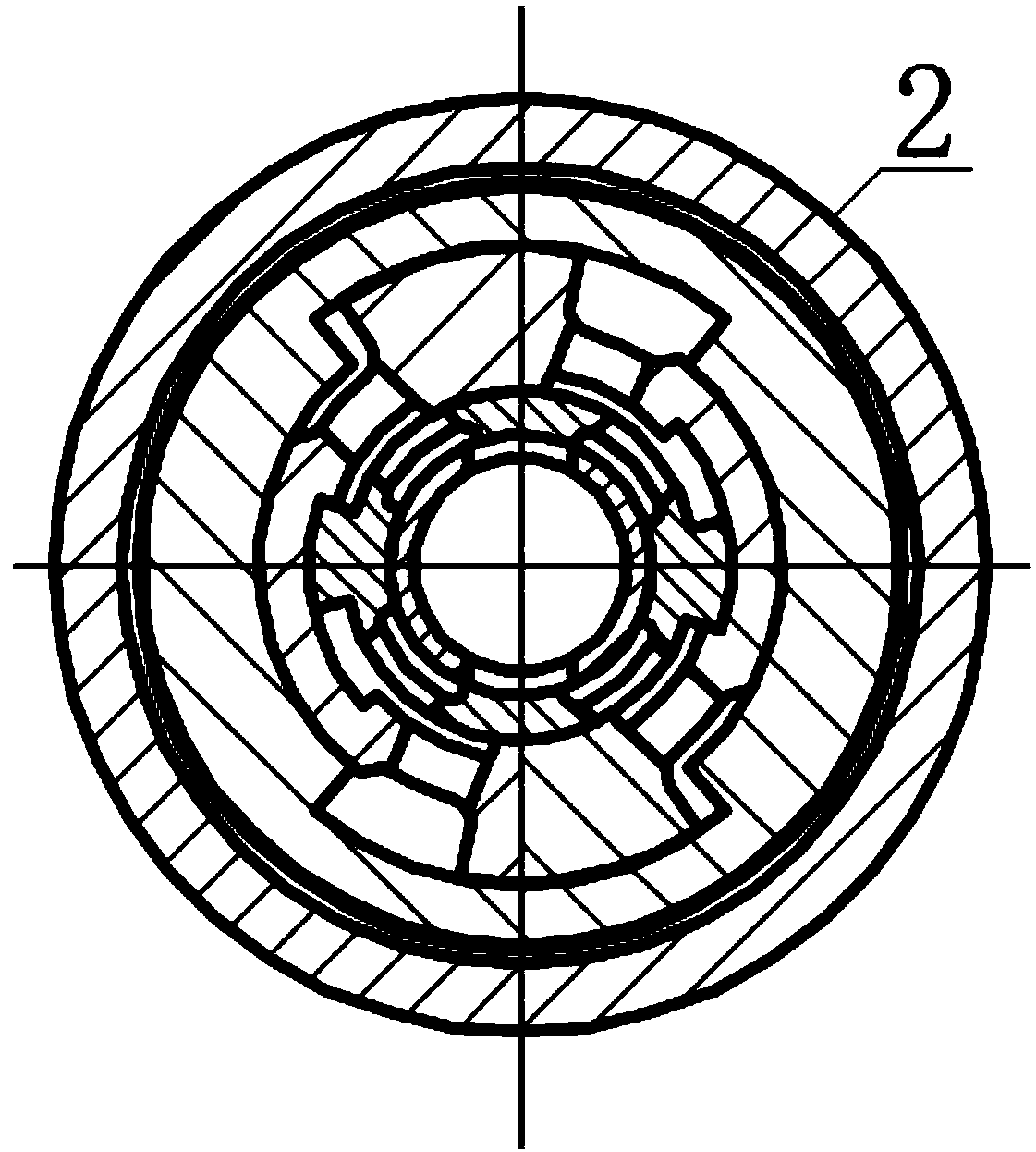

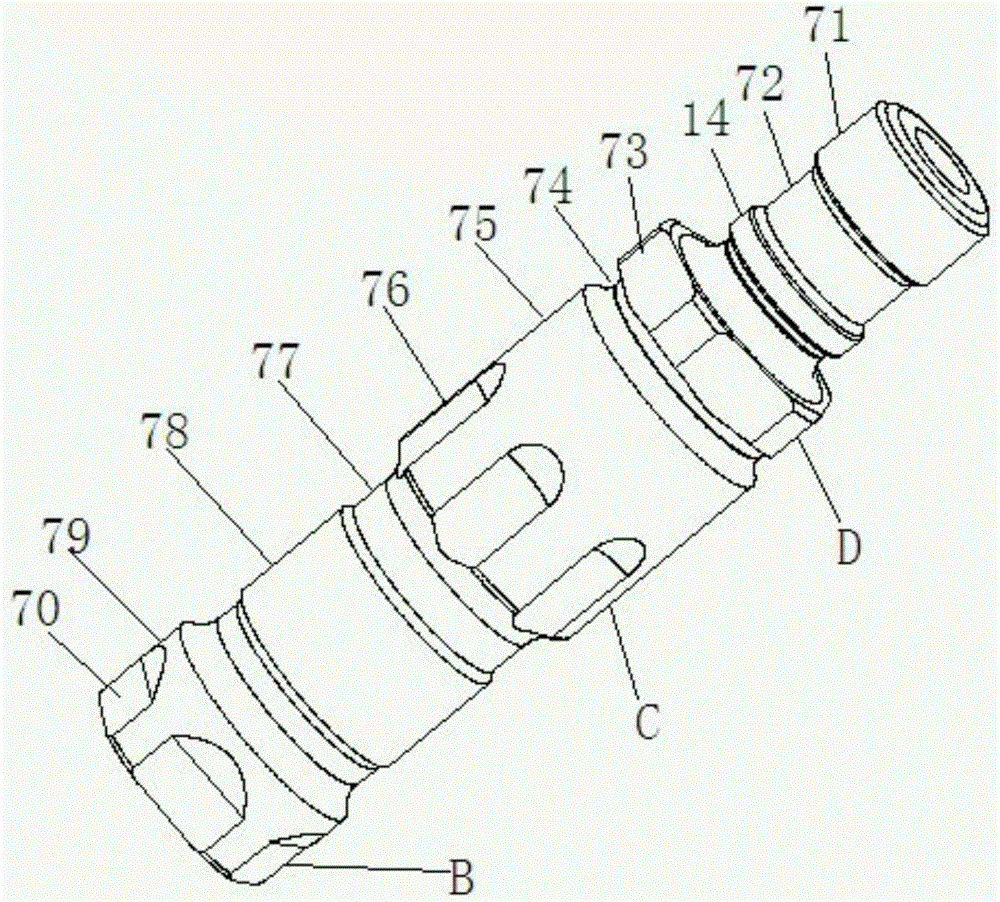

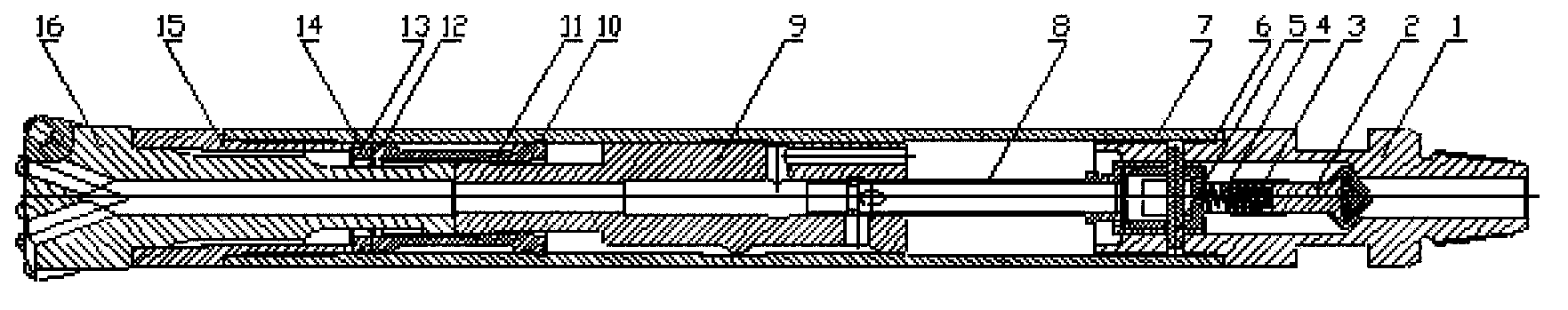

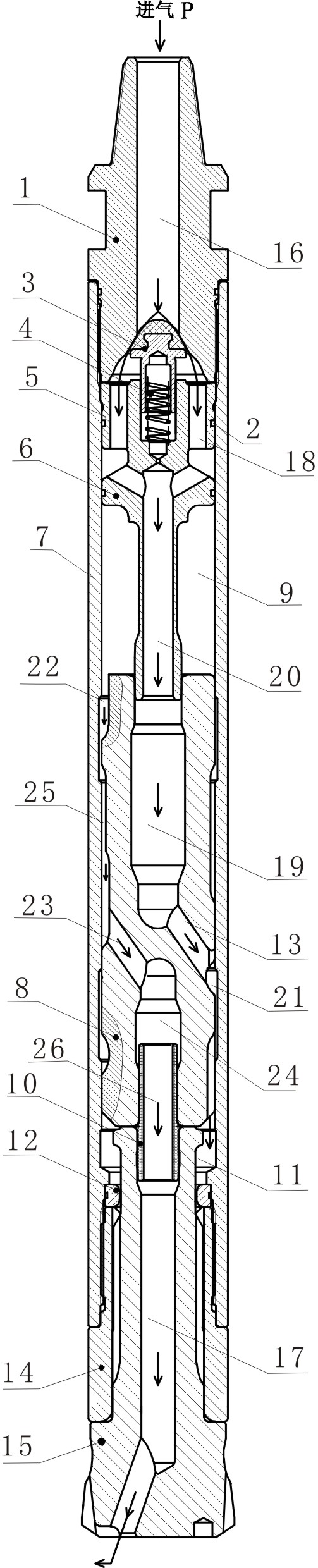

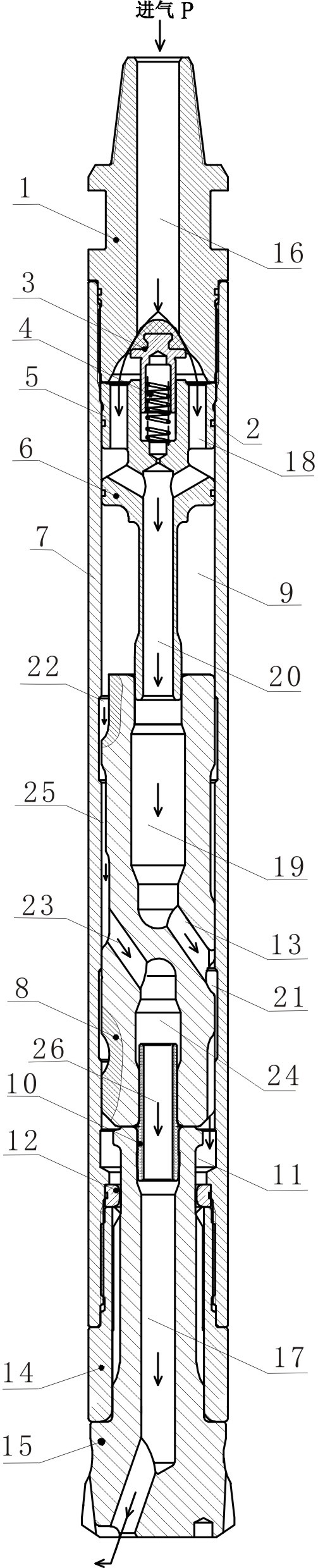

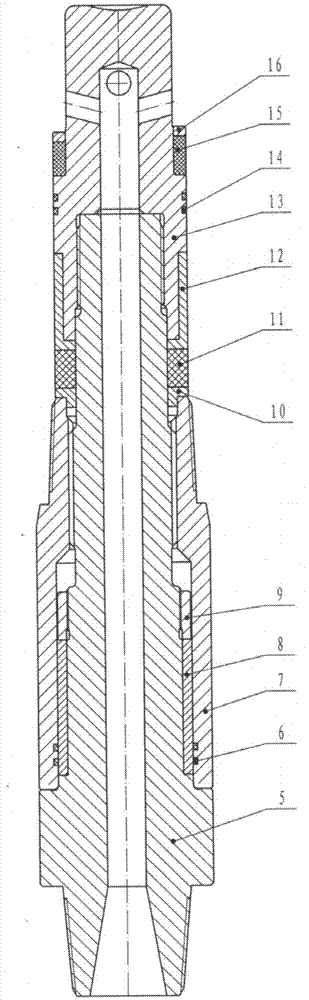

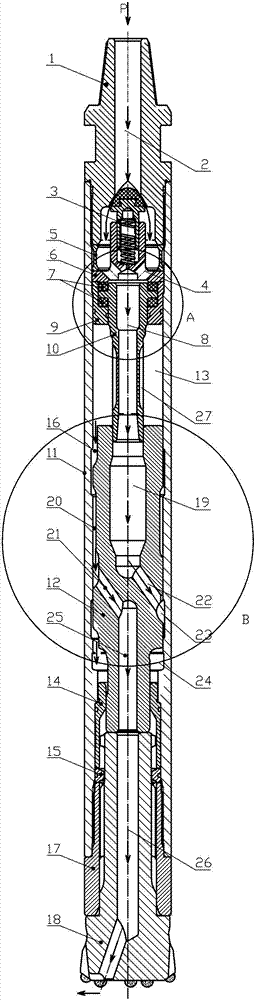

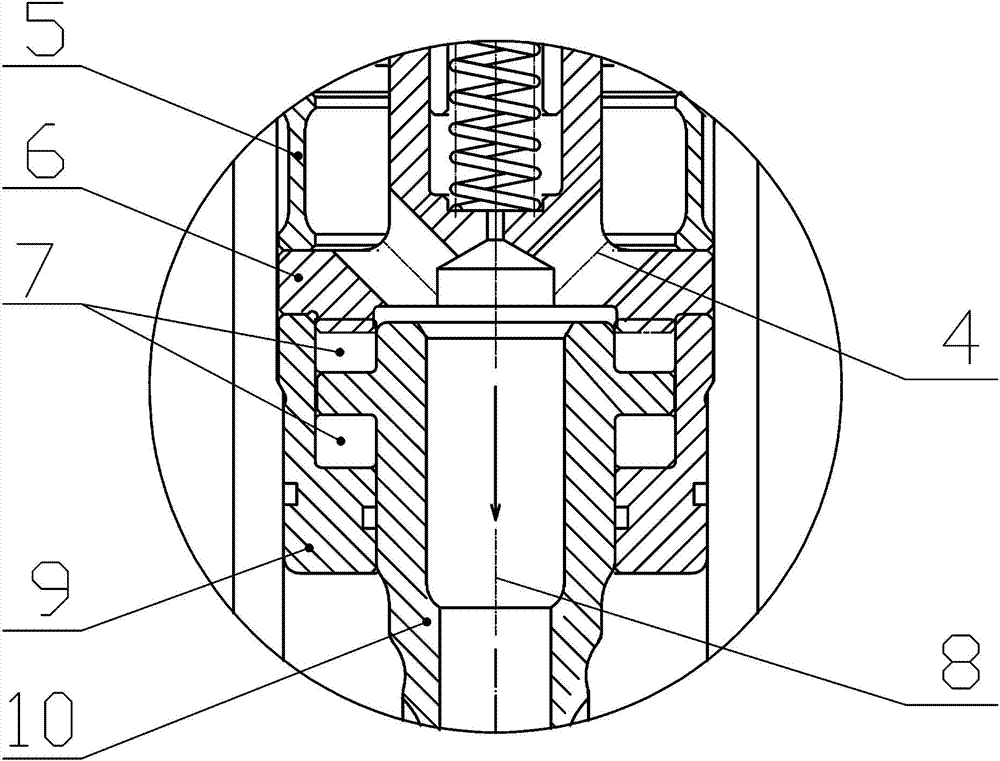

Efficient down-hole hammer

InactiveCN103375131AReliable connectionGuaranteed stability and efficiencyBorehole drivesPistonDrill bit

An efficient down-hole hammer comprises a back joint, a check valve, an air distribution rod, a piston, a cylinder, a clamping ring, a drill head and a front joint. The check valve is a one-way valve and comprises a valve seat, a spring and a steel washer. The slotted piston is provide with a hole, a positioning sleeve is arranged at the back end of a valve end cover, and the air distribution rod, a positive vibration-proof rubber ring and a negative vibration-proof rubber ring are clamped in the positioning sleeve together. The efficient down-hole hammer is not provided with an inner cylinder structure, the air distribution mode is greatly innovated, a vibration-proof fine tuning device arranged between the back joint and the air distribution rod can effectively absorb counterforce of piston motion, the air distribution rod can be subjected to automatic fine tuning so as to keep the assembling verticality, the adaptive drill head is not provided with a tail pipe, and therefore high pressure air leakage is reduced, work efficiency is improved and production cost is reduced. In addition, the piston has a reliable service life.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Method for controlling percussion device, software production, and percussion device

InactiveUS20090188686A1Utilized in drillingIncrease energy contentConstructionsTemperatue controlDevice formPropagation time

A method and software product for controlling a percussion device belonging to a rock-drilling machine, and a percussion device. The impact frequency of the percussion device is set so that the percussion device forms a new compression stress wave to the tool always when reflected waves from the previous compression stress waves reach a first end of the tool. This requires that the impact frequency be set proportional to the propagation time of the stress wave, whereby the length of the used tool and the propagation velocity of the stress wave in the tool material are to be noted.

Owner:SANDVIK MINING & CONSTR OY

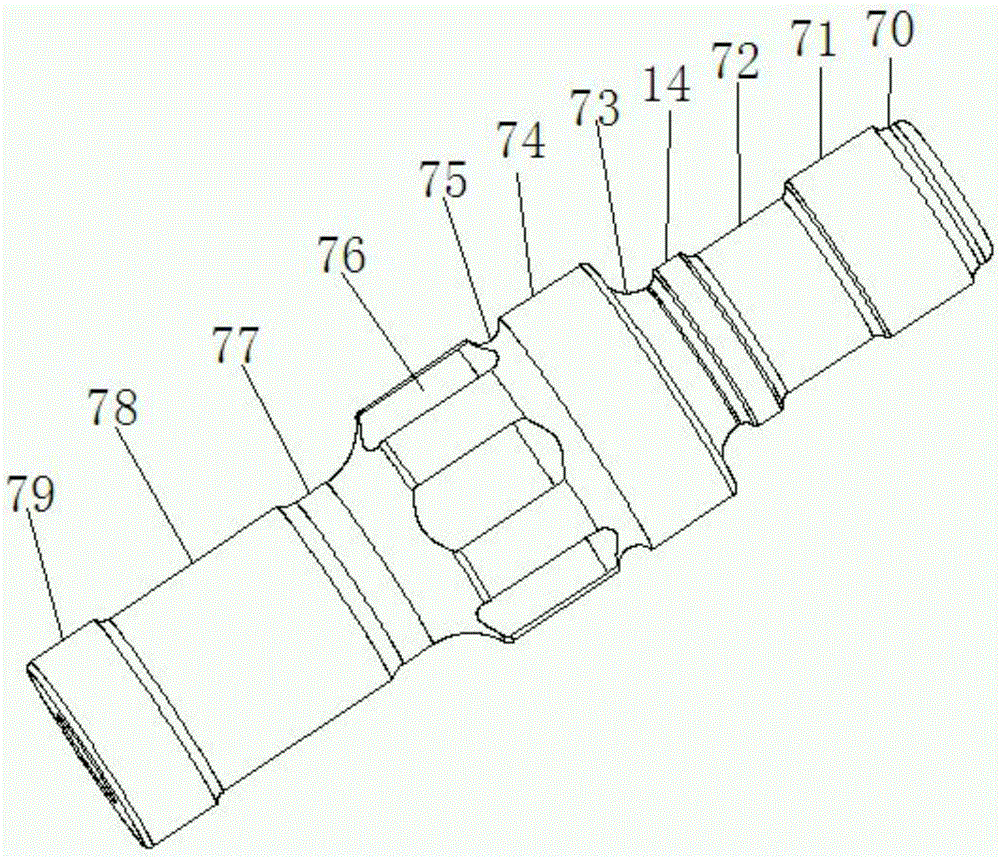

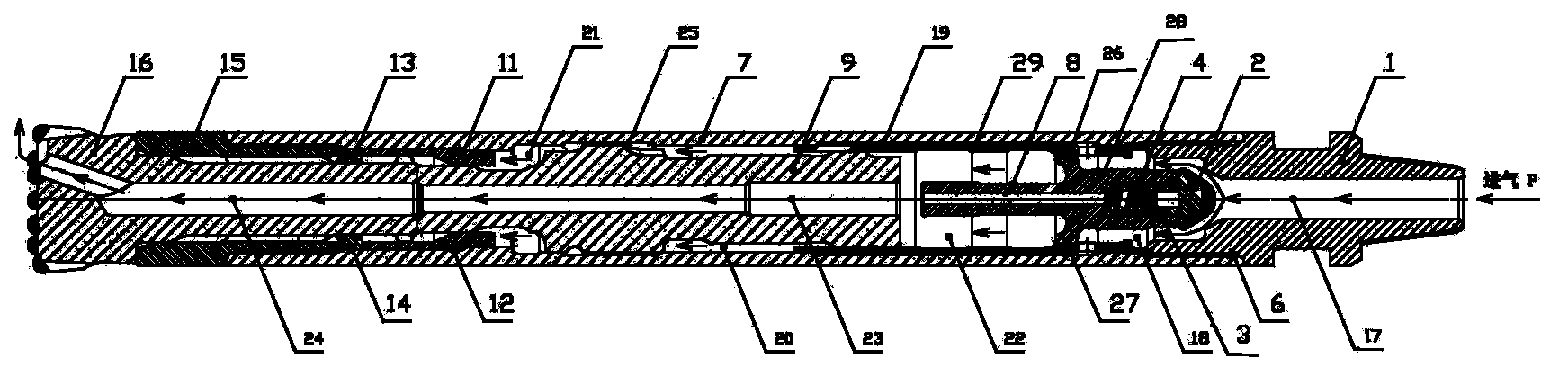

High-air-pressure quick-percussion down-the-hole percussive drill tool

The invention discloses a high-air-pressure quick-percussion down-the-hole percussive drill tool. A spring washer is arranged between an air distributor and a rear joint; a snap ring is arranged between a front joint and a bush; a piston is provided with a piston large end; one end of the piston large end is provided with a piston small path; the other end of the piston large end is provided with a piston tail path; one section of the piston large end is a smooth cylinder; the other section of the piston large end is uniformly provided with air grooves; an annular ventilating groove is formed between the air grooves and the smooth cylinder; an annular lug boss is arranged at a position, which is close to the piston large end, of the piston small path; the annular lug boss, the piston large end, an outer cylinder and the bush form a buffering air cavity; the piston tail path is connected with a cylindrical end; a piston tail end is arranged at the tail end of the cylindrical end; front air holes are uniformly formed in one end of an inner cylinder; tail oblique air holes are uniformly formed in the other end of the inner cylinder; arc grooves are uniformly formed in the inner wall of the inner cylinder; and a compressed air chamber is formed between the arc grooves and the tail oblique air holes. The high-air-pressure quick-percussion down-the-hole percussive drill tool is high in drilling speed, not easy to jam, low in failure rate and low in energy consumption; work efficiency is improved greatly; and energy and cost are saved.

Owner:HUNAN XINJINGANG MACHINERY EQUIP

Special hammer device for nuclear power station

InactiveCN103149004AHigh impact energyIncrease the effective strokeShock testingNuclear power plantCam

The invention discloses a special hammer device for a nuclear power station. A direct-current motor is fixedly installed on a base through a motor seat, an output rod of the direct-current motor is provided with a lifting cam, the lifting cam is in fit connection with a roller, a roller shaft of the roller penetrates through one end of an impact rod and is fixed through a bolt, an elastic washer is arranged between the bolt and the impact rod, the lower bottom surface of the base is fixedly connected with one end of a slide sleeve of the impact rod, the other end of the slide sleeve of the impact rod is provided with a cover plate, the impact rod penetrates through a soleplate and the slide sleeve of the impact rod and is vertical to the base, the inner end of the impact rod slide sleeve, which is close to the soleplate, is provided with an impact rod slide sleeve seat, the impact rod is provided with a spring retainer ring, a spring is arranged between the impact rod slide sleeve seat and the spring retainer ring and sleeved on the outer side of the impact rod, and the other end of the impact rod is provided with an impact head. The special hammer device is large in impact energy, long in maximal effective stroke of the cam, high in precision, high in impact frequency and light in weight.

Owner:HANGZHOU DIANZI UNIV +1

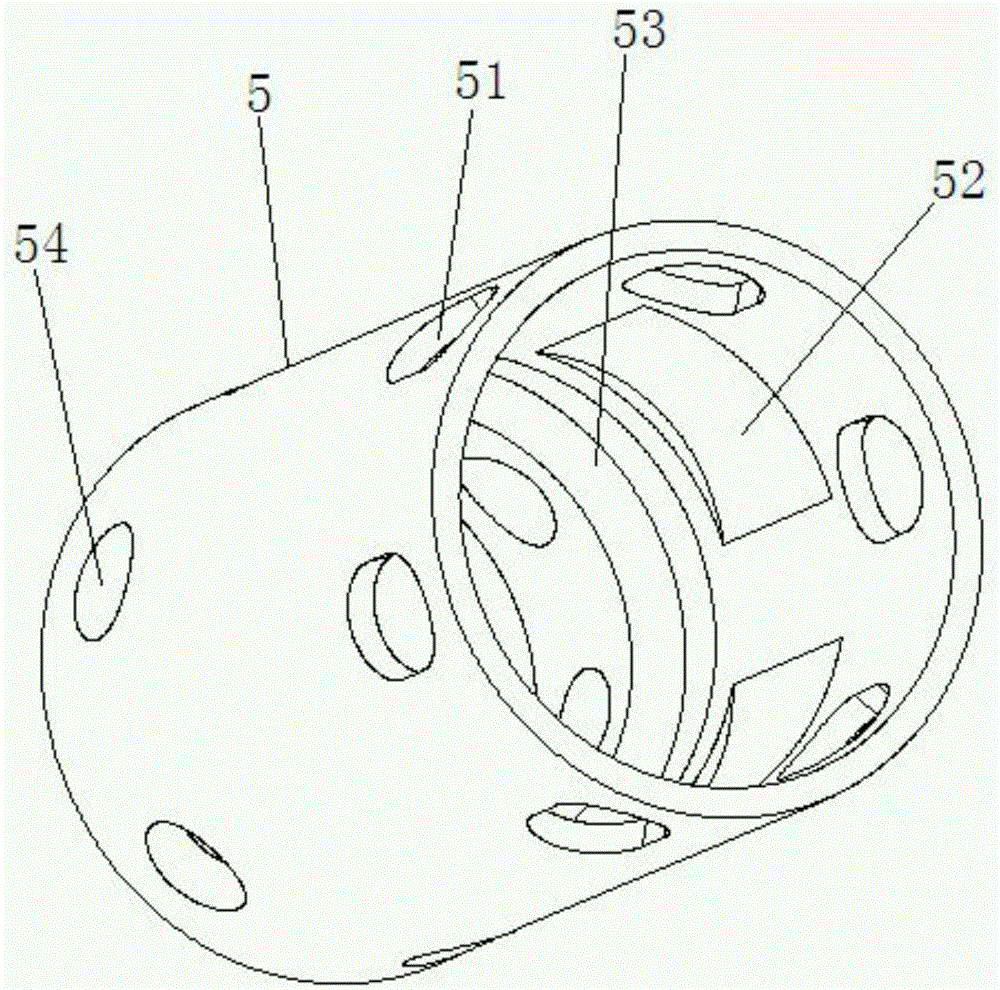

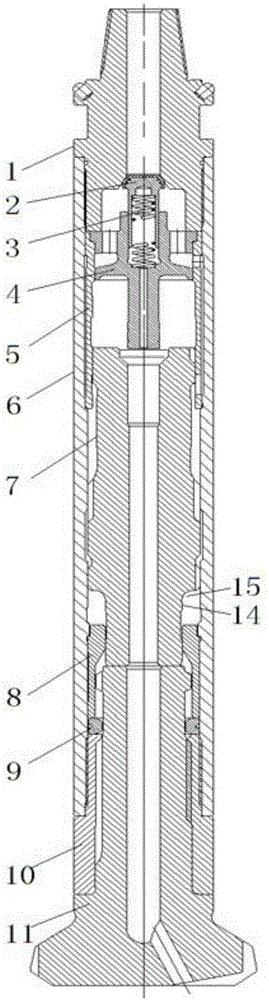

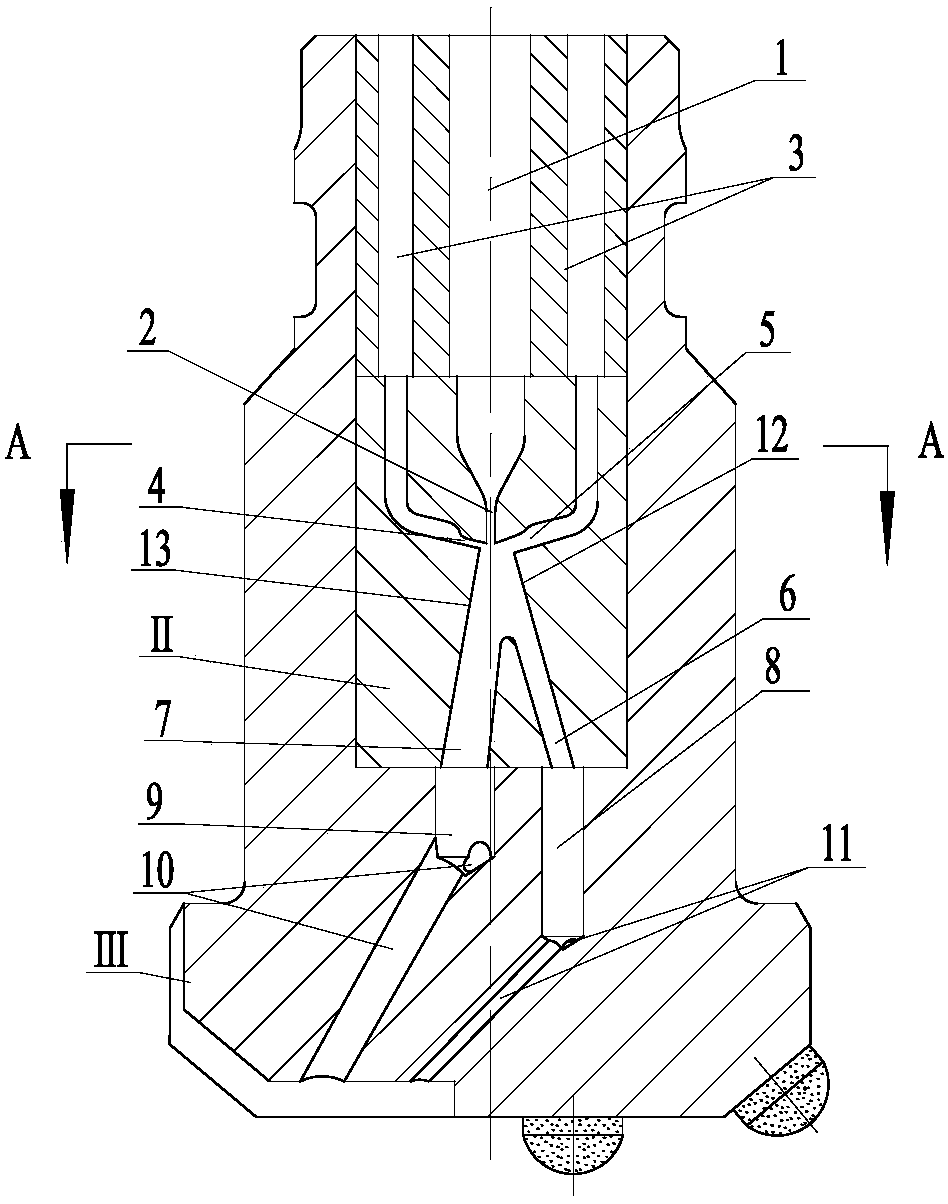

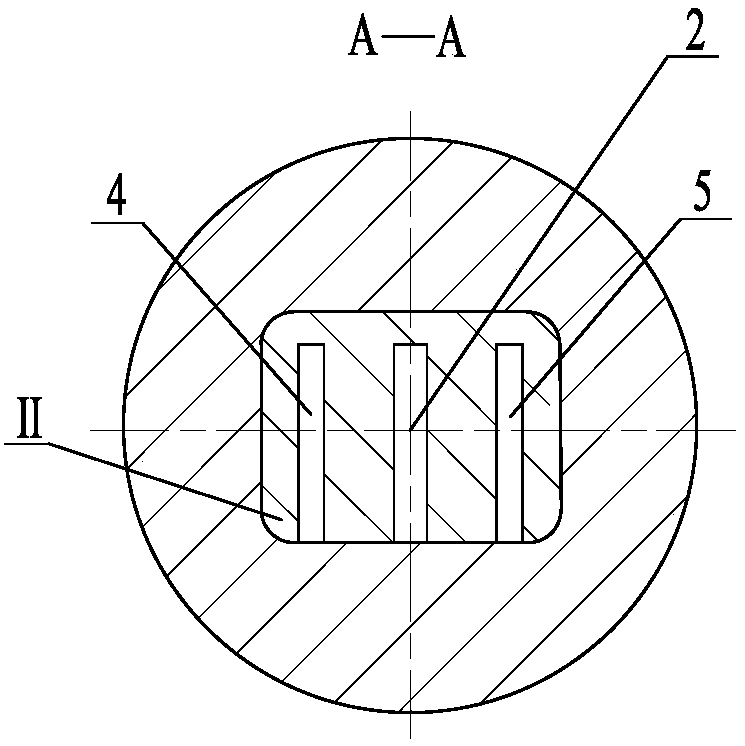

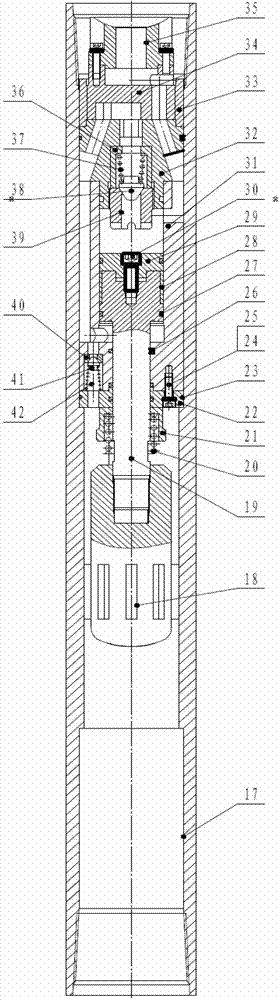

Torsion impact device

The invention discloses a torsion impact device, and belongs to the field of petroleum drilling and rock and soil drilling. The torsion impact device is consisted of a top joint, an outer tube, an inner tube impact assembly and a suspension device. The upper end of the top joint is connected with a drilling tool, and the lower end of the top joint is connected with the outer tube through a thread;the inner tube impact assembly is arranged in the outer tube; and the suspension device is positioned on the inner side of the lower end of the inner tube impact assembly and fix the inner tube impact assembly to the outer tube, the suspension device is constituted by assembling together a spring seat, springs, a suspension pin, a control limiting sleeve and a semicircle card which are arranged from top to bottom, and the inner tube impact assembly is constituted by assembling a flow assigning core tube, a filtering tube, a hammer body, a swing hammer, a rotary valve and a throttle nozzle. According to the torsion impact device, a valve control method is adopted to assign flow, and the swing hammer is driven to swing to output impact torque to a PDC drill pit. The torsion impact device has the characteristic of being high in adaptability and functional reliability, and the impact torque and the impact frequency of the torsion impact device are drastically improved, so that the drilling efficiency is improved.

Owner:JILIN UNIV

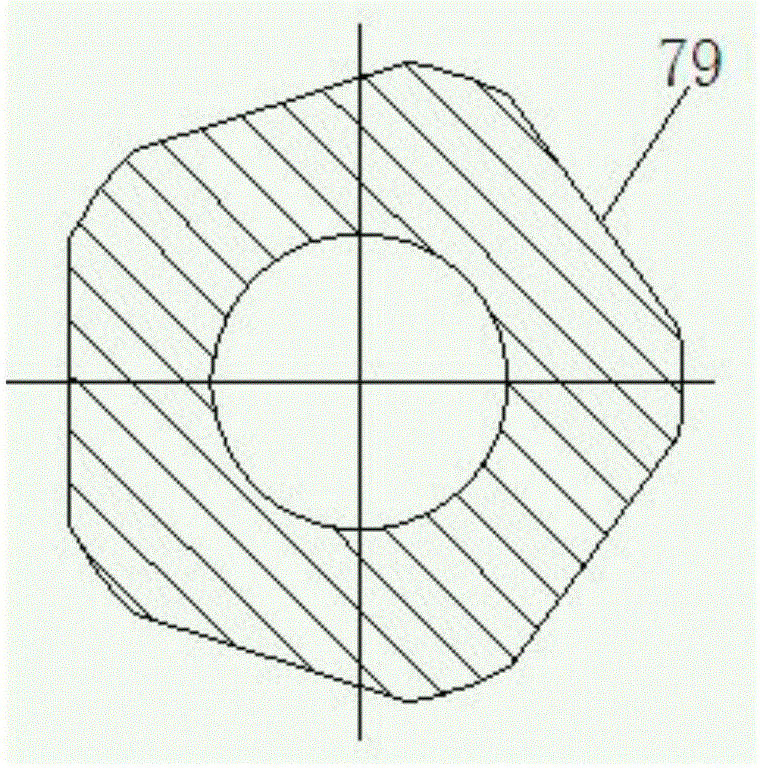

Quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool

The invention discloses a quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool. A check valve spring is arranged between a check valve and an air distributor; a drill bit sleeves a front joint; a bush is connected with the tail of the drill bit in a sleeving manner; a snap ring is arranged between the front joint and the bush; a piston is a hollow cylinder; a piston large end is arranged on the piston; a piston small path is arranged at one end of the piston large end; a piston tail path is arranged at the other end of the piston large end; one section of the piston large end is a smooth cylinder; the other section of the piston large end is uniformly provided with air grooves; an air polyhedron is arranged between the piston small path and the piston large end; an annular ventilating groove is formed between the air polyhedron and the piston large end; the piston tail path is connected with a cylindrical end; a piston tail end is arranged at the tail end of the cylindrical end; plain-sawn air grooves are uniformly formed in the piston tail end; front air holes are uniformly formed in one end of an inner cylinder; tail oblique air holes are uniformly formed in the other end of the inner cylinder; and a trapping lug boss is arranged on an inner cavity of the inner cylinder. The quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool is high in drilling speed, not easy to jam, low in failure rate and low in energy consumption; work efficiency is greatly improved; and energy and cost are saved.

Owner:HUNAN XINJINGANG MACHINERY EQUIP

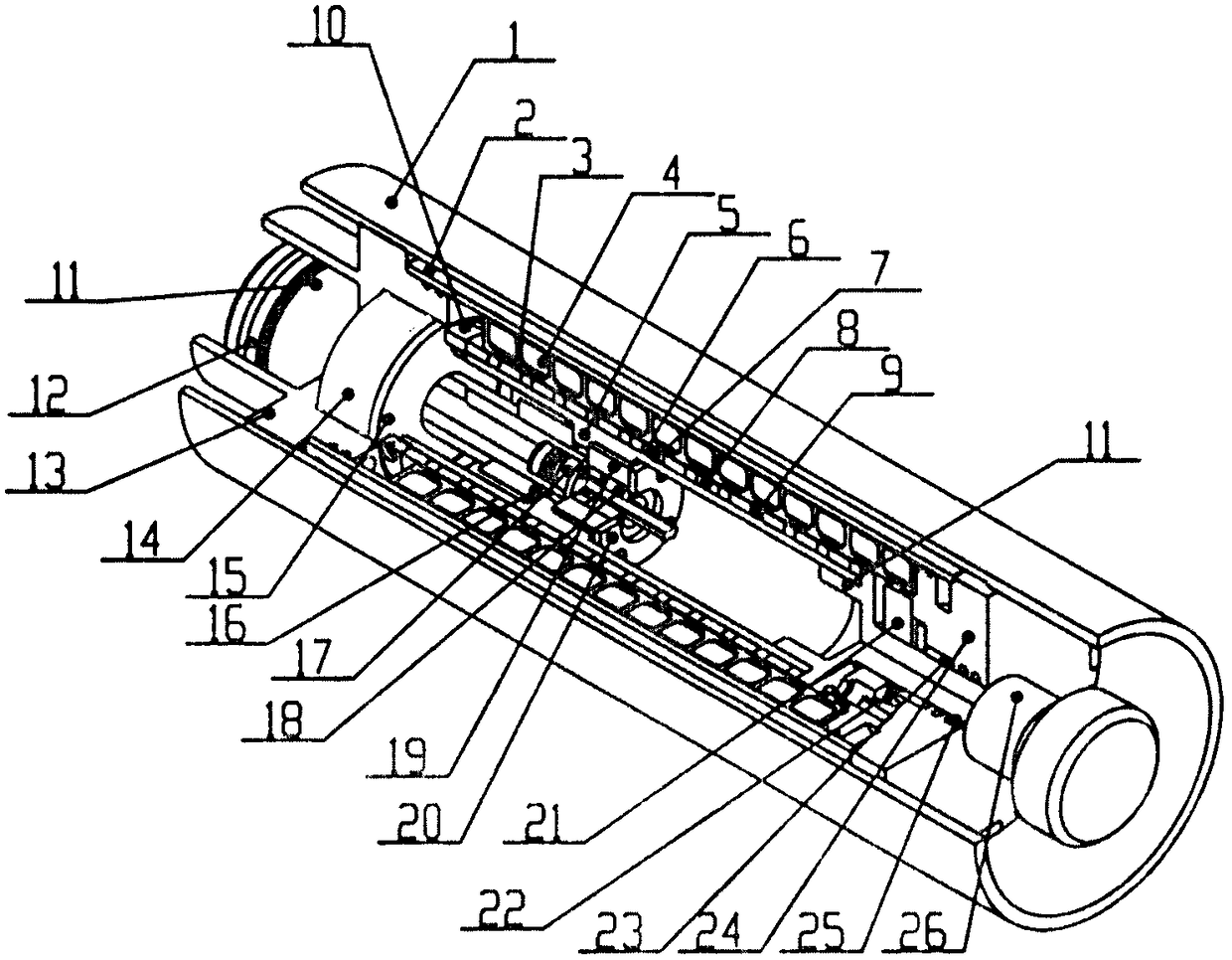

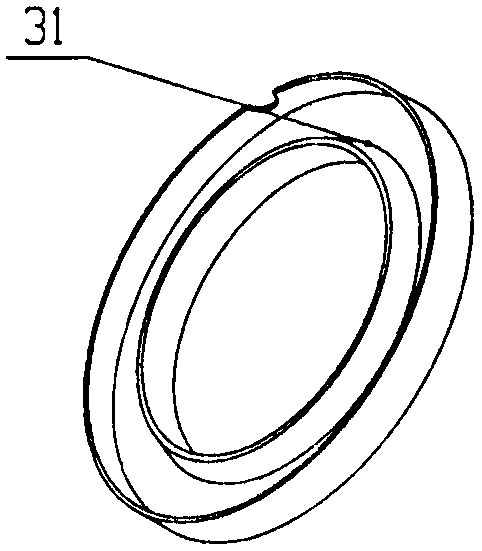

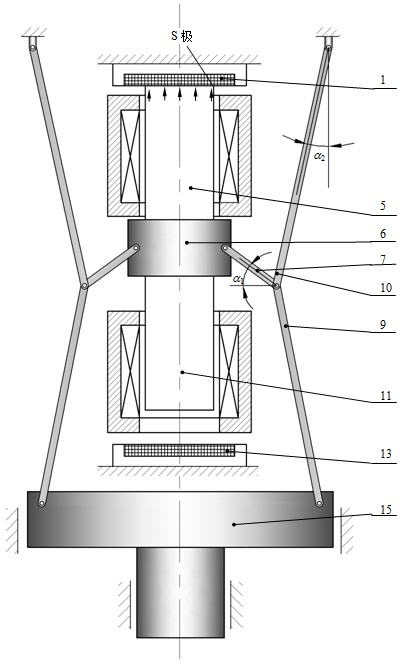

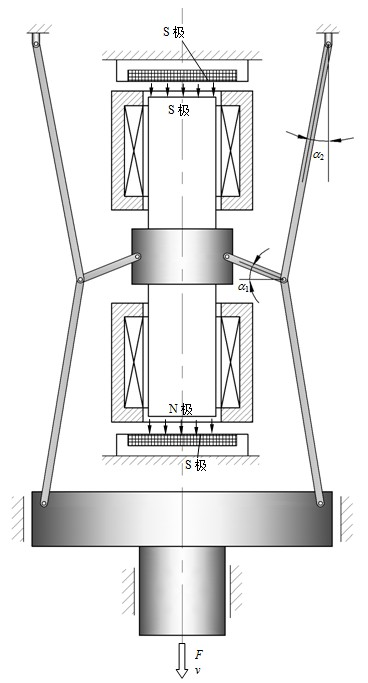

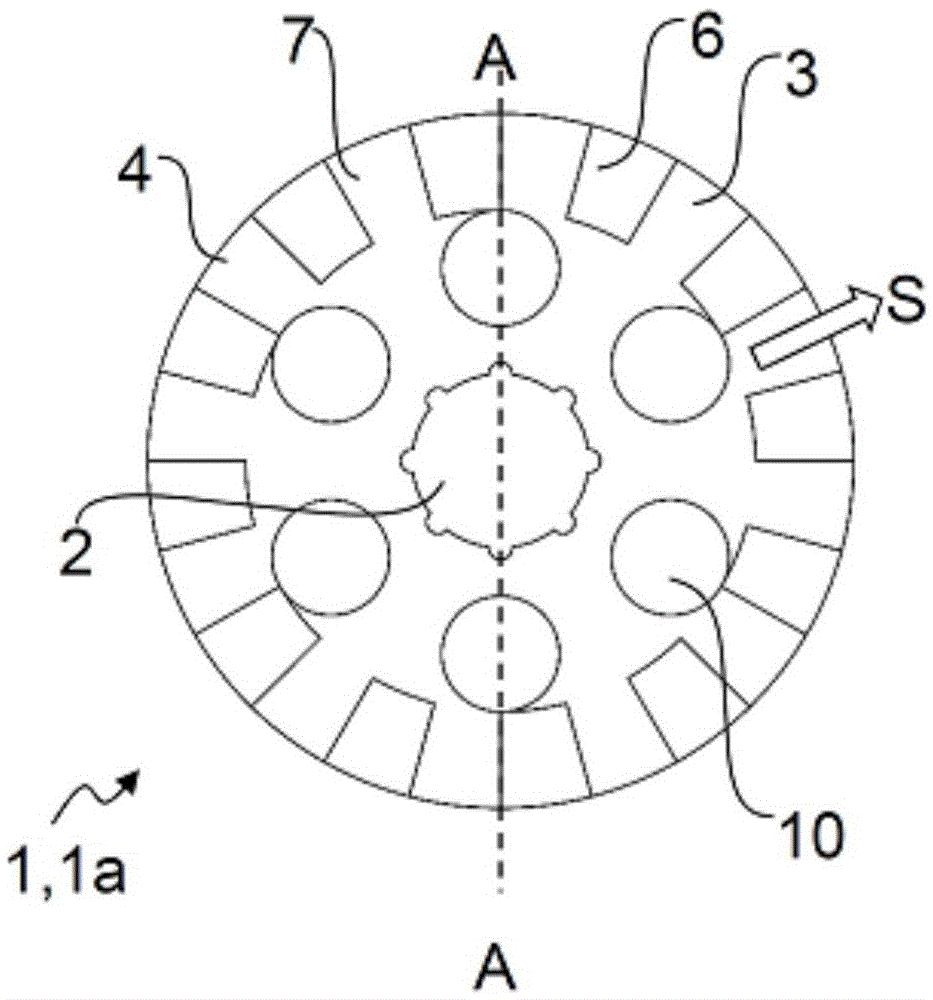

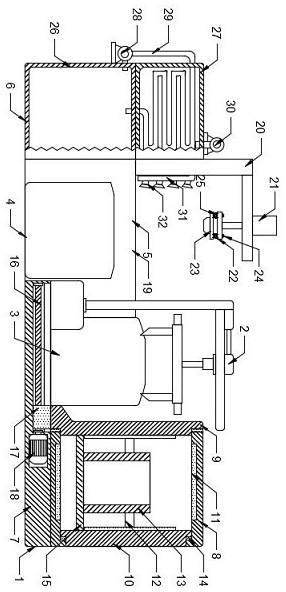

Linear permanent magnet motor system for high-frequency impact

InactiveCN108825122ALight in massBalance the pressure difference inside and outsideBorehole drivesCooling/ventillation arrangementRock tunnelRoad surface

The invention relates to a linear permanent magnet motor system for high-frequency impact. The linear permanent magnet motor system for the high-frequency impact mainly comprises a stator system, an active cell system and a mechanical system. The linear permanent magnet motor system for the high-frequency impact is characterized in that the stator system comprises an outer cylinder, an inner cylinder, a stator iron core and windings; the active cell system comprises an active cell shaft, a plurality of sets of permanent magnets arranged by halbach, the permanent magnets comprise N poles, magnetic field outward center poles, S poles, magnetic field inward center poles, magnetic steel press rings and active cell upper end heads; and the mechanical system comprises a protector piston, a seal,a multifunctional rear supporting cover, a return stroke energy storage capsule, a capsule stress cover, a linear bearing, a displacement sensor body, a sensor moving ring, a moving ring mounting seat, a moving ring gland, an anti-collision rubber block, a front linear bearing, a front fixed seat, a front moving seal and a punching hammer. The linear permanent magnet motor system for the high-frequency impact has a wide application range, is mainly used for high-frequency auxiliary impact devices for oil drilling at high temperature and high pressure, and can further be used for occasions requiring high-frequency reciprocating impact movement, such as resonance crushing heads of cement pavements and tunnel rock tunneling auxiliary impact equipment.

Owner:ZHENGZHOU UNIV

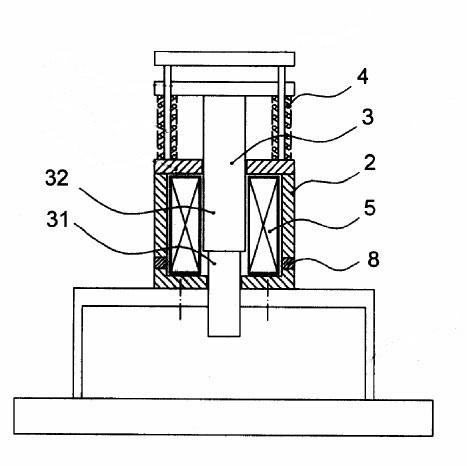

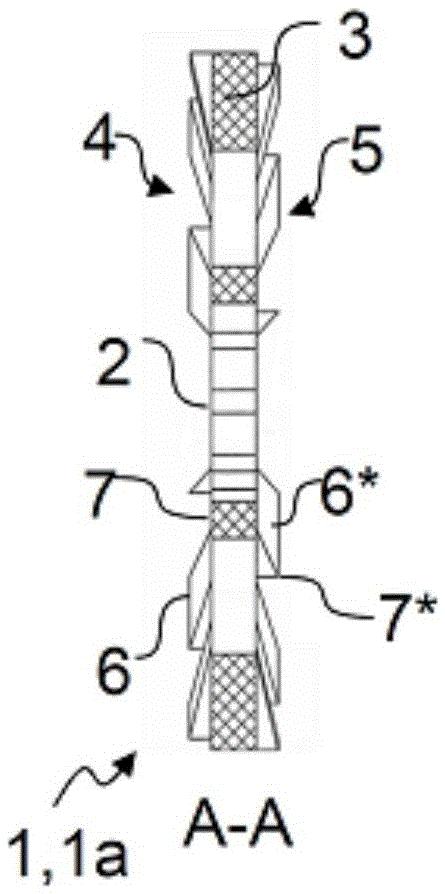

Force-increasing electromagnetic punching machine of permanent-magnet assistant machinery

The invention discloses a force-increasing electromagnetic punching machine of permanent-magnet assistant machinery, which comprises electromagnetic driving devices; each electromagnetic driving device consists of a yoke, an electromagnetic coil and an armature. The electromagnetic punching machine comprises two electromagnetic driving devices which are arranged up and down, wherein an upper armature and a lower armature of the two electromagnetic driving devices are connected through a transition body. An upper permanent magnet fixedly connected with a machine body of the punching machine is arranged above an upper electromagnetic driving device, and a lower permanent magnet fixedly connected with the machine body of the punching machine is arranged under a lower electromagnetic driving device. Under a condition that the input power is the same, the resultant force of a punching head moving downwards is increased, the impact force of the punching head can achieve more than 20 times of electromagnetic driving force, the speed of the punching head moving downwards is increased while the resultant force is increased, therefore the impulse of the punching head is increased, and the punching effect is good. A second-level toggle-rod mechanical force-increasing device is adopted. When all angles are appropriately selected, the amplification coefficient of force can achieve more than 6.7, and the impulsive force of the punching head is large. The force-increasing electromagnetic punching machine can be used for punching materials with higher hardness.

Owner:SUZHOU UNIV

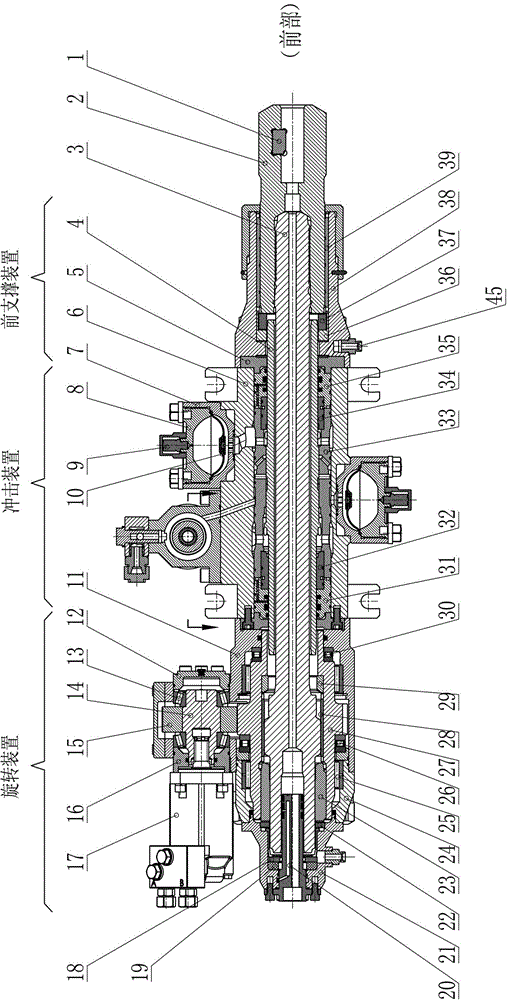

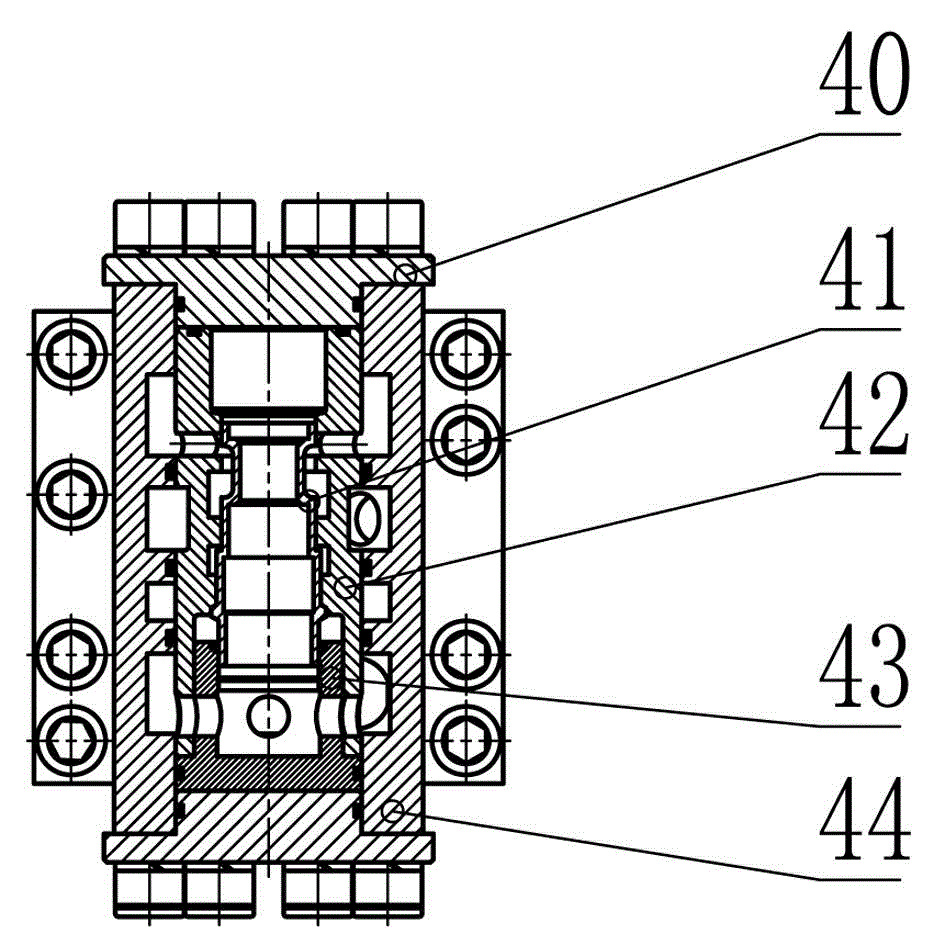

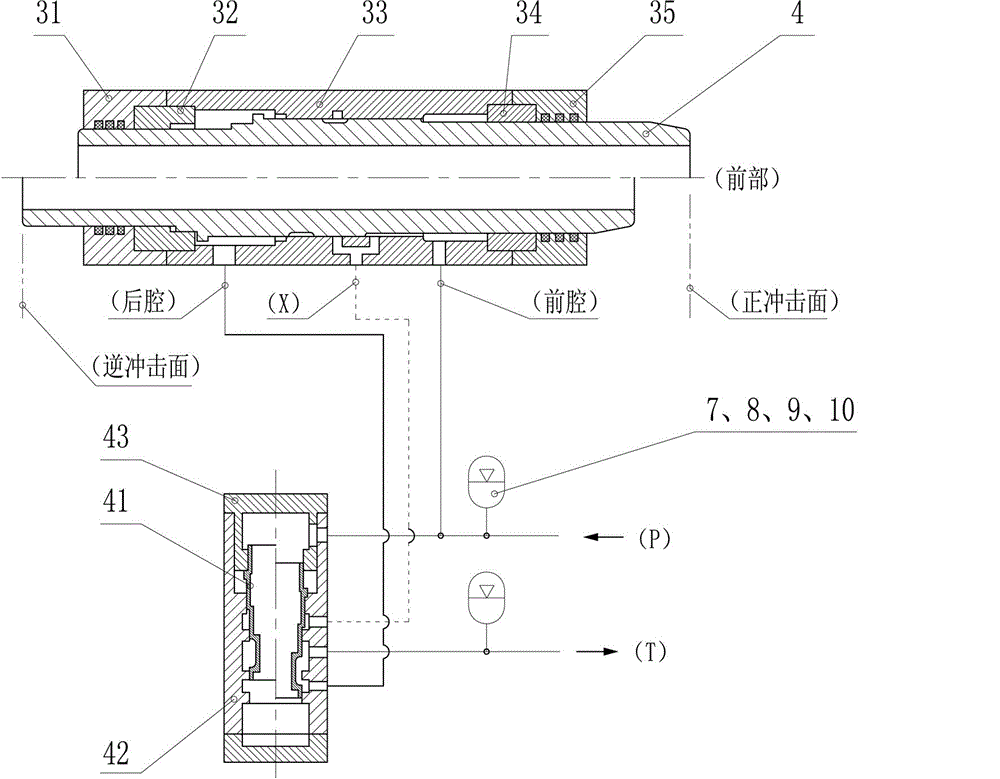

Double-impact integral hydraulic tapping machine

InactiveCN102912052AImproved power to weight ratioHigh impact frequencyBlast furnace componentsBlast furnace detailsControl functionEngineering

A double-impact integral hydraulic tapping machine comprises a borer assembly. A front support device, an impact device and a rotary device are sequentially arranged on the outer portion of the borer assembly from front to back, a backstop assembly is arranged at the rear end of the borer assembly, a rotary joint assembly is arranged at the outer end of the backstop assembly, the borer assembly comprises a rapping rod, a drill stem connecting sleeve is connected to the front end of the rapping rod, and the impact device comprises an impact functional module and a reversing control functional module. The double-impact integral hydraulic tapping machine has the advantages that the double-impact integral hydraulic tapping machine is adaptable to hard iron notches, is high in reverse impact output power and prevents the problem of stem withdrawal; a forward impact device and a reverse impact device are integrated, reverse impact operation can be carried out by retreating a trolley when the drill stem is required to be withdrawn, the stem withdrawal time is shortened, and misoperation is avoided; the double-impact integral hydraulic tapping machine is in a modular design, and is high in maintainability and low in failure rate; and the double-impact integral hydraulic tapping machine is high in protection performance, and the service life of equipment is long.

Owner:YICHANG YANSHI TECH DEV

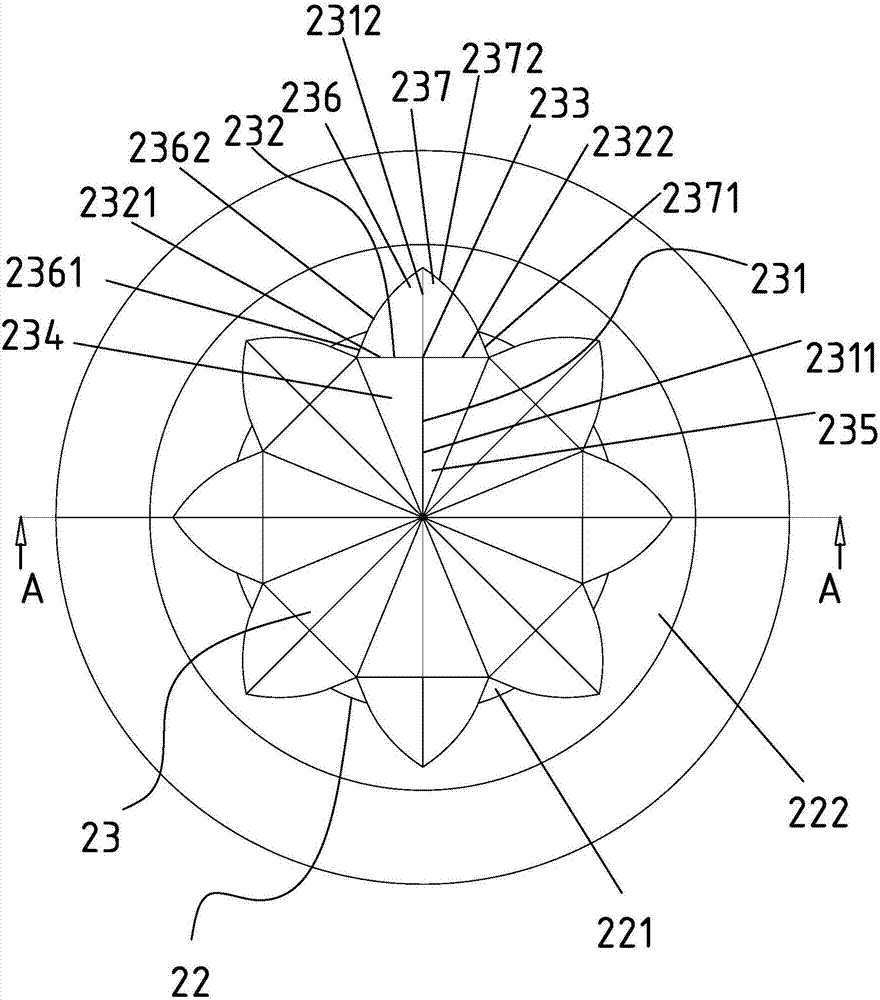

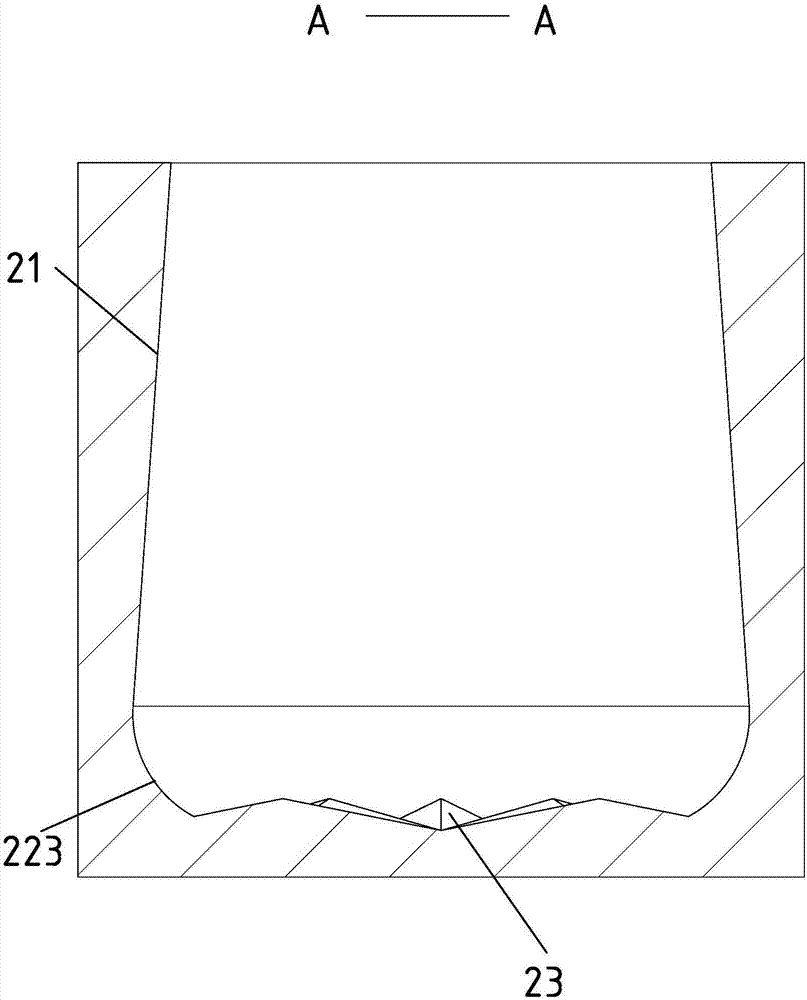

Ball-milling tank and planetary ball mill with same

InactiveCN106964431AIncrease contact areaIncrease frictionGrain treatmentsEngineeringCentrifugal force

The invention discloses a ball-milling tank and a planetary ball mill with the same. The ball-milling tank comprises a tank cover and a tank body. The tank body is provided with a non-cylindrical-surface side wall inner wall, and the tank bottom of the tank body is provided with a plurality of protrusions which are evenly distributed by using the center of the tank bottom as a center. According to the ball-milling tank and the planetary ball mill with the same, the tank bottom of the ball-milling tank of the ball mill is designed to be provided with the rhombus protrusions, the contact area of the tank bottom and abrasive is increased, and the tank bottom is turned to be provided with fixed grinding balls participating in the grinding process of the abrasive; the rubbing action of the tank bottom and the abrasive is increased, and the impact force and impact frequency of the abrasive are greatly increased; due to the fact that the inner wall of the side wall of the ball-milling tank is designed into the non-cylindrical-surface side wall inner wall, mold withdrawing is conducted outwards, the abrasive is pushed to the tank bottom under the effect of centrifugal force, the grinding effect on the abrasive by the protrusions is improved, the grinding efficiency and quality of the planetary ball mill are greatly improved, and the property of an original planetary ball mill is improved.

Owner:NORTHEASTERN UNIV LIAONING

Piston guide sleeve type valveless double-cylinder down-hole hammer

InactiveCN103573182APrevent jumpingReasonable assembly designReciprocating drilling machinesConstructionsPiston GuideEngineering

A piston guide sleeve type valveless double-cylinder down-hole hammer comprises a rear connector, a check valve, an air distributing rod, a piston, a cylinder body, a guide sleeve, a clamping ring, a drill body and a front connector. The check valve is a one-way valve and is provided with a valve seat and a spring. The piston is a long and thin piston with a duct, the air distributing rod and an air inlet base at the rear end of the check valve are of an integrated structure, an inner cylinder is arranged in the cylinder body and on the outer sides of the air distributing rod and the piston, and in a piston moving process, the matching end of the piston and the air distributing rod is arranged in the inner cylinder all the time. The air distributing rod and the check valve seat are integrated, the structure is simple, functions of location, damping and air suction can be achieved, and the hammer is stable and reliable during working. The piston is free of a radial hole structure, compressed air can reach a front air cavity and a rear air cavity through the shortest paths, and hammer efficiency is improved.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

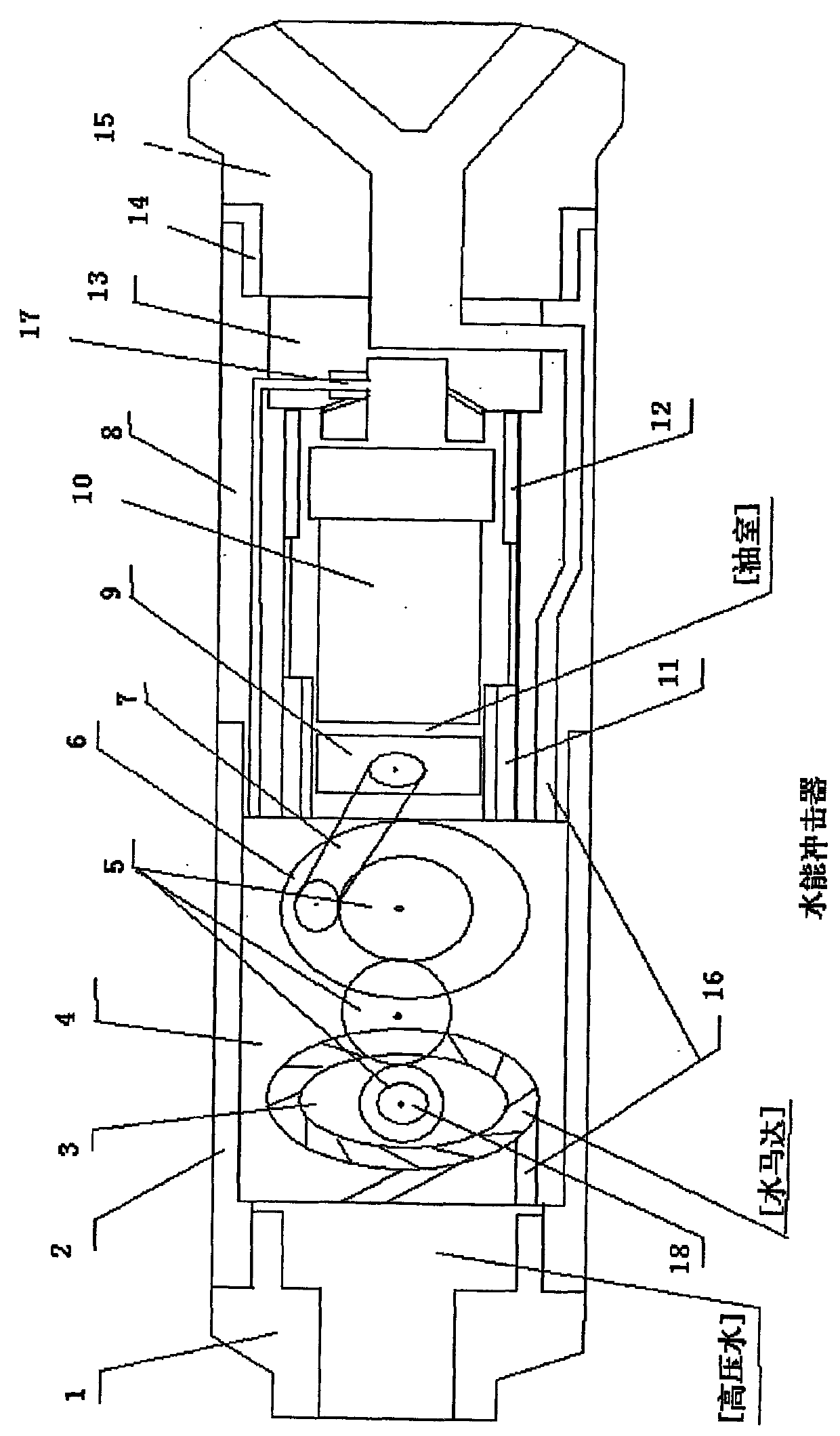

Hydroenergy impactor

InactiveCN102817555AAvoid wasting powerSave energyReciprocating drilling machinesConstructionsOil separationEngineering

The invention discloses a hydroenergy impactor. The impactor is characterized in that firstly, water having a medium or water serves as power, and compared with a pneumatic impactor, the impactor can save more than 70% energy and saves a large amount of energy for the country; secondly, medium water is used as hole washing liquid, the impactor can be suitable for complex geological drilling and can also be used for drilling deep petroleum gas holes or super deep holes, and the pneumatic impactor is not suitable for complex geology and deep holes; thirdly, a 'water motor' can control the rotating speed through the flow of high-pressure water, and the rotating speed and the impacting frequency are high; and fourthly, water-oil separation is achieved, a lubricating system is provided, and the service life of the impactor is prolonged.

Owner:涂文斌

Hydraulic impactor

PendingCN110344754ASolve the problem of traffic lossImprove volumetric efficiencyBorehole drivesLiquid mediumUpper joint

The invention discloses a hydraulic impactor, and belongs to the field of hole bottom power machines. The hydraulic impactor is driven by a pressure rinsing liquid medium to work and comprises an upper joint, a flow distribution core tube, an outer tube, a flow distribution seat, a cylinder sleeve, a piston, a jump ring, a retaining sleeve, a first semi-circular clamp, a limit sleeve, a control valve, a plug, a punch hammer, a second semi-circular clamp, a spline sleeve and a drill bit. The impactor is simple in structure, small in volume loss and pressure loss and high in energy utilization rate, has the wide-spectrum working characteristics, can meet large ballistic work output requirements on the structure, can implement impact rotation drilling with rotation as main under the working condition with small flow, can implement impact rotation drilling with impacting as main under the working condition with large flow, improves the drilling footage speed in a multiplied manner, helps to reduce the construction cost of the fields of petroleum and water well drilling, mine and geological prospecting and the like, and particularly helps to accelerate the development and utilization ofnew energy dry hot rock.

Owner:JILIN UNIV

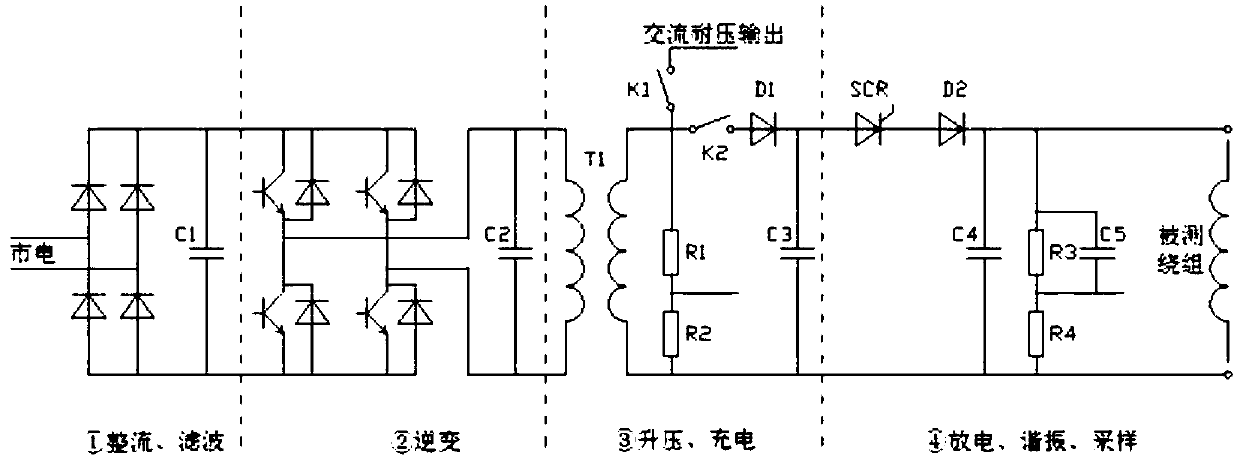

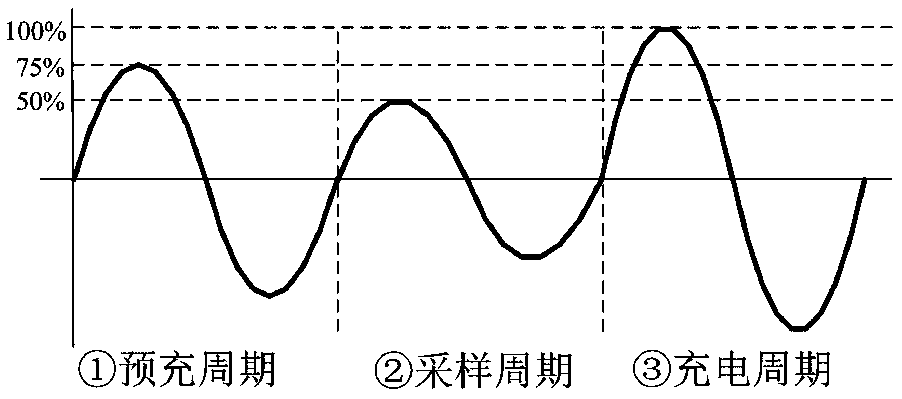

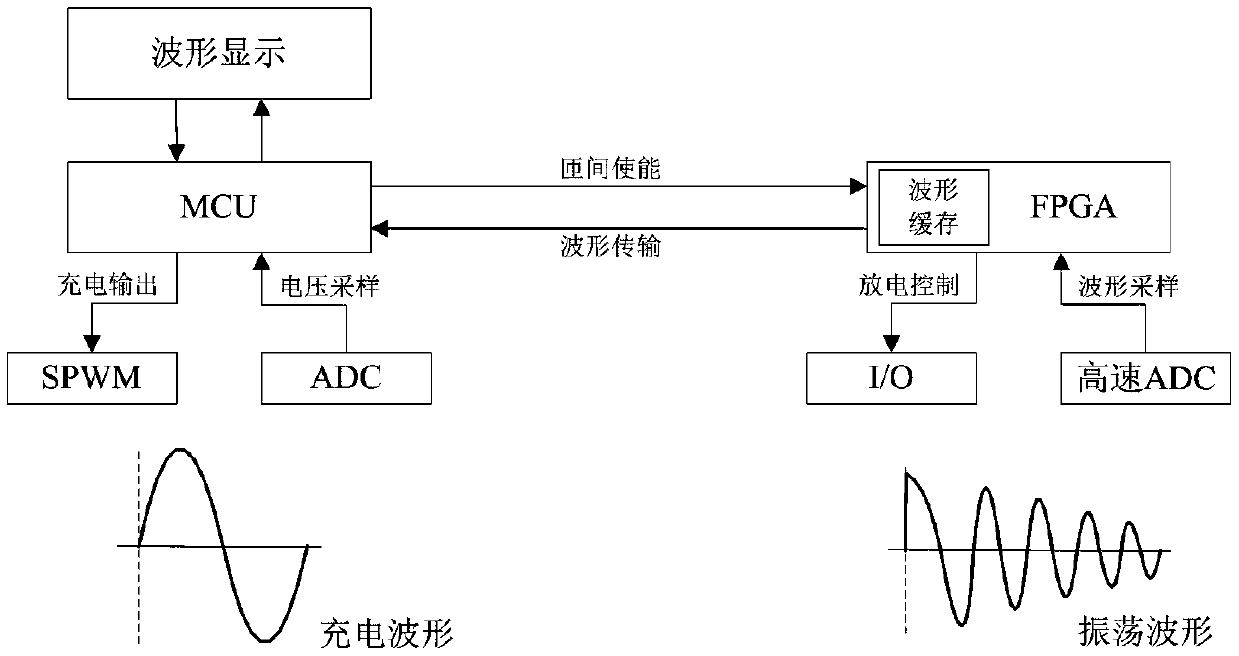

Interturn rapid continuous impact test device and method

ActiveCN109581157APeak AccurateIncrease output powerTesting dielectric strengthHardware architectureDual core

The invention discloses an interturn rapid continuous impact test device and a method. The device comprises an MCU, an FPGA, and a rectifying and filtering module, an inverter module, a boost chargingmodule and a discharge resonant sampling module which are connected in sequence. The invention aims to simplify an interturn charging, sampling and frequency control circuit in the motor integrated tester, which reduces the cost and improves the reliability. By using a rectified inverter charging method with a larger output power and optimizing a dual-core processed parallel hardware architecture, the time for a single interturn test can be shortened to 50ms or even shorter. As a result, the impact frequency of an interturn continuous test can be improved, and the detection rate of interturnpoor insulation can be improved.

Owner:青岛艾诺智能仪器有限公司

Piston tail pipe type impacter of valveless single-cylinder type downhole

The invention discloses a piston tail pipe type impacter of a valveless single-cylinder type downhole, which comprises a cylinder body, a rear joint, a front joint and a drill bit; an air distributing seat provided with an axial air-distribution seat pore canal is hermetically arranged in a cylinder body; a check valve is arranged on the air distribution seat; an air distribution rod is provided with an air distribution rod big end and an air distribution rod small end; the air distribution rod and a check valve seat are of an integrated structure; the air distribution rod small end is arranged in a piston air-supply chamber on a piston; the inner diameter of a middle part of a piston air-supply chamber is more than the outer diameter of the air distribution rod small end; the piston is provided with a piston big end and a piston small end; a rear air chamber is formed between the air distribution rod and the piston small end; a front annular channel and a rear annular channel are formed between the cylinder body inner wall and the cylinder body outer wall; a piston surface air groove is formed on the outer surface of the piston; and a front air chamber is formed between a drill bit tail pipe and a piston big end. The piston tail pipe type impacter of the valveless single-cylinder type downhole, provided by the invention effectively overcomes the defects of the traditional impacter of the valveless single-cylinder type down hole, and has the advantages of high working efficiency, good reliability and greatly increased pneumatic efficiency.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

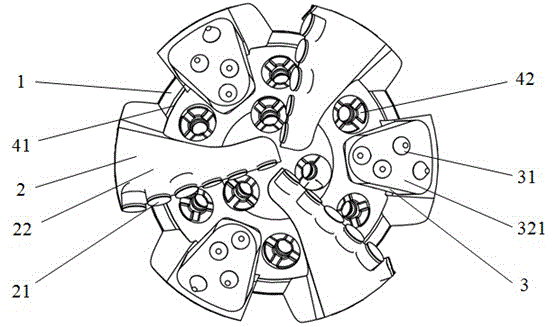

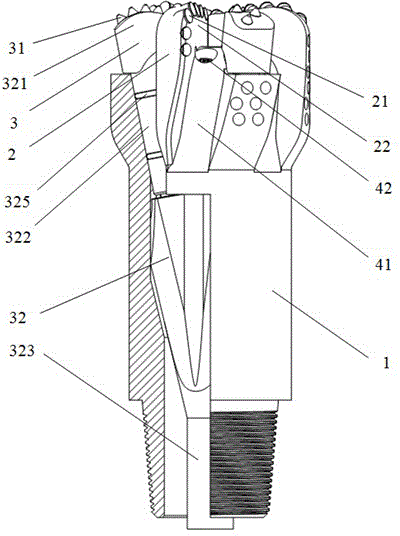

Dual-controlling-channel impulse jet ball-tooth bit

The invention relates to a dual-controlling-channel impulse jet ball-tooth bit including a pressing head, a dual-controlling-channel monostable jet element, a bit body and an inner channel. The dual-controlling-channel monostable jet element, the upper pressing head and the peripheral bit body are welded to form a whole. One big and one small controlling channels and one big and one small fluid exits are formed in a dual-controlling-channel bistable jet element and connected with big and small nozzles of the bit correspondingly. During the process of collision and separation between a ram andthe bit, one of the dual controlling channels is periodically opened and closed in the process, impulse jet is created by the high frequency switching of fluids inside the jet element, and the cleaning effect of the bottom of nozzle holes is intensified. Sharp pressure increase produced by the bit collision not only does not bring negative influence to the ram impacting process, but also facilitates ram return starting, shock frequency is increased to some degree, and rock breaking efficiency is increased.

Owner:CENT SOUTH UNIV

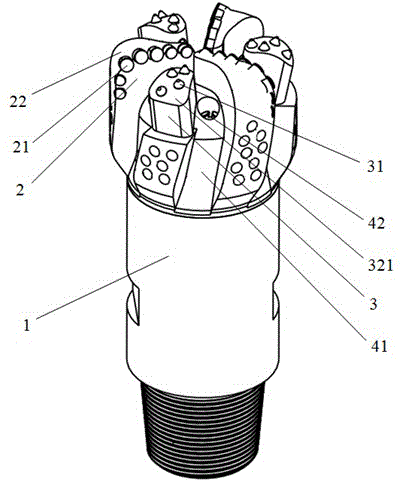

A scraping-impact compound drill bit

ActiveCN102678055BReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringFoundation engineering

Owner:SOUTHWEST PETROLEUM UNIV

Quick-drill pneumatic hard rock drill

ActiveCN102900355AHigh shear forceIncrease propulsionConstructionsReciprocating drilling machinesAtmospheric pressureCylinder block

The invention discloses a quick-drill pneumatic hard rock drill which comprises a host machine, an operating valve and a propulsion unit, which are independent of one another and are connected with one another. An air suction nozzle communicated with an air distribution valve is arranged on a base of the host machine; the air distribution valve is in a fin type structure and consists of a valve body, a valve block and a valve rod; a valve cavity is arranged inside the valve body and is respectively communicated with a front chamber and a back chamber of a cylinder body through left and right air passages; the seesaw-like valve block is installed in the valve cavity through the valve rod; under the action of air pressure, the two ends of the valve block can respectively close or open the left and right air passages to enable a piston rod to move with high frequency; and a rotating device is arranged on a machine head. According to the invention, a new fin type air distribution valve which is flexible in change-over is adopted, so the impact frequency is greatly improved. The rotating device realizes primary transmission by adopting worm-and-gear principle, the transmission ratio is big, and the transmission efficiency is high. The quick-drill pneumatic hard rock drill is small in size, light in weight and convenient to operate, and is applicable for various propulsion modes.

Owner:青岛达邦钻机有限责任公司

Method for controlling percussion device, software product, and percussion device

InactiveCN1984755AIncrease contactReduce exposureConstructionsReciprocating drilling machinesPropagation timeReflected waves

The invention relates to a method and software product for controlling a percussion device belonging to a rock-drilling machine, and to a percussion device. The impact frequency of the percussion device (7) is set so that the percussion device (7) forms a new compression stress wave (p) to the tool (8) always when reflected waves (h) from the previous compression stress waves reach a first end (8a) of the tool. This requires that the impact frequency be set proportional to the propagation time of the stress wave, whereby the length of the used tool (8) and the propagation velocity of the stress wave in the tool material are to be noted.

Owner:SANDVIK MINING & CONSTR OY

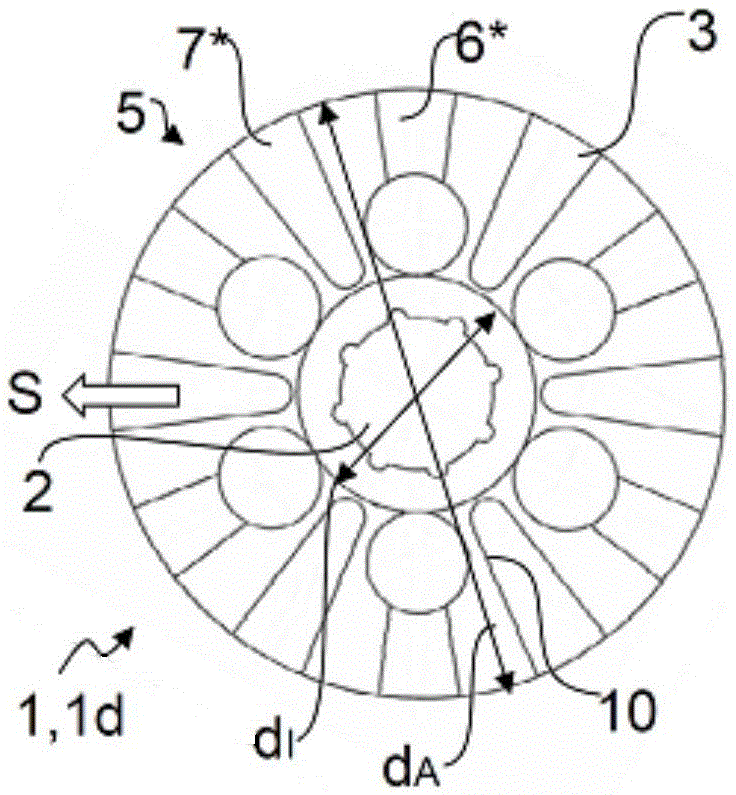

Agitator bead mill and grinding disc for agitator bead mills

ActiveCN105833948APromote activationImprove shock effectGrain treatmentsEngineeringMechanical engineering

The present invention relates to an agitator bead mill for processing and, in particular, for grinding a grinding material by means of a grinding body. The mill comprises an agitator having a rotatable axial shaft of a stirrer and a disc having at least one substantially vertically arranged agitator shaft in the axial direction. The disc has two end sides, and the end side has an end-side plane of an agitator shaft configuration that is substantially orthogonal to the axial direction of the agitator. According to the invention, the disc comprises an area in which a first end side of both end sides has a first raised portion and / or a first recessed portion with respect to the first end side flat surface. Further, the disc comprises an area in which a second end side of both end sides has a second raised portion or a second recessed portion with respect to the second end side plane. The flow path for the product stream comprising the milled material and the milled body is formed by the ridges and / or depressions on the respective end sides. The invention also relates to a disc for stirring a bead mill.

Owner:耐驰精细研磨技术有限公司

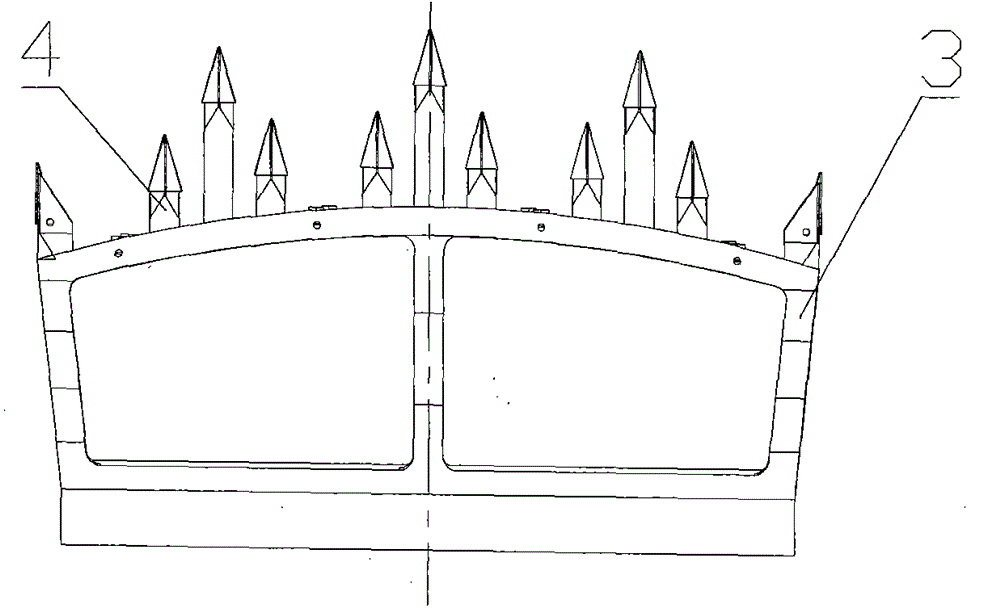

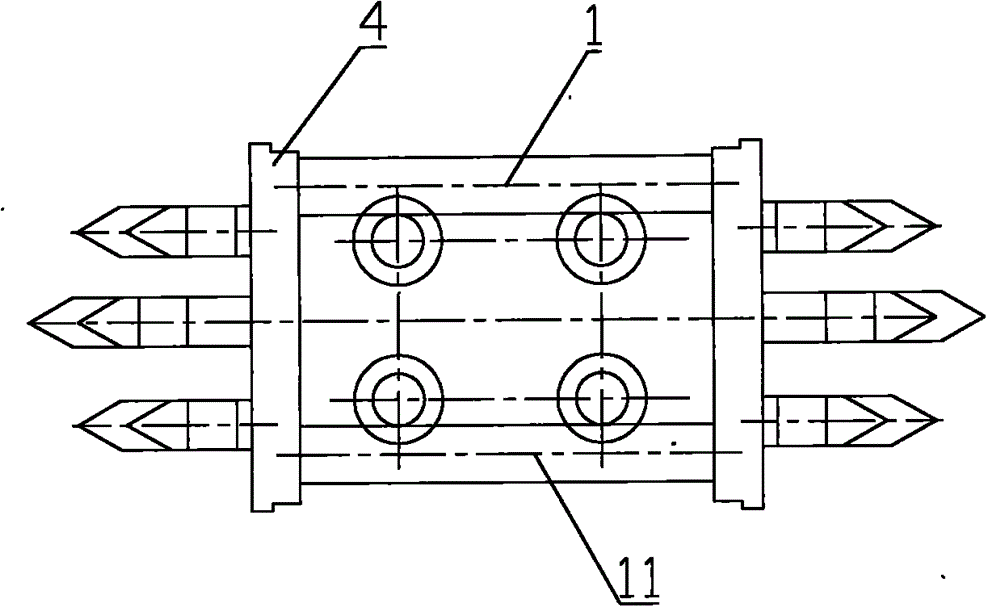

Impact head strengthening and centralizing method by using dual back recesses and impact head strengthening and centralizing device by using dual back recesses for applying the method

ActiveCN103953338AReduce resistanceImprove efficiencyDriving meansCutting machinesRolling resistanceReciprocating motion

The present invention relates to the field of machinery and provides an impact head strengthening and centralizing method by using dual back recesses and an impact head strengthening and centralizing device by using dual back recesses for applying the method, and the method and the device are particularly applicable to the fields of mining or engineering machinery. The device comprises a dual back recess guidance mechanism, an impact support mechanism, a drive mechanism and impact heads, etc. The dual back recess guidance mechanism comprises a rolling friction dual back recess structure and impact guidance elements, etc. The rolling friction dual back recess structure comprises an upper rolling friction grove and a lower rolling friction groove. A power impact element drives the impact guidance elements to reciprocate. The impact guidance elements are disposed within the space of an external guidance roller. The impact guidance elements increase the centralizing height of the impact heads, and are in rolling friction with the reciprocating movement direction of the dual back recess structure and centralizing tooth holders of the impact guidance elements.

Owner:刘素华

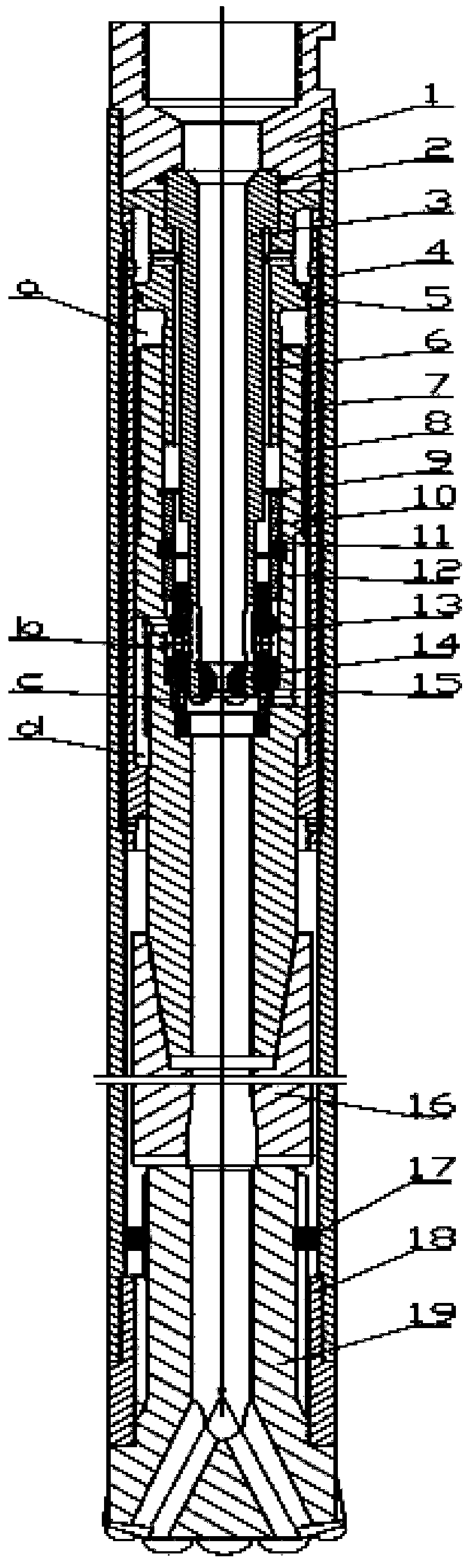

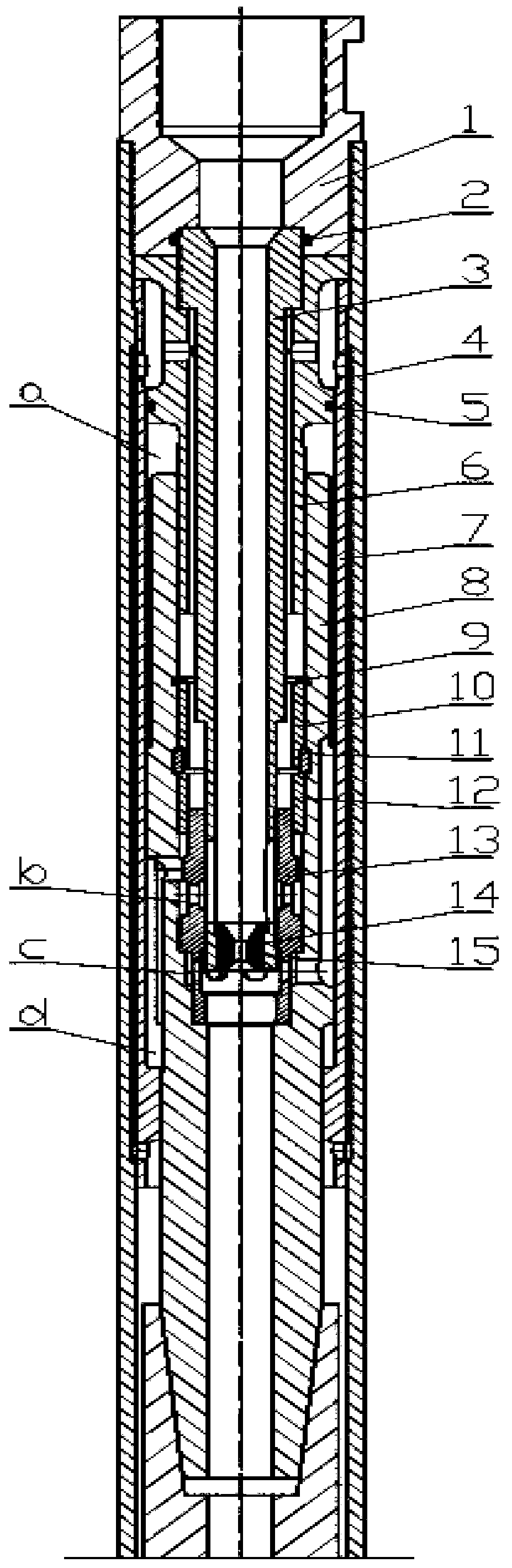

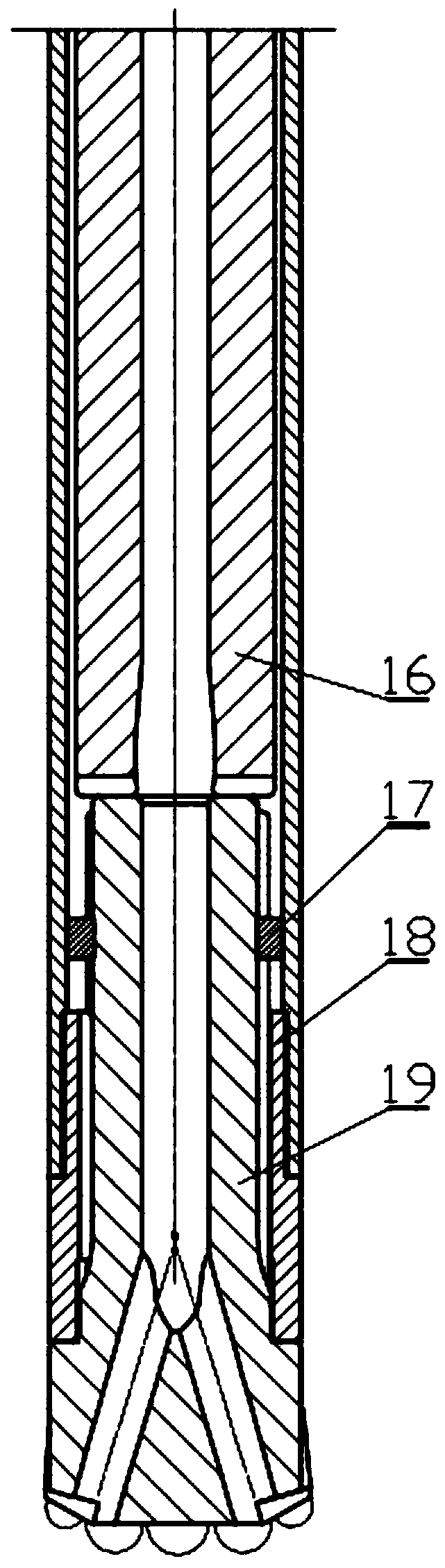

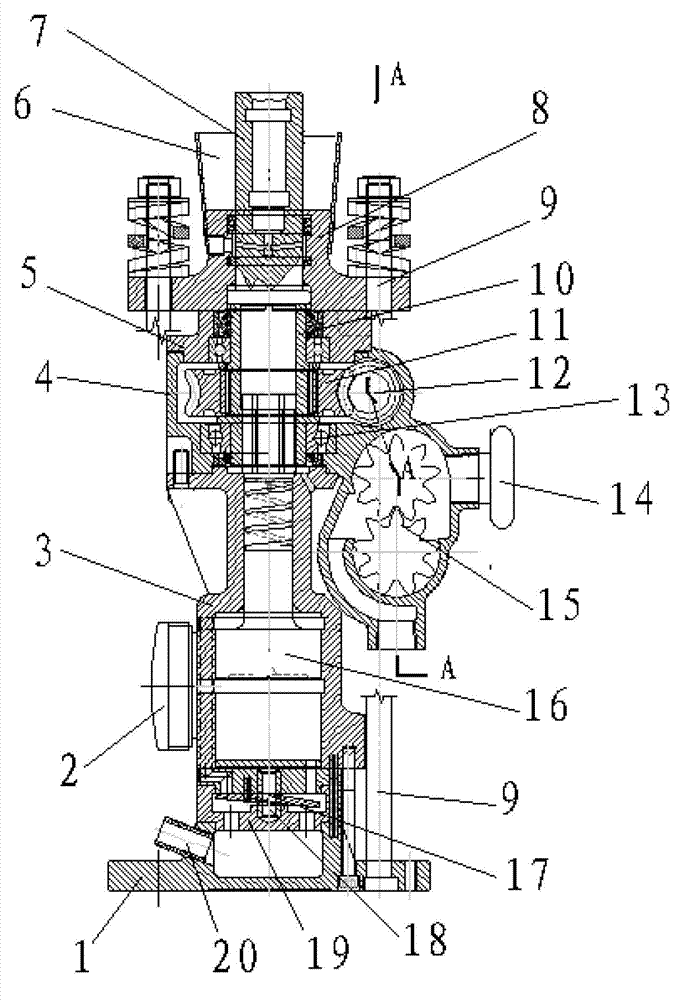

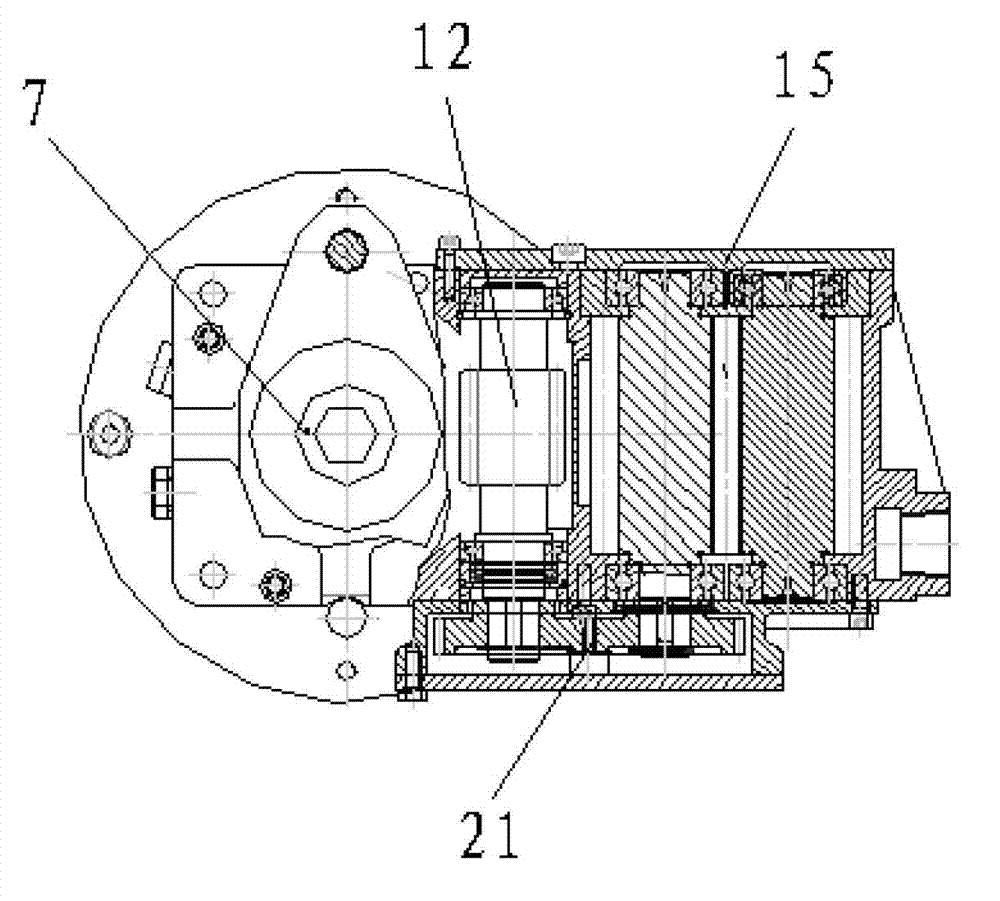

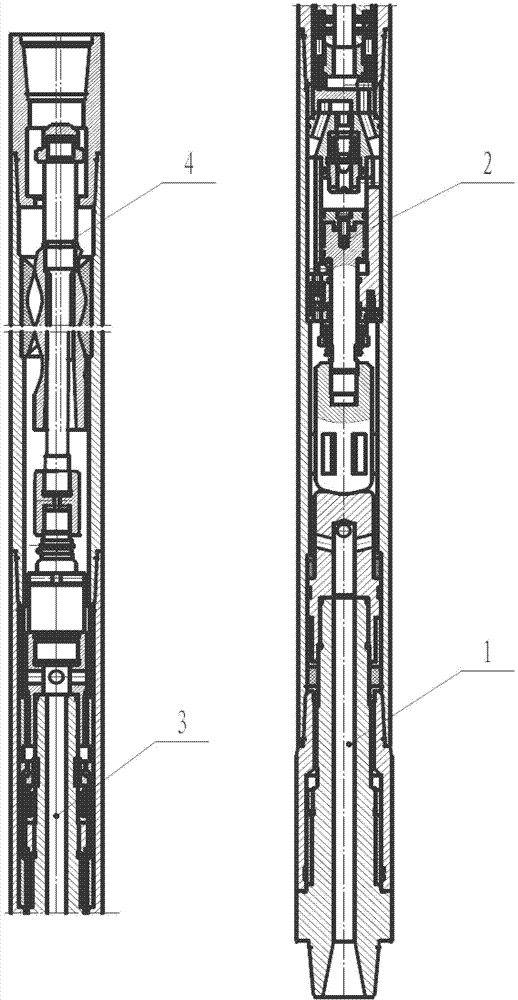

Percussion drilling tool

InactiveCN102852455BSmall recoil forceSolution to short lifeConstructionsReciprocating drilling machinesHydraulic cylinderReciprocating motion

The invention discloses a percussion drilling tool, which relates to a drilling tool and solves the problem of low drilling efficiency on the hard formation of a deep well by the traditional drilling tool. The percussion drilling tool disclosed by the invention comprises a main shaft mechanism, an impact mechanism, a stationary shaft transmission mechanism and a motor mechanism, wherein the main shaft mechanism is positioned on the lowest end of the drilling tool; the upper end of the main shaft mechanism is connected with the impact mechanism capable of generating impact action; the impact mechanism comprises a hydraulic piston device, a rotary reversing valve and a pressure-limiting device; and the motor mechanism is positioned on the upmost end of the drilling tool and mainly consists of a motor and a flexible-shaft type universal mechanism. When the percussion drilling tool works, the drilling tool is driven by an external power mechanism to rotate, the drilling fluid is used for driving a motor rotor to rotate so as to drive a stationary shaft in the stationary shaft transmission mechanism to rotate, the rotary reversing valve is driven to reverse so as to change the fluid flowing direction at the inlet and the outlet of the hydraulic cylinder, so that the piston generates reciprocating movement, the hydraulic energy of the drilling fluid is converted into impact energy on the main shaft by the piston, and therefore the main shaft generates axial impact movement.

Owner:李少江 +1

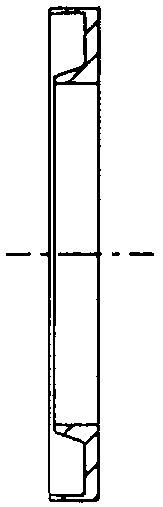

Valveless single cylinder blind hole channel down-hole hammer

A valveless single cylinder blind hole channel down-hole hammer comprises a cylinder block. The upper end of the cylinder block is connected with a rear connector. A one-way air inlet channel of the rear connector is matched with a check valve mounted in a check valve seat. The lower end of the cylinder block is connected with a drill bit through a connector. The check valve seat is provided with an air distributing hole. A positioning sleeve is disposed below the check valve seat. The inner wall of the positioning sleeve is matched with an air distributing rod. A plurality of rubber rings are further disposed between the inner wall of the positioning sleeve and the air distributing rod. The air distributing hole is communicated with a central duct of the air distributing rod. The lower end of the air distributing rod is matched with a piston upper air supply chamber at the upper end of the piston. The piston upper air supply chamber is communicated with a piston upper exhaust hole. A piston lower air supply chamber which is communicated with a piston lower exhaust hole is disposed at the lower end of the piston. A guide sleeve is disposed between the lower end of the piston and the cylinder block. By the valveless single cylinder blind hole channel down-hole hammer, operation stability of the hammer is improved, the service lives of the rubber rings are prolonged, and reliability of an air distributing mechanism is improved.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Hydraulic excitation high-frequency linear impact device

ActiveCN109469058AInfinitely change the impact frequencyHigh accelerationBulkheads/pilesHydraulic cylinderHigh acceleration

The invention relates to a hydraulic excitation high-frequency linear impact device, and belongs to the field of machines. The hydraulic excitation high-frequency linear impact device comprises a hydraulic cylinder, an impact hammer, an impact seat and an impacted body; the hydraulic excitation high-frequency linear impact device is characterized in that the hydraulic cylinder is an unequal-diameter hydraulic cylinder with double output rods; a piston rod of the hydraulic cylinder is connected with the impact hammer, a small-diameter piston rod cavity oil cavity of the hydraulic cylinder is connected to a control oil pipe, a large-diameter piston rod cavity oil cavity of the hydraulic cylinder is connected with a high pressure oil pipe, the high pressure oil pipe is connected with an inputoil pipe, the control oil pipe is connected with the impact valve, and the impact valve is connected to a control motor. The hydraulic excitation high-frequency linear impact device is small in overall quality and high in impact frequency, the impact hammer has high accelerated speed, and high-frequency large impact force can be generated. The work efficiency can be improved, and the effect of rapid pile sinking can be achieved.

Owner:许慧保

Large steel ingot rapid forging method and device

ActiveCN112247040AHigh impact frequencyReduce momentumForging press detailsProcess efficiency improvementIngotMicro cracks

The invention discloses a large steel ingot rapid forging method and device. The method comprises the following steps: 1, placing a steel ingot at a heating device, quickly heating the steel ingot to1250 DEG C, and keeping the temperature; 2, rapidly lowering the temperature of the outer skin layer of the steel ingot obtained in step 1 to 725 DEG C; 3, placing the steel ingot at a forging press to be forged and pressed, and increasing the impact frequency of a forging and pressing head while reducing the punch impact force during forging and pressing; 4, after forging and pressing to the designed size and appearance, rapidly cooling to 500 DEG C, and keeping the internal crystallization size of a forging; and 5, placing the steel ingot obtained in step 5 into an annealing furnace. According to the large steel ingot rapid forging method and device, forging and pressing of a steel ingot body can be achieved through the forging and pressing head, through cooperative arrangement of a spring, a sliding rod and a fixing plate, the impact force of the forging and pressing head is reduced through the spring while the impact frequency of the punch is increased, and defects such as micro-cracks in the surface of the steel ingot body can be effectively prevented.

Owner:山东润金重工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com