Agitator bead mill and grinding disc for agitator bead mills

A technology of stirring ball milling and grinding disc, applied in grain processing and other directions, can solve the problems of inability to activate, unbalanced eccentric disc, insufficient power of milling body, etc., to achieve the effect of activation enhancement and radial flow enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

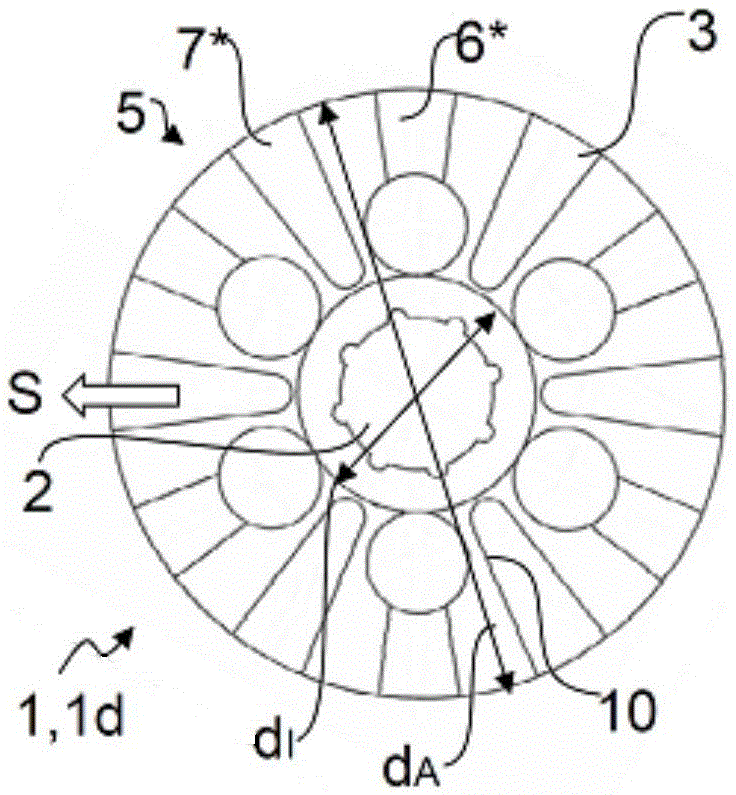

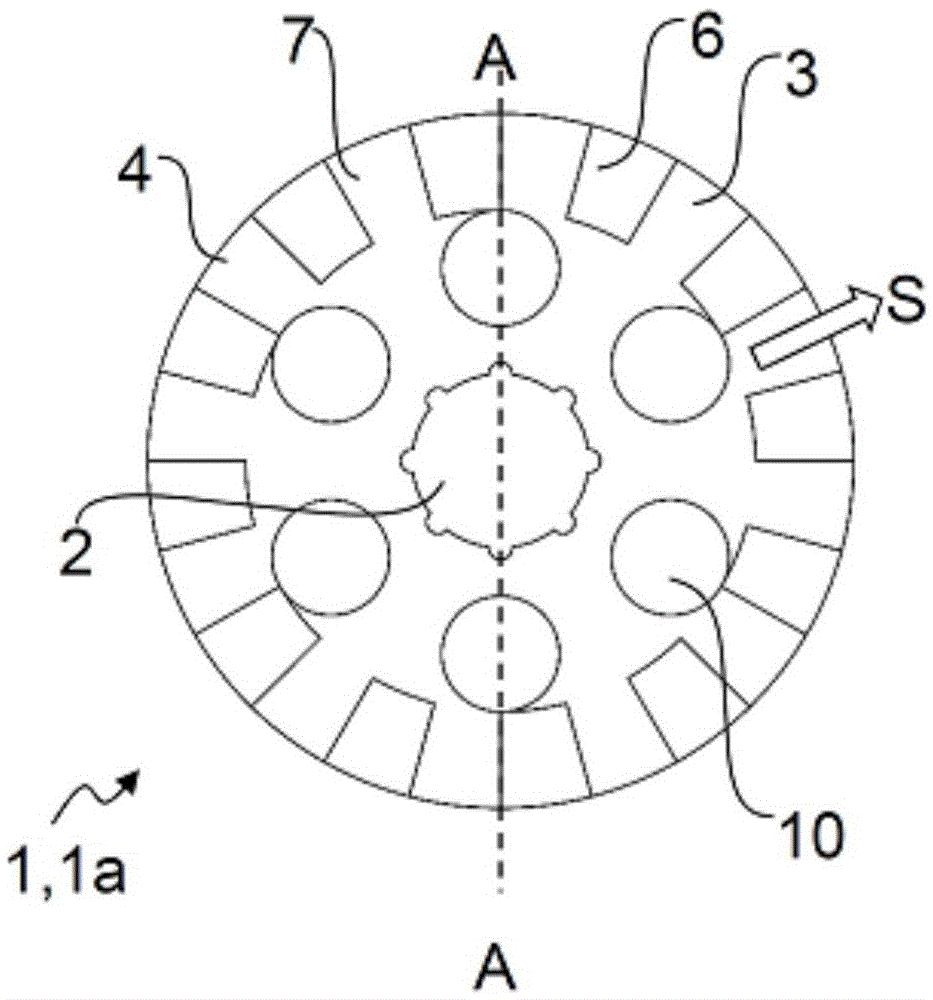

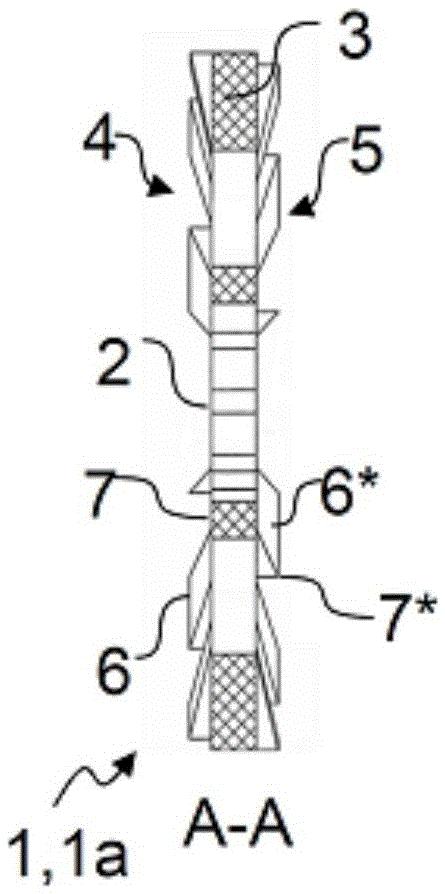

[0031] Figures 1A to 1D Various views of a first embodiment of a grinding disc 1 , 1 a according to the invention are shown. especially Figure 1A A top view of the first end side 4 of the grinding disc 1 a is shown, Figure 1B shows the grinding disc 1a along the Figure 1A A cross-sectional view of the cut line A-A shown in, Figure 1C shows a side view of the grinding disc 1a and Figure 1D A schematic perspective view of the grinding disc 1a is shown. The grinding disc 1a comprises a circular disc body 3 with a central shaft hole 2 for the stirrer shaft of a stirrer (not shown). Furthermore, the grinding disc 1 a has through-openings 10 for grinding material and grinding bodies.

[0032] The grinding disc 1 a has a bead 6 , 6 * on both end sides 4 , 5 respectively. The depressions formed between the elevations 6 , 6 * are also referred to below as grooves 7 , 7 * which correspondingly do not penetrate completely through the grinding disc 1 a. The elevations 6, 6* a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com