Efficient down-hole hammer

A down-the-hole impactor, a high-efficiency technology, is applied in drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. Ensure high efficiency and stability, small shaft diameter change, and few holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

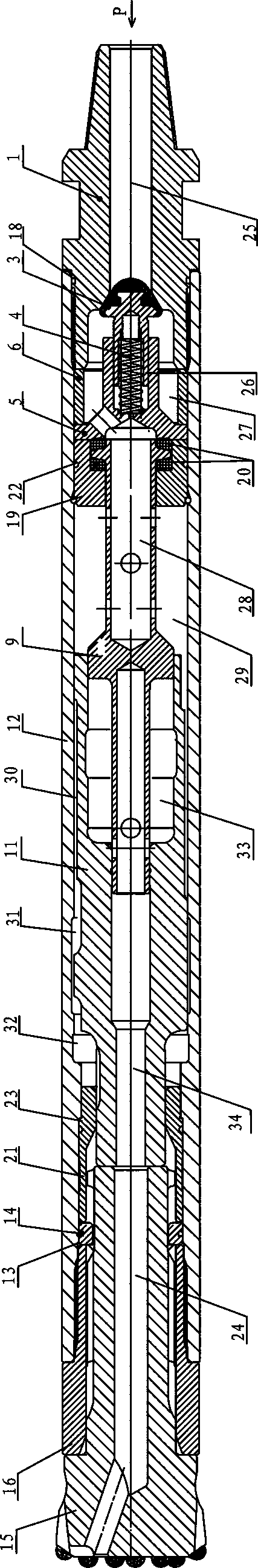

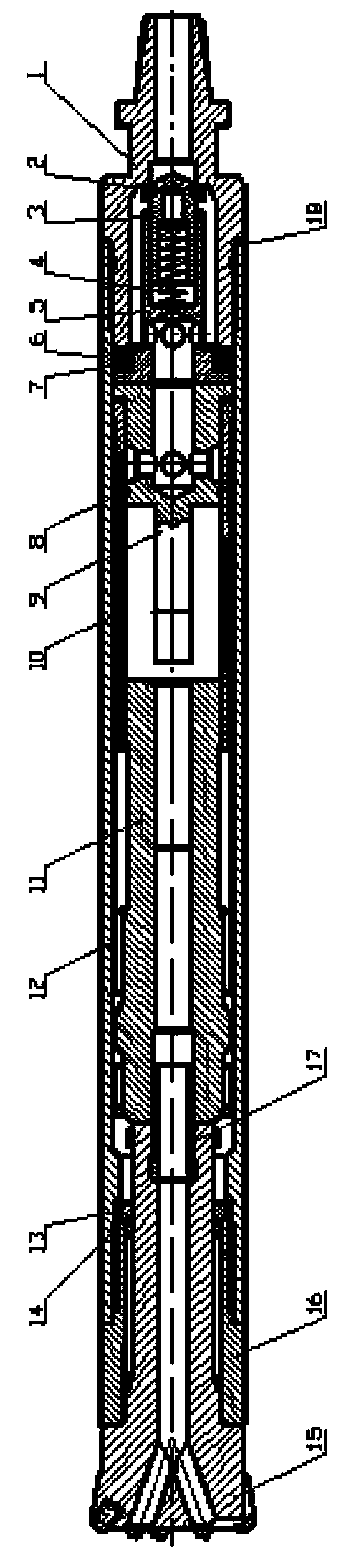

[0028] Such as figure 1 As shown, a high-efficiency down-the-hole impactor includes a rear joint 1, a check valve 3, a gas distribution rod 9, a piston 11, a cylinder body 12, a snap ring 14, a drill bit 15 and a front joint 16. The check valve It is a one-way valve, which includes a valve seat 5, a spring 4, and a steel washer 6. The piston is an elongated piston with a hole, and a positioning sleeve 19 is arranged at the rear end of the valve end cover. An anti-vibration rubber ring 20 is clamped together inside the positioning sleeve. A steel washer 6 is fixed between the rear joint 1 and the valve seat 5 .

[0029] Preferably, a guide sleeve 21 is provided at the rear end of the snap ring between the piston and the cylinder. An O-ring 23 is provided on the mating surface of the guide sleeve and the cylinder body. An O-shaped sealing ring 13 is provided on the mating surface of the snap ring and the cylinder body; an O-shaped sealing ring 18 is provided on the mating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com