Abrasion test method of air valve and seat ring

A wear test and valve technology, applied in the field of power machinery, can solve the problems of inconvenient data sorting and regular exploration, unfavorable progress and cycle control, accuracy and precision effects, etc., to improve reliability, shorten test time, and improve accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

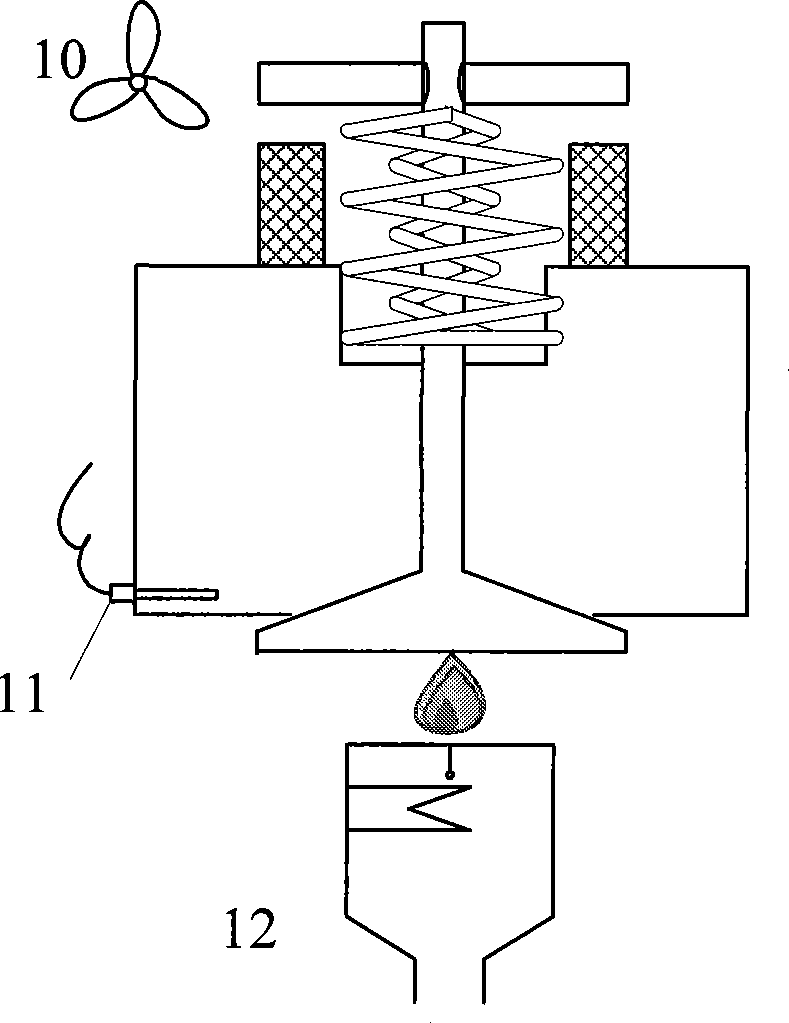

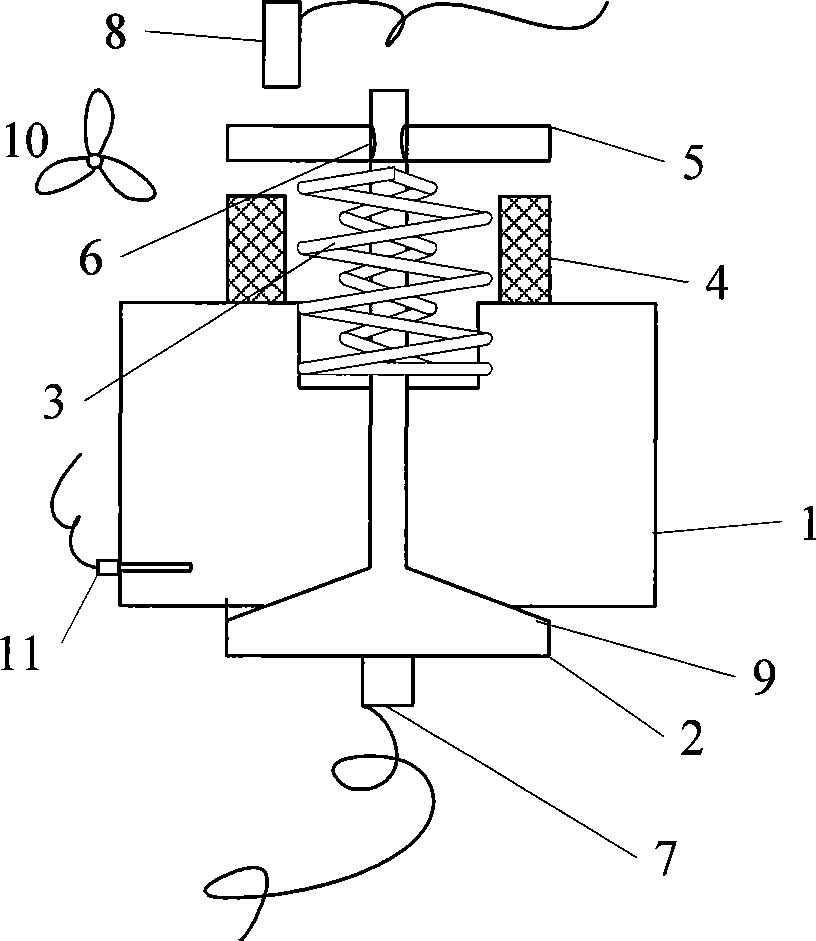

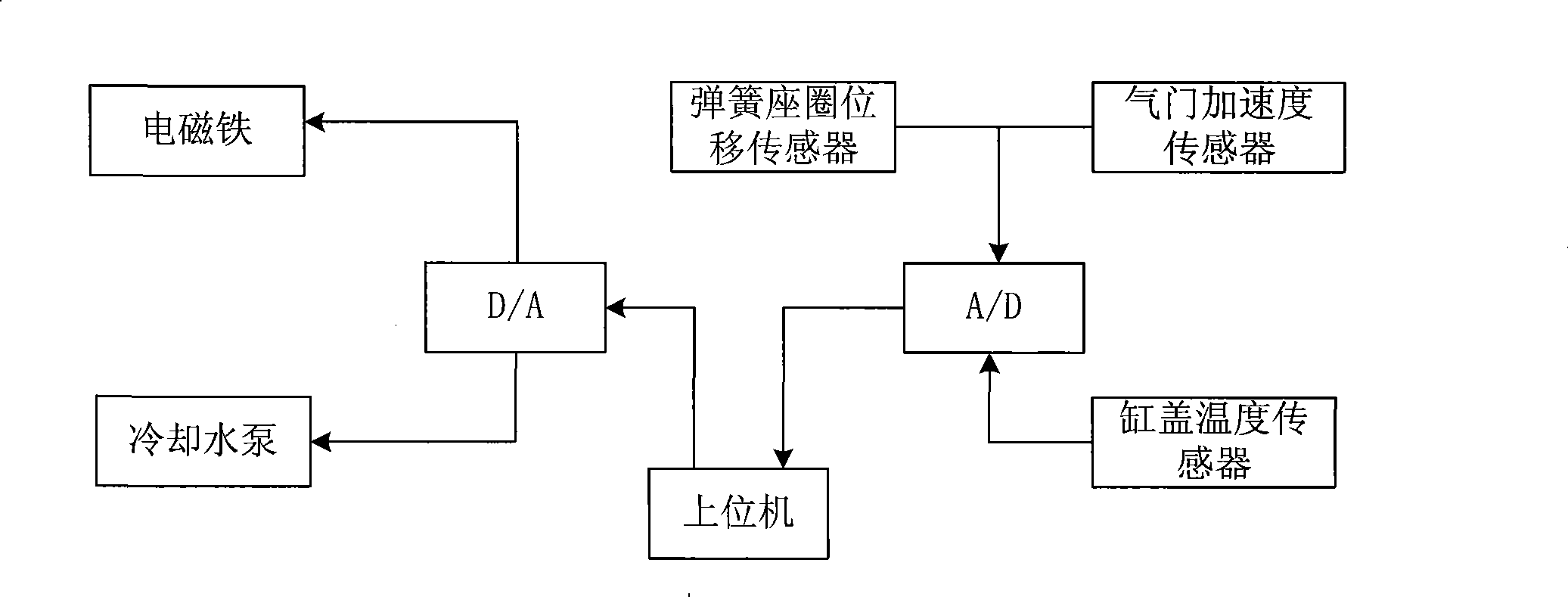

[0030] like figure 1 , 2 As shown, the new valve and seat ring wear test system diagram is divided into test state and calibration state state diagram. It includes: cylinder head 1, valve 2, valve spring 3, electromagnet 4, spring seat 5, valve lock clip 6, valve acceleration sensor 7, spring seat displacement sensor 8, valve seat 9, electromagnet cooling fan 10 , the cylinder head temperature sensor 11, the burner 12, the valve 2 is located on the cylinder head 1, the cylinder head temperature sensor 11 is installed on the cylinder head 1, one end of the valve spring 3 is supported on the cylinder head 1, and the other end is pressed against the spring seat ring 5 Above, the spring retainer 5 is fixed on the valve 2 with the valve lock clip 6, the electromagnet 4 is installed on the cylinder head 1, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com