Percussion drilling tool

A technology of percussion drilling and percussion mechanism, applied in the field of percussion drilling tools, can solve the problems of high axial vibration frequency, low drilling efficiency, and high drilling efficiency, and achieve the effects of stable impact force, high drilling efficiency, and elimination of sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

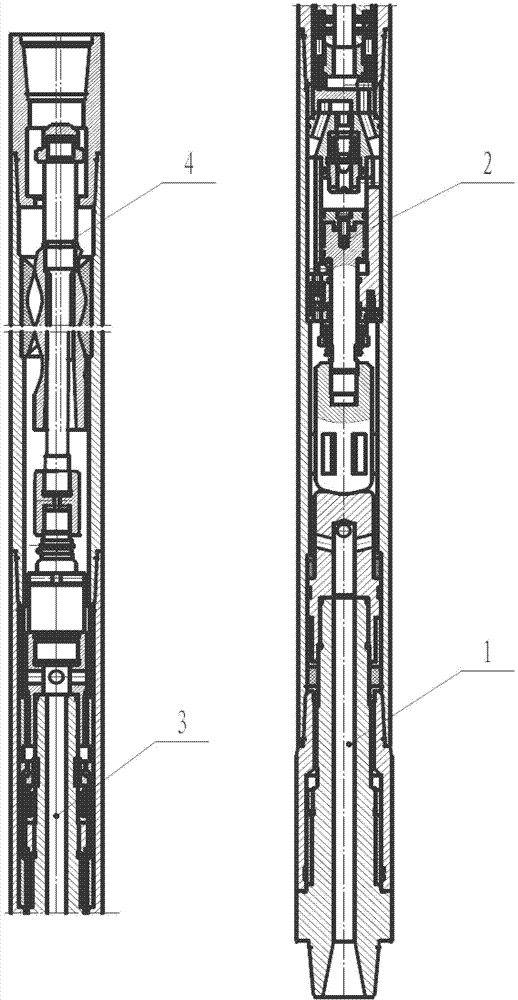

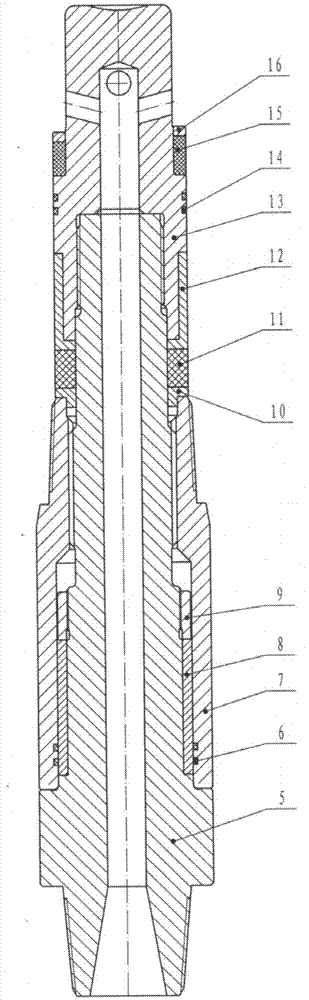

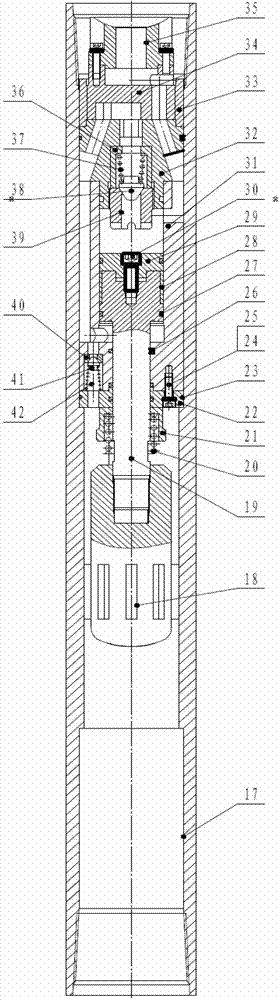

[0071] Embodiments of the present invention provide a percussion drilling tool, such as Figure 1 to Figure 6 As shown, it includes: an outer casing; a motor mechanism 4, a fixed-axis transmission mechanism 3 connected to the motor mechanism 4, an impact mechanism 2 for generating an impact effect, and a spindle mechanism 1 for installing a drill bit, which are sequentially arranged in the outer casing;

[0072] The impact mechanism 2 is arranged below the fixed shaft transmission mechanism 3 and above the spindle mechanism 1. The impact mechanism 2 includes: a hydraulic piston device and a rotary reversing valve, and the hydraulic piston device includes: a hydraulic cylinder 31, a piston 19 and a pressure limiting device ;

[0073] The motor mechanism 4 rotates under the action of the drilling fluid pressure, and drives the rotary reversing valve through the fixed shaft transmission mechanism 3 to change the fluid flow direction of the inlet and outlet of the hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com