Hydraulic impacter

A technology of hydraulic impactor and high-pressure oil port, applied in the field of hydraulic impactor, can solve the problems of difficult processing, poor rock breaking (breaking) effect, etc., and achieve the effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

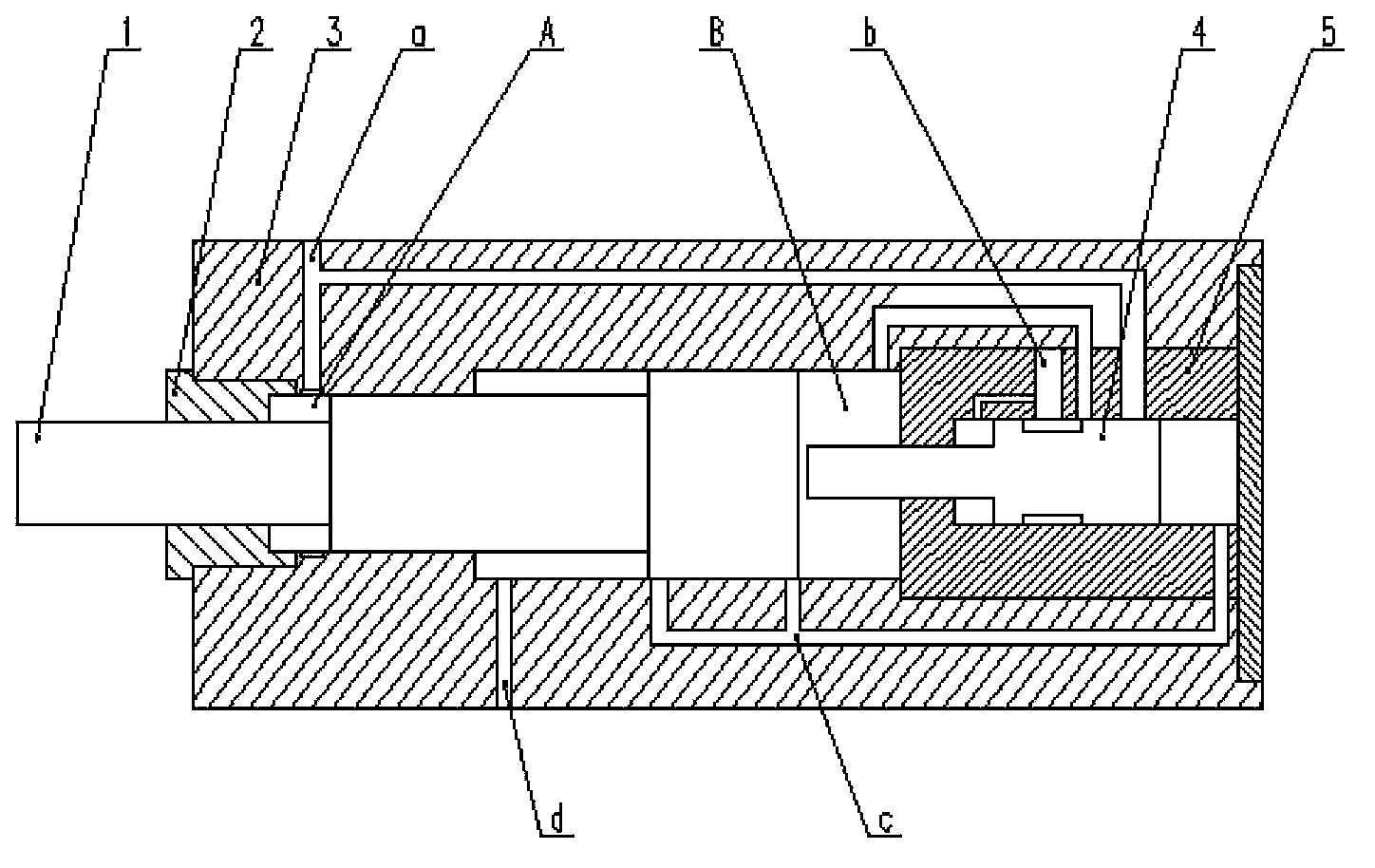

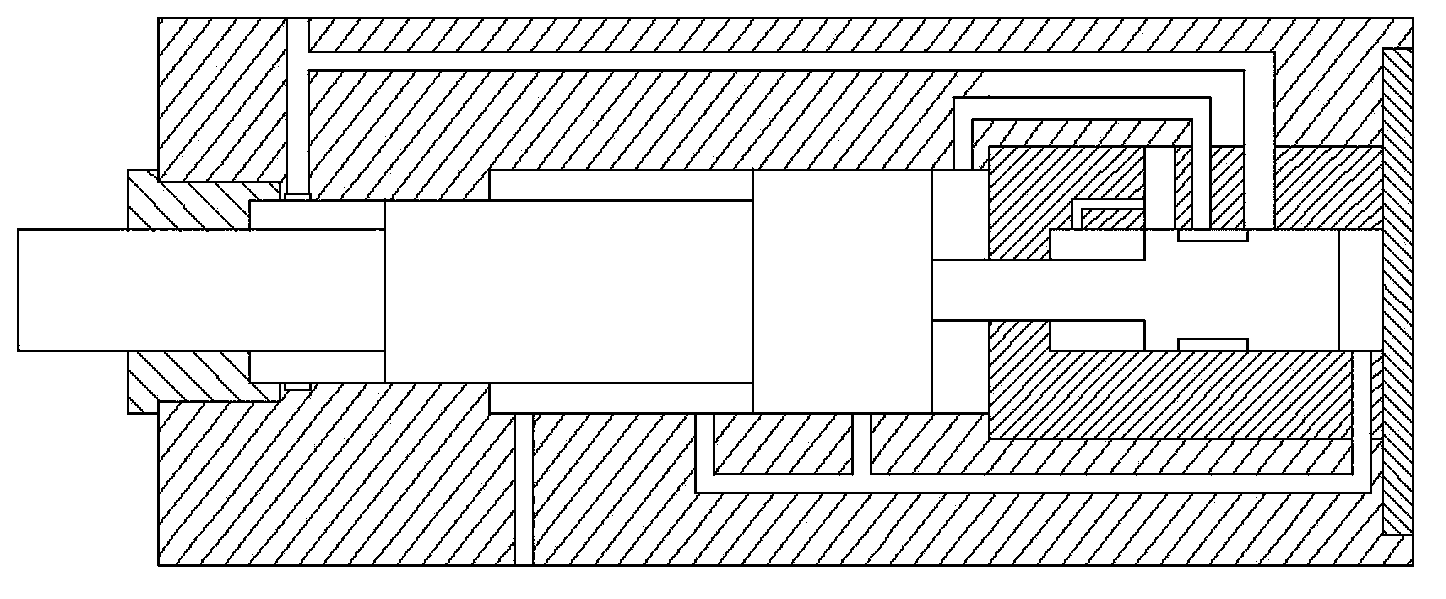

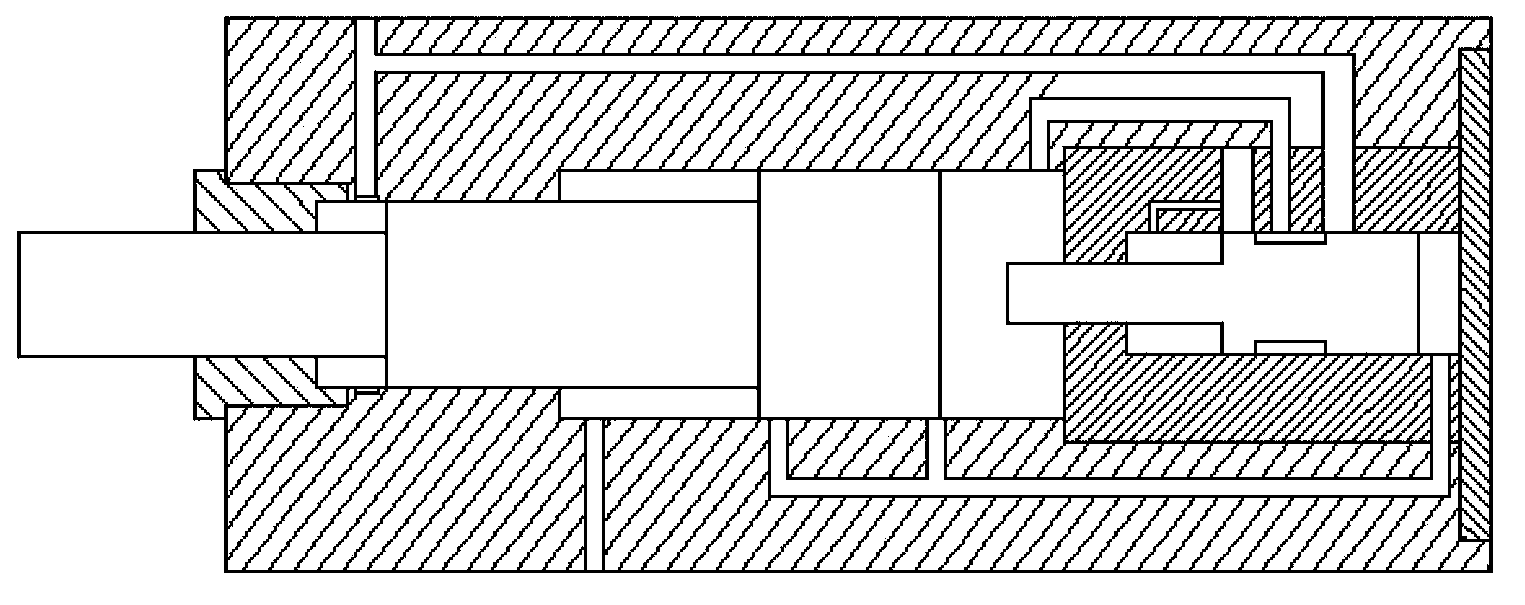

[0020] like Figure 1 to Figure 4 Shown, a hydraulic impactor, see figure 1 , The hydraulic impactor is composed of a three-stage piston 1 whose diameter gradually increases from the striking end, a guide sleeve 2, a cylinder body 3, a columnar flow distribution valve core 4, and a valve sleeve 5. figure 1 The state shown is the initial state of the hydraulic impactor. At this time, the front chamber A of the piston hydraulic impact mechanism is connected to the high-pressure oil through the high-pressure oil port a, and the rear chamber B is connected to the first oil return port b. The piston 1 is under the action of the high-pressure oil. Make return acceleration movement to the right, the oil port connected to the feedback oil passage c and the rear cavity is closed, the rodless chamber of the spool is connected to the second oil retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com